VAZ 2110 – steering wheel vibrations

Car owners often face the problem of play and wobble in the steering wheel. Thus, vibration on the steering wheel of a VAZ 2110 is a fairly common phenomenon, observed more often at a speed of 90 km/h. The shaking increases more and more when driving exceeds 100 km/h, regardless of the road surface. Let's try to figure out in this article why vibrations occur on the steering wheel of the VAZ 2110?

Steering wheel wobble on rough roads and turns

If such vibration is observed on the steering column when cornering, then, with a high degree of probability, the cause is failed silent blocks and CV joints. It is not difficult to identify similar problems. You just need to perform the required inspection of the car on a lift or pit, and based on the results of such diagnostics, replace the failed spare parts

You should also pay attention to the front wheel hubs and bearings, which can often fail on broken Russian roads, which leads to the steering wheel wobbling when cornering

When driving on uneven roads, you may often experience increased vibration in the steering column. Many car owners mistakenly believe that such vibrations are a normal phenomenon when driving on uneven roads. However, in reality, such a beating of the steering wheel indicates certain problems with the car’s suspension.

First of all, you need to check the tire pressure. It is quite possible that such vibration or the car pulling to the side is caused precisely by incorrect tire pressure.

You should also inspect the bushing and steering rack. It is best to entrust such diagnostics to professionals who will be able to determine the condition of certain components of the car using one visual inspection and recommend that you repair the car.

Steering wheel wobble when cornering at high speed may indicate wear on the shock absorbers in the front suspension. In this case, it is necessary to hang the wheels on a stand, check the condition of the radiators and, if necessary, replace them. Remember that shock absorbers are replaced in pairs, so you won’t be able to save money by replacing just one failed shock absorber.

We explore the engine compartment and engine sounds

If you determine that the vibration is coming from under the hood, most likely the cause will be improper operation of the engine or the mounting points of vibration-loaded elements.

Problems related to internal combustion engines:

- Engine tripping. Many car owners have encountered a situation where, when accelerating or driving under tension, the engine begins to shake, and the thrust is much weaker than before. In this case, comprehensive engine diagnostics is necessary. The problem may be hidden in the ignition system: worn-out spark plugs, GDP, module and other elements, the malfunction of which leads to misfire in one or several cylinders at once. Possible burnout of valves, insufficient fuel pressure, etc. There are so many reasons that the topic deserves separate detailed consideration.

- Engine support cushions. Vibration during acceleration will appear because an increase in engine speed increases the centrifugal forces acting on the car body. When you sharply press the accelerator pedal to the floor, noticeable shocks may be observed. Made of hard rubber, even new cushions will cause vibrations.

Gearbox and clutch drive

It is also worth paying attention to the mounting locations of the gearbox. Perhaps the reason may be hidden inside the gearbox housing. In the case of a manual transmission, for a more accurate diagnosis, you should pay attention to the factors causing vibration or beating. If symptoms only appear at a certain speed limit, try driving it alternately in different gears. For example, if vibration is noticeable at 70 km, first engage 2nd gear, then 3rd (of course, if the gearbox ratios allow). This way, you can more accurately identify the transmission components that cause vibration.

If there is deformation of the input shaft in the gearbox, vibrations will be noticeable when accelerating in any gear.

An unbalanced flywheel can also cause the symptoms discussed. At the same time, it is worth paying attention to the clutch and release bearing.

If the car has an automatic transmission, check the oil level and condition. An indicator that is too low can cause shocks and vibrations.

Exhaust system

Improper mounting of the engine exhaust system can lead to noticeable vibrations in certain engine operating ranges.

Wheels are loose

This problem is easy to identify and fix, as it causes vibration at speeds of 100-120. The VAZ-2110 will make a characteristic dull sound. The problem is the loose nuts and bolts securing one wheel or several. Do not neglect checking, it can be dangerous. The wheel may simply unscrew while driving.

The beating itself is very reminiscent of vibrations on the steering wheel and body when the reason was in the wheels and tires. The difference here is that this shaking begins at low speeds. This phenomenon can be observed at different speeds.

So, we found out for what reasons vibration occurs on the body when driving at speeds of more than 100 kilometers per hour.

How to change the damper mounts of the power unit

Lada 2110 on your own?

Balancing required

Runout on the steering wheel and car body with increasing speed is inevitable if the wheels are not balanced. The uneven distribution of mass relative to the center of the wheel rim leads to such consequences. The action of multidirectional centrifugal forces leads to the appearance of multi-frequency oscillations, which are felt as a beating in the car interior.

The problem may manifest itself in the following cases:

- Installing new tires. Replacing tires on rims or putting new rims on old tires must be accompanied by balancing. Even for the manufacturer, achieving ideal weight distribution and geometric parameters seems to be an extremely difficult task.

- Loss of old balancing weights. This is especially true for light alloy wheels, where the weights are glued to the inside of the wheel. Let us remember that in the case of stamped rims, the weights are placed in the outer shoulder of the rim.

- Deformation of the rubber or disk due to falling into a deep pothole, a strong impact with the curb and other similar obstacles.

- Natural imbalance. During operation, any wheel will lose its established balance. It is recommended to carry out scheduled balancing every 15-20 thousand km.

