The VAZ 2107 clutch is designed to connect the engine crankshaft and the gearbox input shaft with the possibility of briefly stopping the transmission of torque. The reasons for its failure can be very diverse. However, all of them can be easily diagnosed and eliminated on their own.

- Reasons for replacing and adjusting the VAZ 2107 clutch

Replacing the clutch - Clutch adjustment

- Clutch slipping

- Tools and materials

Video: do-it-yourself adjustment of the VAZ 2107 hydraulic clutch

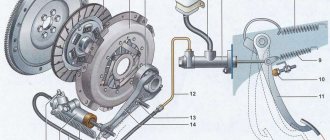

The design of the VAZ 2107 clutch mechanism

The seven uses a wet clutch mechanism. It consists of:

- directly the pedal, brought into the salon;

- master cylinder;

- pressure pipes;

- working cylinder;

- clutch fork;

- release bearing;

- clutch basket and disc.

Some car enthusiasts modify the mechanism by discarding the hydraulics and installing a dry drive. The process is justified by the greater accuracy of the modification and the absence of the need for frequent maintenance.

Most common breakdowns

Every car owner of domestic brands is familiar with the concept of slipping and dragging, this applies to the clutch.

- in the first case: when the pedal is fully lowered to the bottom position, the clutch disc itself slips a little, thereby not providing the transmission with the required amount of power;

- in the second: the clutch pedal, which is completely flooded down, cannot move the basket away from the flywheel, because of this the car moves even when the rocker is in the neutral position. This situation is extremely negatively reflected in the control process itself, since the speeds will turn on either too early or too late.

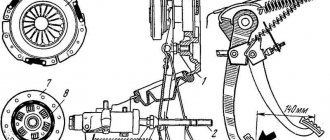

How does the clutch drive work?

The principle of operation of the mechanism is as follows.

- The driver presses the pedal.

- The piston of the master cylinder pumps pressure into the system, excess fluid goes into the expansion tank.

- The contents of the system move along the lines and enter the working cylinder.

- The piston of the working part pushes the fork and opens the bearing.

- The clutch disc moves away from the basket and the engine is disconnected from the gearbox.

Device and main problems

In short, a clutch is a transmission link between the engine crankshaft and the transmission input shaft. In this case, pressing the pedal disconnects these 2 nodes: the engine continues to run, and the driver can change gears.

Clutch device VAZ-2107

VAZ 2107 has a dry single-plate clutch. The master cylinder of the hydraulic clutch drive is located under the pedal, when pressed, the pusher moves and presses on the cylinder piston, generating pressure. The brake fluid that fills the hydraulic drive is squeezed out and goes into the working cylinder. The piston of this cylinder is combined with the clutch fork by an adjusting rod.

When you press the pedal, it moves the fork, moves the release bearing and separates the discs. As a result, the torque from the crankshaft flywheel is no longer transmitted to the gearbox and it becomes possible to change gear. If the clutch unit malfunctions, when you press the pedal, the gearbox shaft continues to rotate and it becomes impossible to change gears. If the clutch is adjusted incorrectly, worn out, or oiled, the discs may begin to slip, which will result in their overheating. It becomes impossible to continue using the machine. Therefore, at the first sign of a malfunction, it is worth starting to repair and adjust it.

Hydraulic drive malfunctions

They consist of leakage of brake fluid due to wear of the cuffs of the main and working cylinders; the flexible hose may burst; Sometimes when the pedal is pressed, the car starts to move on its own - this is wear on the master cylinder.

When to adjust the clutch drive

The standard adjustment procedure is required as routine maintenance or emergency repairs. Usually the reason for performing the operation is such problems.

- Gear shift violation - positions are engaged with knocking, crackling or extraneous sounds.

- The clutch switch response threshold has been violated. A dip of 25 to 35 mm is considered optimal.

- Increased fuel consumption. If the mechanism is faulty, excess gasoline consumption can be up to 20% of the reference value.

- Knocking out positions. During acceleration of the vehicle, the gears “fly out”.

- Dissonance when revving the engine. When you press the gas pedal, the internal combustion engine spins up, and the car lags behind.

