Electric power steering is designed to make driving life easier. It helps to turn the steering wheel in a parking lot without putting much effort; in modern cars it prevents accidents and makes driving easier. It is more reliable and better than the hydraulic booster, but it still breaks down, although less often. Let's sort it out main malfunctions in the operation of the electric amplifier and how they manifest themselves in order to be prepared for repair costs.

Minuses

However, we must admit that the electric power steering also has weak points. There are few of them, but they still exist. What should you pay attention to?

Failure of the electric booster can be indirectly confirmed by a sudden increase in idle speed. Electrical problems can occur due to water and dirt getting into electrical connectors. Malfunctions of the electric power steering in the electronics may be due to loss of signal from the torque sensor on the steering shaft, or lack of communication between the electronic control unit and the speed sensor.

The electronic brains themselves can get wet and then become inoperable. Alternatively, after dipping into a deep puddle.

But most often we observe depressurization of the insides of the steering mechanism due to rupture of the protective covers.

What’s especially offensive is that such a disaster could have been prevented if you had looked under the car in time. Corrugated covers usually tear in severe frosts or off-road in deep ruts. As they say, under external influence. I replaced the torn cover in a timely manner and saved an expensive unit from destruction. If you missed it, there’s no escape; you’ll have to fork out a hefty sum.

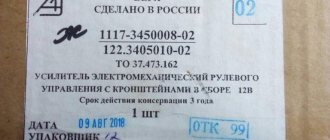

Technical characteristics of the EUR

| Name | Index |

| Rated voltage, (V) | 13,5 |

| Operating voltage, (V) | 10-15 |

| Maximum current, (A) | 55 |

| Current at rest, (A) | 0,5 |

| Moment of resistance at rest, (Nm) | 0,8 |

| Weight, (kg) | 9,3 |

| Operating temperature, (⁰С) | -40…65 |

Adviсe

Nowadays, manufacturers of electric power steering, to simplify monitoring the condition of the internals, place a special control plug on the body of the mechanism.

Its flatness is clearly visible when viewing the car from below. If moisture has accumulated inside the steering rack housing, a depression appears in the center of the plug. There an annular drainage hole opens into which a small pin falls. In good condition, the pin is invisible, it is flush, flush with the plane of the plug.

If this valve has worked, then when disassembling the mechanism, the sad picture is revealed in all its glory. Sometimes it is still possible to properly rinse, clean, lubricate and sort through everything. But more often the verdict is the same - you need to buy the entire critical assembly.

Therefore, in order not to expose your budget:

The conclusions are simple, as always: learn your equipment and take care of what is in your hands. Have a nice trip with a working car!

Source

How to check the EUR yourself

To understand what is broken in the amplifier, you need to diagnose it. Not every car owner has a diagnostic scanner; some people like to repair the car themselves. In this case, you can determine the malfunction of the electric amplifier yourself using a paper clip. This option is suitable for Kalina and Priora cars.

"Paperclip" method

We disassemble the protective cover of the steering column and get to the amplifier control unit. We find a black block with six wires. It is necessary to close contacts 7 and 6 between each other - “ground” and “K-line”. If you look at the block from the side of the wires, then the countdown goes from right to left, from top to bottom. You need a brown wire - contact number 7 and an empty socket, not used - number 6 in a row.

Turn off the ignition, insert a paper clip into the contacts, make sure that it does not short-circuit the other wires. Turn on the ignition and count the number of flashes of the warning light on the dashboard. One long signal, and then several short ones, these are the ones that need to be counted. Let's look at the decoding of fault codes for Kalina's electric booster :

In practice, this method may not always show real breakdowns. In this method, the control unit checks itself, and it needs to be checked under load. There were cases when it generated false errors, and the fault was hidden in the electric power steering ECU.

Electric power steering, breakdowns and malfunctions

Electric power steering is undoubtedly a very useful invention. Today, almost every passenger car model is equipped with this device.

The electric power steering allows you to reduce the physical effort that the driver puts into turning the steering wheel. The electric power steering began to reach the “masses” in the mid-nineties; before that, hydraulic power steering technology was used for steering assistance. It is still used on large models, since the electric amplifier is still not so powerful. In general, this is where the shortcomings of the electrical system in front of the power steering end.

