In the article:

- The pedal has become too hard

- How to make sure the vacuum booster is working properly

- The brake pedal is too soft

- Results

The braking system is the most important component of any vehicle.

Automotive designers pay special attention to brakes, realizing that safety on the road and people’s lives depend on their impeccable operation. The brakes of modern cars are quite reliable, however, you need to remember that any parts during operation are subject to mechanical, thermal, chemical and other types of loads, and therefore wear out and may fail. Brake system parts are no exception, only in this case the cost of a malfunction can be very high. Certain signs that appear during braking can warn that something is wrong with the brakes - extraneous sounds or strong vibrations, the car pulling to the side, uneven or noticeably decreased braking efficiency and an increased braking distance. But the first thing people usually pay attention to is the behavior of the brake pedal. It can become too tight, so that you have to press on it with force, or, on the contrary, it can suddenly turn out to be too soft, or even fail completely. All this complicates braking and can lead to serious consequences. Let's talk in more detail about what causes such symptoms and what to do in such situations.

Problem with brakes 2110

Discussion closed by moderator

Re:By the way, how to download the ZTC? -I have one piston coming out well and the second (which looks backward) barely on the left rear wheel

Will the automatic brake pads not work? Will the drum get dressed later? Will the pistons press all the way in?

If, during normal or hard braking, the car pulls to the side, regardless of whether it is to the left or to the right, first of all you need to deal with the car’s braking system.

Of course, the reasons may come from faults in the chassis, steering, suspension, but still, the brakes are the main thing you should pay attention to.

The pedal has become too hard

Sometimes a relatively tight brake pedal can be a feature of some car models. This nuance needs to be clarified if you have just purchased a car or are testing it before purchasing.

If everything was fine, but at some point you noticed that the pedal suddenly became “wooden” and you had to press on it with considerable force, then most likely the malfunction is related to the vacuum brake booster. It is this device that is designed to reduce the physical effort required to perform braking.

The ease of pressing the pedal occurs due to the difference in pressure in the atmospheric and vacuum chambers of the amplifier. Between the chambers there is a diaphragm with a rod that pushes the piston of the main brake cylinder (MBC), which, in turn, pumps brake fluid into the system lines and further to the working brake mechanisms. The vacuum in the vacuum chamber is created by an electric pump, and in gasoline engines the source of vacuum is often the intake manifold.

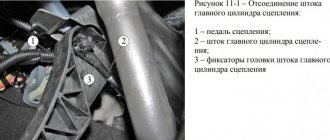

In the initial state, the cameras are connected to one another. When the pedal is pressed, the vacuum chamber is connected to the source of vacuum through a check valve, and the atmospheric chamber is connected to the atmosphere through an air valve. As a result, the diaphragm with the rod is drawn into the vacuum chamber. This reduces the force required to press on the GTZ piston. The vacuum amplifier can be made as a separate element or form a single module with the GTZ.

The most vulnerable element here is the rubber hose connecting the intake manifold to the vacuum chamber. Therefore, first of all, you should check its integrity and, if necessary, replace it.

Violation of tightness may be accompanied by non-standard behavior of the engine during braking - tripping, increasing or decreasing speed, sometimes fuel consumption increases. This is due to air leakage through a damaged hose and the entry of a lean mixture into the engine cylinders.

If the vacuum pump creates a vacuum, you need to check its serviceability.

In the vacuum booster itself, the air filter may become clogged, the diaphragm may be damaged, or one of the valves may lose mobility.

If necessary, you can purchase a new vacuum brake booster or try to repair the existing one. Be careful when disassembling - there is a spring inside, as well as a number of parts that can be easily lost. It must be borne in mind that during reassembly after repair it is not always possible to sufficiently ensure tightness, and therefore normal operation of the device.

When replacing the vacuum booster, it is not necessary to disassemble the turbocharger, and therefore there is no need to bleed the brake system.

The brakes can also become hard due to damage to the cuffs in the turbocharger or working cylinders and, as a result, a tighter stroke of the pistons in them. Treatment is to replace damaged parts or the cylinders themselves.

Device

Hydraulic brakes are installed on the machine and operate generally reliably. They are double-circuit and have a diagonal distribution. That is, if one part suddenly fails, then braking by another circuit is possible. For the sake of safety, the VAZ 2110 brakes operate diagonally, one circuit is the right front and left rear wheels, the other is also diagonal.