- Clutch lever failures, this also includes an increase or absence of operating play in the system.

- Early or late operation of the mechanism when the pedal is pressed.

Unit tuning, which spare parts are best to choose

If you do not want to install Russian-made spare parts, or cheap Chinese fakes, you can replace them with “thoroughbred” parts. First of all, pay attention to the following manufacturers:

Valeo is a well-known manufacturer of automotive parts. This French company sells spare parts both to other manufacturers and to the retail chain; in operation since approximately 1923. Clutch discs from this manufacturer give car owners softness and comfort. Their parts are also some of the most reliable in the world. One set is enough for a VAZ to successfully drive more than 100,000 kilometers. Despite all the positive feedback, their clutches are quite expensive.

The Luk clutch is an innovative solution that incorporates a torsional vibration damper for both the driven and pressure plates. The part is distinguished by vibration damping - which means you are guaranteed comfort while driving. In the Russian Federation, Luk collects only positive reviews, not only because of the quality, but also the low cost.

KRAFTtech – clutch made in Turkey. Pleasant soft squeeze, resistance to high temperatures and flywheel wear. Reviews about this clutch are different, or rather not only positive, but also negative. The Kraft company sells spare parts at affordable prices, this is especially noticeable when considering foreign analogues.

Source

Diagnosis of clutch faults VAZ 2107

There are a number of breakdowns that indicate that the car requires urgent repairs.

Clutch slipping

This occurs during sudden acceleration. The engine steadily picks up speed, but the car is “late” in accelerating. The process may also be accompanied by jerking, jerking and extraneous noise.

The situation greatly wears out the friction disc and negatively affects fuel consumption.

Clutch leads

This is caused by improper adjustment or airing of the system. The friction linings do not move completely away from the basket and gears are difficult to engage.

Jerks when starting and changing gears

It requires pumping and adjustment of the mechanism, when the car jerks when you put it in gear. The disc may slip at the start or rapid acceleration due to its wear.

Noise when clutch is disengaged

When the car vibrates slightly and an extraneous sound comes out when the pedal is fully depressed, the clutch basket and clutch disc do not completely separate.

This occurs when the device settings fail.

Noise when clutch engaged

The cause and consequences are the same as above.

Pedal failure and lack of clutch

Here the matter is more serious. The pedal can only fail if the mechanism is severely damaged. In 90% of cases, the cause is hidden in the head cylinder or basket. Operating a car with such a problem is strictly prohibited.

The clutch disengages, but the pedal does not return to its original position

This malfunction is often solved in a trivially simple way - the return spring may fly off or burst. The hydraulic system in the VAZ 2107 is a design where there are no return devices, except for mechanical parts.

Everything is solved by replacing the damaged element.

Tight grip

Some car enthusiasts complain that the clutch pedal is pressed extremely hard. In addition to the hydraulic system, movement difficulties are caused by souring of the moving joints and jamming of the release bearing. To fix the problem, you must completely disassemble the entire system.

The clutch disengages at the beginning or end of the pedal stroke

In this case, everything is quite simple - the system requires adjustment. The procedure is primitive and is completed in 20-30 minutes. The only caveat is that you will need an assistant.

Why it stalls - reasons and their elimination

The clutch usually slips due to the following:

- There is no gap between the pressure bearing and the fifth basket;

- the clutch drive is not adjusted;

- oil gets on the discs;

Depending on the cause of this problem, the repair progress is determined. If the problem is with the diaphragm spring, it will have to be replaced with another one. When the friction linings wear out, the driven disk is replaced. When repairing/removing linings, the gaskets are checked. If they are in poor condition, they are also replaced with new ones. If oil gets on the driven disc, you will need to treat it with kerosene and clean it with fine sandpaper.

Disc oiling

Grease may get on any side of the flywheel and pressure plate due to an increased oil level in the gearbox housing or a leak in the rear crankshaft bearing. To solve the problem, diagnostics are performed and the cause of the leak is eliminated - the seals are replaced, then the spare parts are cleaned.