Another breeding ground for imbalance is often the constant velocity joint. It serves as a device for the movable articulation of the drive shaft and gearbox, which allows the transmission of torque in different planes (internal CV joint). At the other end of the drive shaft for articulation with the hub (outer CV joint).

Most often, the cause of vibrations lies precisely in the internal hinge. In the case of a tripod-type design, wear out of the rollers is observed. In especially severe cases, the bearing may even “fall apart”. It is also possible to produce a tripod glass.

A similar malfunction can be caused by a torn boot, which can no longer protect against dirt and dust flying from under the wheels. Therefore, periodically check the integrity of the CV joint boots.

Drive shaft

It will be worth mentioning that a car with a drive of irregular geometric shape is guaranteed to experience vibration when accelerating. A bent drive shaft will not only rotate around its axis, but also provoke parasitic centrifugal forces. As a result, the car will receive additional vibrations as it accelerates.

Cardan

The problem is typical for cars with rear-wheel drive and all-wheel drive. Wear of the cardan joint leads to vibration during acceleration. If you encounter a similar problem, pay attention to the following elements:

- crosses;

- suspension bearing;

- directly to the driveshaft. An unbalanced cardan will lead not only to beating, but also to subsequent destruction of the joints.

There were cases when the cause of runout at speed was play in the gearbox shank. This also needs to be paid attention to.

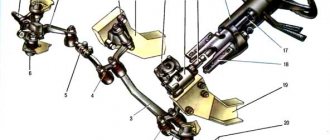

About the rake

Also, the reason is hidden in the steering rack. It must be remembered that the clearances of the suspension elements themselves do not cause vibrations or beating on the steering wheel. The unfixed part becomes a catalyst. But the main problem is the wheels, and you need to start from this. The steering wheel of the VAZ-2110 also shakes at low speed due to a faulty power steering mechanism. In this case, the rack is directly connected to the rods - hence the vibrations. In this case, experienced car owners advise inserting a rubber element into the steering shaft cardan. A ball with a diameter of 22 mm made of synthetic rubber will do. But the material wears out and cracks over time. As a more durable solution, you can use a cube with a side of 20 mm from the bumper of classic VAZ models.

Causes

Your wheels may need balancing

. Yes, an unbalanced wheel can create unpleasant vibrations throughout the body, transferring them to the steering wheel. Visit a tire shop, where a mechanic will use a special device to check the quality of wheel balancing and perform it if necessary. If after such a repair the beating does not go away, we look for the problem in another place.

Brake pads need to be checked

on the front wheels. If they are worn enough to require replacement, the steering wheel may start to wobble. Moreover, brake pads on all cars are consumables, and this element must be replaced after a certain amount of mileage. Keep an eye on this.

Have you replaced your brake pads and the runout hasn't stopped? Then you should check the tie rod ends. There should be no play in them; to check this, ask an assistant to hold the steering wheel while you pull the steering rods on both sides (to do this, you must first raise the car with a jack).

Most often, the reason lies precisely in this node. If there is no play, we go further down the list and check the steering rack; its wear can also cause the steering wheel to shake at low speeds.

It would be a good idea to check the ball joints; perhaps they have exhausted their service life. You can also check the cardan transmission. In the Volkswagen Golf example above, the driveline was the cause. By searching through it, the problem was solved.

Sources:

https://masteravaza.ru/rulevoe/rul/vibraciya-na-rule-vaz-2110-490 https://avtoexperts.ru/article/vibratsii-na-rule-prichiny/ https://zen.yandex.ru /media/id/5aab78e5dcaf8e4afd569fce/5bbb81a244c10400ae66e415 https://ddcar.ru/blog/remont/bet-rul-na-skorosti-kakovy-prichiny-i-chto-delat https://autoflit.ru/431-chto-delat -esli-rul-bet-na-maloy-skorosti-ili-pri-tormozhenii.html

DUAL MASS FLYWHEEL

Symptoms of damping flywheel failure:

- creaking, grinding noise when starting and stopping the power unit;

- rumbling sound when the engine is idling;

- vibration transmitted to the body and interior (with non-critical wear only in cold weather).

The reason for this behavior is the backlash of the elements of the spring-damper system, which is designed to dampen torsional vibrations. On cars with manual transmission, to check the flywheel, just squeeze the clutch. If the engine begins to run smoother and vibrations have decreased, it means that the reason for unstable idling is the dual-mass flywheel. The owner of a car with a robotic gearbox is left to rely on indirect signs and defects after disassembly.

KNOCKING AND UNEVEN OPERATION IN COLD

Accelerated wear of cylinders and pistons is a real problem for many owners of Volkswagen and Skoda cars with gasoline engines. Recently, cases of scoring in cylinders on Hyundai cars have become more frequent. Due to the tendency to lighten the CPG elements, reduce the thickness of the piston rings, the flame zone and the length of the skirt, repositioning the pistons is associated with heavy loads. Local overheating associated with operating a car in traffic jams (disturbed air flow, long periods of idle time), improper engine warming up in winter, lead to wear of the CPG.

As a result, the engines begin to knock when cold. As it warms up, the knocking, and with it the increased vibration in the body, stops.

