If a VAZ-2110 stalls on the road, many drivers are lost and do not know what action to take. It’s unlikely that your car will be repaired on the road, so the first thing to do is get to a service center or your garage.

This problem will occur quite often if you ignore it the first time. You will need to carry out a few fairly simple operations to identify the source of the problem. In extreme cases, you will have to go to a service center for professional help.

If the engine does not start: troubleshooting methods

If the most unpleasant thing happens, you should not make useless attempts and only discharge the battery by rotating the crankshaft. You may still need a charge of electricity if you succeed in repairing the car. At least for the starter to work.

First of all, you need to check whether the fuel pump is working, whether there is enough fuel, whether the ignition works. Maybe the problem is in the injectors that have failed, but this happens very rarely. Their O-rings, vacuum hoses, and gaskets wear out more often. The same goes for the electronic control unit (ECU), for the most part it works properly for a long time.

The fuel pump and its operation are controlled by sound

If it is missing, it is important to ensure that the wiring is in good condition. The sufficient voltage supplied to the fuel pump is 12 V. The pressure created during its operation by the fuel supply system should be about 2-3 bar

The pressure created during its operation by the fuel supply system should be about 2-3 bar.

When fuel stops flowing, the pressure drop occurs over time, not immediately. If this happens almost immediately, then you need to check the fuel regulator, unless, of course, it is leaking. You can turn off the fuel pressure regulator for a short time to make sure the system is working.

All connections that may affect the operation of the computer should be checked. There is a good chance that there is a disconnect somewhere. In this case, a good signal of operability is the illumination of the Check Engine indicator. If it exists, then there is still hope. However, cars produced by VAZ do not allow you to determine the error code and, accordingly, localize the fault without using a tester.

A large number of errors most likely indicates a completely detached part. Next, you should measure the voltage supplied to the network. Typically, a running engine consumes 14 V, its cranking results in a voltage of 8 V, and an idle one - 12.5 V. You should definitely make sure that the drive belt and camshaft are intact, which will not be very difficult.

Finally, you should completely disconnect everything from the ECU except the crankshaft timing sensor, but if you do not understand the actions being performed, it is better not to risk it. If the VAZ 2110 stalls after the work done above, you need to check how clogged the air filter is. If it has not been replaced or cleaned for a long time, it is better to do it right now.

It wouldn’t hurt to check the fuel pump, as mentioned earlier, compare the actual coolant temperature with the sensor readings (a deviation of 5 °C is allowed), as well as the voltage. In addition, it is worth wiggling the various connectors. This may seem funny and absurd, but it happens that the reason is precisely a poor connection. Finally, you should inspect the camshaft belt.

Didn't find the information you are looking for? on our forum.

We recommend reading:

Replacing the float in the gas tank of a VAZ 2107, removal and installation with photo

What gasoline to use in Lada Granta, manufacturer's recommendations

Cooling system for VAZ 2110, 8 and 16 valves, principle of operation, main malfunctions

VAZ 2114 burned out valve symptoms

VAZ 2107 injector, idle speed floats, reasons

Replacing the thermostat on a VAZ 2107

VAZ 2114 how to reset daily mileage on

The interior smells of gasoline, viburnum, the main reasons, how to eliminate

How to check the serviceability of the throttle position sensor

One of the problems may also be faulty operation of the DPZD. It is this part that is tested last, since the problems described above often arise. However, you should not ignore testing this sensor, because sometimes it helps save a lot of time.

https://youtube.com/watch?v=Yo4iu55VJLE

Here's how to do it correctly:

This sensor is located on the throttle pipe and is connected to the throttle axis. Secured with two screws

When removing the sensor, you should pay attention to the condition of the throttle valve, whether it is coked. If it does, then it will have the same symptoms as with problems arising with the sensor, but it can be checked even without removing

To do this, you need to measure the voltage at the DPSD terminals when the ignition is turned on. It should not be higher than 4B. Then you need to check the voltage at the DPSD terminals while the damper is moving. There should be no changes to it. If there are sudden changes, this indicates that the sensor is faulty.

Now you know what to do if your VAZ-2110 stalls and how to deal with the problems without resorting to the help of professionals and wasting money. We hope that our advice will be useful to you in a difficult situation.

Testing the mass air flow sensor

VAZ-2110 with 8 valves and an injector stalled. The question immediately arose - what to do in this case? If the cause of the problem is not the IAC, then the mass air flow sensor should be tested.

