Classic models of the Volzhsky Automobile Plant are highly reliable. The steering mechanism of the VAZ 2107 car has a complex structure and provides reliable control in different road conditions. In the process of modernizing the machine, a safety column with a composite shaft was developed and installed. The size of the steering wheel installed on it allows the driver to easily maneuver. Full rotation of the wheel from lock to lock is 3.5 turns. The steering column transmits force to the drive through a composite shaft.

The steering mechanism of the VAZ 2107 is quite informative, but at the same time it does not tire and does not complicate driving the car. It is somewhat difficult to turn the steering wheel (despite its rather large diameter) when parked, but after starting to move, the resistance weakens significantly. A working steering mechanism has a small amount of play, the limit value of which is determined by the rules of the road and the operating manual. The rod system and the large number of parts in the gearbox cause this phenomenon. In general, the steering on the seven is quite reliable.

↑ Control system diagnostic sequence

If there are any malfunctions in the steering (knocks, increased free play of the steering wheel or, conversely, its tight rotation, etc.), inspect the steering parts.

Carry out the inspection on an overpass or in an inspection ditch in the following order. Clean the steering gear parts and steering gear housing from contamination. Set the wheels to a position suitable for driving in a straight line.

When turning the steering wheel in both directions, make sure that:

- free play of the steering wheel does not exceed 5° (when measured along the wheel rim no more than 18–20 mm);

- there are no knocks in the hinges, joints and steering mechanism;

- the steering gear housing and the pendulum arm bracket are securely fastened (tighten the threaded connections if necessary);

- there is no free play in the ball joints of the rod and in the bracket of the pendulum arm, and the worm shaft does not move in the axial direction;

- the steering wheel turning force (when installing the front wheels on a smooth plate) does not exceed 196 N (20 kgf).

When turning the side link adjusting couplings, make sure that their clamps are securely tightened.

Check the condition of the ball joints and protective caps as follows.

Repair and maintenance

Over the years of operation it has been proven that the steering on VAZ 2107 vehicles has impressive reliability. However, this does not take away the fact that the machine requires periodic inspection and repair.

- When performing maintenance, it is important to check for increased play as well as increased wear on the ball joints. To do this, you need to turn the steering wheel from one side to the other. If the wheels do not respond when the steering wheel is turned 5 degrees from its original position, this indicates severe wear. Here you will need to repair the steering column on a VAZ 2107.

- To avoid the need for urgent and rather expensive repairs of the steering gear on a VAZ 2107, it is necessary to change the oil in the worm gear housing. This is done at intervals of 60 thousand kilometers. Leaks may occur through the seals, so they are carefully checked 2-3 times a year. This is one of the weak points of the system.

- The swing arm should be inspected by slowly rotating the steering wheel from side to side. If the parts move in a vertical plane, then surgical intervention is required.

To do this, the drive and steering mechanism are dismantled completely or partially. Everything depends directly on the nature of the breakdown.

Check which parts have defects and what has failed. Inspection is required for each component of the mechanism. If parts are worn out, there is no point in trying to repair them. There is only one way out - a complete replacement of worn-out components of the steering system on a car from a Volga company.

If problems arise with the steering, it is advisable to contact a professional service station.

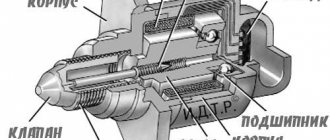

Photo of the VAZ 2107 steering gearbox

You can replace the gearbox yourself, but the process is complicated and requires at least minimal experience and skills.

The VAZ "Seven" is a true classic of the domestic automotive industry. Unlike modern LADAs, they are more reliable and durable, which is proven by the huge presence of these cars on our roads.

Of course, the VAZ 2107 has long been outdated, it does not have a hydraulic booster, and you have to apply sufficient force to turn and maneuver. But for connoisseurs this is not a problem.

Almost all cars, regardless of brand and class, are equipped with a steering mechanism and the VAZ 2107 is no exception. The safety of driving vehicles directly depends on the condition of this structure, which must be periodically inspected, adjusted, and, if necessary, repaired.

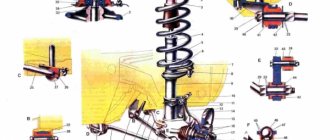

↑ VAZ-2107 steering diagram

1 - lateral thrust; 2 - bipod; 3 - medium thrust; 4 — pendulum lever; 5 - adjusting coupling; 6 — lower ball joint of the front suspension; 7 — right steering knuckle; 8 — upper ball joint of the front suspension; 9 — right steering knuckle lever; 10 — bracket for the pendulum arm; 11 — bearing of the upper steering shaft; 12, 19 — steering shaft mounting bracket; 13 — pipe of the steering shaft mounting bracket; 14 — upper steering shaft; 15 — steering gear housing; 16 — intermediate steering shaft; 17 — facing casing of the steering shaft; 18 — steering wheel; 20 — fixing plate of the front bracket; 21 — coupling bolt for fastening the universal joint; 22 — body spar.