If we talk about the advantages, the electric power steering is much lighter and more compact, has almost no effect on fuel consumption, and allows you to change the power steering mode. In most cases, the EUR operates without starting the engine, with the ignition on. Finally, power steering failure is a much more serious problem, as it is most likely associated with a leak from the hoses. If not, then it will still take a long time to figure it out; the power steering has many more additional design elements than its electromechanical counterpart.

Electric power steering

However, electric power has been installed on production cars for decades, and it is obvious that during this time it too has had misfires. As experts who repair electrical and electronic systems of a car note, the main problems in the operation of the EUR are associated with a blown fuse. Very often, the electric power steering breaks down due to a burnt-out motor. This usually occurs due to contact with moisture. If you do not have special skills, it is better to solve these problems in a car service center. However, no less often, a service station is contacted with a failure of the steering shaft rotation sensors.

Sometimes the electric power steering fault light comes on after replacing the battery, for example, in a Volkswagen Golf. Owners should not panic, because in most cases this disease can be cured by driving the car about fifty meters. Nissan Micra drivers often encounter malfunctions associated with the electronic unit or motor, which is installed directly on the steering shaft, which is why even mild impacts on the side wheels can damage the mechanism. Repairing or replacing the EUR is not the cheapest pleasure. While the price of this service for Russian cars is even more or less acceptable (10 thousand rubles for Lada Kalina), then for owners of inexpensive Japanese or German foreign cars it will cost no less than 50 thousand rubles.

Source

Differences between EUR and power steering

The electric amplifier differs from the hydraulic one in the absence of fluid and the pump necessary to pump this fluid. Also, the hydraulic power steering operates entirely on mechanics, unlike the electric power steering, in which mechanics are involved only in the rack and steering wheel. EUR is much simpler and easier to maintain, but in terms of repairs it is much more expensive.

Advantages and disadvantages of EUR over power steering

Although the EUR is more modern and technologically advanced, it has both advantages and disadvantages over the power steering.

Advantages:

- The simplest design that does not require constant monitoring of the liquid level (dixtron);

- There is no need to service the power steering pump, since it simply does not exist;

- Reduction of force with increasing vehicle speed;

- Ability to programmatically adjust steering wheel force;

- Reliability of the design;

- Compact, no bulky pump in the engine compartment and no extra hoses;

- The simplicity of the steering rack and its reliability, since it is dry and there is simply nothing to leak in it (everyone knows very well about the disease of “wet” racks);

- High power consumption, at some points the electric power steering can take up to 40% of the electrical power of the car’s generator and cause voltage drops in the on-board network;

- Possibility of overheating of the electric motor when driving on a dirt road (track) up to the complete shutdown of the power steering;

As you can see, the more modern power steering has many more advantages, which is why it is gaining great popularity among cars at the present time.

What malfunctions threaten the EUR on Kalina and what are the ways to eliminate them?

Electric power steering is a component used to provide more comfortable driving. Not so long ago, domestically produced cars began to be equipped with EUR, in particular, in this article we will talk about Lada Kalinas. What malfunctions can occur with the Kalina EUR and what troubleshooting methods are there? Find answers to these and other questions below.

Fuse box

Check if the fuse is working, if it fails, replace it. It is very easy to check, check the integrity of the thread inside the fuse. Changing a 50 amp relay to a 30 amp one will also help.

Newer versions of Kalina are equipped with electric amplifiers from Hyundai, which has a positive effect on its reliability. However, there are still thousands of cars with the domestic version, which malfunctions and breaks down from time to time. Now it will be easier for you to repair the electric power steering on Kalina yourself. The main thing to remember is that not every amplifier shutdown is a breakdown. And you can find the problem yourself and fix it, but somewhere you will have to go to a service center.

Electric power steering is a device designed to provide more comfortable driving. Not so long ago, domestically produced cars began to be equipped with amplifiers. ESD in a Lada Kalina car - what are its malfunctions, what are they, and what are the most effective solutions? Read about it below.

Causes of EUR failure

Why does the electric power steering on the Lada Kalina not work, turns off and refuses to work, what are the signs of a steering wheel with power steering knocking, jamming, biting or squeaking? To repair the system yourself, you need to know how diagnostics are carried out and what causes precede the breakdown. Most often, the failure of the amplifier is caused by a breakdown of the unit itself and the amplifier fails. Problems of this type are resolved by thoroughly checking the system to identify the exact problem.

