Chevrolet Niva error codes: decoding and description of meanings

The popular Russian-made model is very widespread in the CIS countries due to its optimal cost and increased cross-country ability, which is critically important in the conditions of domestic operation.

Motorists buy cars for off-road travel and small towns, where the quality of roads leaves much to be desired. The disadvantages of the car include weak wiring - when the load increases to the design limit, on-board electronic systems often fail, which causes software failures. Chevy Niva error codes appear on the dashboard display or are detected using special equipment, but the common thing is that they all indicate a malfunction of a specific component.

How to check the sensor

Before buying a new MAF sensor, you need to make sure that the old one is faulty. First you need to clean the air flow sensor with a special spray for sensors. Then look at the condition of the air filter. Replace if necessary. In more than half of the cases the malfunction will be fixed.

In order to diagnose the cause of error P0102, you need to do the following:

- Erase the error code from the ECU.

- Connect a scanner or on-board computer to the OBD-II connector and make a test drive.

- If the error comes on again, check all the potential culprits: filter, connector, wiring harness.

In addition, you need to check the electrical circuit using a multitester and measure the voltage between the contacts of the block.

When the ignition is turned off, the connector from the sensor is disconnected. Then the ignition is turned on and the voltage is checked between contacts 2 - 3, 3 - ground, 3 - 4. Between contacts 2 and 3 the voltmeter should show 10 volts, between 3 and 4 - 5 volts, and between 3 and ground there should be no voltage.

After checking, you need to install resistance between pin 5 and ground. In normal condition it will be 4 - 6 kOhm. If the measurement data does not correspond to the nominal value, then there is either a break or a short circuit in the wiring. Resistance diagnostics are performed with the ignition off.

Only after the previous check can a conclusion be made that the MAF sensor is faulty.

Chevrolet Niva error diagnosis

The most reliable way to identify what is wrong with a car is to diagnose electrical appliances and equipment. The procedure allows you to accurately identify breakdowns and quickly repair your car.

There are two ways to detect a problem in a car.

Self-diagnosis VAZ 2123

The simplest procedure allows the motorist to independently identify the damaged area and repair the damage. Thanks to the successful firmware of the on-board computer, some errors are displayed on the standard display. In this case, nothing happens on its own - you will need to perform several steps manually:

If the manipulations are correct, one of the indicated codes will appear on the display, and each Niva Chevrolet error number will be responsible for its own section of the highway:

At the same time, you need to accurately understand that, for example, when error 10 is on the display, the Chevrolet Niva tells the driver that there are several problems (standard, unambiguous codes are summed up).

You should also know that Niva Chevrolet self-diagnosis errors do not reflect the exact location of the breakdown. Codings can only show the section of the wiring where you need to look for the cause of the malfunction. Also, these encryptions may be the result of a software failure after an unsuccessful wash or disconnection of the battery. To obtain more accurate data, the user needs to connect a special diagnostic scanner.

OBD-II error P0102 VAZ – Low voltage level of the air flow sensor (MAF sensor)

Error P0102 VAZ means that the engine control unit (ECU) receives low voltage from the mass air flow sensor (MAF sensor). Often associated codes are P0100, P0101, P0103 and P0104.

Low MAF sensor voltage can have several causes.

- the voltage at the sensor is below normal or required for correct operation of the ECU.

- The most common cause is a clogged air filter, which is restricting the air flow from the filter to the air flow sensor.

- The wiring or the MAF sensor itself are located close to high-voltage components, ignition wires, generator, which can cause interference if they malfunction.

- The MAF sensor may be dirty, which also causes this error. It is enough to clean it with a spray.

- The air flow sensor must operate within a certain range of values in order to provide the correct signals to the engine control unit. Perhaps other sensors are giving incorrect values.

Diagnostics using third-party equipment

More precisely, errors on Chevy Niva can be identified by connecting additional equipment. The technique is more technically complex, but allows us to determine the cause of a breakdown or failure with minimal error. In this case, the sequence of actions is as follows:

If all actions are performed correctly, all available information and any errors in the form of encrypted codes will be displayed in the desktop window.

