The VAZ 2109 starter has a classic electric motor design with a brush assembly, winding, gearbox and return electromagnetic relay. The principle of operation of the mechanism is to spin the engine crankshaft until the ignition cycle is fully started - the fuel mixture in the cylinders ignites and the generator turns on. The starter is powered in the general electrical circuit of the car from the DC battery; after the crankshaft drive is activated, when its torque becomes greater than the flywheel rotation speed, the retractor return relay gives an impulse to the return clutch, turning off the drive unit.

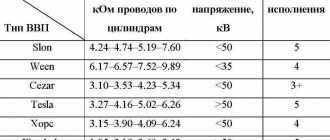

Standard starters on the VAZ 2108, 2109 models and modification 21099 “Samara” are interchangeable and are suitable for any of these models, both in terms of technical characteristics and installation fasteners. Over the entire production period, VAZ models of this series were equipped mainly with three types of starter with original numbers:

- 3708 – basic version with a ring collector and a rotary drive. Its power is 1.3 kW with a current consumption of 40 A.

- 3708 is a modernized version of the previous one with a cylindrical collector, a power of 1.3 kW and a current of 60 A.

- 3708 - an improved starter for the Lada-Samara family with a cermet bushing for the working part of the armature shaft with a power of 1.5 kW and an idle current of 80 A.

The differences in the design features of these starters are small - changes were made to the elements of the commutator units, Bendix drives and some materials of the bushings made of cermets. Version 5712.3708 was later equipped with a planetary drive gearbox.

Characteristics of the VAZ starter of the ninth model

Every driver knows that if the car does not start, the reason may be a faulty starter. In order to diagnose and repair a mechanism, you need to know its structure.

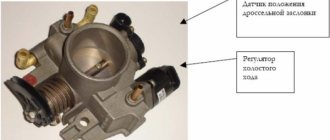

Location and purpose

The main purpose of the starter is to spin the crankshaft, thanks to which the engine starts. Naturally, it is located close to the engine. It is usually located in the engine compartment on the driver's side under the power unit. Depending on the location, when dismantling the unit, you will need to remove either the engine protection or the air filter. Finding a starter is not difficult. It has the shape of a cylinder, and wires are connected to it, which are secured with a nut.

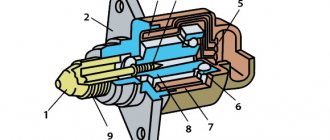

Design and principle of operation of the unit

This unit is a small electric motor. Its design consists of a bendix with brushes, two windings and a movable rotor. Magnetic fields of opposite values are created on two windings - starter and rotor. The mechanism is supplied with voltage, which is transmitted to the rotor using graphite brushes. Thanks to Bendix, rotational movements are transmitted to the flywheel.

The device includes:

- a sleeve that connects to the solenoid relay;

- overrunning clutch, which ensures movement in only one direction;

- gears.

Over time, the parts of the Bendix wear out and it begins to slip. In this case, it needs to be replaced. The cause of the malfunction is contamination of the mechanism, but cleaning does not help restore functionality. Mechanism parts wear unevenly; after washing, they cannot fully perform their functions.

The principle of operation of the starter mechanism is to convert the electrical energy it receives from the battery into rotational movement of the drive gear. An electric current is applied to the poles of the electric motor using a brush assembly. At the same time, the clutch extends and the flywheel crown is connected to the gear. The starter rotates the crankshaft and thus helps start the engine. When the engine is started, the clutch takes its original position (video author - Mikhail Nesterov).

Starter mechanism malfunctions

If any difficulties arise with starting the car, this unit is the first to be suspected, but now, knowing the design of the VAZ 2109 starter, you will quickly figure out where to look. Various sounds similar to metal grinding should also alert you; it is quite possible that your VAZ 2109 will need to disassemble the starter. The reason may lie in the flywheel, and its crown will need to be replaced. In this case, the car will most likely start, just not right away.

But if the car does not start and there are no alarming sounds, then you may have to replace the clutch. Disassemble the starter and dismantle it, try turning it in both directions. If it rotates freely, then calmly throw away the failed part. You can understand that it is necessary to remove and replace worn starter brushes installed on a VAZ 2109 by a characteristic click, after which the expected engine start will not take place.

