What can we say in conclusion? The gearbox always works in intensive mode, and breakdowns occur frequently. This is why it is so important to know what the input shaft bearing looks like, signs of failure, and methods for replacing the part yourself. We advise you not to delay repairs, otherwise you will have to repair the entire gearbox.

The situation is as follows: when you start the car, the gearbox makes noise. When you press the clutch it doesn't make any noise, it's a clutch release. When you accelerate into 3rd, and 4th, and 5th, there is a howling noise when accelerating. If you press the clutch, the sound disappears - is it the input and output shafts or not?

- Reverse does not work - 4 answers

Topping up oil in the gearbox on Kalina - 3 answers

If you press the clutch while driving and the sound disappears, then it is most likely the clutch. The shafts continue to rotate. But not necessarily , since the direction of the load on the shafts changes. Make a connection and then it will be clear.

So this means: I’m telling you how the clutch and gearbox work when the clutch is disengaged and when it is engaged.

To begin with, let me remind you that the clutch is constantly engaged, and when the pedal is depressed, the clutch disengages. Then it goes like this: we start the engine, the gear shift lever is in the neutral position, the engine crank/shaft rotates, the flywheel rotates accordingly, the clutch is attached to the flywheel, and of course the driving clutch disc (basket) and the driven clutch disc rotate. Well, since the input shaft of the gearbox is connected through the middle part of the driven disk (through the hub), it also rotates and rotates in the bearing, which is located in the front of the gearbox.

Signs of a faulty input shaft bearing. Learn this list

In order to call for service in a timely manner, you need to know the signs of a faulty input shaft bearing.

In principle, this work can be done independently. You don't even have to disassemble the gearbox to do this. Moreover, such a problem is not uncommon. Drivers generally often encounter failures of various bearings. After all, they stand on almost every shaft and take on significant loads. In principle, almost all such structural elements fail with similar symptoms. Therefore, having encountered such a malfunction once, next time you will accurately determine the cause. And taking into account indirect signs, determine exactly the place where the breakdown occurred.

Replacement

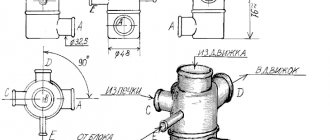

To fix it, it is recommended to completely disassemble the box, but in fact this work can be done without “splitting” the gearbox. In any case, you need to remove it. Before removing the box, disconnect the battery, remove all the chips from the box and unscrew the speedometer drive. On some models, it may be necessary to remove the exhaust system "pants". Only after this is the gearbox removed.

After removing the box, the bell should be removed. Otherwise, it will interfere with further work. It is also advisable to clean the box from dirt.

On most gearboxes, the bearing is secured using retaining rings. They are removed using a screwdriver. You need to pry them off and loosen them a little, after which they can be easily removed. For greater convenience, you can take the ring with tweezers. After this, you need to use a screwdriver to pry the bearing by the ring groove, and at the same time you need to move the input shaft forward.

Next, a pry bar is placed between the bearing and the box. For this you will need an assistant. He will hold the montage. Your task is to press out the bearing with careful but strong blows on the input shaft. During the process it is necessary to rotate the shaft. In total this can take up to 20 minutes. There are special pullers, but using them on an unassembled box is problematic. To disassemble a gearbox, you need to have experience in such work.

Before installation, the bearing is lubricated with engine oil. It should be pressed in carefully. To do this, the shaft is pulled forward. The bearing must be driven into place with light blows of a small hammer. You should knock on the inner ring, and do it evenly, in a circle. After pressing the bearing into place, make sure it is working properly. It should spin absolutely calmly. Afterwards the box is assembled in the reverse order and installed on the car.

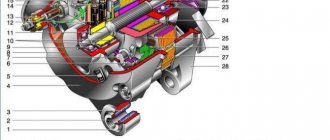

Device

Needle bearings are mainly used to support the shaft. The use of thin and long rollers allows the thickness of the ring to be minimized while maintaining high load resistance.

Fastening the part has its own characteristics. During operation, the element wears out its installation location. Due to increasing play and vibrations, the part is gradually destroyed, and then it is necessary to replace it.

The gearbox is noisy in the VAZ Kalina

VAZ (Lada) Kalina I 2004 - 2013

The situation is as follows: when you start the car, the gearbox makes noise. When you press the clutch it doesn't make any noise, it's a clutch release. When you accelerate into 3rd, and 4th, and 5th, there is a howling noise when accelerating. If you press the clutch, the sound disappears - is it the input and output shafts or not?