Steering knuckles

The most reliable element in the VAZ-2107 steering device is the steering knuckle. It is durable and very strong, but when repairing the suspension it sometimes has to be removed. The steering knuckles hold the wheel hubs. This element is fixed on the lower and upper arms using movable ball joints.

When turning the steering wheel, the gearbox uses levers to turn the fist in the desired direction. This ensures that the car turns in the desired direction. The elements are made of cast iron, so they can easily withstand high loads. One of the most common breakdowns is deformation from strong impacts on the suspension, from driving on uneven roads and after an accident. The following symptoms may also appear:

- Increased play due to a broken hub bearing and severe wear on the knuckle axle.

- Uneven or rapid tire wear.

- When driving on a flat road, the car gradually moves to the side.

Uneven tire wear can be caused by incorrect wheel alignment. Therefore, before blaming the steering knuckle for all the troubles, you need to carefully diagnose the entire front suspension. It is quite possible that there is excessive wear on the silent blocks or tie rod ends.

↑ Checking the ball joints of the steering rods

- First of all, check the movement of the rod tips along the axis of the fingers. To do this, using the lever and support, move the tip parallel to the axis of the finger.

- The axial movement of the tip relative to the finger should be 1–1.5 mm. This movement indicates that the pin insert is not jammed in the rod tip socket and moves along with the pin, compressing the spring. Replace the hinge with a jammed insert.

- While rocking the steering wheel in both directions, check by touch that there is no free play in the steering rod joints. If you feel free play in the ball joint, replace the tie rod end or tie rod assembly.

- Check the condition of the protective caps of the steering rod ball joints.

- If the protective caps are in good condition and ensure cleanliness inside the hinges, then the service life of the latter is practically unlimited. When moisture, dust, etc. gets into the hinge, premature wear of its parts occurs.

The cap must be replaced if it has cracks, ruptures, and also if lubricant penetrates out when squeezing it with your fingers.

Trouble-shooting

As the vehicle is used, individual components of the steering mechanism gradually wear out. For comfortable and safe driving, as well as to prevent uneven tire wear, any defects in the steering mechanism must be corrected in a timely manner.

Steering gearbox

To identify problems with the steering column, the unit will need to be removed from the car. To do this, you need to prepare the following list of tools:

- a set of keys;

- knob;

- heads;

- steering rod puller.

Dismantling is carried out in the following sequence:

- We drive the car onto an overpass or lift.

- We unscrew the fastening of the cardan to the column shaft.

- We unscrew the nuts that secure the tie rod pins to the bipod, and then use a puller to squeeze out the pins.

Let's disassemble the mechanism for troubleshooting parts:

- Using a 30mm wrench, unscrew the nut holding the bipod.

Inspect the roller and worm for wear or damage. The gap between the bushings and the bipod axle should be no more than 0.1 mm. The rotation of the bearings should be easy and without jamming. Any defects on the internal parts of the bearing are considered unacceptable, as are cracks on the mechanism body. Damaged parts are replaced with serviceable ones. Before assembling the mechanism, lubricate all elements of the gearbox with transmission oil and perform the assembly:

- We hammer the bearing ring into its seat.

Video: disassembling and reassembling the steering column on a “classic”

Backlash adjustment

To carry out adjustment work with the unit in question you will need:

- key to 19;

- wide flat screwdriver.

The procedure boils down to the following steps:

- We set the steering wheel to a position in which the front wheels will stand straight.

- Using a 19mm wrench, unscrew the nut on top of the gearbox.

With a correctly adjusted steering column, play should be minimal, and the steering wheel should rotate without snagging or excessive effort.

Video: eliminating play in the steering gear

Steering shaft

If, when the steering wheel rotates, there is a large play on the hinges of the intermediate shaft or axial movement of the shaft on the bearings, the mechanism needs to be disassembled and repaired. The work is carried out as follows:

- We remove the “-” terminal from the battery, as well as the steering wheel, plastic casing, steering column switches, and connector from the ignition switch.

- Unscrew the cardan mount and remove the bolts.

