A differential is a device designed specifically to transmit the so-called torque from a car engine to its wheels using transmission elements. A free differential, installed on vehicles during assembly at the factory, cannot affect the other when one of the wheels slips. Differential locking can help achieve different wheel speeds when necessary (for example, on poor, usually dirt roads). It increases torque on one of the wheels, usually the one with the best traction. To achieve this result, a self-locking differential is used. An alternative option could be a forced blocking method. It is important to understand whether it is worth installing a self-locking differential on the Niva, what this will do for the car and how to carry out the installation of the device.

Why do you need a self-block for Niva?

The presence of all-wheel drive in a car does not always give it the status of an all-terrain vehicle. Sometimes, due to the nature of their design, vehicles designed for off-road driving can become trapped on washed out roads. A self-locking differential is an important component of the car if the driver plans to use his Niva to drive on bad roads.

What is a self-block, or limited slip differential? This is a device that ensures wheel locking, and automatically, at the right time. It is an intermediate option between a full lock and a free differential. The self-block combines the capabilities of both of these devices.

The problem of a slipping wheel

A conventional ("free") differential works fine as long as the drive wheels are inextricably connected to the road. But when one of the wheels loses traction (finds itself in the air or on ice), then it is this wheel that rotates, while the other, standing on solid ground, is motionless. If one of the wheels loses traction, its resistance to rotation drops, and rotation occurs without a significant increase in the moment of resistance (sliding friction in the contact patch is less than static friction and does not significantly depend on the slipping speed). At the moment when the wheel begins to slip, the torques on the wheels are not equal to each other, but are inversely proportional to the resistance to rotation of the wheels.

When the car moves in a straight line, the satellites do not rotate relative to their own axis. But each, like an equal-arm lever, divides the torque of the main drive driven gear equally between the axle gears. When a car moves along a curved path, the inner wheel with respect to the center of the circle described by the car rotates more slowly, the outer wheel rotates faster - while the satellites rotate around their axis, running around the gears of the axle shafts. But the principle of dividing the torque equally between the wheels remains the same. The power supplied to the wheels is redistributed, because it is equal to the product of the torque and the angular velocity of the wheel. If the turning radius is so tight that the inside wheel stops, then the outside wheel rotates at twice the speed as when the car is moving in a straight line. So, the differential does not change the torque, but redistributes the power between the wheels. The latter is always larger on the wheel that rotates faster.

Types of mechanisms

There are two main types of self-locking differentials, which include several more subtypes. The first type is devices that lock depending on the angular velocities on the vehicle axles. They can be:

- disk;

- with viscous coupling;

- with electronic locking.

The second type is mechanisms that lock depending on the torques on the axes. These include worm differentials.

There are also center and cross-axle differentials. They involve the distribution of torque between the axles and wheels, respectively. Depending on the moment of distribution attributable to the axles or wheels, symmetrical and asymmetrical types of mechanisms are distinguished. On vehicles called all-wheel drive, three types of differentials are installed at once: two of them are interwheel, and one is interaxle.

On the Niva it is possible to install electronic, mechanical (it is a conventional mechanism combined with a viscous coupling), and pneumatic differentials.

The electronic self-block has a very big advantage. To use it, just press a button. It works in automatic mode, but only when the car is traveling at a certain speed, which is below a threshold value. The system turns off when the speed exceeds the set speed.

The pneumatic differential is a mechanism mounted on two axles. The advantage is compactness. In its work it uses pneumatic systems.

The mechanical self-block is the simplest in its design; it is cheaper than pneumatic and electronic devices. The mechanism consists of two semi-axial and two spacer couplings, pins and springs. Quite a reliable design, despite its simplicity.

Advantages of forced blocking from IZH-TECHNO

What are the advantages of our forced blocking over existing analogues?

- The first and no less important point is ease of installation and the availability of all components necessary for installation. The differential assembly with lock is installed in its standard place in the gearbox. You can avoid the need to modify the transmission or purchase certain parts such as dog clutches or original axles. Our locks are compatible with OEM axles. To assemble it, you only need a standard set of plumbing tools. No welding machine or angle grinder.