Expert opinion

Ruslan Konstantinov

Automotive expert. Graduated from Izhevsk State Technical University named after M.T. Kalashnikov, specializing in “Operation of transport and technological machines and complexes.” More than 10 years of professional car repair experience.

You can also detect a breakdown by ear; experienced motorists know this. Moreover, it is possible to detect malfunctions by ear even before the entire unit fails. It is enough to listen carefully and identify starter problems by the characteristic sounds: 1. When you turn on the ignition, a sticking sound is heard, the engine does not start or starts with difficulty. The problem may lie in several points. The most obvious option is a discharged battery or the terminals are not firmly secured. This may also be due to a violation of the integrity of the wiring of the starter and traction relay 2. The sound of difficult rotation. A similar noise is made by the starter rotor if the traction drive is in good condition. The problem arises due to battery discharge, contact oxidation and common wear and tear. 3. Slipping. The sound occurs due to wear and breakage of the rings on the coupling. 4. The jamming sound is due to the rotor moving too tightly. Problems with the starter can also be judged by other sounds, which can be caused by faulty bearings, loose fasteners, etc. Also, a situation often arises when, after starting the engine, the starter gear does not move in the opposite direction, and a characteristic sound is heard from the engine compartment . This means that the traction drive does not work or the lever is stuck; it is necessary to immediately turn off the engine and eliminate the malfunction, since further operation will lead to rapid wear and failure of the starter.

Geared vs conventional: which starter should you prefer?

A conventional starter does not have a gearbox; the rotational motion is transmitted directly to the crankshaft. Therefore, its design is simple and allows you to carry out repairs at home. Due to the fact that the electric current supplied to the device instantly engages the flywheel crown and gear, the engine starts, which is called “half-turn”. Classic units, due to their simple design, are reliable devices that can withstand electrical influences, but can fail when exposed to low temperatures.

The principle of operation of the gear unit is the same as that of the classic unit - the conversion of electrical energy into mechanical energy.

The difference is in the design - a gearbox is included, which is located between the armature and the bendix. In addition, the windings are equipped with permanent magnets, which increased the reliability of the mechanism. Geared devices are increasingly conquering the car market. In order to figure out which starter is better, you should find out the advantages and disadvantages of each of them.

Advantages of the classic version:

- simplicity of design;

- high maintainability;

- availability of spare parts;

- low cost.

The disadvantages include the following:

- the need for high starting current;

- rapid wear of parts;

- unstable operation at low temperatures;

- large weight and dimensions.

In general, an ordinary unit can be assessed as a reliable device when used correctly.

The gear unit has the following advantages:

- light weight and small size;

- can operate in a wide temperature range;

- long service life;

- economical energy consumption (40% less than usual).

Thanks to the presence of a gearbox, starting reliability at low temperatures has increased. Since a small current is required to start the power unit, the likelihood of a successful start increases in winter.

The disadvantages are the following:

- lack of spare parts;

- complex repairs;

- low quality gearbox.

The reliability of a device depends on the quality of its components. Therefore, a mechanism with high-quality components will last a long time without repair.

Photo gallery

Solution

- First you need to put your “nine” in neutral gear, and also turn on the parking brake.

- After this, the hood opens, you need to find the red cable on the retractor.

- Using a thick screwdriver, you need to short-circuit the terminals on this component. When a short circuit occurs, sparks may fly in different directions - there is no need to worry, this is a normal situation.

- Then you need to try to start the engine. If you notice that the starter starts to work normally when screwing in, then the problem is not with it. If the device does not turn, then most likely it will need to be changed.

- If the mechanism is working properly, the red wire from the solenoid relay must be removed, and voltage from the battery must be applied to this terminal. If there is a pop, the relay will be fully operational. If there was no clap, then most likely the reason lies precisely in the relay.

- Check the contacts on the starter, it happens that due to oxidation it stops turning.