As practice shows, often the inoperability of the electric amplifier (failure) is associated with a breakdown of the speed controller.

Because the speed controller sensor ensures activation and deactivation of the electric power steering under different driving modes. The amplifier on Kalina works if the car is moving at low speed. When the speed begins to increase, the booster automatically turns off, allowing for safer machine control when driving at high speeds.

So, briefly about the reasons for the inoperability of the EUR:

Priora EUR control unit

This part serves to calculate the force applied to the steering wheel and the force that the electric motor applies to the steering wheel shaft. The block is also responsible for turning off the power steering at speeds above 100 km/h for a more sensitive understanding of the car.

The EUR control unit on the Lada Priora is located near the power steering electric motor on a special bracket.

Diagnostics

To check the amplifier in a car, you need to remove the plastic trim on the steering column; to do this, unscrew the bolts securing it from the bottom.

Then you will need to get to the 8-pin plug, its pinout is as follows:

More accurate results will be obtained by checking the amplifier using a scanner. But since such equipment can usually only be found at service stations, you can try to check the operation of the system with a paper clip.

To check you need to do the following:

How to understand where to look for the cause by the blinking indicator icons:

Error codes

c1044 - incorrect sequence of the rotor position sensor (RPS)

c1621 - incorrect voltage 5V

c1622 - speed signal circuit failure

c1011 - car engine speed signal circuit, no signal - the signal from the idle sensor (or the standard tachometer through a voltage limiter) is divided by 4 and applied to the tachometer input,

c1022 - error, voltage of the main output of the torque sensor - it is possible that the shaft cover has rubbed the insulation and the middle, green wire shorts to ground

Removing the electric amplifier

- If you decide to repair the electric power steering, then first of all you need to dismantle the steering column switches. Next, you need to disconnect all the blocks with wires from the control panel - if you need to remove the ignition switch, then to do this you need to unscrew three self-tapping screws. A Phillips screwdriver is used for this.

- After completing these steps, you can dismantle the lower cross member of the control panel. To do this, press the clips that secure the wire block, and then disconnect them from the system control unit. Only after these steps can you disconnect the block from the switches themselves.

- The bracket itself is fixed with several nuts, they are unscrewed.

- The entire steering column must be carefully lowered. You need to find the screw that secures the cardan to the assembly shaft. This screw is unscrewed, while you need to hold the nut to prevent it from turning. After dismantling the screw, the terminal clamp must be released, then the intermediate shaft is carefully removed. To prevent installation problems, the location of the shaft, as well as gears, must be marked with a marker. If the marks on the shafts are not aligned, this will lead to problems with the system. When removing the electric amplifier, do not damage the wiring under any circumstances.

- As for installation, the procedure is carried out in reverse order (the author of the video is Murzik Bely).

Simpler, but even more expensive: what breaks in steering racks with electric power steering, and how they are repaired

Having studied in the most thorough manner all the shortcomings of hydraulic power steering, the designers eventually came to the conclusion that it would be cheaper and more reliable to give the “reins of power” to electrical systems. There are many advantages: the absence of working fluid and tubes with hoses, and the reduced weight of the entire system... In addition, thanks to electronic control, you can make the steering wheel rotate independently, as, for example, in a system with automatic parking. But every coin has a flip side: over time, no less, or even more, problems have emerged than in hydraulic systems. Today we will talk about these problems, as well as ways to eliminate them.

Features of work

Before we start talking about the types of electric amplifiers and their characteristic problems, let's say a few words about the algorithm of their operation. Immediately after starting the engine, a self-diagnosis of the system is performed to confirm its functionality. In the neutral position, the electric motor does not work: the entire system is waiting for active action.

As soon as you start turning the steering wheel, the signal from the steering angle and torque sensor goes to the ECU, which in turn gives a command to the electric motor, which makes your life easier. Moreover, the nature of the operation of the electric booster will be different depending on the speed of the car: in this way, progressive operation of the electric power steering is achieved. After going through a turn and gradually removing force from the steering wheel, the system will return the wheels to the neutral position.

Surely, owners of front-wheel drive cars with a transverse engine have noticed how the car pulls a little to the side during an active start. This is due to the different lengths of the drive shafts on the right and left sides. So, models with electric power steering can also steer the wheels a little, thereby compensating for the slip. In general, the force on the steering wheel is completely under the control of the EUR - and therefore it is on its conscience that the “emptiness of the steering wheel” and the “artificial force” that is so often talked about and about which numerous journalists complain.