This device allows you to brake efficiently (without skidding and other troubles) even in the event of a malfunction, if the brakes in one of the circuits are lost.

Let's consider the design of the brake system. The hydraulic drive includes a vacuum booster, as well as a dual-circuit regulator that creates pressure in the rear brakes.

The brake caliper design is described in this article:

In addition, the hydraulic drive is equipped with pipelines divided into two circuits, hoses and brake mechanisms that provide braking to the front and rear mechanisms.

The hydraulic drive is activated by a pedal located in the cabin (middle). Here are the main components of the hydraulic drive:

- Vacuum booster.

It is designed in such a way that it creates pressure on the master cylinder piston, and thus causes braking; Vacuum brake booster - Pressure regulator drive.

It is through it that the working brake fluid flows to the rear brake mechanisms; Brake pressure regulator drive - The pressure regulator itself.

Already from the name it is clear that this device is responsible for the force of pressure, its decrease or increase. He does this depending on how loaded the rear axle of the car is; Pressure regulator - Main cylinder with pistons, equipped with a reservoir.

The filler neck of the tank is equipped with an emergency fuel level sensor; Master brake cylinder - Brake mechanism for the front wheel.

Its main parts are the disc, pads and wheel cylinders. The mechanism also provides an indicator to prevent complete wear and malfunction of the linings; Front wheel brake - Brake mechanism for the rear wheel. Unlike the front disc brakes, the rear ones are drum brakes. This is the factory configuration. However, many car owners believe that their device does not provide high-quality braking, and change them to disc ones.

The brakes require attention. Without waiting for the warning light to come on, indicating a critical level of fuel fluid or wear of the linings, and even more so, without allowing the brakes to completely disappear, you need to carry out preventive checks.

Particular attention should be paid to all connections and hoses, since the “escaped” brake fluid will not make it possible to brake, and from here it’s not far from tragedy.

How to make sure the vacuum booster is working properly

First you should do a visual check. Make sure there are no brake fluid leaks and the booster housing is not damaged. Check the integrity of the hoses and the tightness of their connections to the fittings. If necessary, tighten the clamps.

A hissing sound that occurs when you press the brake pedal may indicate a leak. This hissing often persists for some time after the engine is turned off and then it can be heard quite clearly.

There are several ways to check the performance of the vacuum booster.

- The engine must be stopped. Press the brake pedal 6-7 times in a row to equalize the pressure in the booster chambers, and then squeeze the brake all the way and start the engine in this position. If the amplifier is working properly, a vacuum will appear in the system. Due to the pressure of the diaphragm, the rod will move, pulling the pusher along with it. And since the pusher is mechanically connected to the pedal, it will lower slightly, and this can easily be felt with your foot. If this does not happen, it means that a vacuum has not arisen in the system. If you have any doubts, try the second method.

- Turn on the engine, let it idle for a few minutes, then turn it off. Press the brake fully two or three times and release the pedal. If the vacuum booster is working normally and there is no air suction, then the first one or two presses will be soft, and the subsequent ones will be noticeably tighter. If you don't notice any difference in the pedal travel, then there is a problem with the amplifier.

- With the engine running, depress the brake pedal and, while holding it down, turn off the engine. If you now remove your foot from the pedal, it should remain in the lowered state for some time, thanks to the remaining vacuum in the vacuum chamber of the amplifier.

Prevention measures

I can say from personal experience that the detailed cleaning procedure is quite complicated. This will definitely take more than one hour.

To minimize the number of repetitions of such operations, be sure to lubricate the caliper twice a year for preventive purposes. It is optimal to use professional special lubricants designed specifically for this element. But regular WD40 is also an alternative. It will definitely protect against corrosion.

Plus, visually inspect the condition once a year. Make sure that the assembly is free of damage, dirt and signs of corrosion. Make sure that the boot does not rupture during operation. Otherwise, the caliper will not last long after this.

You need to monitor all brake systems, including periodic adjustment of the handbrake. After all, this is also an integral part of vehicle safety.

That's all for me. If you have any questions, ask them in the comments. We will try to answer quickly.

Subscribe, leave reviews, tell your friends about our project!