Dirt inside

Sometimes sand and dust that gets on the working surface of the brake elements can cause vibrations. This happens especially often in rainy weather, when dirt sticks to the disc along with water. Over time, it dries and forms a hard layer. It can serve as a counterbalance weight, causing your steering wheel to vibrate when braking. Sometimes dirt gets on the inside of the disc or on the wheel flange. The solution to the problem is high-quality washing of the brake system elements under high water pressure.

Ways to eliminate vibrations

After competent, professional installation of the causes of engine vibrations, they must be eliminated as soon as possible. The methods of “treatment” are very diverse, it all depends on the “diagnosis”.

Low compression

One of the reasons for engine tripping is low compression levels in the cylinders. This may occur due to the failure of any part that is part of the cylinder-piston group. In order to fix this problem, you will have to resort to disassembling the engine itself.

The cause of low compression may be a worn piston, piston rings and/or valves. In this case, the most optimal and rational option for eliminating vibration will be only a complete professional replacement of defective parts.

If you replace it yourself or restore it, further, more significant breakdowns may occur, and therefore costly repairs of the entire power plant.

Uneven air flow

If air enters the combustion chamber disproportionately, this can be corrected by simply replacing the air filter. You should also carefully inspect the air supply system for cracks and chips. It is recommended to replace the mass air supply and throttle sensors.

Incorrect fuel supply

In this case, professional car mechanics advise performing the following algorithm of actions:

- carefully inspect and clean the injectors;

- if after this the problem has not been resolved, then the injectors must be completely replaced;

- carry out an inspection of the condition and operation of the fuel pump, if necessary, replace the assembly;

- identify and reset ECU errors

Ignition system

When diagnosing early or, conversely, later ignition timing in the system, you should pay attention to the condition and soot of the spark plugs, as well as the integrity of the high-voltage wires. If replacement is required, it is best to do this with the entire set

Engine mounts

If the fastening elements become loose or the engine mounts fail, it is necessary to strengthen the fastenings accordingly and consistently. Check the pillows for cracks and other defects; if necessary, replace them in pairs or completely.

In addition to the above measures, to eliminate strong vibrations emanating from the engine, proper installation of the timing belt, professional balancing of the crankshaft, as well as replacement of CPG elements of different weights (worn out) may be relevant.

Thus, the “dancing” of the power unit can occur for various reasons, which are also eliminated accordingly, each according to its own algorithm. Eliminating the causes of vibrations is a necessary process, since such vibrations, in addition to causing discomfort to the driver and passengers, can lead to expensive repairs of the car engine itself.

In addition, one of the common causes of strong vibration is the spontaneous loosening of fasteners. And if a major engine overhaul is an expensive procedure, but still fixable, then loose bolts and nuts, especially while the car is moving, can lead to irreparable consequences.

Damage from vibration

ATTENTION! A completely simple way to reduce fuel consumption has been found! Don't believe me? An auto mechanic with 15 years of experience also didn’t believe it until he tried it. And now he saves 35,000 rubles a year on gasoline! Read more"

At speed, vibration of the car body is not only discomfort for the driver and passengers, it is also harmful to the car as a whole. After some time, cracks appear in the car body due to vibration. In addition, bolts and nuts begin to unscrew spontaneously, which leads to dangerous consequences in the future. Thus, there is a risk of emergency situations. In addition, vibrations are harmful to human health, cause vasoconstriction, impair blood circulation, lead to the deposition of salts in joints, reducing mobility, with prolonged exposure.

Replacing a VAZ steering wheel

Steering wheel play VAZ 2110

For each steering wheel, factory standards apply, according to which the permissible force on them and the resistance that the structure itself can withstand are determined. That is why, if you plan to replace the steering wheel, it is recommended to give preference to a traditional steering wheel with an additional braid made of materials that provide higher reliability of contacts with the surface of the steering wheel rim. The procedure will require the following materials and tools:

- Phillips screwdriver;

- Head “24”;

- New steering wheel;

- A piece of wire or wire;

- Chalk, marker or something else for marking.

Removing the steering wheel

Replacing a steering wheel is not as difficult as it seems at first glance. When replacing the steering wheel, it is first removed. This procedure is carried out in the following order:

- First, the car must be installed on an inspection ditch or lift;

- Then the hood of the car is lifted and the terminal of the “negative” wire is disconnected from the battery terminal;

- Markings are applied to the steering wheel and dashboard;

- Then the seven screws securing the steering column casings are unscrewed and the lower steering column casing is removed;

- By unlocking the steering column adjustment lever, the column moves down. After this, moving up reveals the upper steering column casing;

- Using a screwdriver, pry up the cover plate of the signal switch and remove it;

- Using a Phillips screwdriver, unscrew the two screws that hold the horn button and remove the cover;

- Using a 24mm socket, the nut that secures the steering wheel to several threaded screws is unscrewed so that it can move;

- With rocking, the steering wheel is pulled along the shaft splines.

- Before finally removing the steering wheel, you should remember, or better yet, mark its position relative to the shaft, as well as the position of the turn signal switch in relation to the plastic ring;

- After unscrewing the nut, the steering wheel is removed;

- After aligning the two wheels, the mark is transferred from the removed steering wheel to the new one that is planned to be installed.

Installation of a new steering wheel

Installing a new steering wheel is performed in the reverse order of removal:

During the installation process, the steering column switch is set to the neutral position, after which installation can be carried out.

