Most car owners dream of improving their car and making it more powerful and manageable. By installing a compressor on a VAZ 2114, you can increase engine power by 20-40% or more.

If you intend to install a compressor on your car, you need an integrated approach. Its installation is most often accompanied by modification of the engine. Otherwise, this can lead to serious damage and rapid engine failure.

Compressor for VAZ 2114

TURBO - NOT TURBO

In short, there are now many design varieties of compressors. Some work using the energy of exhaust gases (TURBO), others - using a drive (NOT TURBO). It is the latter that we will talk about today. By the way , which is better, a turbine or a compressor, you can read at the link.

If you examine the design of such units, you can identify a certain similarity in structure. Namely, such compressors operate from a drive that does not require intervention in the standard engine systems, namely the lubrication and exhaust gas system, which is very important! This design is really very simple - a direct connection is established with the “crankshaft”, which allows the engine and supercharger to interact perfectly during acceleration. That is, the higher the speed, the faster the “crankshaft” rotates, and accordingly the supercharger spins! Thanks to this interaction, there is practically no such thing as “turbo lag”. Also, an additional advantage is the lack of operation at high temperatures, like with TURBO options, which means that the service life is greatly increased - after all, there is no need for the “turbine” to cool down, that is, “turbo timers” or “boost controllers” are not necessary, we just turn off the car and work stops. The site autoflit.ru recommends doing exactly the same. If you're interested, come in.

Advantages

Compared to a turbocharging system, compressors have the following advantages:

- The engine increases power immediately after starting, because the unit drive is connected to the crankshaft of the internal combustion engine. The turbine reaches full power only at certain engine speeds.

- The engine does not overheat, and there is no need to install additional fans.

- The additional pressure is small enough to make drastic changes to the engine. Most often, you can limit yourself to reducing the compression ratio.

Rotary types

Compressors that are used quite widely. The main advantage is the average price, long service life, high frequency of supplied air, smooth and stable operation, quick response to the crankshaft speed.

The air in this system is not compressed, it seems to go inside, and then it is forced into the engine by blades, which are made in the form of a rotor. That’s why they got the name – compressor with external compression. The downside is that as the inlet pressure increases, the efficiency decreases.

The structure most often consists of two rotors, on the inlet and outlet windows, see photo. They are located transversely.

The disadvantages of this design are:

1) Efficiency depends on the clearances between the shafts and other parts.

2) The largest heating of all other types.

3) Strong noise and vibration of the shafts.

4) Not very strong pressure, about 0.7 bar maximum.

To summarize, it becomes clear that this type is far from ideal. Some can - why are the blades screw-shaped? There are two reasons here, the first is an increase in air pressure and the second is a decrease in noise (although it helps little).

Screw type

This is a more advanced and reliable supercharger design. The principle of operation here is also simple - compression occurs by changing the volume of the cavities between the body and the rotation screws (a kind of rotors). The air here moves diagonally. The big advantages of this option are high efficiency up to 85%, as well as high air pressure (from 1 bar to higher), this is achieved by high speeds, sometimes up to 12,000 rpm. It is because of this that the body can be made more miniature. It must be said that this option is often used on racing cars due to its reliability and small body.

The only downsides are the complex structure and repairs, which increases the price of the final product. If such a drive compressor fails, it needs to be repaired at specialized stations, preferably from the manufacturer.

As you can see in the design there are two rotors, with serrated spiral teeth. Their profiles fully correspond to each other when in contact, which makes the design very reliable.

About choosing a car air conditioner

We list the main parameters that the owner of a VAZ 2114 should focus on when choosing an air conditioner:

- operating voltage - 12 volts;

- temperature of the air supplied - from 7 to 18°C;

- power consumption - from 2 kilowatts;

- type of refrigerant used - R134a;

- lubricating fluid - SP15.

All of the above parameters correspond to air conditioners produced by the following companies:

- "FROST" (model 2115F-8100046–41);

Air conditioners from are the most popular among VAZ 2114 owners - "August" (model 2115G-8100046–80).

- the second most popular supplier of air conditioners for VAZ 2114 owners

They are installed by almost all VAZ 2114 owners.

Installing air conditioners from other cars is extremely rare, since a lot of problems arise with them. In particular, the piping system in such an air conditioner may be either too short or too long. Therefore, it will have to either be built up with something or cut off.

