What is a generator

A generator is an alternating current device that produces electromagnetic excitation during operation.

The generator design has a built-in rectifier unit, equipped with diodes made of silicon, as well as an electronic voltage regulator. Thus, the unit creates electrical energy from mechanical energy and energizes the car’s battery, and also provides energy to its devices and systems. The connection diagram for the generator on Niva-2121, 21213, 21214 is shown in the figure.

Based on the type of friction, bearings are distinguished:

Sleeve bearings, in which the supporting surface of the axle or shaft slides along the working surface of the bearing;

Rolling bearings, which use rolling friction by installing balls or rollers between the supporting surfaces of the axle or shaft and the bearing.

According to the direction of action of the perceived load, bearings are divided into:

radial, taking up radial loads;

persistent, receiving only axial loads from the shaft

Radial-thrust, bearing simultaneously radial and axial loads.

Rolling bearings consist of two rings, rolling elements (of various shapes) and a cage (some types of bearings may be without a cage), which separates the rolling elements from each other, keeps them at an equal distance and directs their movement. Along the outer surface of the inner ring and the inner surface of the outer ring (on the end surfaces of the rings of thrust bearings), grooves are made - raceways, along which the rolling elements roll when the bearing operates. Such bearings are called industrial bearings.

There are also loose bearings, consisting of a cage and balls inserted into it (see figure below), which can be pulled out.

In some machine components, in order to reduce dimensions, as well as increase accuracy and rigidity, so-called combined supports are used: the raceways are made directly on the shaft or on the surface of the housing part.

There are rolling bearings made without a cage. Such bearings have a larger number of rolling elements and a higher load capacity. However, the maximum rotational speeds of full complement bearings are significantly lower due to increased torques of rotational resistance.

In rolling bearings, rolling friction occurs predominantly (there are only small losses due to sliding friction between the cage and the rolling elements), therefore, compared to sliding bearings, energy losses due to friction are reduced and wear is reduced. Closed rolling bearings (with protective covers) require virtually no maintenance (lubricant replacement), open ones are sensitive to the ingress of foreign bodies, which can lead to rapid destruction of the bearing.

A sliding bearing is a support or guide of a mechanism or machine in which friction occurs when mating surfaces slide. A radial sliding bearing is a housing with a cylindrical hole into which a working element is inserted - a liner, or a bushing made of antifriction material and a lubricating device. There is a gap between the shaft and the bearing sleeve hole filled with lubricant, which allows the shaft to rotate freely. Calculation of the bearing clearance operating in the mode of separation of friction surfaces by a lubricating layer is carried out on the basis of the hydrodynamic theory of lubrication.

The calculation determines: the minimum thickness of the lubricating layer (measured in microns), pressure in the lubricating layer, temperature and consumption of lubricants. Depending on the design, peripheral speed of the axle, and operating conditions, sliding friction can be dry, boundary, liquid, and gas-dynamic. However, even bearings with fluid friction go through a phase with boundary friction during startup.

Lubrication is one of the main conditions for reliable operation of a bearing and provides low friction, separation of moving parts, heat dissipation, and protection from harmful environmental influences.

liquid (mineral and synthetic oils, water for non-metallic bearings)

plastic (based on lithium soap and calcium sulfonate, etc.)

solid (graphite, molybdenum disulfide, etc.)

gaseous (various inert gases, nitrogen, etc.)

The best performance properties are demonstrated by porous self-lubricating bearings made by powder metallurgy. During operation, a porous self-lubricating bearing, impregnated with oil, heats up and releases lubricant from the pores onto the working sliding surface, and at rest it cools and absorbs the lubricant back into the pores.

The Tehnoprofsnab company carries out comprehensive supplies of industrial goods to enterprises in the region, as well as to other cities and regions of Russia. RTI, ATI, Lifting and storage equipment, metal and plastic containers, thermal equipment, bearings, overalls and footwear, personal protective equipment. The company strives to strengthen its position in the market, form new relationships and develop unique areas that are interesting, primarily for our clients. One of the developed types of activity is small-scale production of rubber goods (rubber products). Both shaped and non-shaped.

The generator in the car plays a particularly important role; this electric machine supplies the entire on-board network of the car with electricity. No car can operate for a long time without a working generator, so its role in the car is very important.

This article will focus on the generator on the Niva car, describing in detail the types of generators installed on the Niva, as well as their characteristics, possible causes and signs of malfunction.

Nature of the malfunction

The main characteristics of the generator installed by the manufacturer in Niva 21214, 21213, 2121 will be considered using the example of generator type 9412.3701:

- current – 80A;

- voltage – 13.2 V,

- rotation is right.