- After tightening the nut, the head is removed and the wire is removed, after which the nut is tightened.

- Also, when installing the steering wheel, you should turn the turn signal switch ring so that the pin on the hub fits into the groove of the ring (the ring returns the turn signal switch to its initial position when the car exits a turn).

- When replacing a steering wheel with a new one with an adapter, it becomes necessary to install an adapter on the shaft. The new steering wheel is installed in such a way that it cannot come off while driving. The central nut is secured, after which the decorative plug is put on.

- Then the negative wire is connected to the battery, the functionality of the sound signal and the steering column switch is checked.

How is a malfunction diagnosed?

To identify the runout of one of the front wheels, you will need a jack, wheel chocks and a wheel wrench. The diagnostic procedure is as follows:

- Park the machine on level ground and pull the handbrake all the way. Additionally, secure the car with boots placed under any rear wheel.

- Jack up the front wheel until it hangs off the ground. On vehicles with front-wheel drive and all-wheel drive, be sure to move the gearshift lever to neutral.

- Rotate the suspended rim with your hands. If you feel stuck in a certain position, remove the wheel and check that the uneven disc is rubbing against the pads, causing strong vibration when braking.

The essence of the diagnosis is simple: after operation, the brake pads move back just enough to free the rotating surfaces. The lining must be forced apart to its maximum open position. If the metal working part is bent, then when rotating the part will begin to get stuck between the pads.

If the vibration does not cause the car to deviate from a straight path while driving and does not cause the steering wheel to twitch, check the suspension and chassis components. Drive the vehicle into the inspection ditch and jerk the steering rods to check for play. The performance of shock absorbers is checked by rocking the car up and down with body weight. After applying force, the machine should swing no more than 1 time.

How to eliminate runout?

When your car's steering wheel vibrates slightly during heavy braking, you can simply do nothing and drive on, taking appropriate safety measures. The trick is to avoid decelerating too quickly, otherwise the problem will get worse and you risk losing your vigilance and running off the road.

Recommendation. Before further operation of the car, make sure that the culprit of the steering wheel runout is a defect in the brake disc, and not other reasons.

If the beating is quite noticeable and really threatens the safety of people (vehicle passengers and pedestrians), the deformed disk should be replaced or restored. The first way is associated with significant financial costs - spare parts for some brands of cars are quite expensive. In addition, the brake discs must be replaced in pairs, otherwise during moments of sharp deceleration the front part of the car will begin to pull to the side.

Disc restoration involves turning on a specialized machine . The equipment of advanced service stations makes it possible to process metal without removing the defective part from the machine. The procedure will be cheaper than purchasing and installing new spare parts.

When the car shakes when braking, regardless of speed, you need to look for and fix the problem elsewhere:

- Make sure that the linings of the rear and front wheels are not flooded with brake fluid. A secondary symptom is a decrease in its level in the expansion tank.

- Check the functionality of the brake calipers and wheel cylinders. The cause of vibration is often a jammed piston, and fluid leaks are often caused by a leaky cuff.

- Sometimes the steering wheel starts to vibrate after replacing the pads. This symptom indicates low quality of installed spare parts.

In some cases, vibration appears due to broken brake pads. The malfunction is accompanied by an extraneous sound of grinding or rubbing against metal.

The wheel alignment is broken

Directly depending on the incorrectly set angle, vibration can only occur during acceleration or in a certain speed range. Incorrect wheel alignment can be detected very quickly - tires wear unevenly.

If only the outer or only the inner part is wiped, then this is the same situation. The problem can be corrected by adjusting the angles. Then 100-120 km/h will disappear.

But the camber/toe has been adjusted, but the problem has not gone away. The angle has been corrected, that's a fact. But the car owner decided not to change the tires, because they can still drive. But the tires “drive” the way they are used to. This means that you need to change the tires or drive at low speeds for a period of time, then the tread will wear out evenly and the problem will be solved.

Danger of resulting vibrations

It's fair to say that slight vibrations during braking often don't lead to any immediate problems. Usually they can continue to manifest themselves with the same intensity for several months, even years.

In case of light vibrations, in order to extend the life of the car and not have to deal with repairs, be sure to exclude any maneuvers that require emergency braking.

If you do not brake sharply, pressing the brake pedal to the floor, there is a good chance of avoiding expensive repairs in the next 1-2 years. It all depends on the specific circumstances.

But at the same time, when vibrations continue for a long time, they have a negative impact on the braking system, chassis and suspension. As a result, the service life of these components is reduced, which subsequently results in expensive and complex repairs.

By not making repairs when slight vibrations occur that become noticeable in the steering wheel, in the short term you can save some money on diagnostics and repairs. But if we talk about long-term prospects, then there is no question of any savings. By postponing a visit to a car service center, you gradually increase the amount of money that you will have to invest in restoring a car worn out by vibrations.

As soon as you feel a strong and sharp blow to the steering wheel, pressing the brake again, some unit has almost failed, and during the next braking it may fail completely. It is strongly not recommended to delay until such a situation arises. This is already a matter of your safety and life, since a breakdown while the car is moving can result in a serious accident with all the ensuing consequences.