- Reverse does not work - 4 answers

- Extraneous sounds on the left side when driving at 5 speed Lada Kalina - 3 answers

- Topping up oil in the gearbox on Kalina - 3 answers

- First gear sometimes doesn't engage well - 2 answers

- Gears are difficult to engage on Kalina - 2 answers

If you press the clutch while driving and the sound disappears, then it is most likely the clutch. The shafts continue to rotate. But not necessarily , since the direction of the load on the shafts changes. Make a connection and then it will be clear.

So this means: I’m telling you how the clutch and gearbox work when the clutch is disengaged and when it is engaged.

To begin with, let me remind you that the clutch is constantly engaged, and when the pedal is depressed, the clutch disengages. Then it goes like this: we start the engine, the gear shift lever is in the neutral position, the engine crank/shaft rotates, the flywheel rotates accordingly, the clutch is attached to the flywheel, and of course the driving clutch disc (basket) and the driven clutch disc rotate. Well, since the input shaft of the gearbox is connected through the middle part of the driven disk (through the hub), it also rotates and rotates in the bearing, which is located in the front of the gearbox.

So, in neutral gear the release bearing may make noise, but if this is it, then when the clutch pedal is depressed the bearing begins to rustle, growl or squeak (or some other similar sound). If this sound came from a faulty clutch, then most likely some sounds would persist when squeezing, and there would be problems when shifting gears (it would be difficult to engage or disengage gears, or the clutch would drag or slip).

This means that it is most likely that the input shaft bearing is noisy. When you press the clutch pedal, the driven disc is released from the pressure of the basket and stops, and the input shaft stops accordingly, so the noise stops, the shaft bearing has stopped and does not rotate.

As you accelerate, the speed increases, the noise of a faulty bearing turns into a howl. When changing gears, you lower the speed, depress the pedal, the clutch disengages, the input shaft and bearing stop - the sound disappears.

And finally: a lot of Russian cars suffer from such noises and howls, if not immediately, then soon after the car starts operating. Apparently, this is the quality of our input shaft bearings or is it their tolerances and fits that the designers have not worked out properly.

Try our service station selection service

Creating an application is absolutely free and will take you no more than 5 minutes

For a long time now, the bearing of the gearbox input shaft was howling, and only at a speed of 35-40 km/h there was silence further, although it might have happened on the highway too, but I didn’t really notice, since it’s no longer quiet enough to listen. I changed the clutch at the same time and decided to give it up. Here is the entire replacement procedure.

Those who have hands and grow from where it is necessary or who do not want to give it to the service can go through it; there is nothing complicated in principle. Here is the entire replacement procedure. Place the box vertically with the dome down.

We unscrew the upper gearbox cover, all the bolts are visible. Next, we lock the gears together with an aluminum plate so that they do not spin and first loosen the nuts, unscrew them and the shift fork bolt. We put something under this whole thing and carefully remove everything from the shaft together, in principle you can remove it one by one, but only carefully, otherwise the synchronizer will fly apart and remember how it was. We remove the gear from the secondary shaft in the same way. Next, unscrew the cover plate, there is one bolt there.

Next, remove the retaining rings of the bearings of the primary and secondary shafts. Next, unscrew the bolts connecting the gearbox halves around the entire perimeter and do not forget about the 3 bolts under the dome and the gearbox ground bolt. Next, unscrew the reverse rod bolt (located next to the frog) and the frog too. Next, with gentle movements, we push the drive shaft flange from below, using a non-metallic thread, I used a piece of textlit. It doesn't sit there very tightly, so we remove it.

When everything is unscrewed, we carefully try to lift the lid; there are places on the halves to pry it off. When the lid goes, we pull it up, it sits on the rod and does not come off right away. We take pictures and see the following. We unscrew the 2 bolts of the gear pusher to move it freely. Next, we lift the secondary shaft up a little, but do not take it out and try to remove the primary shaft, the bearing sits there freely (at least it did for me) this is its normal state. We are trying to remove the shaft.

We remove the bearing and install a new one. Its registration number is: BB1B 630857 for 1.8 144 l. Since 98 Manual transmission. I also changed the differential drive seals so as not to have to go through it again, but everything will be 100% dry!) We also look at the condition of the shift fork.

In principle, twin spark boxes are tenacious. I don't think it will be very good. Great wear and tear. Next, we assemble everything in the reverse order, do not forget to degrease and seal the caps and halves, as well as tighten the nuts of the fifth gear and the secondary shaft. A small but very important nuance! When you put on the middle cover, guide the gearshift rod into the grooves towards the forks and tighten the gearbox half. It's like he has to go there.

Well, try switching speeds. That's all, enjoying the silence, good luck to everyone with the repair! Bearing 573 rub. Gray sealant 130 rub. Differential seals - 2 pcs.

Repair, features and technical specifications

Inside a VAZ 21118 car, like any other, there is always a gearbox. For a model such as Kalina 1118, this device is a mechanical type design, which is equipped with one reverse stage, as well as 5 forward stages.

