Hi all! In this text we will talk about such easy tuning of the intake system as installing a throttle valve of increased diameter: https://motorring.ru/product/89

What does this give us? It allows the engine to pass the greatest amount of air. And the easier it is for him to do this, the greater the output power will be. Let me remind you that the diameter of the stock damper on VAZ 2108-2115 cars is 46 mm. Accordingly, when installing a throttle with a diameter of 52-56 mm on a car, in theory, the power should increase, which we will check later.

Throttle valve device

The design of the throttle body is not as simple as it might seem at first glance. Among other things, it is also part of the engine cooling system. It has channels for coolant circulation. It is also equipped with pipes, one of which is connected to the engine crankcase ventilation system, and the second to the gasoline vapor recovery system.

Idle speed control

The idle air control is an electromechanical device whose task is to maintain a certain crankshaft speed when the throttle valve is fully closed. For example, while the engine is warming up or the load changes, when additional equipment is turned on. The design of the idle speed controller is as follows: inside the housing there is a stepper electric motor, to which a spring-loaded conical needle is connected. When the engine is idling, the needle, moving back and forth, adjusts the cross-sectional area of the bypass air channel through which air passes when the damper is fully closed.

The throttle valve can have two types of drive:

- mechanical, like VAZ-2109, VAZ-2110, VAZ-2114;

- electric, which is used on most modern cars.

Mechanical drive

For the VAZ-2109, VAZ-2110 and other outdated models of the Volzhsky Automobile Plant, the throttle valve is connected to the gas pedal via a steel cable. The mechanical drive has a very simple design and low cost, so it is still used on many inexpensive cars.

Electric

If the throttle valve is equipped with an electric drive, then there is no direct connection between it and the gas pedal. The principle of operation of an electric damper does not change, but its design is much more complex. Simplified, such a node works as follows. The force of pressing the gas pedal is recorded by a special sensor, which transmits this information to the engine control unit, the throttle opening angle is determined by the throttle position sensor, and also transmits the corresponding signals to the control unit. The controller constantly compares these values and sends commands to the electric motor to increase or decrease the damper opening angle.

Car service nuances

It's no secret that many car owners prefer repairs at service stations. There are many reasons for this.

If you need to clean your throttle body, you won't have to pay a lot of money for it. Today such a service costs about 500 rubles.

But there are several nuances that should be taken into account when visiting a service station.

In addition to cleaning the damper, the technicians will begin to assure you that additional cleaning of a number of components is required, as if without this the repair will not be complete and the effect will not be achieved. All this is a banal attempt to charge you more money for unnecessary work. They may start telling you that the damper is cleaned every 15, or even 10 thousand kilometers, they will offer their services, maybe even provide a discount as a regular customer. Again, the simplest trick. This figure is completely untrue. The frequency of cleaning the throttle valve on a VAZ 2114 car recommended by the manufacturer is 60-70 thousand kilometers. But in practice it turns out to be about 50-60 thousand kilometers.

You just need to monitor the condition of the unit and pay attention to the symptoms of contamination that we have already introduced you to today.

https://youtube.com/watch?v=Xh9LUV37tiE

Whether to do the work yourself or have it done at a car service center is entirely up to you. The most important thing is not to let the problem get worse, as it can result in really expensive repairs.

Loading …

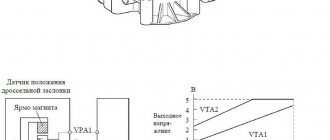

Throttle position sensor

This sensor is a potentiometer. When you press the gas pedal, the position of the damper and the voltage supplied to the controller changes. When closed, the voltage is 0.7V, when fully open it is 4V. In accordance with these data, the sensor controls the fuel supply.

If a malfunction of the position sensor occurs, the controller will not be able to correctly determine the position of the damper. This results in the following malfunctions:

- in all engine operating modes, the speed begins to fluctuate; at idle, the speed will be increased;

- when you switch off the gear (neutral) while driving, the engine may stall;

- Sometimes the CHECK light may come on.

To check the functionality of the position sensor, you can use a multimeter. With the ignition on, the probes are connected to connectors B and C. Changing the position of the damper should lead to a change in voltage.

» alt=»»>

Damage diagnostics

How to understand that an injector needs to be replaced, checked or repaired? Even without sensors, you can understand that repair of fuel system elements is required if there are 1 of 2 main signs in models 2107, 21074:

- Unstable engine operation. Sometimes it may stall or have difficulty starting.

- A much less obvious sign is loss of power. This effect is noticeable if you mostly drive at medium speeds, but at high speeds it is very noticeable.

- The last sign is recorded only by sensors - the pressure inside the system increases.

The cause of such failures is clogged injectors; even diagnostics are not needed. Cleaning helps restore the engine to its original performance. If the problem has not been resolved after cleaning, it is worth checking the tubes and injectors for damage or breakdowns. In such cases, it is better not to start repairs, but simply replace the damaged parts with new ones.

Sometimes it is impossible to determine on your own where the damage is, and only then will diagnostics at service centers come in handy. A blockage can cause quite serious damage to the VAZ 2107 injector, as well as rupture of channels. The pressure that arises inside the system can easily destroy the most fragile parts. Here you won’t be able to fix the situation with your own hands, even if you have a complete diagram of the car at hand. There is only one conclusion - you need to devote a lot of time and attention to cleaning injectors and do it regularly.