What are electric amplifiers?

These systems are divided primarily according to the location of the power unit (electric motor): on the steering column (almost under the steering wheel) or on the steering rack. In the first case, the steering mechanism will be the most common, for example, as in a V8 or Nissan Micra, and in the second, an electric motor or drive is integrated into the design. Today, in practice, we will look at a more interesting option with a rail-mounted amplifier.

On the steering mechanism itself, the electric motor can be installed in different ways - either separately, or as part of the body of this steering mechanism. There is also a distinction between the type of rack rod drive: an additional gear or a movable screw-nut connection.

In the latter case, the electric motor can transmit rotation through a belt drive, or the drive can be direct (as in Lexus GS racks).

To understand when and how much it is necessary to “help” the driver turn the steering wheel, the system uses data from several sensors - a torque sensor on the steering gear shaft, a steering wheel position sensor, a crankshaft speed sensor and wheel speed sensors. The only sensor that relates directly to the power steering system is the torque sensor.

More about the device

Now let's look at three different designs: rack-and-pinion steering, parallel-drive racks, and direct-drive racks. Each of them has its pros and cons – now we will outline which ones.

Racks with an additional gear incorporate an electric motor that rotates a gear through a worm gear, very similar to the one we rotate through the steering shaft. In this case, on the rack itself there are two notches of teeth. Everything about this design is not bad, but the friction losses are high: after all, it is a worm gear. With this design, the electric motor often has its own housing.

Parallel drive racks are the name given to a mechanism in which rotation from an electric motor is transmitted through a belt to a nut, or, more precisely, to a “screw-nut” pair.

The screw here is a rod with a thread on one side and a serration of teeth on the other.

Between the nut and the screw there are balls through which rotation is transmitted - they also act as a bearing. It works like this: when you start turning the steering wheel, an electric motor comes into action, rotating the nut in one direction or another, helping you turn the steering wheel.

Direct drive racks are a third option in which the steering rack housing is partly an electric motor housing, and the rack rod runs inside it. The rotation from the electric motor is transmitted through the already familiar “screw-nut” pair.

So, these are the main types of structures. Communication with the service technician allowed us to find out another important feature: there is a fundamental difference between Japanese and European slats. The Japanese “hide” the electric power steering control unit away from the steering mechanism itself - as a result, a long trail of wires stretches to the electric motor for control, communication and diagnostics. Europeans mount the control unit next to the electric motor or directly on it.

It’s hard to say which approach is correct. In the case of the “Japanese”, in order to remove the entire system, you need to pull out several meters of wiring and find the control unit itself - but in this case the unit is safe. With a European rail there will be no problems in terms of dismantling: disconnect two or three connectors, unscrew a couple of fastening bolts - and that’s it. However, the control unit in such a scheme is subject to various external influences.

Primary diagnosis

The initial diagnosis of a car arriving at the service area is based on data received from the car owner: for example, a constant knocking noise or only when turning, a biting steering wheel, uneven force on the steering wheel or its absence. Based on this, the rail is dismantled and connected to a special stand (ours is MSG MS561) and errors are read. Using the stand, they simulate the operation of the engine in various modes and study the operation of the steering mechanism in more detail. This is done to localize the fault and understand whether the problem lies in the hardware or in the electrics.

In order about the problems

First, let's talk about the mechanical part of the system. Everything here is the same as with other slats: almost any problem is associated with the rupture of the slats’ boots and the ingress of water and dirt into it. Water means inevitable corrosion, and dirt means excessive wear of rubbing surfaces.

Wear of the side bushing is perhaps the most harmless thing that can happen to the rack rod. Washing out the lubricant from the screw-nut pair can lead to the pair biting or even jamming of the steering mechanism in one position.

In parallel drive mechanisms, moisture entering the belt leads to a sharp increase in its wear and, ultimately, rupture. A sharply increased force on the steering wheel is what the driver feels in this case.

It is rare, but it happens that due to moisture, the bearing of the electric motor is corroded - then you will hear the frantic howling of the latter during operation.

Wear in the gearing of the pinion shaft and rack rod is also a potential cause of boot rupture. But here you can try to cure the disease by tightening the rod stop.