Gearbox from Lada Kalina.

Technical features of the gearbox

The drive gear block is engaged by the input shaft. This is important to consider when repairing a gearbox. As for the input shaft itself, a constant clutch is created for it with the front gear elements that perform similar functions.

When repairing the secondary shaft, we must remember that it has a hollow structure. It is thanks to this that the oil reaches the driven gears without any problems.

Inside the mechanism you can also find driven bearings and synchronizers. When replacing the backstage on your own, this part can also be replaced. This also requires repairing the gearbox driveshaft.

The design of the gearbox is such that repairs cannot be done without the use of special circuits. In this case, the radial clearance on the roller bearings is no more than 0.07 millimeters.

Repairing the gearbox is also a rather complicated process. Especially considering that 0.04 millimeters should not exceed the same figure, but for ball analogues.

Location of the checkpoint backstage on the Lada Kalina.

The oil sump is responsible for supplying oil. It is located in the area of the front bearing, fixed behind the output shaft. Major repairs often affect such details. If you select the desired thickness of the rings, it will be possible to adjust the tension indicator. The dimensions of the seals are easy to find in the instructions; these parts can be replaced without problems, even at home.

When repairing the gearshift knob, you must remember that the driven gear of the gearbox on this machine is attached to the differential flange. Through the saloon, the atmosphere is combined with the box itself, located at the top of the structure we are considering.

Lever repair is not the only operation that needs to be carried out from time to time. Sometimes it is necessary to replace bearings; this is done when extraneous noise appears. A gearbox repair kit must be purchased if excess noise becomes noticeable when pressing or releasing the clutch pedal.

All control drive elements of the Lada Kalina gearbox.

The repair manual says that the box is controlled using a drive, which consists of several elements:

- Switch rod.

- Spherical bearing.

- Lever arm.

According to the manual, cable structures are always equipped with jet traction, then the gears do not turn off on their own. One of the ends of the rod is connected to the lever, and the other to the motor. If the seals of the internal joints are faulty, it is necessary to carry out independent repair of the gearbox. But before replacing them, you need to completely change the oil. The front wheel drive is completely disconnected.

Servicing the gearbox involves using a screwdriver to remove the necessary parts. But you will need to purchase a mandrel with the necessary parameters in order to carry out the pressing.

Three axes are present on the shift system. One axis is equipped with a three-arm lever for selecting and disengaging gears. There is no gearbox on the second axle, but there are brackets that block rotation. After every 75 thousand kilometers, this design is completely changed. Gearbox lever play should also alert you, as should failure of other parts.

Price regulations

Transmission replacement as an alternative to major repairs

If you need a Lada Kalina gearbox, you can buy a used transmission unit today on favorable terms. The optimal units in terms of cost and quality are offered by our workshop. What kind of offers are on the market today? It should be noted that the situation with gearboxes is similar to that with Kalina engines. On the Internet you can find many current offers with quite significant price differences. What are the reasons for the latter? I would like to believe that it is solely the technical characteristics of the units sold. But practice shows that this is not entirely true. We can only say for sure that used transmission units are cheaper than the original ones presented in spare parts stores. to compare how much a manual transmission costs for a Kalina (price of a rebuilt one, price of a new one). If you want to save money, feel free to give preference to used ones. What does replacing a gearbox give a car owner? First of all, saving time. You can find a box in good condition and dismantle/install it in a workshop in a matter of hours. Defecting the original box will take much longer. And the result may be worse than expected. This is especially true for transmission units that are at the limit of working resources.

Current benefits of replacing the box

In addition to saving time, it is important to be able to optimize costs when restoring the functionality of a vehicle. The price of a Kalina gearbox is determined by its actual condition. The newer the unit, the more expensive it costs, everything is logical here.

As for defective boxes, different price options are possible. But the trend is clear. The cost of boxes increases in proportion to their safety margin. Also among the benefits should be noted the receipt of a guaranteed functional unit. Used boxes have passed the real test of practice and time. The risk of manufacturing defects is eliminated, and the latter, alas, are not uncommon today.

When to change the gearbox and how to choose it?

Don't want to bother with repairs? We offer an effective alternative - replacing the transmission unit. Removal and installation of the Kalina gearbox, the price of the service in the workshop is affordable, performed by experienced specialists as quickly as possible, with a guarantee of quality. Is your car's transmission badly worn out? We recommend replacing it with a used one, but with a good margin of safety. This option is optimal if you want to get a working unit at a reasonable price.