Below are some tips on how best to do this:

- First, disconnect the connector at the sensor from the on-board system. The engine is controlled by a controller, and after this action it will begin to operate in emergency mode; this is not dangerous during a short test. If the car becomes faster, then most likely the cause is the mass air flow sensor, and it’s time to clean it.

- You should replace the damaged sensor with a properly working one, and then see how the engine performs. If it gets better, you need to clean or replace your own mass air flow sensor.

- Carefully inspect the air intake. To do this, you need to remove the clamp responsible for the fasteners and inspect the air intake from the inside. There must be no oil or condensation there. If any of this is detected, you need to clean the air intake with special means.

- You can test the mass air flow sensor using a multimeter. You need to change the operating mode to the voltmeter and set the second level. On the sensor you will see two wires - green and yellow. The yellow wire serves to transmit signals to the controller, and the green wire transmits ground. Then you need to turn on the ignition and take measurements between these wires. The engine must not be running during this process. If the readings are at the level of 1.01-1.02, then the sensor is in perfect order. If the readings range from 1.02 to 1.03, it’s time to clean the sensor, and if it’s higher, it’s time to replace the sensor with a new, working one.

These tips will help you understand the possible reasons for the malfunction of the mass air flow sensor and the car's plug. As you can see, it is not difficult to do this yourself, without contacting a car service.

VAZ 2110 stalls at idle

Possible reasons for the VAZ 2110 engine stopping at idle

Let's look at one of the common problems for the VAZ 2110 car. This is a Russian-made sedan, usually with a 1600 cc engine and a 5-speed gearbox.

It often happens that when stopping in neutral gear, the tachometer drops the revolutions to 500, and then the readings become standard - 800-900 rpm. After some time, the car begins to stall altogether.

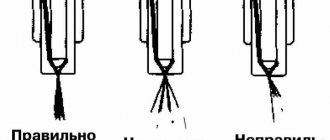

The first thing car enthusiasts do in such a situation is to decide that the problem is that the injectors are dirty and cannot spray fuel as expected. This can happen due to many impurities in gasoline, the quality of which has recently left much to be desired. If the assumption is correct, then the control unit, receiving a signal from the injectors, increases the amount of fuel supplied, which can cause the engine to stop. If after cleaning the injectors the picture does not change, and the car continues to stall when braking at traffic lights and pedestrian crossings, another reason should be considered.

Another “troublemaker” can be the idle speed sensor. You should just replace it and see how the car behaves. If you don’t want to spend money on a new sensor without making sure that the old one is faulty, just ask the lucky owner of a working car for half a day. “Tens” remains a popular model and I think you can borrow this sensor from someone you know. If the experiment showed that the problem is not at all with the idle speed sensor, then you should contact computer diagnostics.

The oxygen sensor may be faulty and the fuel mixture may be too rich. You can also find out the readings of the mass air flow sensor from the diagnostics. With increased voltage, more than 1.01 Volts, the control unit receives false information from it, which may cause the engine to stall. Replacing this sensor will eliminate the problem, and you will continue to operate your “ten” without problems.

Note to managers of public utilities: High-quality Russian special equipment at competitive prices. Auto-hydraulic lifts and aerial platforms - https://autokan.ru

Speed sensor

The sensor is located directly in the gearbox. One of the signs of its breakdown is unstable idle. Sometimes the engine stalls in this mode, but more often the speed fluctuates. An additional symptom is the speedometer not functioning properly.

First of all, the sensor must be checked for integrity. Be sure to consider its contacts and the wiring leading to them. Contaminants are removed, and it is better to apply Litol to the cleaned surface.

If cleaning does not help, you will have to test it. For this:

Reasons why a car won't start

Typical reasons for the VAZ 2110 are as follows:

- The ignition timing is broken (8 valves);

- Malfunctions of the gas distribution mechanism;

- Incorrect connection of the security system, as a result of which standard modules block the flow of current to the coils;

- Failure of spark plugs;

- Damage, defect of crankshaft and camshaft sensors (16 valves);

- Fuel pump clogged;

- Clogged cleaning element;

- Low battery charge.

The above list is not exhaustive and may be supplemented with new factors in each situation.

If you have experience and skills in servicing the equipment, proceed to troubleshooting yourself. Otherwise, seek help from service station specialists to carry out diagnostics using digital equipment.