My car is 8 years old, the brakes haven’t worked for a long time, I just couldn’t get around to it, I’ve been hatching the idea of improving them for a long time, in the end it was the fact that when braking the pedal was elastic, and when I pressed the floor there was no feeling of the blocking limit. what to do, I started by replacing the front brake discs, installed 14″+ Ferroo pads, the brakes became more effective, especially when braking for a long time they retained their properties and to achieve a certain deceleration you need a little less effort, the euphoria did not last long, you quickly get used to good things, at times there were better, at times it was quite annoying, I moved on, no, I didn’t put disks on the rear, there’s no point, the front doesn’t slow down better anyway and there’s no abs, I didn’t put all the cast iron on the rear, the point is to insert rings made of the same cast iron, only aluminum removes and dissipates heat better, I just replaced all the brake hoses because... the old ones lose their hardness over time, I replaced the brake fluid, it also loses its properties in 2-3 years (boiling threshold, etc.), I replaced the rear cylinders, they are susceptible to souring, and of course I installed new pads on the rear, I didn’t bother, I installed a stock one, they brake perfectly, and the sorcerer also adjusted it, according to the book it was 2.0-2.2 mm, I set it to 1 mm, I have gas and 40 kg in the trunk, the rear is raised on cubes + stiff springs. The brakes are much better, more informative, the braking force has decreased, the system works more harmoniously, the force is less, I think, due to the fact that there is no expense for springy tubes, poor fluid, uneven distribution of forces and therefore ineffective. So draw your own conclusion. PS I didn’t change the vacuum, I’m a worker, I don’t want to change it in vain, I don’t regret it now. g.t.ts. also normal, different in physical. characteristics are the same (piston diameters, stroke, etc.), which means if the stock is not defective, then it works the same

- Thank you

- I do not like

4eparat Mar 25, 2009

And I can’t help but think about installing rear brakes from the classics.

- Thank you

- I do not like

boatswain March 25, 2009

And I can’t help but think about installing rear brakes from the classics.

why do you need classics? It’s better to have rear disc ones with a mechanical handbrake. cost 11,000 thousand a set

- Thank you

- I do not like

Vanekkkk 25 Mar 2009

You don't need rear brakes from a classic, I drove it. they are of little use

The brake pedal is too soft

If pressing the pedal has become too soft, it means there are air bubbles in the hydraulics and then the system should be pumped, or there is a loss of working fluid. The first thing you need to do is check the brake fluid level. If it is below the permissible level, the hydraulic system must be carefully checked for leaks. A leak may occur at the connection points between the tubes and fittings due to poorly clamped clamps, and the hoses themselves may be damaged. Working fluid can also be lost in wheel brake cylinders if the seals are damaged. After eliminating the leak, you will also need to bleed the brake system hydraulics to remove air from it.

If the brake fluid is of poor quality, contaminated, or has not been changed for a long time and has lost its properties, then heating during sudden braking can quite easily lead to its boiling, and then the brakes will become “wobbly” and the car itself will be difficult to control. An old, dirty, or inadequate brake fluid can cause seized brake cylinders, damaged seals, and other problems. The conclusion is obvious - pay attention to the condition of the brake fluid and change it in a timely manner.

Another reason for a soft brake pedal is the hoses, which are made of rubber and wear out over time, becoming loose. When hydraulic pressure builds up during braking, they simply inflate. As a result, the brakes become too soft and braking becomes less effective.

An extreme and very dangerous manifestation of soft brakes is pedal failure. This occurs due to significant leakage of fuel fluid or damage to the sealing rings in the gas turbine engine.

An excessively soft brake pedal, and even more so if it fails, requires an urgent solution to the problem. You need to stop immediately, braking with the engine or handbrake, and then find and correct the problems.

Self-diagnosis methods.

Depressurization of a vehicle can be determined immediately if the engine is running unstable - “troit”. This is caused by air entering the intake manifold. During such a failure, the air-fuel mixture entering the cylinder becomes sharply leaner. A sign of a faulty vacuum booster is also the hissing sound it makes. To specify the breakdown, you should press the pedal a few minutes after turning off the engine. If the pedal stiffness does not disappear, then most likely the check valve is broken.

If the vacuum booster is in good working order, the pedal that is “pumped” without starting the engine goes down when the engine starts running.

Results

Other problems with the brake system are also possible - wear or oiling of brake pads, discs and drums, jamming of wheel cylinders and caliper guides. But one thing is clear - the braking system requires serious attention. Regular inspection, prevention and replacement of the vehicle, immediate response to problems and timely troubleshooting will allow you to feel more confident on the road and avoid many unpleasant and dangerous situations.

Use only high-quality spare parts, and in order not to run into fakes, purchase them from trustworthy stores.