When it comes to choosing a transmission unit, it is rational to trust professionals. Do you want to control the selection process yourself? Pay special attention to visual inspection of the offered box. It should not have traces of oil leaks, areas of corrosion, or traces of metal shavings. Also take a closer look at the color of details and elements. It should be light metallic without dark spots or inclusions. We also recommend checking the gearbox oil. It should be transparent and light.

Removal and installation of the gearbox

Servicing the gearbox assumes that the mechanism will have to be removed and its position changed. Before doing this, you need to install the vehicle itself on the lift. The ignition must be turned off completely and the parking brake must be used.

How to repair a gearbox? To do this, disconnect the minus terminal from the battery. The hood must be opened completely. Any manual on gearbox repairs writes about this.

The oil filler cap is also removed. It is necessary to install the previous item after the screen is removed. The gearbox requires loosening the clamp responsible for fixing it. The inlet pipe hose must be disconnected from the corresponding sensor. Gearbox lever play requires the same actions in practice. Then you need to unscrew the air intake nut.

The repair progress further depends on the specific malfunction.

Gearbox Lada Kalina after dismantling and disassembly.

The gearbox can be installed in its original place after the 1st speed repair is completed. SHRUS-4 lubricant is applied to the outer surface of the corresponding bushing in the clutch in a very thin layer. This will also help if the gearbox is loose. The pin fixing bolts are removed from the steering knuckles.

How to remove the transmission?

To remove the box you need an inspection hole or a lift. Also, for work you need a standard set of tools - a wrench, sockets, wrenches and a pry bar. The dismantling process is carried out in several stages:

- First of all, disconnect the terminal on the battery. Then the neutral gear is engaged and the parking brake is released. Raise and remove the rear axle. Next, unscrew the bolts holding the cardan and the gearbox flange. After this, you can disconnect the driveshaft.

- Then unscrew the bolts and dismantle the exhaust pipe of the exhaust manifold, disconnect the oxygen sensor, and remove the starter. Next, inside the car you need to dismantle the console and gear knob.

- After this, remove the box protection and unscrew the clamps that connect the exhaust pipe to the catalyst. After this, you can dismantle the slave cylinder of the clutch system. Next, unscrew the speedometer cable, remove the boot and reverse gear cable. Now you can remove the driveshaft. Then the traverses are unscrewed (you must hold the box so that it does not fall). Finally, you can unscrew and remove the gearbox assembly.

Gearbox lever jammed

In any case, it is necessary to remove the last fastener after the bolt nut securing the left suspension arm has been unscrewed to the body bracket.

Repairing a box cushion is not complete without many of the steps described above.

After this, all that remains is to remove the lever. Another rather important element is the gearbox fork; its condition must also be monitored.

You will need to drain all the remaining oil into the container. A complete gearbox repair also involves removing such parts as the wheel drive from the gears of the differential axle shafts. The plugs are placed in the place where the gears used to be. After the gearbox adjustment is completed, they usually proceed to installing the left suspension support and brackets for the rear of the car.

Any such work, including repair of the secondary shaft, must take into account the general design of the gearbox and the basic principle of its operation. It contains a book on repairing the box. The same applies to the functionality of the component elements, otherwise the gearshift lever support cannot be replaced, like other parts.

Dismantling of the Lada Kalina gearbox at a specialized service station.

The features of the repair are fully familiar only to real professionals. It is better to entrust the work to them if you do not have the proper experience or some practical skills.

It is necessary to completely rinse the mechanism with water before disassembling it to identify a gearbox malfunction. Problems during repair may arise if the part itself is not installed on a special stand. The bracket, which is responsible for fixing the clutch cable and engine suspension, is completely dismantled.

Many people give useful advice on replacing a VAZ gearbox. According to them, in any case you will need to remove the rear cover of the crankcase.

Useful tips

If there is no oil on the bearing, but there is no damage to its surface, then you don’t have to replace it, but simply lubricate it and install it back. This is done if for some reason the required spare part is not on hand. Lubricate the gearbox input shaft bearing (including VAZ) in two ways. The first option involves boiling the part in lithol. It is best to carry out this operation in a water bath. But there is a safer option - lubrication using the injection method. To do this, lithol is drawn into a syringe and lubricant is filled into the bearing. But you need to take into account that such a process requires more time.

I think many car owners have encountered a problem when, when the clutch is released while standing still, noise begins to be heard from the gearbox. These are usually symptoms of a worn input shaft bearing. Therefore, today we will tell you how to replace a noisy or humming input shaft bearing of a VAZ gearbox without disassembling the gearbox itself. Of course, the box will have to be removed from the car, but almost any car owner with the slightest bit of experience in repairing classics can remove it. But not everyone can sort through a box, so we simplify the task. After removing the transmission from the car, we need to remove the bellhousing and then remove the retaining rings. We will see something like this:

Source