- Our lock consists of original parts produced by IZH-TECHNO. Therefore, we guarantee the high quality of its individual parts and locking elements; The high quality of its components is a guarantee that you will not need spare parts throughout the entire service life of the product - there is nothing in it that could break.

- We paid special attention to such a parameter as the durability of satellites. This is not true: it transmits torque to both wheels of the axle and is subject to the greatest loads. The durability of the satellite installation has been confirmed by a series of tests both in laboratory and in real field conditions.

- Lock has four satellites instead of the standard two. This design provides even distribution of torque and is more reliable than factory-installed units. Particular attention was paid to the parameters of the satellites, increasing the thickness and height of the fragment (see photo below):

On the left is the original satellite, on the right is the satellite produced by IZHTEKHNO.

- Pneumatic drive with positive locking. The pneumatic cylinder is hidden in the axle housing and is protected from mechanical influences; it cannot be broken or damaged.

- The differential housing is made with high precision and strict tolerances, which is associated with the absence of vibration and noise in the axles when driving on the highway.

Niva differential housing cover

- blockade speed. By increasing the number of teeth involved in locking the differential, we got the locking mechanism to work faster. You don't have to wait for the wheel to rotate 120 degrees for the system to finally work. In our case, only 9 degrees is enough.

- Versatility. The lock is suitable for all modifications and variants of Niva and Chevrolet Niva cars, can be installed on both the rear and front axles, in steel and aluminum gearboxes on the front axle. Locks are available with 22 and 24 slots.

Read more about the forced locking function on the Niva and Chevrolet Niva in the description on our website.

Characteristics and selection rules

The choice of a self-locking differential is determined by the car model, its operating conditions, driving style and many other parameters. For example, a ball differential increases steering load, which actually changes the driving style of whoever is behind the wheel. This is mainly felt when making U-turns and turns, but can lead to breakdowns of transmission components.

If you approach the choice of a self-block correctly, then you need to take into account which axle of the car the mechanism will be installed on, since the number of splines for different models is different - twenty-two or twenty-four.

The marking on the device packaging will tell you whether it can be used for a given car brand. The blocking coefficient also varies: for example, 0.5 or 0.7. These numbers show the amount of torque transmitted. What to choose is up to the driver.

Self-locking system

Can be configured to the required switching threshold. This can be either a slight slip or uneven distribution of torque among the wheels. Such a connection is not rigid, and therefore does not place unnecessary load on the interaxial connection.

When installing a forced locking system on a Chevrolet Niva, you should remember that a constantly turned on system can put unnecessary stress on the transmission, so you should turn it on only when overcoming difficult sections of the road.

Pros and cons of installing a differential on Niva

If you compare the self-block and the standard Niva differential, you can identify the negative and positive aspects of replacing the latter. First, about the advantages:

- Increases the vehicle's cross-country ability, making it suitable for driving on steep, slippery and uneven sections of the road.

- It is mounted instead of the original differential and does not change the design of the car. It is better to carry out the installation at a car service center, but it is quite easy to do it yourself.

- The full differential operates automatically during the driving process, without requiring additional actions or any driver training.

Now about the disadvantages of installing the mechanism:

- The steering wheel becomes tighter, which will require additional effort from the person sitting behind it when driving.

- The service life is shorter than that of the differential supplied to the vehicle by the factory.

- It slightly modifies the control of the car when turning, does not provide an absolute guarantee of locking, however, like the standard mechanism.

Different models of self-locking differentials have their own nuances, which largely depend on the manufacturer, the novelty of the development, and the components used.

Turning the electric lock on and off.

Manual activation of the lock is possible by pressing and holding the button until the lock indicator turns on. Manual shutdown is done in the same way - by pressing a button.

Attention! Engage with the vehicle stationary or at speeds up to three miles per hour with minimal slippage. Switching on at a higher speed may damage the locking mechanism with subsequent denial of warranty repairs.