There are also specialized scanners designed specifically for Chevrolet NIVA. Dealer devices are connected to the place of the standard signaling unit through an output cable.

Separately, we should highlight modern devices designed to connect a smartphone to a car, while reading encodings and controlling operating modes occurs directly from the gadget’s display.

At the same time, you should know what the encodings displayed during diagnostics mean. The code consists of several elements.

The next element is a single digit:

The following digit determines the exact serial number of the line in which the defect was detected:

How to replace it yourself

The air flow sensor is located between the air filter and the massive air pipe connected to the intake manifold.

Once you have established that the VAZ error P0102 pops up due to the mass air flow sensor, you can safely go to the store for a new part. A new sensor costs more than 3,000 rubles and is sold complete with the pipe in which it is installed.

Replacement work takes place with the ignition off. First you need to disconnect the block with wires from the sensor. To do this, press the bottom of the chip on the latch and carefully remove the connector. In this case, you need to pull not by the wires, but by the block.

Using a screwdriver, loosen the clamp and remove the rubber pipe from the sensor. After this, two M6 bolts are unscrewed on both sides of the mass air flow sensor.

After removing the part, you need to look at the markings on the body, since the auto industry installs different ECUs on the same models, and it may turn out that a new working sensor will be incompatible with the controller installed on the car.

The sensor is installed in the reverse order of removal. This eliminates error P0102 for Kalina, Priora, Samara - all representatives of the VAZ family with similar injection engines.

Source

Check Engine

When the ignition is turned on, the indicator should light up, so the ECM checks the serviceability of the lamp and control circuit. After starting the engine, the indicator should go out if the controller memory does not contain the conditions for turning it on.

To protect against random, short-term errors that may be caused by loss of contact in electrical connectors or unstable engine operation, the warning light turns on after a certain period of time after detecting a malfunction in the ECM. During this period, the on-board diagnostic system checks for a malfunction.

What is the MAF for?

An internal combustion engine runs on a combination of fuel and air. For effective operation, a mixture is required that will burn out almost completely in the cylinders, and for this you need to choose the right ratio.

The mass air flow sensor, otherwise known as the MAF sensor, transmits readings to a computer, which selects the exact proportion of air and gasoline corresponding to certain crankshaft speeds.

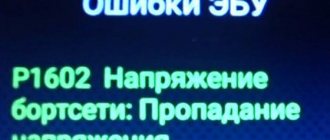

Error P1602

Code P1602 is entered if the following conditions are met:

The codes should be cleared using a scan tool. If the code is entered again, check the power supply circuit from the battery to pin “12” of the controller.

What errors have you encountered on Chevrolet Niva? You will find other reference information on ChevyNiva here.

Share on social networks:

Found an error? Select it and press Ctrl+Enter..

Source

Causes

- Faulty or dirty air flow sensor.

- Debris in the mass air flow sensor.

- Air leak.

- Open air filter housing.

- Incorrect air filter installed.

- Leaks in the PCV (Powered Crankcase Ventilation) system.

- Narrow or constricted inlet pipe.

- Dirty air filter.

- Closed air screen in front of the filter.

- Non-original parts installed (eg cold intake, modified air filter).

- Incorrect mass air flow sensor installed.

- There is an electrical problem with the sensor wiring or connector.

- Faulty ECU (rare).

- The catalytic converter is clogged or the manifold absolute pressure (MAP) sensor is faulty.

Decoding Chevrolet Niva error codes

There is a monochrome display on the car's instrument panel. Basic information about the results and progress of self-diagnosis is displayed here.

The full list of faults is long. The factory table contains hundreds of codes, which is impossible to list. Below are explanations of the most popular faults.

Error 1 1

The power steering system does not work correctly. The module needs to be diagnosed. There may be leaks in the sealing elements.

Error 1 6

The code is an information message notifying about malfunctions in the on-board electrical circuit.