Troubleshooting options

It is clear that if any emergency situations arise with the motor, it is advisable to contact a specialized service. However, this procedure is not always possible. Therefore, it is worth knowing how to independently diagnose the main systems and key parts.

Throttle valve and assembly

When the speed drops at idle and the car stalls, you need to pay close attention to the details of the throttle assembly. Long-term operation of the car on low-quality fuel, untimely maintenance of the air filter can lead to malfunctions of the throttle valve

It periodically jams if debris gets into the equipment.

Throttle valve VAZ 2112

The problem can be solved by cleaning the system. The throttle is cleaned using carburetor cleaners. Using a compressor, you need to blow out the damper under the pressure of compressed air. It is not recommended to touch the screws located inside and on the side. If cleaning does not correct the situation, the device must be replaced. This operation is not particularly difficult.

Crankcase malfunction

There is an oil trap in the crankcase ventilation system of the engine. Its contamination can also lead to interruptions in engine operation. Crankcase gases do not allow the engine to function normally, the speed fluctuates, the internal combustion engine stalls.

Sensors

If a gasoline car stalls at idle, then one of the sensors is likely to break. In injection cars with an electronic engine control system, the engine usually starts normally, but then it stops working. It's worth checking here:

- Electronic car indicators;

- DRХХ – device that regulates idle speed;

- Air flow meter (air intake in the carburetor);

- Sensor indicating the position of the throttle curtain.

Electronic control unit in VAZ 2114

Interruptions in the operation of any sensors immediately affect the behavior of the electronics - errors appear in the car control unit. The “brains” of the machine receive unreliable information. It is not transmitted correctly to the engine. It starts working with parameters that do not correspond to reality. Self-testing of this device is not possible. You need to contact a professional for service.

Diagnostics of mass air flow sensor

The idle air control device is usually to blame for engine malfunction when the car idles poorly. But you pressed the gas pedal and the engine started. In the latest VAZ modifications, error information appears on the instrument panel.

When diagnosing, you must use a multimeter. If a part is faulty, it is recommended to replace it with a new one. All sensors are reasonably priced. It is better to start checking with parts that have a simpler design. Then gradually move on to complex devices. We must not forget that the problem may lie not only in the sensors themselves. It is also necessary to check the wiring to them and the presence of stable contact.

Carburetor

If the VAZ carburetor stalls at idle speed, then the jets may become clogged. Low-quality gasoline, deposits from the gas tank, contain small particles of debris. They can easily disrupt the operation of the fuel injection system. It is worth replacing the filter in front of the carburetor and cleaning the device itself. The dispensing part is cleaned using a cleaning solvent, which is sold in aerosol cans. Another reason is often a prolonged lack of carburetor adjustment.

In a mechanical fuel pump of carburetor cars, the filter mesh may be clogged with dirt. This reduces the performance of the device. Wear of the membrane and its destruction often leads to clogged carburetor channels.

What to do

Diagnostics consists of several stages, taking the form of a visual examination:

- Checking the filling status of the tank with gasoline.

- Fuel pump operation.

- Filter cleanliness.

- Cleanliness of fuel injectors.

- The ignition system is working properly.

- Serviceability of the electronic control unit.

Insufficient amount of gasoline in the fuel tank is the most common reason for engine stopping. Experienced drivers know that the gas tank level arrow readings should not always be trusted, especially when it comes to older models.

The second most common reason that requires appropriate diagnostics is failure of the fuel pump. As a result of a breakdown, the device stops pumping the combustible mixture into the engine. In addition to a visual inspection, the problem is also revealed by the characteristic buzzing sounds made by the pump’s electric motor, which it makes even after the ignition is turned off. Additionally, the condition of the device is checked using a pressure gauge - its readings must be at least 2.7 atmospheres.

A clogged filter means that even with a working pump, fuel cannot flow to the engine. The filter element of good devices does not allow even the smallest particles of debris to pass through, which are contained in almost any fuel, but as a result it becomes dirty quite quickly.

The cleanliness check is carried out using the starter turned on - it is activated by first removing the hose coming from the filter. If a stream of gasoline flows, everything is in order; when not, the filter element needs to be replaced. Not only the filter, but also the injectors can become clogged easily, especially if the fuel quality is average or lower. To diagnose them, remove the ramp and move it aside. Crank the starter - during normal operation of the system, the nozzles spray the combustible mixture. If there is no such effect, then the driver has encountered a breakdown.