We will deny warranty if the locking coupling or pins are damaged. After passing a difficult section, the blocking must be turned off.

On the Chevrolet Niva it is possible to turn on all three differentials at the same time

. Thanks to this, the vehicle’s cross-country ability increases several times when driving off-road.

. In this case, when the driver turns on the forced locking, the wheels “become” connected to each other. This helps ensure that they rotate evenly.

Differential assembly

If the center lock is forcibly engaged, then the front ones are also rigidly connected at once, which guarantees an even distribution of traction to all four wheels. Thus, the vehicle’s cross-country ability will be increased several times.

, which makes the Chevrolet Niva a real SUV.

Not all cars are equipped with blockers, and therefore they will be vulnerable off-road. In this regard, Chevrolet is a unique car that can move with both one-wheel drive and all-wheel drive.

, which allows him to feel confident even on mountain roads.

Forced blocking should be enabled in the following cases:

- When overcoming difficult sections of the route. In this case, the blocking should be turned on in advance, even before leaving for such an area.

- On steep climbs or slopes when wheel slip is possible.

- When driving on sand.

- When driving on snow or ice.

When the Niva moves on a regular road with a smooth surface, it will not need to lock all wheels. They will adhere normally to the surface and not slip, since the traction force from the engine will be distributed evenly over them. For this reason, when the car is moving on a good road where the wheels will not slip, the use of a differential will not be required.

Also interesting: Niva engine purchase || Niva engine interchangeability

Peculiarities

Just because a vehicle comes with all-wheel drive does not mean it has all-terrain capabilities. Often, due to their design features, SUVs fall into the treacherous traps of sandy and washed-out roads. Domestic cars are far from an exception. There is an assumption that the self-locking differential on the Niva will be an important addition, especially if the owner plans to actively use the car in off-road conditions.

The limited slip differential, or self-block, as the part in question is also called, provides wheel stop automatically at the required time interval. It can be described as an intermediate option between the free analogue and complete blocking. The capabilities of both devices are optimally combined in the self-block.

My review of Dak and Racing

It just so happened that I had to use the two mentioned types of self-blocks. Their price at the time of purchase was almost the same - ten thousand, the installation is also the same, but the result is completely different.

If the DAK failed after about six months, and not in intensive use, but when driving on ordinary forest roads, then the Togliatti one (val racing) is still working.

Maybe I was just unlucky, but I have repeatedly come across reports that there are problems with the quality of the metal in the production of DAKs. So think for yourself.

Is it necessary?

There are a huge number of opinions about whether a self-block is needed at all, and the most polar ones - from “why is it needed” to “is absolutely necessary.” As always, the choice is a personal matter and everyone must make it themselves.

It seems to me that everything depends on how and where you move in your car. If you go to the country or mostly on asphalt, then you definitely don’t need a self-block.

The situation is approximately the same if your hobby is off-roading and you are engaged in conquering impassable roads. Here, such “half measures” as self-locking will not work and here you need a full manual differential lock.

However, if your task is to overcome not too severe off-road conditions, driving along a wet, broken forest road, i.e. normal conditions without extreme conditions, then self-block can be a good helper in such conditions.

Maybe it seems to me, maybe I have the self-locking set up this way, maybe that’s not the issue, but often when the car starts to “slip”, a jerk in the opposite direction suddenly appears. It’s as if the car first went to where the wheel was blocked, and then it gained momentum again, and the car jerks in the opposite direction.

A self-locking differential for the Niva is a good addition that, if used correctly, can significantly improve its off-road properties.

Varieties

There are two main groups of self-locking differentials. The first type works depending on the angular speed parameters along the axes of the vehicle. In turn, these modifications are divided into several subtypes, namely:

- disk versions;

- models equipped with a viscous coupling;

- options with electronic action.

The second type includes mechanisms that are locked in accordance with the torsional moments on the axes. This group includes worm modifications.