Pendulum

The pendulum arm itself rarely fails, but the bearings or bushings located inside sometimes have to be replaced. To work, you will need a set of wrenches and a steering rod puller. We dismantle the mechanism in the following order:

- We remove the right front wheel from the car, unscrew the fasteners and use a puller to press out the pins of the steering linkage rods.

- Unscrew the pendulum mount to the right side member.

Replacing bushings

Repair consists of the following steps:

- Unscrew and unscrew the pendulum axle nut.

Trapezoid

A complete replacement of the steering linkage is necessary in the case when all the joints have large wear. We prepare the following set of tools:

- ring wrenches size 13 and 22 mm;

- pliers;

- hammer;

- puller;

- a ruler at least 20 cm long or a tape measure;

- devices for removing the wheel - jack, wheel wrench, wheel chock;

- rags, fabric gloves.

Steering rods on a VAZ 2107 are removed as follows:

- We jack up the front of the car and remove the wheels.

- Unscrew the ball pin and unscrew the nut.

When the work on replacing the trapezoid is completed, it is necessary to check the wheel alignment angles at the service center.

Tie Rod Ends

The extreme rods of the steering linkage fail more often than other hinges. Therefore, if there is a need to replace them, it is not necessary to completely remove all the rods. The tips are changed as follows:

- Repeat steps 1–3 for removing the trapezoid.

- Using a ruler, measure the length of the old part at the centers of the plugs.

Where is the trapezoid located?

The steering tips and rods are located in the lower part of the engine compartment, in close proximity to the interior partition. You can see them on a lift or overpass, or when turning the steering wheel to its extreme position. The design of the trapezoid consists of the following elements:

- Two lateral rods (left and right short).

- One medium pull.

- Tips – total quantity 6 pieces.

The design also contains a pendulum lever - it is installed on the right side in the engine compartment.

Where is the trapezoid located?

The steering tips and rods are located in the lower part of the engine compartment, in close proximity to the interior partition. You can see them on a lift or overpass, or when turning the steering wheel to its extreme position. The design of the trapezoid consists of the following elements:

- Two lateral rods (left and right short).

- One medium pull.

- Tips – total quantity 6 pieces.

The design also contains a pendulum lever - it is installed on the right side in the engine compartment.

Carrying out replacement: step-by-step guide

You immediately need to decide how many rods and tips need to be replaced. Based on this, you can understand whether it is worth changing the VAZ-2107 steering linkage assembly, or its individual elements. Sometimes it turns out that completely replacing a trapezoid is much more effective - its service life is much longer than that of a restored one.

To replace you will need to perform the following manipulations:

- Place the car on a viewing hole or overpass. It is imperative to remove the wheel from which the repair will be carried out.

- Straighten and remove the cotter pin, after which you can unscrew the nut from the tip pin. You do this using the key at “22”.

- Install a puller on the tip and turn its bolt, squeezing the pin out of the hole.

It is advisable to treat all threaded connections with WD-40 penetrating lubricant before starting work. The price of the assembled VAZ-2107 steering linkage will be about 2000 rubles. And it is much easier to dismantle it than each rod separately.

After pulling out the first finger, proceed to the second - repeat the manipulations described in points 2 and 3. After this, the traction can be completely removed. To disrupt wheel alignment as little as possible, you will need to measure the length of the old rod and ensure that the new one has the same size. But this does not mean that after repair there is no need to adjust the camber and toe - this procedure is mandatory.

Carrying out replacement: step-by-step guide

You immediately need to decide how many rods and tips need to be replaced. Based on this, you can understand whether it is worth changing the VAZ-2107 steering linkage assembly, or its individual elements. Sometimes it turns out that completely replacing a trapezoid is much more effective - its service life is much longer than that of a restored one.

To replace you will need to perform the following manipulations:

- Place the car on a viewing hole or overpass. It is imperative to remove the wheel from which the repair will be carried out.

- Straighten and remove the cotter pin, after which you can unscrew the nut from the tip pin. You do this using the key at “22”.

- Install a puller on the tip and turn its bolt, squeezing the pin out of the hole.

It is advisable to treat all threaded connections with WD-40 penetrating lubricant before starting work. The price of the assembled VAZ-2107 steering linkage will be about 2000 rubles. And it is much easier to dismantle it than each rod separately.

After pulling out the first finger, proceed to the second - repeat the manipulations described in points 2 and 3. After this, the traction can be completely removed. To disrupt wheel alignment as little as possible, you will need to measure the length of the old rod and ensure that the new one has the same size. But this does not mean that after repair there is no need to adjust the camber and toe - this procedure is mandatory.