Read, it may come in handy: How to replace rear springs on a VAZ-2107

The free stroke according to technical conditions is 30-35 mm, the full stroke is 140 mm. Any deviation from the norm is associated with a malfunction of the transmission and requires adjustment work. The parameter is checked using a ruler. To do this, determine the distance from the pedal to the center of the platform. The adjustment is made on a pit or lift using open-end wrenches 13 by 17 mm and 17 by 19 mm. We clean the adjusting rod and nuts with a brush and treat them with WD-40. Next, the lock nut is loosened, and by rotating the adjusting nut we change the gap. If the free play needs to be reduced, we lengthen the thrust; if it is increased, we shorten it. After completing the work, tighten the locknut.

Damaged release clutch

How to finally adjust the clutch on a VAZ 2107

After all manipulations, it is necessary to check the functionality of the system. To do this, you need to start the engine and let it warm up. Then, with the engine running, you need to depress the clutch and, without accelerating, engage the rear rocker position. In this case, the presence of extraneous sounds and rattles is not allowed. The position is turned on easily - without additional effort.

Next, you can start moving at first speed and then increase the position to maximum (5). When driving, the presence of extraneous sounds or grinding noises is strictly unacceptable; the pedal is pressed evenly, without dips or jerks.

The last stage is acceleration at each gearbox speed, while the set of engine speeds fully corresponds to the acceleration of the car. If there is dissonance, the clutch disc slips and recalibration is required.

Complete disassembly with gearbox removal

The work must be done on a lift or in a pit. First of all, remove the battery

We continue disassembly by removing the rod from the gear shift lever. Then you will have to use a screwdriver to unscrew the screws securing the cover that covers the hole in the car body. This completes the manipulations inside the car dealership. What needs to be done next:

- Remove the exhaust pipe (exhaust system) and resonators;

- Then remove the starter from the flywheel housing and move it to the side;

- Disconnect the cardan from the rear axle and gearbox.

To be able to remove the box, remove the cross member of the rear engine mount and the speedometer drive cable. You also need to disconnect the hydraulic drive cylinder from the gearbox and move it to the side.

Next, you will need to remove the bolts that hold the clutch housing cover in place (key 10) and proceed to dismantling the box, and since it weighs a lot, it is worth putting a good support under it.

Read, it may come in handy: Replacing the elastic coupling, suspension bearing. Features of replacing the joints of the cardan shaft crosspieces

After this, use a socket wrench to unscrew the bolts from the flywheel housing. Now, in order to remove the box, you will have to carefully move it back, slowly removing the primary shaft from the hub of the clutch driven disc. This must be done carefully so as not to drop the box and injure yourself. That's it, the box is removed.

Video about disassembling the clutch using the example of a VAZ 2106, suitable for the “Seven”, a small difference only in the interior

Why and how to bleed the clutch on a VAZ 2107 in your garage

The reason for bleeding the clutch is air in the hydraulic system. Air bubbles tend to shrink, which reduces the performance of the device. It’s easy to bleed the clutch in a VAZ 2107 at home. To do this, it is enough to have a set of primitive tools and a little patience.

Motorists prefer to do their own repairs because the procedure is expensive, and performing the entire process on your own is not difficult.

Preparing to bleed the clutch system

To bleed the line and do it correctly, preparation must be done.

- Drive the car onto a viewing hole, overpass or lift, where you secure it.

- Clean the expansion tank cap and fitting from dirt. Garbage entering the system is unacceptable.

Stages of the clutch bleeding process

The procedure is performed in a certain sequence.

- The protective cap is removed from the fitting and the hose is put on it.

- The second end of the tube is lowered into a bottle with TJ previously poured into it.

- Brake fluid is also poured into the expansion tank to the maximum mark.

- Next, the assistant gets into the car and presses the pedal several times; during the last push, you should press the lever to the floor and hold it.

- After this, use wrench No. 8 to unscrew the fitting on the working cylinder and the waste with air bubbles is squeezed out into the bottle. After the pressure has dropped (the pedal has failed), the valve must be closed.

- The procedure is repeated until the air is completely removed from the system.

Tools and materials

In order to cope with the operations of adjusting the transmission on a VAZ 2107 with dignity and quality, the driver will need the following tools:

- set of wrenches;

- bottle with hydraulic fluid;

- flat-head screwdriver;

- container for draining waste liquid;

- a small amount of rags;

- ruler or tape measure.