In addition, there are inter-axle and inter-wheel self-blocks. With their help, torque is distributed between axles or wheels, respectively. The design of the mechanism, which can be symmetrical or asymmetrical, directly depends on the moment of force dispersion. On all-wheel drive SUVs, three sets of differentials are installed simultaneously, two between the wheels, one between the axles.

Location

On vehicles with a single drive axle, the differential is located on the drive axle.

Tandem axle vehicles have two differentials, one on each axle.

On vehicles with all-wheel drive, there is one differential on each axle. It is not recommended to drive such vehicles on hard-paved roads with all-wheel drive engaged.

On cars with permanent all-wheel drive, there are three differentials: one on each axle (axle-axle), plus one that distributes torque between the axles (axle-axle).

With three or four driving axles (wheel arrangement 6 × 6 or 8 × 8), an inter-vehicle differential is also added.

Which is better to install a self-locking differential on the Niva?

A domestic SUV can be equipped with an electronic, combined, mechanical or pneumatic self-block. The first type model has a significant advantage over other versions. To activate it, you just need to press a button. The mechanism operates automatically, but only if the car is moving at a speed that is less than the threshold. The system shuts down when it reaches a mode higher than the nominal parameter.

The pneumatic version is a device mounted on both axles. The advantages of the mechanism include its compact size; the operating principle is based on the use of a pneumatic system. Self-block mechanical type is the cheapest and simplest in design. Reliability and operational efficiency depend on two semi-axial and a pair of spacer couplings, as well as pins and springs.

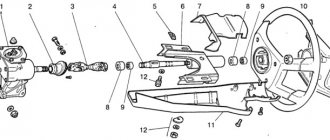

Device

The basis of any differential can only be a planetary gear, which, due to the mechanics of its operation, is the only one of all rotational motion gears that can solve the problems facing a differential in a transmission. The term “planetary differential” is redundant - any differential is planetary. Its performance as a differential absolutely does not depend on its composition or shape, or on the choice of specific links for driving or driven. Any in its simplest version - a three-link planetary mechanism without any control elements - can perform the functions of decomposing one flow into two interconnected ones or adding two independent flows into one. The choice of other links as leading ones, and others as driven ones, is determined only by the required kinematics of the differential’s connections with other transmission elements and the peculiarities of the mechanics of the differential operation in the chosen format of distribution of functions between the links. The addition of control elements and the use of so-called complex planetary mechanisms gives the differential the ability to mutually equalize the angular velocities of flows and the ability to actively control these velocities.

Sectional view of the differential of a Porsche Cayenne

The canonical, most famous type of differential is the cross-axle differential of a car, made on the basis of a simple (that is, three-link) spatial planetary mechanism of a circuit with four bevel gears. The planetary carrier of such a differential actually serves as its entire body - this is the driving link ➁. The two gears are satellites on a common axis ➂. And the two gears are two suns - two driven links ➃. Power is supplied to the housing (carrier) through a rigidly fixed driven gear of the main transmission, which in turn is paired with the drive gear ➀ formally there is another element of the transmission, despite the fact that the differential with the driven gear often looks like a single assembly unit. Power is removed from two suns, to which in this case shafts with CV joints are attached.

Parameters and selection criteria

The definition of a self-locking differential on a Niva is influenced by the car model, operating conditions, driving style, and other objective and subjective factors. For example, the ball version increases the load on the steering column, which radically changes the way the driver drives. This is fully expressed during turns and turns; if handled improperly, it leads to deformation of transmission parts.

The correct approach to choosing self-blocks is to take into account which axle of the vehicle will be equipped with the specified mechanism. This is due to the fact that the number of splines differs for different modifications. There can be 22 or 24 of them. Pay attention to the markings on the packaging. Usually there is information there, is it possible to install devices for a certain brand of car? Another point is the degree of transformation of the torsional moment (0.5 or 0.7). Here the choice depends on the owner of the car.

Advantages and disadvantages

To find out which is the best self-locking differential for the Niva, you need to compare the advantages and disadvantages in relation to the standard analogue of the car. The benefits include:

- Increasing the vehicle's maneuverability on steep, sliding and bumpy surfaces.

