4.1/5 — (54 votes)

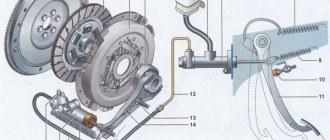

1 - clutch housing, 2 - working cylinder rod, 3 - fork, 4 - adjusting nut, 5 - lock nut, 6 - return spring, 7 - friction linings, 8 - driven clutch disc, 9 - steel casing, 10 - drive disc ( basket).

Today, the article will talk about procedures such as replacing and adjusting the 2106 clutch with your own hands. As we like to repeat, everything can be done without the help of car service specialists; there are no difficulties in repairing VAZ cars and there cannot be any. Often, drivers try to solve all the problems with the car on their own, because the cost of maintenance is absurdly high.

Even despite the fact that the VAZ 2106 has not been produced for ten years. And we will try to help as much as possible with the repair. If you have any questions, leave comments, share your experience, and describe unusual situations. After all, the topic is quite interesting and rich.

Clutch mechanism of a VAZ 2106 car

A device with the simplest design that ensures the engagement of the power plant and gearbox. The mechanism is primitive, which makes its repair and maintenance as accessible as possible for the average motorist.

Description of design

Here are the elements:

- clutch pedal;

- master cylinder;

- pressure main;

- working cylinder;

- clutch fork.

Inside the structure there is a special liquid that ensures the transfer of impulse from the pedal to the fork.

How does the clutch drive work?

The principle of operation is this.

- The driver presses the pedal.

- The master cylinder piston, connected by a hinge to the pedal lever, forces fluid through the cylinder, creating excess pressure inside the line.

- The oil passes through the pressure line and enters the working cylinder.

- Next, the piston is pushed out and the clutch fork moves.

- The mechanism comes out of the hook and the motor is disconnected from the gearbox.

The principle of operation is the same for all modifications and versions. Some car enthusiasts install a dry clutch. The actual difference is only in the working element - the classic one contains liquid, the dry one contains a cable.

Clutch failure

Among the most common “diagnoses” of auto mechanics are:

- Breakdown of the head or working cylinder seal. Liquid flows out of the system, causing it to become airy.

- The pressure line is clogged or coked. The problem is a consequence of using counterfeit oil or not replacing it in a timely manner.

- Mechanical damage to the fork or working cylinder. The parts are located at the bottom of the car. Typically, users can damage the mechanism when driving over off-road roads or curbs.

- The easiest problem is the spring stretching or falling out of the mounting groove.

Symptoms of malfunctions

Problems arising from improper clutch adjustment.

- The car jerks. This means that the disc does not move far enough from the basket and that when the drive is pressed, the motor is not completely disconnected from the gearbox.

- The gears don't want to turn on. The symptom that arises in the above problem is similar.

- When you press the gas pedal hard, the car does not respond or accelerates too slowly. Jerking may also occur during steady driving.

- The clutch pedal is falling/too hard and the gears will not engage.

general information

The clutch needs to be adjusted every time the car owner detects the above “symptoms”. The Zhiguli 2106 model has this problem more often than other cars. Therefore, it is necessary to inspect the state of operation of this sector for preventive purposes. After all, if the clutch “flies”, the car simply will not budge.

The main purpose of the unit is to transfer torque to the wheels of the drive axle. The VAZ-2106 has rear-wheel drive and a friction, single-disc dry clutch. The levers in the “six” are moved using a hydraulic subsystem, not cables. It includes:

- main cylinder;

- working cylinder;

- high pressure auxiliary hoses.

When is clutch adjustment necessary?

It is not difficult to understand that the mechanism needs to be adjusted. The machine itself will tell you this. The following factors are clear signs of disorder of the unit.

- Pedal dips - when you press, you feel your foot drop to a certain level.

- Loss of elasticity under pressure.

- The car begins to move at the beginning or end of the pedal stroke.

- Loose lever or complete lack of working play.

- Difficulty shifting gears.

- Slipping of the clutch disc during acceleration and braking of the car.

Other deviations in the normal operation of the gearbox unit and unit are also acceptable.

Clutch adjustment options

If it is necessary to adjust the mechanism, the machine begins to behave inappropriately. The pedal sinks, changing gears becomes more difficult, jerking and jerking appear.

There are factory recommendations that establish strict tolerances for backlash.

What pedal stroke is considered normal?

In the correct position and in fully working order, the movement of the pedal until the mechanism disengages is 2.5-3.5 centimeters. The reference standard is established by the manufacturer and is considered a recommendation value.

Some car enthusiasts reconfigure the system to suit themselves, adjusting it within the range of 45-55 mm.

How to measure your car's pedal travel

Experienced craftsmen recommend measuring the stroke like this.

- A ruler is applied to the pedal at an angle of 90 degrees.

- Next, note the pedal height in centimeters.

- Press the lever until it stops.

- Make a mark on the ruler.

Measure the difference in values; normally, free play is limited to 25-35 mm.

Frequency of setting

There is no strictly established time interval for servicing the mechanism. The manufacturer insists that clutch adjustment is mandatory after performing any repair and service work related directly or indirectly to the device.

Eg:

- replacing the clutch disc/basket;

- pumping of highways;

- installation of new cylinders.

List and values of parameters

The task of adjusting the drive is to create distances - gaps between the clutch functionalities:

- between the main cylinder piston and the pusher;

- between the thrust flange friction ring and the trip bearing.

The first play is created by adjusting the limiting screw of the clutch pedal lever. The distance by which the piston can be removed from the pusher is in the range from 0.1 to 0.5 mm. Then the free play of the lever will be, respectively, from 0.4 to 2 millimeters.