The ignition system is a problematic element in the fuel system of a car. When there is no spark, the engine will not be able to work. But more often it does not exist due to breakdowns of the wire or spark plugs, thanks to which a spark occurs and its strength is sufficient to initiate the operation of the power plant. Visually, on properly working spark plugs there is no deposit on the working surface and the gap between the electrodes is sufficient. Plaque or lack of clearance directly prevents the formation of a spark.

Faulty wires often have damaged insulation, causing current charges to flow from them to the crankcase. Check the formation of a spark by first unscrewing the spark plugs and placing them on the valve cover. Having done this, the starter is turned sharply and wait for a distinct spark to appear on the electrode of the spark plugs. In case of its complete absence, replacement of the latter is required.

- crankshaft rotation speed;

- camshaft positions.

If any of them is faulty and does not give the required signal, the spark plugs cannot produce a spark. Also look at the contact connectors, which often fly out of their sockets while driving. To diagnose faults, you may need a special tester. You have a better chance of dealing with this problem if you contact a specialized service center.

The car stalled while driving and will not start

You don’t expect a sudden stop of the engine on the road from models such as Lada Kalina, Granta or Niva, Daewoo Nexia. Unfortunately, it often happens in such popular cars as Renault Logan or Ford Focus 2. For these brands, it is often associated with the banal loss of sensor contacts from the connectors while driving.

The car stalled at idle and will not start

The car owner starts the car and accelerates with the engine already warm. It seems that everything is working fine, but as soon as he stops pressing the trigger, the power plant stalls. This usually happens due to:

- throttle valve clogged;

- throttle sensor failure;

- air filter clogged;

- idle speed sensor failure;

- poor quality fuel.

Of the above, problems with sensors can only be solved by replacing them. Throttle valve failures are determined by floating speed.

The car crashed and stalled and would not start

If a car's engine is running rough, and then it suddenly stops starting, the problem lies in the ignition for the vast majority of vehicles. Check contacts, spark plugs and other system elements.

The engine stalls when hot and does not start until it cools down.

The headache that owners of models such as Lifan 170F or Gazelle 405 and Gazelle 2115 face first is when the car drives normally, and then suddenly stalls and after a while, having cooled down, starts again. The cause of the malfunction lies in the incorrect operation of the fuel pump and is “treated” by replacing it.

The car stalled and will not start, the starter spins at idle

Owners of Lada Priora and GAZ 2106, as well as some other brands, from time to time encounter a problem when the car stalls, does not start, and the starter spins at idle. If we exclude incidents in the form of a clogged exhaust pipe or lack of gasoline, we can identify the main reasons for what is happening:

- thickening of engine oil or freezing of diesel fuel;

- pump failure;

- rotation of the flywheel crown due to the clutch of the flywheel with the bendix;

- Bendix jamming.

These problems that prevent the car from driving can be fixed with your own hands.

The car stalled while driving and will not start, the starter does not turn

Owners of Opel cars, as well as some other brands, sometimes encounter a situation where not only the engine stalls, but the starter does not even turn when trying to start it. And in most cases, the reason lies in insufficient battery charging.

The car stalled in the water and will not start

Situations when a car stalls after driving through a puddle, although not very often, do occur. This occurs due to water splashing onto the ignition system wires and sensors. The problem can be solved by simply airing it so that the moisture evaporates. You can speed up the process in hot weather by additionally wiping the devices with a dry cloth. To avoid a recurrence of the situation, it is better to use protective equipment.

From personal practice, drivers know well that when overcoming deep puddles, the crankshaft sensor often suffers due to its low location. Just wipe it down and within a few minutes the machine will be operational again. There are also more serious problems. Some car owners have to deal with engine water hammer - water gets into the engine. When this happens, the power plant makes a sound like a pop before stalling. It is better to leave troubleshooting to specialists.

The engine stalled while driving and will not start: injector

Motors with fuel injection installed on such popular car brands as VAZ 2109, 2110, 2112, 2114 are slightly different in design compared to carburetor engines. There are some peculiarities in identifying problems that cause it to stall. More often this happens due to:

- contamination of the air flow sensor;

- contamination of the throttle assembly;

- lack of fuel pressure;

- wear or jamming of the idle air regulator;

- depressurization of the intake manifold;

- malfunctions in the ignition system.

By checking the indicated elements, diagnostics of the injector operation begins, regardless of whether it has 8 or 16 valves. In general, checking the condition of the engine of such a device is more difficult than that of a carburetor. Although there are simple cases: for example, when there is no spark.