- There is no need to make changes to the design of the machine, since the self-block is mounted in place of the standard element. It is recommended to carry out installation work in a specialized workshop or do it yourself.

- The mechanism in question operates automatically and does not require special training for the driver.

Disadvantages of installing a self-locking differential on a Niva:

- steering becomes tighter, which requires additional effort;

- the working life is less than that of the factory element;

- driving style changes when cornering;

- there is no complete guarantee of blocking.

Various modifications of self-blocks have their own nuances, depending on the manufacturer, type of development, and installed components.

Design and principle of operation

From a technical point of view, the differential is designed quite simply, but at the same time it is able to withstand enormous loads. What's inside this node and how does it work?

By its type, it is a planetary gearbox with all the necessary elements.

- The final drive gear supplies rotation from the gearbox to the differential.

- The driven gear is connected to both the main gear and the satellite gears.

- Satellites are fixed in the “cup” of the driven gear, so that they rotate with it.

- Axle gears are connected to the satellites and do not contact the rest of the differential elements.

Shown in detail in the video below.

- The main gear shaft comes from the gearbox, from which rotation is transmitted to the driven gear.

- The driven gear and the “cup” (carrier) attached to it receive torque.

- Rotating, the driven gear and cup set the satellite gears in motion.

- The satellites, in turn, transmit rotation to the axle shafts.

- With an equal load on the axle shafts (when the car is moving on a straight road with a uniform surface), the satellites do not rotate. Only the driven gear works, in the cup of which the satellites are fixed, and they rotate together with it, without rotating around their axis. Thus, the torque is distributed equally on the axle shaft, 50:50.

- When the car turns and one of the wheels should slow down and the other should speed up, the satellites begin to move. Due to the bevel gear, they rotate, slowing down one axle shaft and accelerating the second. In other words, they redistribute the torque in the required proportion, up to 0:100 without loss of force.

- When one wheel slips, the locking mechanism is activated, without which the wheel that rotates faster would lose all the torque. Without blocking, the car stops when at least one wheel hits a slippery surface.

When moving in a straight line

When a car moves in a straight line on a smooth surface with a hard, dry surface, both axle shafts rotate at the same angular velocity. The side gears are at rest relative to each other, the entire differential is very similar to a monolithic structure.

The satellites, being connected through their teeth to both semi-axial gears, do not rotate relative to their axes. The moment is distributed equally between the axles if the differential is symmetrical and free, that is, without locking. However, with blocking in this ideal case it will be the same.

When turning

When turning, and this is the normal operating mode of the differential, since ideal straight lines do not exist in nature, one of the wheels will always rotate faster. The satellites will begin to move relative to their axes, but the connection between the semi-axial gears and the body will not be lost. That is, the moment will continue to be transmitted from the body to the wheels, and everything in the same 50/50 ratio.

This is very interesting to consider from a power point of view. The torque is the same, but the speed of the wheel outer from the turn is greater, that is, proportionally more power is transferred to it.

And this is not surprising, since the higher the speed, the higher the losses, which are compensated by the addition of power. In this case, there will not be the slightest interference with the rotation of the wheels at different speeds, unlike a rigid connection.

When slipping

Things are much less pleasant when one of the wheels hits a relatively slippery section of the road and slips during acceleration. There is no grip on the road, which means the moment of resistance of the coating drops sharply. But this moment is always equal to the traction moment, this is the law of physics. This means the traction torque will drop.

A free symmetrical differential divides the power in half between the wheels. It's always 50/50. That is, when the torque on one drops to zero, on the second it will reset automatically. The car will begin to lose speed, and if we are talking about starting off on ice or liquid mud, then it will simply remain there, unable to get out of the ambush.

This is the main disadvantage of a free differential. It can only transmit the force that a wheel in worse conditions can handle. Even if the second one is on dry, clean asphalt, the car will not go anywhere. All the energy will be spent on the rapid and useless rotation of the slipping wheel.