The fastening and sealing system of the “non-original” air conditioner will also have to be seriously modified, and it is far from certain that the modification will be successful and the resulting system will retain its tightness. New ventilation holes will likely have to be cut into the dashboard, which will inevitably raise questions when passing the next inspection. All these points make installing air conditioners from other cars impractical, especially if stores have ready-made solutions specifically for the VAZ 2114.

Centrifugal type

The most common ones on internal combustion engines operate using so-called blades or “blades”. If we compare them with the previous two, then this type is the most compact of all, and it is also simple in manufacturing technology, which reduces its final cost. It can often be confused with the TURBO version (which is powered by exhaust gases), due to its similar design, but this is completely wrong, these are two completely different devices.

The principle of the structure consists of an inlet part, a working part (blade-blade) and a diffuser, which can be either bladed or bladeless. An air intake made in the shape of a “snail” is also required for installation.

The air, having passed through a special filter (by the way, is also required, otherwise all the dust will be inside the engine), enters a special inlet which gradually narrows (for minimal air losses during supply), then goes to the wheel. The impeller is mounted on a special mount, but there have been cases when it was placed on the shaft itself. Next, through a mechanical transmission (drive), it is connected to the crankshaft.

Such options are the most common on our domestic cars (in particular VAZ). They are chosen for their durability, low price, versatility and compactness.

The disadvantages of such compressors are low efficiency at low speeds, but at high speeds the engine power can increase up to 30% of the nominal value. At rpm from 4000, the pressure can reach 0.5 - 0.6 bar.

About refilling the air conditioner

After installation, the air conditioner must be recharged. In addition, this device will have to be refilled at least once every 3 years, since up to 10% of freon can leave the system within a year, even if the circuit has never been depressurized. Freon R-134a is now used everywhere as a refrigerant.

Most air conditioners now use R-134a freon

And to pump it into the air conditioner you will need special equipment, for which you will have to go to a spare parts store.

To refill air conditioners, special cylinders with pressure gauges are used.

And you need to buy the following there:

- set of couplings and adapters;

- hose kit;

- R-134a freon cylinder;

- pressure gauge

Refueling sequence

Let us list the main stages of pumping freon into the system.

- There is a plastic cap on the low pressure line in the air conditioner. It is carefully cleaned of dust and opened.

- The fitting located under the cap is connected to the hose on the cylinder using the adapter included in the kit.

- The car engine starts and idles. The crankshaft rotation speed should not exceed 1400 rpm.

- The air conditioner turns on maximum air circulation throughout the cabin.

- The freon cylinder is turned upside down, the tap on the low pressure adapter slowly opens.

- The filling process is constantly monitored using a pressure gauge.

- When cold air begins to flow into the car interior and the hose near the adapter begins to become covered with frost, the refueling procedure ends.

Video: refilling the air conditioner yourself

Installing a compressor on a VAZ

Needless to say, our domestic market mainly consists of AvtoVAZ products, this is where young “tuners” start, so the most common question is - can it be installed on a VAZ?

Of course it is possible, and the last one, the centrifugal type, often already comes as a complete set, for installation specifically on our cars, that is, the so-called “KIT kit”.

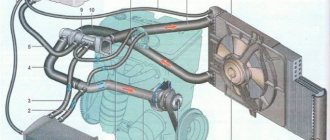

Installing the system is quite simple. However, first you need to install an enlarged gasket between the block and the cylinder head. This is what the manufacturer advises. Below is an exaggerated connection diagram:

1) Set up the air intake filter.

2) Attach the body to the bracket

3) Connect the crankshaft drive.

4) Fasten the drive belt

5) We use it.

Now a short video for understanding.

What can be achieved - as I wrote above, at high speeds the pressure can reach 0.5 - 0.6 bar. If you correctly configure the fuel injection, flash the ECU, or reconfigure the carburetor, you can achieve 30% at the top! This is very significant.

I will end here, I think my article was useful to you.

Similar news

- The wipers (windshield wiper blades) squeak and do not clean well. What the...

- Restoring the leather on the steering wheel or how to paint it. Details + vi…

- Dry fog for cars (treatment). What it is? And for what...

Add a comment Cancel reply

What's better?

The answer to this question can only be given by the owner of the VAZ 2107. A cheaper option would be to install a conventional compressor. It won't take much time or money.

But if you want your car to “fly”, then you need to install a turbine.

As stated above, this is a more complex procedure in which you will need to change some components of the car and invest a lot of money in such tuning. But you will definitely be pleased with the result.