Why is it necessary to modernize the throttle valve on VAZ-2109, 2110, 2115

Spare parts stores sell throttle assemblies with valves of increased diameter (52, 54 and 56 mm) for VAZ-2109, 2110 or 2115 cars. According to the sellers, by installing such a valve instead of the standard 46 mm one, the car owner will receive significant advantages: the car becomes more responsive to the gas pedal, problems with idle speed disappear, the car's dynamics improve, and this is especially noticeable if you replace the standard air filter with a zero-resistance filter. The main argument that they try to convince car owners is that the engine requires more air to operate efficiently, for which it is necessary to replace the standard throttle assembly with an improved one. They even give figures: the diameter of the VAZ-2109 or VAZ-2110 receiver is 53 mm, and a damper with a diameter of 46 mm allegedly “strangles” the engine.

Many VAZ-2109 and VAZ-2110 owners succumb to persuasion and replace the standard device with an improved one. After this, indeed, the engine works better and the car drives more dynamically. The reason for the improvements actually turns out to be much more prosaic: instead of the old, dirty throttle body, which had long been in need of thorough cleaning, the owner installed a new one. As a result, the engine returned to normal operation, which is perceived by the owners as the promised responsiveness and agility of the car.

Correction of a factory miscalculation

It is quite common for a throttle assembly to come out of the factory with something that cannot even be called a defect, but can still be attributed to design errors. In theory, air should flow into the space behind the throttle, for which a channel of approximately 2.5 mm is specially made.

But the whole problem is that this channel was pressed against the wall of the receiver, thus blocking the possibility of air flow. A slight modification of the throttle assembly can help in this case.

To do this, just take a file and use it to make a small groove in the indicated place. 2 - 3 mm will be enough. But before doing this, it is necessary to remove the throttle.

On a VAZ 2110, the throttle assembly is removed in the following sequence:

- Disconnect the connectors of the sensor that regulates the position of the throttle valve, its drive cable and the XX regulator;

- We partially drain the coolant;

- Next is the removal of the air hose located on the body of the mass air flow sensor. Why do you just need to loosen the clamp;

- We also loosen the clamps: where the throttle pipe is attached to the air hose; where the hose of the 2nd crankcase exhaust circuit is attached to the cylinder head cover pipe. We remove the connected hoses - the air and 2nd crankcase ventilation circuits;

- Having loosened the clamp, remove the hose of the 1st crankcase gas exhaust circuit from the throttle assembly fitting;

- Having loosened the clamps, we remove the hoses supplying and discharging coolant;

- You will need a wrench with a 13mm head, with which you need to unscrew the nuts securing the throttle assembly to the receiver on a VAZ 2110;

- It is now possible to remove the throttle assembly from the studs;

- It remains to remove the sealing gasket and, if your VAZ 2110 has a system that traps gasoline vapors, disconnect the hose for purging the adsorber.

What size should I install the damper then?

By installing a throttle with a diameter of 56 mm on the “stock” motor, we will give the motor the opportunity to process air even more easily, compared to 52 and 54 mm, and even more so 46 mm. After all, with the same pressure on the gas pedal, much more air enters through 56 mm than through 46. But comfort in the cabin will be lost, a jerk will appear at the bottom, and you will also need to work more carefully with the accelerator pedal. In general, without a habit, it will be difficult at first.

52 mm is “neither two nor one and a half.” The effect will be practically unnoticeable! Since the difference with the “stock” one is only 8 mm. Money down the drain, so to speak. It's best to set it to 54 mm, which is what I did. Some kind of golden mean. But this is all theory. Let's move on to practice.

Practice. Effect

Unfortunately, I myself forgot to measure the acceleration “before and after”. But on the well-known YouTube site I found a video of one guy who was just doing this procedure. At first he had a completely stock VAZ-2112 coupe. Acceleration from zero to 100 km/h was around 11.9 seconds. Then he installed a larger throttle (56mm) and it turned out that the acceleration from 0 to 100 took one second less than before, namely 10.9 seconds.

So, let's figure out what are the advantages of this tuning. Firstly, there are no difficulties during installation; it is installed in place of the standard one without any modifications. Secondly, the response to the gas pedal has become more responsive. Thirdly, low price. Fourthly, this tuning does not require any sports brains or tuning.

Disadvantages of a large throttle:

- I personally had troubles with XX (idling speed);

- twitching appeared at the “bottoms” (low revs);

- the car begins to respond more sharply to small movements of the accelerator pedal, as a result, comfort in the cabin disappears and fuel consumption increases.

Conclusion: this spare part is needed by those who “chase power.” Who cares about horses under the hood rather than comfort? Such tuning will not appeal to a careful driver who is used to driving quietly and calmly.

Need for maintenance

The prophylaxis procedure should not be carried out in the absence of obvious reasons. Before starting, you need to carefully evaluate the condition of the throttle valve. If there are no obvious signs of tar deposits and areas of coking, then the reason for unstable operation may lie elsewhere.

Also consider the mileage of the car. Experts recommend resorting to flushing no earlier than after 100 thousand km. But on some cars, for example, a Ford Focus, it may be necessary to flush it after 30 thousand kilometers.

You should know how to clean your throttle body to achieve the desired result. This requires a special carburetor cleaning solution, for example, Abro Carb & Choke Cleaner or similar products. The assembly must be dismantled; only in this case can the maximum effect be achieved, otherwise carbon deposits will remain inside the tubes. Disconnect all pipes from the throttle valve to gain good access to the inlet part of the assembly.

Remove carbon deposits delicately using a clean rag or soft brush. Do not use excessive force; you may damage the valve. The internal elements are coated with a thin layer of molybdenum, which novice car enthusiasts mistake for harmful deposits.

The consequences of zealous cleaning can be different: the moving part of the damper will begin to bite, or vice versa, in the closed position it will begin to let air through. In this case, it will not be possible to do without repairing the throttle valve.