The cost of standard models of electric generators is 5-7 thousand rubles. If the unit breaks down, it is possible to replace its components or completely replace it with the original or analogues. The prices of the most common ones are presented in the table.

| Analogue | vendor code | Cost, in rubles |

| Generator VAZ-2104-21073,21214 | 9412.3701-03 | 5900 |

| Generator VAZ-2104-21073,21214 | 372.3701-03/05 | 3800 |

| Generator VAZ 2121-21213,21214 | 9412.3701 | 5450 |

The table shows that in the process of replacing a generator on a Niva, you can give preference to a cheaper universal analogue.

During the operation of any car, unpleasant situations often arise in the form of failure of one or another element. Niva is no exception, and most often the generator suffers.

If the generator seems to be faulty, it is recommended to check its functionality using a multimeter. To do this, you will need to start the engine and check the voltage at the battery terminals. The standard value that a multimeter should read is 13.6 V.

If the readings during measurement are higher, it means that a break or short circuit in the windings has occurred in the structure. The same can be said about the case when the voltage is below the specified number. This procedure is carried out regardless of the engine: injector or carburetor.

Also, if the breakdown is caused by another reason, you can replace the generator itself. Usually, for replacement, they turn to special service stations, but if necessary, the work can be done with your own hands.

In the design of the generator, copper or copper-graphite brushes are used to supply voltage to the collector plates. Accordingly, the force of electromagnetic induction that occurs when current flows through the armature winding depends on the quality of the contact between the brushes and the commutator plates.

Also interesting: How to protect your car from thieves? Interesting solutions

Since the armature constantly rotates during operation, abrasion occurs and the length of the brushes decreases (the plates themselves wear out to a much lesser extent). To compensate for wear, the brush holder has springs that press the brushes against the commutator plates. But when wear becomes critical, the spring force is not enough to make good contact, which leads to a drop in the current flowing in the circuit.

Generator from Niva 21214

I am returning again to the fruitful autumn of 2011. It was then that I came to the conclusion that for further improvements in electrical equipment it was necessary to install a more powerful generator: I somehow didn’t want to add the additional 9 amperes consumed by the planned fog lights to the standard figure-eight generator (55A).

The choice was made in favor of the KZATE generator 9412.3701

from Niva 21214. Here are its main characteristics: - power 1120 W; — maximum current 80A at 6000 generator rotor revolutions (slightly less than 3000 crankshaft revolutions).

Many advised purchasing a more powerful generator in the 37.3701 housing, which would not require reworking the mounting, but I abandoned this idea, since the generator from Niva 21214 has another significant advantage: its design allows you to change the diode bridge directly on the car without removing the unit. Let me remind you that to replace the diode bridge of a standard generator, it is necessary not only to dismantle the unit, but also to disassemble its housing, which also usually limits the total “gene” resource to two or three bridge replacements.

So, for the conversion you need: - the generator itself 9412.3701; — bracket for the lower mounting of the generator 21214-3701650; — generator mounting bolt 2110 assembled with silent block, counter washer and nut (I provide a photo for clarity);

— bolt M10×1.25×20 (useful only if there is a third hole for mounting the bracket on the cylinder block); — tension bar 21214-3701635; - M8x30 bolt, M8 nut with a nylon ring and a washer for it; — original washer from under the nut of the upper mounting of the generator.

If the wiring provides for the installation of a 37.3701 (2108) generator, then no modifications are required in the electrical part.

Replacement process:

— remove the battery; — remove the standard generator, lower mounting bracket and upper tension bar; — we screw a new bracket onto two or three bolts (depending on the cylinder block), after first removing the steel split sleeve from it; — hang a new tension bar, but do not tighten the nut completely; — install the generator on the bracket using a bolt, install the silent block in place of the split bushing with the metal part forward; — install the counter washer (flat part back) and tighten the nut; — put on the belt and install the M8×30 bolt in the upper mount of the generator; — controlling the possibility of free movement of the generator, tighten the fastening of the tension bar to the pump; — we tighten the generator belt and fix the upper mount of the generator with a self-locking nut, installing two prepared washers under it;

— tighten the nut securing the generator to the bracket; — connect the generator wiring (terminals 30 and 61); — install and connect the battery.

As you can see, everything is simple. I will only note that it makes sense to check the extension of the generator pulley relative to the pump pulley in order to avoid the appearance of a tensile load at the welding points of the latter (for example, I installed a 2 mm thick washer under the generator pulley, thus moving it slightly forward). We will discuss the science of pulleys in a separate post.

.

Don't forget about spare parts. The following are installed in the generator 9412.3701: - diode bridge BV03-105-01 (2110);

— relay-regulator 2123 (or 611.3702-03 produced by Energomash), which differs from relay-regulator 2110 by the presence of a collar for the rubber protection of the brush assembly. In this case, the decimal “tablet” will also work normally (tested).