Painfully banal

If the body vibrates when accelerating, you should not be upset and immediately count out a large amount for repairs. Below are some common and not so common cases that can cause discomfort when driving:

- Dirt or ice block stuck to the inner rim of the wheel rim. Diagnosing the adhesion of dirt is not difficult, since noticeable beating will occur only after off-road driving. In winter, every driver should be prepared for such troubles;

- Incorrect installation of brake and wheel discs. If the mating plane has not been cleared of contaminants or is deformed, this will cause an increase in vibration load during movement;

- discrepancy between the landing dimensions of the wheel rims. Each disk has its own installation parameters, violation of which can lead to imbalance. This mainly concerns disc bolt patterns;

- loose disk fastenings. This is the first thing to check when you notice runout in the steering wheel. The consequences of neglecting this advice can be very dire.

There can be a huge number of possible problems with a car, and a specific breakdown does not always give specific signs of its presence. Drivers often complain about body shaking when accelerating or at a certain speed. There can be quite a lot of problems that determine this indicator. If your car has vibration during acceleration, you should look at all possible breakdowns and immediately replace the failed components.

It is not always possible to tell by the nature of the vibration where exactly the problem lies. On different cars, only the steering column can vibrate, putting it in the driver’s hands, but the entire body can shake. It all depends on the design, nature and degree of damage to the components and assemblies that need to be replaced. Let's look at the main causes of vibration during overclocking.

Rubber

There are often cases when vibration when accelerating appears due to the installation of low-quality tires. Most often these are tires from budget and extra-budget manufacturers. The peculiarity of such rubber is that when checking on a balancing stand, a discrepancy that causes discomfort when driving a car may not be noticed. In the second case, balancing only temporarily delays the reappearance of vibrations. Only replacing the tires will solve the problem.

The next reason for the appearance of unwanted vibrations is typical for owners whose car is shod with low-profile tires. The side cord of such tires does not have the rigidity and elasticity that is inherent in civilian versions of tires. Therefore, prolonged downtime, especially in the warm season, can cause temporary deformation of the tire at the point of contact with the road surface. Therefore, vibration during acceleration may be observed for a short time after the start of movement. The first kilometers should be covered with extreme caution.

Steering wheel vibration at speed due to wheel imbalance

A common cause of this problem is the accumulation of a large amount of soil or snow on the tires. This deficiency often appears for a while. As practice shows, vibration on the steering wheel disappears at a speed of 100 km/h, but may return after a few minutes. It is easy to find out the reason for the steering wheel beating at speeds of 100, 120 km/h with alloy wheels. If you have them made of steel, this will not be so easy for the driver to do, because the ventilation holes here are small. Lumps of earth often collect inside the disk and are not visible to the naked eye.

In order to use only the best consumables when caring for your car, we recommend that you familiarize yourself with the rating of motor oils.

Case from practice

A similar phenomenon began to be noticed by the owner of a Volkswagen Golf; extraneous vibrations appeared in the steering mechanism when the car was moving around 70 km/h

. If the speed was insignificant, vibrations disappeared; after accelerating the car over 100 km/h, they were also not observed.

Taking into account the quality of our roads (which is poor), and plus the vibrations and beatings that a faulty steering mechanism creates, driving such a car turned into torture. The steering wheel just almost jumped out of my hands.

Naturally, the most effective and simplest way is to take the car to a service station.

. But it’s good if you have a familiar auto mechanic who will do everything efficiently. And if not? Then few people will give you a guarantee that the car will be repaired quickly, and the money that will be taken from you will be comparable to repairs.

Yes, such a problem occurs quite often; auto mechanics constantly make money from such troubles, increasing the cost of repairs. They may also impose costs on you for unnecessary manipulations, for example, replacing the entire steering mechanism, because few people want to dig around and look for the real causes of the malfunction. To prevent this from happening, any car owner should at least roughly know the reasons for this behavior of the steering wheel.

Ways to solve the problem

Whatever the reasons for the steering wheel beating, it is necessary to carry out high-quality diagnostics and eliminate the problems. This will make it possible to avoid expensive repairs, and most importantly, prevent accidents!

If the steering wheel shakes at low speed, proceed as follows:

- check the cleanliness of the wheel rims;

- check the balancing and fastening of bolts on the wheels;

- test discs for deformation;

- check the quality of rubber;

- diagnose the suspension;

- examine brake discs and drums;

- check the engine mounting;

- try the quality of the drive shaft.

Wheel rims are easier and faster to clean at a car wash. A stream of water will remove accumulated dirt. Hit the disc with some object, reducing the amplitude of vibrations of the steering wheel, in order to safely drive to the car wash or service station.

Have your balancing done at a tire shop. Balance all 4 wheels, especially if the steering wheel shakes at low speeds. At the same time, eliminate the deformation of the wheel rims and give them their initial shape on a straightening machine.

Replace defective tires. It will not be possible to restore it - you will have to buy new tires and mount them according to the canons of proper balancing.

The beating that occurs during braking can be eliminated at a service station. The machine grinds and restores the surface of the brake discs if the degree of wear is low.

It is better not to fix steering wheel wobble at speed yourself. Only car services will accurately determine the cause of the breakdown and eliminate it. Most workshops work with specific brands of cars; they have a better understanding of the specifics of the models, know the characteristic “sores” and are able to quickly recognize them.