When inquiring from the mechanic about the effect of water on the electric motor, if the drive is direct, we learned that there cannot be any special problems with the motor itself - good insulation of the wires does its job.

Having dealt with the mechanics, we move on to the “source of power” - the electrical part. There are not many potential problems here, but almost all of them are associated with significant costs.

For example, if the electronic system control unit is installed on a rail, it is often not protected in any way, so a pebble flying from somewhere can break the unit cover. And even if you notice this right away (which is unlikely), the unit will still have to be sent for replacement. At the same time, when we say “block,” we mean the entire rail, because blocks are not supplied separately, and at the moment only modest attempts are being made to repair this element. But all attempts are broken against the impregnable wall of the lack of software for programming ECU processors.

Failure of the torque sensor is another unpleasant situation on the road. In this case, the EUR “does not understand” with what frequency and force to help you turn the steering wheel and in which direction.

The amplifier will not turn off completely, since it will “take” the data from the speed sensor and steering wheel angle, but the EUR malfunction indicator will start to light on the dashboard. Moreover, it may happen that you need to turn the steering wheel to the right, but the electric motor will “turn” it to the left.

The sensors themselves can be analog or digital, which is why they have corresponding problems. Analog ones “suffer” from wear: this manifests itself in different forces on the steering wheel or the movement of the mechanism from the central position.

Digital ones, however, also suffer from wear and tear, but not of the sensor itself, but of the cable, which can simply fray.

We treat the rail

Mechanical problems with the rack rod cannot be treated in any way. Corrosion, excessive wear of threads or teeth will send you to purchase a new rod - no grinding or any other treatment is provided here. If everything is in order with the rod, and the cause of the knocking is wear of the side bushing or an increased gap in the gearing, then the bushing can be replaced without problems, and the gap can be adjusted by tightening the rod stop (the same as in the case of hydraulic boosters). Actually, there are simply no other solutions to hardware problems.

But with electrics, as mentioned above, everywhere you look there are problems everywhere. If the errors being read are related to improper operation, then you can try to remove them - but if these are breakdowns... Then the solutions are simple, but expensive. Judge for yourself: the slightest crack in the block cover means, in most cases, replacing the entire steering rack. Corrosion of an electric motor bearing means two ways to solve the problem: replacing the electric motor with the control unit or, again, replacing the entire rack assembly. By the way, replacing the assembly is the verdict of any official dealer: the manufacturer usually simply does not provide the possibility of repairing and restoring the steering mechanism with an electric steering gear.

And if the drive is direct, and water gets inside, then what will happen to the electric motor? Fortunately, nothing: it will be washed with gasoline, dried and sent back to service. Regarding this element of the EUR, the master generally noted that he had never encountered problems associated with the failure of the system’s motor.

A broken torque sensor can be treated by replacing the sensor. The only consolation for a design with an analog sensor may be the possibility of a slight adjustment (±1°) of the EUR. But if the sensor socket is significantly broken, then the adjustment will no longer help.

One of the most common reasons for sensor failure is damage to the boot that is installed above it. It begins to rot due to constant moisture and eventually collapses, sending the sensor for replacement - if such a possibility exists. If it is not there, then... You probably already guessed it: replacing the rack assembly. But the most annoying thing that can happen is a banal breakdown of the connector on the rail, because in this case, nothing other than replacing the rail assembly will help.

If you are lucky and the rack was repaired

Upon completion of the work, the rack is assembled and installed on the car.

After installation, it is necessary to initialize or adapt the EUR. This action is extremely important, since it allows you to “teach” the rack to see all the sensors and extreme positions. If this is not done, then the electric motor will spin “until victory”, as a result of which at the end of the stroke the rod will hit the stop with considerable force. After adaptation, the system will sharply reduce the force 5 degrees before the extreme position, protecting the rod from impact.

By the way, there is another small plus associated with adaptation and the very principle of operation of the electric amplifier. If you remember, in systems with hydraulic booster, you cannot hold the steering wheel in the extreme position for a long time - this can lead to overload and damage to the pump. But with a properly adapted electric power steering, everything will be fine in any position.

In conclusion

Despite the apparent simplicity of the electric power steering system and the virtual absence of the need to maintain it, it is worth remembering that it is still one of the most important systems in the car. After all, the EUR helps control the direction of movement - in other words, it makes movement subject to your will. Using the readings of the wheel, engine, and steering wheel sensors, the EUR requires double attention - therefore, if the slightest oddity appears in its operation, do not wait for a “revolt of the machines,” but go for diagnostics.