Gear starter VAZ 2108, 2109, 21099, Niva from TM ATEK

The gear starter for VAZ 2108, 2109, 21099 is a universal spare device, since its installation is possible on almost any model from the VAZ Samara family. And this is a fairly wide range of cars, and their debut on the market dates back to the mid-80s, and some modifications are still on the production line of the car plant today, moreover, they are in stable demand from buyers. Of course, the proposed starter has little in common with devices that were installed more than thirty years ago, but, thanks to its similar shape and dimensions, it is a completely interchangeable element. The differences, and very significant ones, are in technology.

Progress does not stand still, and through numerous upgrades the developers have achieved the following advantages:

– Reduced electrical energy losses;

– Improved power characteristics;

– Increased service life.

Also, it is worth noting the block structure of the product (the possibility of repairing or replacing individual elements); use of metal and copper components (reliability, durability and safety).

Starter 2108 2109 2113 2114 2115 ATEK is the optimal device for your VAZ, ensuring ideal engine starting in any conditions, even with a “tired” or discharged battery.

You can view the characteristics, check availability and find out the most convenient way to purchase in our online catalog and in the online store of our partners.

Video “Replacing a classic mechanism with a device with a gearbox”

This video talks about replacing a conventional starter with a gear starter (the author of the video is Auto overhaul).

Technical progress does not stand still and is constantly evolving. Every year new technologies emerge, allowing engineers to improve or create completely new parts. This also applies to mechanical engineering. Hundreds of thousands of modern cars are sold in Russia every year. Each of them contains the latest technologies. We will talk about such a small unit as a starter, and we will figure out which starter is better: a gearbox or a regular one.

Advantages and disadvantages of the classic version

So we are actually gradually approaching the answer to the question of which starter is better: gear or conventional. To do this, let's look at the strengths of the classic version. They are as follows:

- low cost;

- high maintainability;

- You can find spare parts almost everywhere.

But there are also some disadvantages, which are expressed in the following:

- high base current required;

- rapid wear of parts;

- does not work well at low temperatures;

- large weight and size.

In general, this is a fairly reliable design with proper maintenance. But development does not stand still, and this has led to more advanced gear starters. Let's look at their strengths and weaknesses.

Diagnostics

To carry out diagnostics, arm yourself with a conventional tester with voltmeter mode.

- Connect the battery terminals to the poles of your measuring device. You will need an assistant to drive.

- After connecting the terminals to the voltmeter, look at the readings of the device. If the battery is working properly, the data will be 11-13 V.

- Turn the ignition key and at this moment measure the voltage. If the losses are only 1-2 Volts, then the starter works normally and does not show resistance.

- If the voltmeter parameters decrease by 2 times or more, the reason is in the starter. Or rather its bushings or brushes.

- Remove the starter and check the relay. Connect the battery terminals to its terminals on the body and transfer it to 12 V. If the overrunning clutch moves in the front cover, then the relay works perfectly. If not, replace it.

Repair

Next, you have to check the condition one by one and take appropriate measures to eliminate problems with the following components of the starter:

Now let's talk about everything one by one.

Brushes

First, assess the current condition of the brushes. In most cases, they are the source of problems with the starter.

- Remove the pair of screws that hold the protective cover in place. The cover is now easy to remove.

- Use a screwdriver to remove the retaining ring from the shaft, and don’t forget about the adjusting washers.

- Unscrew 2 more tie rod nuts. Remove the manifold side cover.

- Use a screwdriver to press out the springs and remove the brushes from the holder.

- Measure the brushes with a caliper or ruler. If the height is less than 12 millimeters, the brushes must be replaced.

- It is also better to replace elements if there are chips, cracks and other defects on the surface.

Anchor

If all is well with the brushes, the next suspect is the anchor.

- Remove the housing with the starter.

- At the anchor, look at the condition of the commutator, check whether the winding is intact.

- If there is carbon deposits on the collector or signs of breakdown, clean these areas with fine sandpaper.

- Check the armature and stator windings using a multimeter in ohmmeter mode.

Overrunning clutch

Parallel checking of the overrunning clutch with the armature will allow you to replace the latter at the same time.

To gain access to the clutch you will have to remove the armature from the front cover. At the same time, change it if necessary.

- Remove the retaining ring located near the overrunning clutch.

- Remove the restrictor ring.