Let's sum it up

If you are unable to find the problem that is causing the body or steering wheel to vibrate in your car when accelerating, you should contact a professional. Do not leave this problem, because it can worsen and create dangerous travel conditions for the driver and passengers of the car. It is necessary to respond as quickly as possible to all possible problems and eliminate them by replacing failed machine elements.

Often, to determine the problem, you don’t even have to go to a service station and use expensive diagnostics. It is enough to inspect the car yourself and determine what problems caused the body vibrations. Have you had similar problems in your experience, and what parts of the machine caused them?

Body vibration at speed means that there are problems with some of the components of your car. Vibration is often caused by faulty steering, destruction of engine or gearbox mounts, and other problems. Vibration in the body during braking can be associated with worn pads or imbalance (wear) of the brake drums (or discs).

Steering wheel wobble when driving due to damaged or poor-quality discs

Both in the VAZ 2110 and other cars, steering wheel vibration at speed can occur due to the fact that the wheels are curved. Any specialist in tire fitting will notice this fact. In addition to dents, there may also be factory distortions on the wheel. If your tires have already served you for several years, they are quite old - this can negatively affect the full operation of the steering wheel. Common signs of tire deformation include:

- poor, worn condition of the cord;

- potholes in the tires due to the fact that you previously fell into holes at speed;

- poor quality production, which can manifest itself in different ways.

Tire imbalance

The reason for this phenomenon may also be defects in the rubber itself as a result of hitting an obstacle or falling into a hole (often at high speed), which causes the carcass elements on the tire to deteriorate and it takes on an irregular shape. This defect is called a “hernia.” It is almost impossible to correct it, but you can try to correct it by balancing the wheel. But even in this case, the steering wheel will vibrate at speeds of 90-100. What to do in this situation? Such a tire will still no longer work as it should, and it will soon have to be changed.

Why does it hit the steering wheel?

The reason for vibration or shock in the steering wheel may be that the steering rod joints and the mechanism itself have failed. There are also often situations when the whole reason lies in the wheels of the car. To figure this out, you should follow the rules below.

Diagnostics of brake discs and pads

Grooves and wear are visible, but you won’t be able to see that the disc has moved.

In most cases, “crooked” brake discs are to blame. People say that they were “led.” You can try to assess the condition of the disks visually, or you can use special diagnostic equipment. It will measure vibration and give an accurate verdict on the condition of the brake system and the need to replace the brake discs.

Now it’s better, but before there were a lot of fakes, and you could run into “crooked” disks even with a new part

Suspension diagnostics

When there is vibration in the steering wheel, the following actions should be taken:

- Turn the steering wheel to the right all the way. In this position of the wheels, it becomes possible to access the traction joints.

- You should check the rubber cover on the hinge.

It must not be damaged. In this case, it may be necessary to replace it. Checking the condition of the boot on the steering tip - Now you need to check the connection between the hinge and the strut arm. To do this, your partner must rotate the steering wheel from side to side. If the gap at the connection exceeds the norm, the tip will need to be replaced.

- In a similar way, you should check the tip on the other side of the car. All actions will need to be performed in the same order.

- Next, you will need to open the hood to gain access to the rack and pinion mechanism.

The partner here must also turn the wheels from side to side. The car owner needs to monitor the condition of the mechanism. If necessary, tighten the fastening bolts and connections of the mechanism. The steering wheel may shake when braking for this reason. Diagnostics of the steering rack condition

Important! There is no need to tighten the nut that secures the mechanism to the base of the body too much. This can lead to broken studs, which are quite difficult to replace yourself.

The tightening should be 16-19 Nm.

Inspection of tie rod connections

Diagnostics of the tie rod connection to the steering rack

Also, attention should be paid to those places where the rack rods and steering rods are connected. If there are gaps in them, they will need to be eliminated

If this is not done, then the steering tips will soon have to be changed. Faulty tips create an increased load on the steering rack and can cause it to fail prematurely.

If the inspection does not reveal the reasons why the steering wheel is beating, then the reason may be in the wheels. They may have a hernia or lack balance.

Hernia on the wheel

In this case, the tires must be changed and balanced at a service station.

Diagnostics and standard causes of vibrations

VAZ 2110 vibration on the steering wheel

There may be several reasons why vibrations are observed on the steering wheel of a VAZ 2110 car. In many cases, a superficial diagnosis will not provide accurate answers, and only a competent, thorough examination will help determine an accurate diagnosis.

Brake pads

As a rule, new motorists who understand little about cars naively believe that shaking and vibration are the result of worn brake pads. Having installed new brake pads, motorists begin to understand that the reasons lie much deeper. Although, if this “disease” has not gone too far, then changing the pads also helps, but for a while. And for the most part, replacing pads with new ones is a waste of time and effort.

Discs

As for the so-called “garage” specialists, they will all say the same thing - vibrations are associated with brake discs that need to be replaced with new ones. And it is imperative to install imported brake discs, since domestic ones do not cope well with their function. What's true is true. The runout of domestic brake discs installed on a car is much greater than even that of old discs installed on an assembly line. In addition, the metal of our discs is often “raw,” so to speak, that is, it is easily affected by the brake pads and wears off.

Note. Installing new brake discs does not completely guarantee that vibrations will disappear. The fact is that the reason may lie even deeper, and changing disks will only give half the effect.