Special thanks for the preparation of the material and consultations to the company Master Service (MSG), contact details +7 (800) 350-99-23 (Moscow), +380 (57) 738-33-08 (Kharkov).

Source

Repair of the electric booster on a Priora, replacement of the EUR

So, you need to replace the electric booster on the Priora or simply check the condition of its contacts. In any case, repair involves complete removal of the unit. Prepare the necessary tools:

- Chisel and hammer.

- Deep head for 8 and 13.

- Extension and ratchet, alternatively you can use a wrench.

It’s quite easy to remove the amplifier itself with your own hands, but in order to get to its mounts and the control unit, you will need to remove many parts of the dashboard: the steering wheel along with the airbag, the casing and the ignition switch. Once these components are removed, repairs to the amplifier can begin.

What does Kalina's power steering consist of?

This unit is an independent device included in the steering mechanism of the Lada Kalina. It allows the driver to turn the steering wheel without much effort, and also ensures softness and smooth operation of the moving parts of the steering system.

Structurally, this mechanism cannot be classified as complex units. The electric power steering has the following parts:

- electric motor;

- gear unit;

- control module;

- sensors that monitor the torque, speed and number of revolutions made by the crankshaft.

The Lada Kalina on-board controller continuously monitors the functioning of this amplifier and controls its operation, but malfunctions do occur and many car owners are very interested in how to eliminate them. The mechanism is activated at engine speeds of 400 rpm. When the speed exceeds 60 km per hour, the electric booster stops functioning. This is done for the sake of safety, because at high speeds the driver must have confident feedback on the steering wheel, which a “light” steering wheel is not able to provide. With increasing speed, a gradual decrease in the magnitude of the force in the mechanism is observed.

How to adjust steering play

And finally, another reason for play in the steering is loosening of the adjusting rods, which are designed to adjust the toe-in of the car's wheels. This is a consequence of poor tightening of the bolts on these rods after adjusting the toe angle, and can lead to the adjusting rod popping out of the tip.

On some modern car models, the swing arms are not welded to the suspension struts, but are bolted together. The weakening of these connections also leads to the appearance of the described trouble. To exclude this option when determining the cause that led to it, you need to lift the front of the car and remove the wheels and check the tightness of the above connections, thereby adjusting the steering.

Relay block Lada Granta

The relays are located in the same fuse and relay box, which is located to the left of the steering column under the cover.

K1 - heater fan relay

K2 - power window relay . If they do not work, also check fuse F2; if this does not help, then the problem may be in the control unit.

K3 - starter relay . If it does not work (does not turn) and this relay is working, check the battery charge level. It could also be a problem with the retractor or the ignition switch and its contacts.

K4 - ignition switch terminal 15 relay

K5 - turn signal and hazard warning relay . If the turn signals come on and do not turn off, this relay may be shorted. Also check fuse F3 (emergency mode).

K6 - windshield wiper relay . Check also fuse F4.

K7 - high beam relay . Also check fuses F14 and F15 and the lamps themselves.

K8 - horn relay . Also check fuse F20, signal switch contacts on the steering wheel.

K9 - low beam relay . Also check fuses F12 and F13 and the lamps themselves.

K10 - rear window heating relay . If the heating does not work, the problem may be in fuse F8.

K11 - engine control unit relay . Also check fuse F1.

K12 - electric fuel pump relay . Also check fuse F21.

Why do steering problems occur?

The main reason is the unsatisfactory condition of the roads. The car's suspension absorbs most of the shock to the wheels, but some of it is still transmitted to the steering mechanisms. It is worth noting that fans of low-profile tires risk much more than adherents of using standard wheels - low tires are unable to smooth out bumps, and this significantly reduces the service life of both the suspension and steering wheel.

But car owners should remember that even with extremely careful driving on a perfectly flat road, they will still have to change individual steering elements. They have a limited service life and some parts are consumables.

Steering design

The design of the steering system in modern cars is almost the same for most models produced; there are only minor differences.

- Steering wheel.

- Cardan-type intermediate joint.

- Steering gear.

- Left and right pulls.

- Internal and external tips.

- Adjustment rods.