- Remove the plastic lever stop, which will allow you to reach the anchor.

- Remove the intermediate support from the shaft.

- Check the condition of the gear teeth. If there are defects, the unit is replaced with a new one.

Bendix or overrunning clutch

Traction relay

Replacing the traction relay is necessary if, when voltage is applied to its terminals, the overrunning clutch does not extend. Sometimes the VAZ 2109 is equipped with collapsible relays. But it’s still better not to repair it, but to replace it with a new relay.

- To remove the relay, unscrew the two screws located on the front;

- Lift the relay, disconnect the armature from the lever;

- Remove the relay from the housing, grabbing the spring and armature. All elements are changed if necessary.

Bushings

Excessive wear on the bushings often impairs the performance of the starter. This is due to the material from which they are made - brass, bronze or copper. Contact with stronger metal causes wear.

- In the case of the VAZ 2109 starter, we have one bushing located in the rear cover, as well as a second one, which you will find in the clutch housing.

- The presence of defects can be determined visually. If the elements have chips, cracks, burrs, or other defects, this indicates wear.

- Try moving the starter shaft transversely. If there is noticeable play, the starter bushings are worn out and need to be replaced.

- When planning to replace the rear bushing, it is recommended to simultaneously change the cover itself.

- The front bushing is removed from the crankcase using a tap of the required size. Tighten the tap like a thread, and resting it against the bottom of the hole, the sleeve will gradually begin to move out of its place.

- Before installing a new bushing, treat the inner surface of the seat with engine oil.

When putting the starter back together after repair, the most significant advice is to clean the surfaces from contamination. This will significantly extend the service life of the repaired unit and avoid breakdowns in the near future.

Be prepared for the fact that attempts to repair the starter will not give the expected effect. In this case, it is better to replace it completely or contact a trusted car service.

Source

Construction and something else

During operation, the internal combustion engine produces a fairly large amount of energy. It is enough for lighting devices, music, wipers, etc. In general, while driving, the main load goes to the generator. In a static position, the motor does not produce anything, so it needs to be started somehow. For this purpose, various types of starters are used along with batteries.

Most often, it is the starter solenoid relay that fails. Its price is fortunately affordable and starts from 500 rubles and ends in several thousand. In addition, the design includes a bendix with a drive gear and brushes.

General information

The first starter used on a car had a number of significant shortcomings. Over time, the design was gradually improved and significantly transformed. The starter is a 4-band electric motor, which is necessary to rotate the crankshaft when starting the engine. It takes energy from the battery and increases the starting current several times. Due to this, any internal combustion engine starts. The principle of operation of the starter has not changed over the years.

Nevertheless, its design has been constantly improved. The weight of the part was reduced, the service life was increased due to the use of higher quality and new materials, etc. All this led to the fact that the starter was transformed quite significantly and even a new type appeared - gearbox. This is exactly what we will talk about now.

Let's sum it up

If you decide to replace this unit, then you first need to decide where the starter is located. This is usually the driver's side under or to the side of the engine. To remove it, you need to make room. Depending on the location, it may be necessary to remove the engine protection or the air filter with the box. Next, disconnect the wires and unscrew the bolts. Determining where the starter is located is not difficult. It has a cylindrical shape, and several wires come from it, secured with a nut. Everything is done quite simply and quickly.

So we answered the question about which starter is better: gear or conventional. Classic starters are good in their own way, but are gradually being phased out. But they also have their strengths, just as gearboxes have their weaknesses. For example, in the outback it will be difficult to find spare parts for a starter with a gearbox, but for a regular one - no problem. The same can be said about repairs - not everyone has encountered gearboxes on the starter and not everyone will undertake it. How much does a starter with gearbox cost? It all depends on the brand of the car; a normal one will cost 5-7 thousand rubles.

The gear starter design is distinguished by a gear transmission between the armature and the overrunning clutch. The safety margin is ensured by increasing the torque in the gearbox supplied to the flywheel of the internal combustion engine.

By analogy with a conventional starter, the gear version uses permanent magnets instead of windings, simplifying the design, reducing its weight and size. Maintainability is practically not reduced; the main causes of breakdowns and repair methods are discussed below.