Grooving brake discs

Grooving brake discs

Usually, when a car runs more than 50 thousand km, complaints about steering wheel shaking increase. The standard diagnostic option in service centers is as follows:

- The chassis of the car is carefully checked;

- The vehicle controls are subject to diagnostics;

- The left steering tip is often replaced;

- Wheels are being balanced;

- Brake discs are either replaced with new ones or sharpened.

The question arises: why buy new brake discs, especially ventilated ones (they are not cheap), if you can simply grind them, which gives excellent results.

Attention! It is noteworthy that sharpening brake discs is not so easy. This requires the skills of a highly qualified turner, who can identify by eye the excess part of the working surfaces, which he can successfully grind off. After this, the surfaces may remain rough, but there is no need to worry about this.

Attention! The minimum permissible thickness of a ventilated disc for a VAZ 2110 is 17.8 mm, and a non-ventilated one is 10.8 mm.

Non-standard reasons

It’s interesting, but it also happens that after sharpening and installing the discs, the vibrations on the steering wheel do not disappear. In this case, an unconventional method can help - turning the hub itself on a lathe, which reduces runout.

Algorithm for grooving the hub

- A special device is attached rigidly and at the desired angle (necessarily strictly perpendicular to the plane of rotation);

- Powerful supports are placed under the car;

- The jack is removed, and the brake caliper is tied firmly to the shock absorber strut.

Note. You need to tie the brake caliper with wire and away from the lathe.

- We start the engine;

- We turn on fourth gear;

- We connect the “machine”.

Note. The chips should be thinly wound around the cutter. After one full pass, the remaining portion will be visibly visible on the hub. After the next few visits, this very “bald patch” will completely disappear.

- The hub is ground to zero.

The grenade fell apart

On a VAZ 2110, the causes of vibration in the steering wheel may be associated with a grenade, although some would-be masters deny this. Features of steering wheel vibration when a grenade is scattered:

- When accelerating, vibrations are clearly felt;

- You feel them and disappear when you coast;

- In the early stages, steering wheel vibration can be felt at speeds of 60-80 km/h;

- At low speeds vibrations are not felt;

- The car may run off the road in the later stages of this disease, especially at speeds above 100 km/h;

- In addition to the vibrations, you also feel a terrible knocking sound, and when you release the gas pedal, the vibration immediately disappears;

- Vibrations can clearly increase in proportion to the number of people in the cabin (the more people there are, the stronger the vibration);

- A strong frontal wind can also cause an increase in vibrations.

If you observe the above symptoms, you need to inspect the grenade. It is noteworthy that a CV joint defect may not be immediately noticed. You'll have to tinker a little, take the shafts with grenades in your hands and twist them, changing the angle.

Wheel balancing is the most common cause of vibration in the steering wheel.

Steering wheel VAZ 2110

Causes of steering wheel beating when braking and turning

Steering wheel wobble at speed often begins due to the fault of the car enthusiast himself. He is inattentive to his duties and does not check the wheels before driving. The steering wheel often shakes at low speeds due to loose wheel bolts. The malfunction gets worse when braking, and the situation becomes extremely dangerous when cornering.

Steering wheel vibrations can also occur due to problems with the car’s suspension. The presence of backlash or failure of one of the chassis elements leads to imbalance.

First of all, determine whether the brake discs are faulty if the vibrations increase during a sudden stop of the car. Problems with the brake drum or disc are among the common causes. Parts become unusable, waves or other defects appear on them. Therefore, you should not overheat the brake elements too much (hold the brake pedal for a long time on a descent) or cool them suddenly (driving into a puddle).

If vibration increases when turning the steering wheel or during other maneuvers, a preliminary inspection is necessary. It will be impossible to find out the reason without this. First of all, check the rods and tips, hubs.

Worn or warped brake discs

These elements are installed on the hub and are clamped by pads when the speed decreases. There is practically no gap between the disc and pads. Therefore, the surface of the assembly must be perfectly flat. The slightest distortion of the disc causes the steering wheel to vibrate at speeds of 90-100 km/h. Warping of brake elements most often occurs due to frequent and intense braking, as well as when driving through deep puddles. The heated disk bends due to sudden cooling. This element cannot be repaired - only replaced.

“However”... “However”

Faulty wheel bearings, loose, worn or damaged suspension parts (bushings, bushings, springs, struts/shocks, tie rods/tie rod ends) can also cause the steering wheel to vibrate when braking.

Vibrations from loose or worn wheel bearings are usually felt in the steering wheel when braking and turning at the same time.

Also be aware that, for example, a faulty wheel speed sensor can send misinformation to the car's computer, which mistakenly activates the anti-lock brake system even when braking smoothly at low speed on dry, smooth pavement.

Attention: the steering wheel should not vibrate when braking! To avoid major and costly repairs, have your brakes and braking equipment inspected when your vehicle is undergoing regularly scheduled maintenance or any repairs.

Balancing methods

There are a couple of ways to balance a particular part:

- Static method;

- Dynamic method.

Each of these methods has its own characteristics.