Removing axle shafts and bearings

To install a self-locking differential on a Niva 4x4, you need to carefully and efficiently remove the axle shafts. A special puller will be required. Otherwise, this is problematic, since the metal sticks to the slots. Stages of dismantling axle shafts and bearings:

- Unscrew all the bolt nuts on the plate element for fixing the axle bearing.

- The brake block is secured with bolts or fittings of a suitable diameter. If you ignore this procedure, the brake lines will come off.

- The axle shaft is removed directly using a special device.

- To dismantle the bearings, you will need a hydraulic press, which will make it easier to fit the race onto the shaft with high precision.

- Unscrew the wheel bearing nut and remove the bushing.

- Unscrew the fastening nut securing the lever with the rotary cam.

- Remove the stupor plate and remove the lever.

- Disconnect all fasteners, disconnect the hub with the brake disc and the knuckle. Dismantle the bearing, having previously fixed the rotating element in a vice. The bearing is also installed by pressing.

Removing the Niva transfer case

To repair the transfer case on a VAZ 21213 (21214), the unit must first be removed. We carry out removal in the following order:

- in the cabin we dismantle the plastic lining of the gearbox and gearbox levers;

- unscrew the knobs of the transfer case shift levers, remove the casing under them;

- disconnect the speedometer cable, for RK 21214 you will need to additionally disconnect the speed sensor;

- we unscrew the bolts with nuts securing the elastic coupling of the front and rear propeller shafts; in order to remove the bolts, the cardan shafts must be turned - they are removed one at a time in one specific position of the shaft;

- We install a jack (or other support) under the transfer case and mark the places where the side supports of the RC were attached. This is done in order to minimize the alignment of the transfer case during installation;

- unscrew the 4 nuts securing the gearbox to the gearbox;

- unscrew the 4 fastenings of the RC supports to the car body;

- Now all that remains is to dismantle the transfer case.

Assembly of the unit

When you have decided on the best self-locking differential for the Niva, you can begin assembling the unit. Initially, they adjust the gaps, which is not so simple. For this purpose, special washers of different thicknesses are used. Alternatively, accuracy is determined using a steelyard. One edge of the cord (about a meter in length) is wound around the flange, and the second is fixed to the scales. Pull the device in the winding, not forgetting to mark the turning point.

To ensure correct functioning of the gearbox, the elements are sealed before assembling the parts. If this is not done, soon after installation defects may appear, even to the point of complete breakdown of some parts. After treating the surfaces with sealant, wait until it dries completely. Next, the gearbox is filled with new oil. All sealing components with deformations and a hint of leakage are replaced. The mechanisms are assembled in a mirror order. After the replacement and installation of parts is completed, you should check the operation of the brake unit. This is very important, since malfunction of parts affects road safety.

DIY self-block installation instructions

To install a Niva self-locking differential, it is not necessary to visit a car service center. It is quite possible to do this with your own hands, provided that the person is well versed in the structure of the car. The type of differential and its installation location are not particularly important.

First you need to decide on a workplace; it should be spacious enough. Using several lifts, you will have to lift the Niva on scales, remove the wheels, then drain the engine oil from the gearbox housing into a container and remove the drive axle drive. To do this, just use a wrench to loosen all the nuts securing the front cover to the gearbox, remove the cover and gasket.

Now it is necessary to reliably and efficiently perform the operation of disassembling the driveshaft, which is very difficult to do without a special puller. The metal is clamped onto the splines of the swivel, which requires a lot of effort, which every person lacks. Dismantling the cardan shaft is carried out as follows:

- Remove all bolts and nuts on the base plate driveshaft.

- The brake mechanism is blocked. This can be done with self-tapping screws or wire. If the mechanism is not secured, the brake hoses may come off.

- The cardan shaft is removable. With the right skill, this can be done manually, but better with a puller.

Then the bearings need to be replaced. To do this you will need a hydraulic press. This will help ensure that the cage fits onto the shaft with fairly high accuracy. To do this, you need to replace the bearings:

- Unscrew the hub bearing nut and remove the hub. Remove the nut securing the lever to the steering knuckle.