Code 2

The float in the fuel tank is out of order or does not respond. The element may have been damaged due to a strong impact or shaking. Wiring failure cannot be ruled out.

Error 8: Shniva

If the system issues a similar failure code, an inspection of the battery and power lines will help correct the situation. The corresponding indicator on the dashboard often lights up.

The error clearly indicates that the voltage in the on-board network is too low.

Code 10

Typically the error consists of two problems. Here there is an open circuit of the float and a voltage drop in the on-board network. Problems are resolved in the order determined by the owner.

Code 11

A similar breakdown indicating two problems at the same time. There is a double meaning of the cipher here, and the combination is determined in the same way as in No. 10.

Error 12: decryption

The system reports a breakdown of the vehicle's control indicator. The Check lamp will not light up even if there is a serious malfunction. As a repair, it is enough to replace the damaged element.

Error 14

The symbol means that the temperature of the antifreeze in the radiator is too high - the engine has overheated. Stop and let the system cool down. It is recommended to check the lines for leaks.

Shniva: error 16

The problem is complex and indicates the presence of errors 4 and 12. Troubleshooting is described above.

P0036 - error

It indicates an open circuit in the oxygen sensor control circuit No. 2. You should find a gap in the line.

Error 0101

The mass air flow sensor shows that the air flow does not correspond to the required one. Engine performance may drop significantly during operation.

Error P0102

He says that the signal coming from the DRV is too low. The problem is that the working part of the sensor is clogged.

Fault 0103

The opposite meaning to the above problem. The sequence of actions during repairs is similar.

Breakdown 0115

The problem is related to the coolant temperature sensor. Replace the faulty element with a new one.

Code 0123

The signal from the TPS is too high. The problem is in the throttle sensor or mechanical part.

Code 0130

Incorrect data from DC1 installed before the neutralizer. Check the sensor for contamination. If the working part is clogged, the entire module is replaced.

Breakdown 0134

Open circuit DC1. The sensor is located under the bottom of the car, which often causes stones and dirt to get into the wiring.

Code P0135

Heater circuit DK1 – no signal. Check the contact groups for oxidation and dirt.

Code 0139

The response of DK2 installed after the neutralizer is too slow. The breakdown is eliminated by diagnosing the sensor.

Code P0141

Heater DK2 is faulty. The code may be displayed as 0141 or 141.

Code P0171

The system issues 0171 - this means that the air-fuel mixture is excessively rich. Check the air line for blockages.

Error P0172

The module transmits a signal - the fuel mixture is too lean. Perform fuel line diagnostics. This is due to parasitic air suction through depressurized connections or worn hoses.

Shniva: error 0302

Multiple misfires in cylinder No. 2. Check the ignition system and fuel supply to the working chamber.

Shniva: error 0131

The signal level from DC1 is too low. The sensor grid is clogged.

Error 0328

The signal from the knock sensor is too high. A breakdown may indicate a short circuit in the internal parts of the sensor.

Error 0327

The signal level from the DD is too low. The power of the power plant often drops. The sensor needs to be checked or replaced with a new one.

Fault 0335

There is no signal from the DPKV. The wiring is damaged or the sensor is faulty.

Error 0336

The problem indicates that the control signal from the DPKV is outside the established limits. The problem is in the sensor.

Breakdown 0339

Incorrect operation of the crankshaft position sensor.

Error 0340

The problem indicates that the DPRV circuit is damaged, shorted, or completely broken.

Shniva: error code p0342

Signal too low. You need to check the control wires.

Breakdown 0343

The algorithm of actions will be the opposite. This is all due to damage to the sensor. The sensor needs to be tested using diagnostic equipment.

Malfunction P0422

Indicates that the catalyst is not working correctly. A similar glitch occurs even with short mileages and in different operating modes. To properly deal with it and not constantly reset the code, you will need to cut out the catalyst or replace the sensor, which does not always help.

Code 0441

The air flow through the valve is incorrect. Conduct diagnostics of the module and remove all contaminants.