Static balancing - performed without forced rotation of the part. This method does not require expensive equipment; it can be used in a garage. However, it should be remembered that the imbalance is not completely removed using a static method. The essence of the method is that the part to be balanced is mounted on prisms or bearings. The element then rotates around its own axis, at the end of the rotation it takes a position in which its heavier side will be located below the axis of rotation. It is important to note that the prism must be strictly horizontal, and the bearings must rotate with minimal resistance. Then the heavy side will outweigh the light side, and the part will deviate from the center because of this.

Dynamic balancing - this method requires the use of constant rotation of the part using special equipment. This method allows you to completely get rid of imbalance, and the method can be used for the most rigid parts of any size (such as the crankshaft, cardan, flywheel, and others). All data on deviations is provided by the computer with high accuracy. By dynamically balancing the parts of the crankshaft, wheel hub, clutch basket and brake drums (or discs), the heavier side is lightened by removing material from it. It all depends on the type of product, whether drilling or other mechanical processing is performed.

About the rake

Also, the reason is hidden in the steering rack. It must be remembered that the clearances of the suspension elements themselves do not cause vibrations or beating on the steering wheel. The unfixed part becomes a catalyst. But the main problem is the wheels, and you need to start from this. The steering wheel of the VAZ-2110 also shakes at low speed due to a faulty power steering mechanism. In this case, the rack is directly connected to the rods - hence the vibrations. In this case, experienced car owners advise inserting a rubber element into the steering shaft cardan. A ball with a diameter of 22 mm made of synthetic rubber will do. But the material wears out and cracks over time. As a more durable solution, you can use a cube with a side of 20 mm from the bumper of classic VAZ models.

Spherical bearing

After that, I checked the wheel shank on the ball joint - there was no shackle. To check the shank in the ball joint, it is necessary to jack up the car and place the ball joint on a static support standing on the ground, so that the wheel is completely in the air (you can use a steel cylinder, a wooden ingot, or a hydraulic jack as a support). Then take the upper part of the wheel with one hand, and the lower part of the wheel with the other hand and try to shake the wheel, pulling the upper and lower parts of the wheel towards you and away from you, respectively. If there is a shank, it means that the ball joint is worn and needs to be replaced.

Steering wheel wobble when braking

The appearance of such vibration and beating of the steering wheel when you press the brake pedal indicates deformation of the wheel brake discs and improper wear of the brake pads. In this case, you must either inspect the brake discs yourself, or contact a service center to perform the appropriate diagnostics. This is quite often noted in cases where, after a series of sharp braking, the car got into a puddle, a sudden cooling of the brake disc occurred, which moved to the side or pronounced scale appeared on it. The repair will consist of both grinding the wheel rims and replacing them with new, serviceable spare parts.

Wheels and chassis

The VAZ-2110 and the entire family, due to front-wheel drive, experience increased load on the front wheels. It is imperative to do balancing, as well as check the condition of the nuts, hub, and the chassis as a whole.

Quite often the wheel itself hits when braking. And not because of balancing, but because of broken bolts and holes. You can try to remove the wheel, move it one bolt forward in a circle, and check the result. Some people wrap one turn of electrical tape, this helps at least diagnose the problem. If the problem disappears for a short time, then the problem is with the disks and fasteners.

Steering rods, steering knuckles, ball joints, levers - all this needs to be tugged on the lift to check for play. Again, when driving, you should carefully listen to the operation of the suspension on turns or bumps. After the trip, check the same hubs by hand for heating.

In principle, the VAZ-2110 is such a car that if there is no steering wheel beat at speeds up to 90 km/h, then this is normal. Driving it at a higher speed is in any case dangerous, even if the chassis is in perfect condition - the issue here is the quality of the parts and the generally weak strength of the car.

Vibration of various elements of the car inevitably occurs during operation, when the moving parts of the chassis and transmission gradually wear out. But among such malfunctions, there is one dangerous malfunction - the steering wheel wobbles when braking. The more the steering wheel jerks after pressing the brake pedal sharply, the higher the likelihood of losing control and flying off the road at a decent speed. To avoid the described emergency situation, it is worth studying the nature of the problem and how to solve it.

Summary

If you study the malfunctions, you can derive a small rating of the prevalence of causes. So, if the steering wheel of a VAZ-2114 shakes at low speed, then in the first place are problems with the integrity of the tires and rims. For many, vibrations were caused by a hernia or a crooked wheel. Then there are breakdowns in the suspension and steering mechanism. But often the problem can be solved by a simple visit to a tire shop. And to eliminate this situation, you should brake well before each large hole and be careful when passing railway tracks. A bump on the sidewall of a tire cannot be restored.

After using the car for a long time, many drivers stop noticing the steering wheel vibrations that occur. But sometimes such beating is a consequence of vehicle malfunctions, and if they are not corrected in a timely manner, driving safety can be greatly reduced.

Wheels do not comply with factory recommendations

A car rim has its own parameters - width, tire mounting diameter, offset, as well as the diameter of the drill, i.e. the circle on which holes are drilled for mounting bolts or studs. For each wheel model, the number of these holes and their diameter are indicated. If the disk parameters are incorrectly selected, the mount will not screw in completely and will not press the wheel tightly to the hub. As a result, the disk has play. If the diameter of the holes drilled does not match, the wheel will also not sit in its place. Of course, it can be planted using physical force. However, the plane of the disk will not coincide with the parameters of the hub. This is not good for the car.