- Remove the hub plate and release the arm from the axle journal.

- Release all locking devices and separate the steering knuckle and hub with brake disc. Remove the bearing by first holding the steering knuckle in a vise. During reassembly, the bearing is pressed in.

Having adjusted the gap in the main gear using special washers of variable thickness, you can begin assembly. Adjusting the gap is difficult and requires special equipment, but an injector changer can be used to ensure accuracy. To work with it, wind one end of a 1 m long cable around the collar and attach the other end to the scale. When pulling the device into the winding, it will be necessary to set the torque.

To ensure proper operation of the regulator, the halves are usually sealed before assembly. Failure to comply with this requirement may result in malfunction of the device and failure of some parts. After applying the sealant, wait a while for it to harden. Then fill the transmission housing with new oil. All sealing joints that were damaged during disassembly, as well as those that show signs of oil leakage, should be completely replaced with new ones. Now you can begin to reassemble all the mechanisms in reverse order.

After completing all work related to the replacement and assembly of parts, it is necessary to check the operation of the braking devices. Their malfunction may affect road safety.

Whether you can do something like a Niwa differential lock depends on why the driver needs it. If you need to move to difficult areas, this will be necessary. If the driver also intends to drive on a regular asphalt road, then installing a limited slip differential in the Niva is hardly worth it. What type of unit to choose and where to place it depends on the driver’s preferences.

The reason for the popularity of the Niva and Chevy Niva is that they are just as comfortable to drive on public roads as off-road of varying difficulty.

However, different operating conditions place different demands on a vehicle's transmission.

When off-road, it is sometimes necessary to transmit torque to both wheels, which is accomplished by locking the differential.

But as soon as you leave the ground on familiar asphalt, the differential needs to be unlocked again.

This is where the forced blockade of the Niva River comes to the rescue.

The main advantage of locks of this type over the so-called Niva self-locking differential is that the process of locking the mechanism becomes completely controllable.

When needed, simply press the limited slip differential lock on/off button to have full control of the lock.

The locking is driven by a pneumatic drive, the operation of which we described in our review of the differential lock for UAZ vehicles with a Spicer axle:

What are users saying?

As reviews indicate, it is not advisable to install a self-locking differential on a Niva in all cases. If the driver intends to constantly operate the vehicle on serious and difficult off-road conditions, installing a self-block makes sense. When driving regularly around the city or on a country road, this idea is irrelevant. The existing factory analogue copes well in such cases on its own, and it has a longer service life.

In addition, users recommend installing the mechanism themselves only if the owner has the appropriate skills and a clear understanding of the design features of the vehicle. Otherwise, use the services of a car service. The choice of the configuration of the self-block and the location of its installation depends solely on the preferences of the owner of the machine.

A few words about the Chevrolet Niva transfer case

I think it’s time to talk about the transfer case of the Chevy Niva, because those who just bought this car, at the very beginning of use, do not really know how to use the transfer case, what the rules are, and in general, when to lower the gear and when to lock it. Let's figure it out now. It’s a pity, of course, that I didn’t record a video on today’s drive along a fairly washed-out road. Well, never mind, I’ll record it and show it clearly on video. For now, in words.

In general, the transfer case switches to a lower gear, as well as to lock, and it is possible and even necessary to do this at the same time. It’s convenient on the Shevik - this is done with one lever.

Turn it down - right up. Add lock - Pull the lever all the way to the left. Look at the switch handle, it's written there. Letter designation - L(low) - low, N - neutral, H(high) - high, that is, normal.

It looks something like this - we are driving across the field in normal second/third gear. Suddenly there is a terrible puddle ahead. We stop and turn down the car.

You may ask - how long does it take to turn on the blocking and then turn it off? There is another nuance here - very often, many owners of the Chevrolet Niva have a problem with the blocking - it does not turn off. It just jams and that’s it, you have to drive on the highway with the blockage. This, you understand, is very harmful for the machine and in such cases you must turn it off.