The second play is determined by the free play value made by the pusher. Its values are as follows: from 4 to 5 mm. And the gap separating the bearing from the ring should be 2 mm. At the end of the adjustments, the free play of the pedal lever is from 25 mm to 35 mm.

Setting up the VAZ 2106 clutch

You can check whether the clutch position on a VAZ 2106 is set correctly in this way.

- Place the car in neutral and warm up the engine to operating temperature. With the engine running, without touching the accelerator lever, turn on the “R” position. The response to the action should be a smooth movement of the lever without extraneous sounds or excessive force.

- During the operation of the car, all gearbox positions work clearly, there are no crashes, squeaks, or crunches.

- During sharp acceleration, the increase in engine speed is proportional to the acceleration. If the clutch disc slips, the engine starts to spin up without a manual transmission.

If any malfunctions or malfunctions are detected, it is necessary to perform more detailed diagnostics of the unit. You may need to replace the disk or repair the basket.

Examination

To make sure that everything is done correctly, simple checks should be carried out upon completion of the work.

- Set the gearbox to neutral. Start the engine and warm up the car to operating temperature. Reduce the gas to such an extent that the crankshaft speed becomes minimal. Depress the clutch pedal and shift to reverse gear. In this case, there should be no extraneous sounds: tapping, creaking, etc. If, nevertheless, some extraneous noise occurs, it means that the work was carried out incorrectly.

- When the car is moving at a speed of 40-45 km, depress the clutch pedal and change gears. There should also be no third-party sounds.

- At the acceleration stage of the VAZ-2106, you need to observe the correspondence between the increase in speed and the increase in crankshaft rotation speed. Proportionality and the absence of slipping indicate that the adjustment was made correctly.

The check must be done to make sure that the car is in good technical condition, which is important in terms of the safety of the driver and his passengers. At the end of the work, it is recommended to bleed the system by filling it with brake fluid to remove any trapped air. This procedure is also easy to carry out yourself using a set of inexpensive and accessible tools and materials.

If the adjustment does not show the desired result, it should be done again. Since the 2106 is quite an old model, the last car was produced before 2006, it is worth inspecting the clutch parts and replacing them if necessary.

Source

How to properly bleed the clutch on a VAZ-2106

The sequence of the operation is as follows.

- Drive the car into a pit or put it on trestles. Securely secure the car.

- Clean the expansion tank and bleeder fitting from dirt. The latter is located on the working cylinder.

- Open the RB cover.

- Check that the fitting can be unscrewed and put a pre-prepared hose on it. Place the other end of the tube into the waste container.

- The assistant sits behind the wheel and pumps up the pressure 4-5 times by pumping the pedal. At the end you need to pinch and hold it.

- Next, the shut-off fitting is unscrewed and the liquid, along with the air, goes into a container for draining the waste. At the same time, you need to monitor the oil level in the RB and add it if necessary.

- When the bubbles are completely released, the fitting closes.

- To eliminate any remaining air in the line, it is recommended to repeat the operation 2-3 times.

Major breakdowns

Despite the high cost of the design, the VAZ-2106 clutch breaks quite often. The clutch cylinder fails and leaks appear. This happens for the following reasons:

- Excessive wear on the slave and master cylinder parts.

- Using brake fluid not recommended by the vehicle manufacturer.

- A decrease in the liquid level in the expansion tank due to its damage or loosening of the pipe clamps.

The price of the VAZ-2106 clutch master cylinder is 400-600 rubles, depending on the manufacturer. But you can also find more expensive parts. The repair kit is a little cheaper - about 300 rubles.

We change the clutch with our own hands without removing the transmission

The operation is performed like this.

- Place the machine on a viewing hole or a lift and securely secure it to prevent it from rolling away.

- Disconnect the cardan and slave cylinder from the gearbox.

- Remove the protective cover of the mechanism and the traverse.

- Unscrew the box cushion.

- Using your hands or using a lever, push the gearbox housing away from the power unit until it stops. For insurance, you can install a support under the box.

- Next, you will need to unscrew the 6 bolts securing the basket from the flywheel.

- The box basket needs to be moved all the way and the clutch disc pulled out through the resulting gap.

- Similarly, slide the basket back and remove it.

- The last step is to dismantle the release fork and remove the bearing of the same name from the gearbox input shaft.

- Installation of new parts is carried out in reverse order.

Pedal dips

A dip in the pedal is one of the main signs that the VAZ-2106 clutch mechanism has become unusable. The clutch master cylinder may have lost its seal. But you shouldn’t blame it right away; you need to carefully examine all the elements of the system. The pipes connecting the cylinders must not have brake fluid leaks. There should also be no traces of it on the cylinder bodies themselves. If the pedal fails, the clutch will not work normally.

The following problems may occur:

- Difficulty changing gears.

- Drop in fluid level in the expansion tank.

- When used for a long time in this mode, the release bearing, basket, and disk fail.

If you notice a pedal failing, try to carry out repairs as quickly as possible, since with each press the fluid will come out of the system.

Replacing the master cylinder

The work of replacing the clutch master cylinder on a VAZ-2106 is carried out in almost the same way. It is fixed opposite the pedal. The master cylinder rod is connected to the pedal mechanically. The replacement procedure is as follows:

- Drain the brake fluid from the system.

- Unscrew the hose going to the expansion tank.

- Unscrew the tube going to the working cylinder.

- Unscrew the two bolts that secure it to the partition.

After this, the master brake cylinder is removed and repaired or completely replaced.