Error 0444

Indicates an open circuit in the power supply of one of the elements of the fuel vapor recovery system. Perform a full circuit diagnostic and repair the open circuit.

Error 0500

There is an incorrect signal from the DSA. The speedometer may show too high or low a speed. If there is a problem, the entire sensor is replaced.

Error P0504

The electrical circuit controller sensor is damaged. This responds to the DPPT - the system indicates that the actual position of the brake pedal is different from the set one.

Malfunction P0507

This indicates that the idle speed control is blocked. In this case, XX will be too high relative to the established norm.

Code 0508

The problem is due to incorrect engine speed detected by the automatic transmission control module. The system tries to correct them on its own. The breakdown can only be repaired at a service station.

VAZ error 0102 - Low signal level of the mass air flow sensor

Let's consider error 0102 on injection cars of the VAZ family, in particular VAZ 2112, VAZ 2114 .

Code P0102 is associated with incorrect signal from the mass air flow sensor (MAF). The following symptoms may occur:

- Increased fuel consumption

- The engine takes a long time to start or does not start the first time

- Lost traction from the engine

- Idle speed floats

First of all, you need to check the presence of power to the sensor and the presence of ground, check the resistance of the sensor. Resistance must be measured between pin 5 and ground. The resistance of the working mass air flow sensor varies between 4 - 6 kOhm (read more below).

To check the condition of the MAF sensor, check the voltage (set the measurement limit in the voltmeter to 2 Volts) between contacts No. 3 (negative wire) and contact No. 1 (positive wire) as shown below:

Compare the voltage readings with the data:

- Voltage: 0.99 - 1.01. Voltage of the new MAF sensor. The sensor is fully operational

- Voltage: 1.01 - 1.02. The sensor is in good condition.

- Voltage: 1.02 - 1.03. The sensor is in good condition. No replacement required.

- Voltage: 1.03 - 1.04. The sensor life is coming to an end. The sensor will need to be replaced soon.

- Voltage: 1.04 - 1.05. The sensor resource has been used up. It is necessary to change the mass air flow sensor in the near future

- Voltage: 1.05 or more. The sensor is faulty

Error information

If the malfunction appears periodically, there is a high probability of damage to the wire insulation, poor connection to the ground of the car. Conduct a visual inspection of the wiring to the sensor, check the connection to ground, whether the connector is fully inserted. Measure the resistance of the sensor and the presence of power, while moving the wire along its entire length. The value of resistance and power should not change (read more below).

Check if the air filter in the air intake system is clogged. If the air filter is clogged, this will lead to dust getting on the mass air flow sensor, which is highly undesirable and leads to malfunction.

How to diagnose a problem

Measure resistance: IGNITION TURN OFF.

Using a tester, measure the resistance between pin “5” of the connector and ground.

- Resistance is within 4.6 kOhm, the mass air flow sensor or its connection is faulty.

- Resistance is about 0 Ohm - short to ground in wire 4 F, or the controller is faulty.

- Resistance more than 100 kOhm - wire 4 G is broken, or the controller is faulty.

Source

The VAZ fault code P0102 is not permanent.

If this error code is not permanent, check the reliability of the connection of the block to the sensor, the correct routing of the harness, the presence of insulation damage, as well as the connection of additional consumers to the harness. When inspecting the connection block, pay special attention to possible damage to the contact locks, connections to wires, loosening and oxidation. If necessary, remove the contact from the connector and carefully bend it for a better fit to the mating contact.

When checking the correct installation of the harness, make sure that the harness is not laid near high-voltage wires and the exhaust manifold. In addition, it should not have visible damage. Move the connector and harness with the diagnostic equipment or on-board computer connected and the ignition on. If an error appears during this, it indicates a broken wire or poor contact in the block. If this error appears under heavy load and the throttle valve is opened more than 50%, then the cause is most likely a clogged air filter.

After eliminating the malfunction, it is necessary to erase the fault code from RAM using diagnostic equipment or by disconnecting the battery for 15 - 20 seconds.

Source