In bright sunny weather it is sometimes difficult to see. Be careful. Well, about turning off the center wheel - I managed to turn it off just when reversing. Needless to say, now I turn it on only in the most dire cases. In the rest of the others, lower gears are quite enough for me.

Just today I went to the lake to check if the ice had melted. The road was washed out, the snow had already melted and turned into liquid mud, and it’s not safe to drive through such mud on my AT tires. It feels like it’s being dragged in all directions, but the most important thing is that I’m driving, I don’t get stuck, and sometimes the ruts were almost to the very bottom; when you shuffle, it always becomes unpleasant)) After some short drives, the car looked “military-like” - all covered in mud , went to the city - people look around))

And here’s another observation of mine: it’s better to drive through mud slowly but surely. This applies to lower gears - if the mud is serious, then I always drive in first, pushing hard, trying to feel the wheels spinning in the mud. If you accelerate a little, you can immediately “burrow”, this is the case when there is no hard covering under the liquid mud.

When you turn on the second lower gear, the car accelerates, but if you get into a mud hole, there is a risk that the engine will “choke” (it is very difficult to spin the wheels in the second gear when stuck) and you will stall. Needless to say, stalling in a deep puddle can be dangerous. Therefore, if you decide to overcome a puddle or muddy area with acceleration (very often this makes sense), then be prepared in the middle, if you suddenly start to fall through, immediately switch from 2 to 1 low, so as not to stall.

All this knowledge - when to go in first and when in second, when to turn on the lock and when not necessary - all this comes with experience. You’ll ride in the mud and you’ll already begin to understand that it’s better to take the puddle over there with acceleration without locking, and that clay hill with potholes - only at 1 lower gear and with the locking on. Think with your head first, and don’t rely on the car to pull it out. The Chevrolet Niva is an excellent car, if you don’t be stupid.

I remember when we were making our way to an abandoned village, we got to one really dangerous place, and there was a UAZ standing there and didn’t dare to drive through. We scouted around and decided that we would pass. And we drove by, leisurely, pushing hard, without particularly accelerating.

Therefore, one more rule (which I always adhere to) - if the place is dangerous, there is a risk of getting stuck, then get out of the car, poke it with a branch, find out the depth of the puddle, rut, feel for a solid place where you can drive. This is the job of the navigator, so let your partner get out of the car and don’t be lazy. Spend 5 minutes on reconnaissance so that you don’t have to spend several hours later getting out of an ambush.

Self-locking differential on Niva: is it worth installing?

Niva car is a type of off-road vehicle. This car is designed for driving on not the best sections of the road, off-road.

What is a limited slip differential?

A self-locking differential is a device based on a screw design. Increases the cross-country ability of vehicles, in particular such as Niva. When installing a differential, the car can easily overcome difficult sections of the road and terrain where driving is difficult. Therefore, installing a “self-block” on a Niva increases and improves the capabilities of this machine.

Center lock

There are devices that are designed only for off-road vehicles. They are not installed on cars for normal city driving. One of these “helpers” is the Center Differential. It distributes movement across axes. Its purpose is to transfer the rotating movement of one source to others . That is, if the rear or front wheels slip and the car cannot move, then the driving dynamics are distributed to all wheels. The operation of the center lock is based on a simple principle - the torque (rotation of the wheels) is divided between the front and rear axles . This effect makes it possible for the car to continue moving. Agree that this is a very good invention for cars - SUVs, which also includes the Niva.

Differential lock

Forced blocking not only complicates the design but also automatically makes it more expensive and less reliable. But if you install a differential lock yourself, this is usually caused by the desire to replace the standard differentials with a forced locking mechanism. This can negatively affect the operation of the transfer case, so it is necessary to select those parts that will be compatible specifically with the Chevrolet Niva.

At the moment, among the solutions presented on the market, the most popular are those made on the basis of:

- pneumatics

- electronic control

- self-locking

Each of them has both advantages and some disadvantages in operation.