A similar set is probably present in every person who, to one degree or another, has encountered procedures for repairing various vehicles.

Clutch check

To check the clutch bleeding, just follow a simple sequence.

- Raise the handbrake all the way.

- Depress the clutch and start the engine.

- Try to change gears, but no extraneous sounds or blockages should appear.

- Engage a random gear and smoothly release the pedal.

- Approximately halfway through the stroke, the engine should begin to twitch and stall. This indicates proper operation of the coupling device.

Replacing the master and slave cylinders

The clutch has become soft: causes and repairs

The master cylinder creates pressure in the hydraulic system, transmitting force from the pedal pusher to the working cylinder rod. It lasts a long time, and the repair kit often requires replacement, rather than the cylinder itself. The slave cylinder serves to transmit force to the clutch fork pusher. Hydraulic fluid from the master cylinder presses against the piston in the slave cylinder and operates the fork.

Their malfunctions are manifested by dips or tight movement of the clutch pedal, difficult operation of the gearbox (gears are switched with a crunching sound, vibration). Visually, a problem with the main or working cylinder can be seen by fluid leaks.

The clutch cylinder is replaced if the “mirror” of the cylinder or its other elements are damaged, which happens quite rarely. Replacement parts wear out much more often, and then you can simply install a new repair kit.

Replacing the master cylinder, video

The master cylinder is located next to the brake booster, below the brake reservoir. Its dismantling is done in the following order:

- Pump out the liquid from the cylinder expansion tank (with a rubber bulb or a syringe with a hose);

- When there is no liquid left in the expansion tank, remove it from the cylinder (disconnect the rubber fasteners);

- Unscrew the nut that secures the pipeline to the cylinder, hose pipeline to the side;

- Loosen the clamp that secures the hose to the cylinder and remove the hose;

- Unscrew the nuts that secure the cylinder, remove it, and pour out the remaining liquid.

After dismantling, you need to inspect the cylinder for wear of metal parts and rubber gaskets. If necessary, replace the repair kit or install a new cylinder. Installation is done in reverse order.

Replacing the working cylinder, video.

The slave cylinder is located next to the gearbox, on the clutch housing. It can be accessed both from below and from the engine compartment. Dismantling procedure:

- Loosen the nut that secures the hose to the cylinder. Do not remove the nut completely, do not disconnect the hose;

- Use pliers to remove the tension spring;

- Using pliers, straighten and remove the restrictive cotter pin from the pusher;

- Remove the bolts that secure the cylinder to the clutch housing;

- Remove the bracket that was attached to the cylinder with these bolts and to which the tension spring was attached;

- Remove the cylinder by sliding the pusher out of the hole in the clutch fork;

- Now you can completely unscrew the nut and remove the hose from the cylinder. As with the master cylinder, installation is done in the reverse order.

Drive problems are often caused by poor-quality hydraulic fluid.

When working, pay attention to its color and consistency. Often wear products accumulate in the liquid and they begin to act as an abrasive.

Important Tips and Recommendations

Experienced drivers and mechanics recommend following simple rules to extend the life of the device.

- Do not overpress the pedal. This causes the disc to heat up and can cause it to wear out quickly.

- Use only high-quality brake fluid.

- Check the functionality of the device in a timely manner.

- If extraneous sounds or plugging occur, it is necessary to diagnose the mechanism.

Basic faults

The slave cylinder has several rubber seals, which often become unusable or become oily, causing the car’s clutch to “slip.” Replacing old seals with new ones will require using a lift or inspection hole, since the main cylinder is located in an inconvenient place.

It is advisable not to touch the flare nut, otherwise additional adjustment will be required later. In order to replace the gaskets without removing the master cylinder, certain skills and experience are required.

Another cause of clutch malfunction may be wear of the release bearing.

To replace it, you will have to dismantle the gearbox. Brake disc linings wear out just as often, which is easy to notice by the characteristic noise when the pedal is released. And the most common problem with a clutch malfunction is air getting into the system. Air can be removed by bleeding.