Finally, I will say that the increased maintainability of the 21214 generator has already saved me a lot of time: for example, a couple of weeks ago the diode bridge failed right on the highway, but replacing it with a spare one (which is always present in the trunk) took only an hour.

Source

371.3701 is installed on the VAZ-21213 carburetor engine 9412.3701 is installed on the VAZ-21214 injection engine . These generators are structurally similar and are synchronous AC electrical machines with electromagnetic excitation, with a built-in rectifier based on silicon diodes and an electronic voltage regulator. The generator rotor is driven by a V-belt from the engine crankshaft pulley.

Generator 371.3701

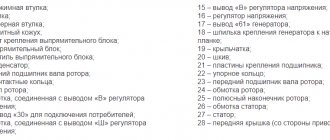

1 – clamping sleeve; 2 – bushing; 3 – buffer sleeve; 4 – protective casing; 5 – screw for fastening the rectifier unit; 6 – rectifier block; 7 – rectifier block valve; 8 – capacitor; 9 – rear bearing of the rotor shaft; 10 – slip rings; 11 – rotor shaft; 12 – brush connected to terminal “B” of the voltage regulator; 13 – pin “30” for connecting consumers; 14 – brush connected to terminal “Ш” of the voltage regulator;

15 – terminal “B” of the voltage regulator; 16 – voltage regulator; 17 – output “61” of the generator; 18 – stud securing the generator to the tension bar; 19 – impeller; 20 – pulley; 21 – bearing mounting plates; 22 – thrust ring; 23 – front rotor shaft bearing; 24 – rotor winding; 25 – rotor pole piece; 26 – stator winding; 27 – stator; 28 – front cover (drive side).

Replacement methods

- Replace the brush assembly with the voltage regulator relay (chocolate). As is known, maintaining charging at the same level is carried out by adjusting the voltage supplied to the generator armature winding. For reliable contact, the brush leads are attached to the contacts of the voltage regulator relay by soldering. To simplify car repairs, brushes, brush holder and relay regulator are most often sold assembled. The advantage of the complete replacement method is its simplicity. For example, the low cost of the assembly for many VAZ cars makes separate replacement of brushes very impractical.

- Replace brushes separately. To do this, you will have to remove the old brushes and solder new copper-graphite products in their place (of course, for DIY repairs you will need a soldering iron, flux, solder and basic soldering skills). As in the case of complete replacement, the feasibility of the method largely depends on the cost of new rods. The point is not only the high price of parts for generators of many foreign cars, but also the fact that for some models (especially for old low-volume cars) it is simply impossible to buy a relay-regulator with brushes assembled. It is proposed to eliminate charging problems by purchasing a new generator. In this case, replacing worn-out elements is the only way to save a considerable amount. If you want to change the generator brushes yourself, you may encounter a lack of new parts for sale for your generator model. In this case, you should select suitable copper-graphite brushes from another car. For proper operation, the length of the rods is important (should not be less than that of new or slightly worn original rods) and the length of the copper flexible contact. New brushes should move freely in the brush holder. In fact, the shape of the new rods does not really matter, since they can be processed perfectly with a needle file.

Also interesting: Niva car steering gear

Replacing bearings in the KZATE generator

Well, as planned, I decided to replace the bearings in the gene.

There was no criticality yet, but there was some noise from the generator, so I decided not to delay it. I ordered new bearings 62022RSH SKF and 63032RSH SKF in advance. There were no better options.

Parsing the generator is quite simple, so nothing supernatural.

To remove the pulley, I used a ribbon (cable) clamp. Well, the head is 24. You can’t clamp the pulley in a vice, it will either become an egg or burst)

To remove the bearing from the housing (which is 6303), I first used a screwdriver and a hammer to straighten the flattened parts of the housing inside so that it would not interfere with the exit. Well, then I found a suitable bushing and knocked it out.

The shaft is a little more difficult. There was no puller, so I slowly tapped it with a screwdriver and a chisel on both sides. But everything was sorted out without any problems.

The bearings were generally good; in the larger ones, noise from the balls and dry grease could be heard.

The old ones have a plastic separator, the new ones have an iron cage inside. I added good lubricant to the new ones in advance. Pressing and assembly in reverse order. Along the way, I checked the diode bridge, everything is fine, resistance is 650-670 for all. The three-level regulator still has 70% brushes. So everything is ok. ! It is worth paying attention that when installing a diode bridge, there must be PCB washers under the places where the winding wires are attached to the diodes.

Also, I updated the limiter on the driver’s door, otherwise the door closes itself constantly) I didn’t install it from Largus, because it’s expensive and in fact no more useful than a regular one. And the price is 200 rubles versus 600 per piece. To order 21230610608200 LADA

That's all for now