The crankshaft sensor is a fragile element of the system and replacing it is the only way to repair it. The way to find out whether it is really faulty is to use a special multimeter, available only to specialists.

Diesel engine stalled while driving and will not start

A VAZ with an injector starts and immediately stalls

A few reasons:

- Fuel-injected cars may behave this way due to a faulty fuel pump. It's in the tank. It is very easy to check its functionality. If you turn the ignition key to the first position and listen, you will hear the pump working, pumping gasoline into the system.

- Severe contamination of the fine fuel filter can also cause the car to stall after starting. The filter simply does not have time to pass the required amount of gasoline.

- ECU errors quite often lead to problems with starting the engine, not receiving signals from certain sensors, or receiving them in a distorted form. It is best to diagnose such breakdowns in specialized services.

What to do if cars with automatic transmission stall?

If your vehicle has an automatic transmission, then the problem should be found in the electrical supply. If you abruptly switch from one gear to another, or while switching gears while braking, the settings may be distorted, and the on-board computer will receive a signal to turn off the engine.

Also, models with automatic transmission may stall due to malfunctions of the hydrodynamic transformers of the gearbox. This problem mainly manifests itself during acceleration and requires urgent intervention from car service specialists.

Problems with Solex carburetors

In addition to all of the above, engine speed drops if the fuel level in the carburetor (float chamber) is incorrectly adjusted. As a result, there is either not enough gasoline in the fuel mixture or too much of it. When adjusting the VAZ 2107 carburetor, it does not need to be disconnected from the engine.

Follow these steps:

- remove the air filter housing by unscrewing all fasteners;

- remove the carburetor cover;

- check the position of the floats. To do this, separate and bring them together to achieve the correct location.

It is necessary to achieve such a position of the floats so that they move freely without clinging to the walls of the chamber in which they are located. It will not be superfluous to measure the distance from the protrusions on the floats to the paper gasket. The distance should be within 0.75–1.25 mm. Use a feeler gauge to measure.

What to do if it is far from normal? In this case, you need to adjust the height of each of the floats.

As we have seen, there are many reasons why the engine stalls. To start the engine correctly, you need to check and eliminate all the above faults. Afterwards, if the problem is not resolved, you will have to contact specialists.

What to do if the VAZ injector starts and stalls at idle? This problem most of all concerns old cars, since with age various contaminants accumulate in the fuel system and in the vehicle, as well as sensors and mechanisms wear out - all this will inevitably lead to changes in engine operation.

We will describe in order all the reasons that lead to this problem.

The first thing to check is the mass air flow sensor (MAF). The sensor's sensing element becomes dirty and wears out with age, which is why its resting voltage increases and its reaction time to changes in air flow increases. If the quiescent voltage exceeds 1.035V, you should think about replacing the sensor, because it will no longer be able to give inflated readings on air flow. The electronic control unit will supply more fuel and the mixture will be over-rich - and this will have a very bad effect on all engine operating modes, as well as on idle stability. The idle air control (IAC) can also affect the stability of the engine. Rod jamming is the most typical malfunction in it. In addition, with age, natural wear and tear occurs on the components of the regulator, and this leads to problems with movement. The usual service life is 100-150 thousand km. Only with the help of special equipment can you check the IAC, and it is better to replace it with a new one immediately if a malfunction is suspected. Very often it is enough to simply clean the throttle assembly from dirt. It's easy to do it yourself

These are the most basic cases that you need to pay attention to. Atypical situations will follow. Sometimes the problem is a leaky intake manifold.

You need to check the gaskets, vacuum hoses, injector O-rings, and the vacuum brake booster and manifold plugs. The easiest way to find air leaks is with a smoke generator. Pay attention to fuel pressure. You also need to check the ignition system and spark plugs in particular.

In conclusion, it should be noted that without special equipment, a complete check of the system is impossible. Only with its help can the fault be accurately identified.

During the operation of a car, a common situation is that after turning the ignition key, the car starts, the engine starts to work and stalls after a few seconds. As a rule, 3-5 seconds pass from start to stop. Before the engine stops completely, it is also noticeable that the power unit shakes and works very unstable.

This happens as a result of a decrease in speed, the resonant effect of the rotating one, etc. When you try to start the engine again, the engine may no longer start, or the situation described above may repeat again.

The reasons for this problem vary. The main thing is that if the car starts and stalls, this indicates that in-depth diagnostics are needed. Next we will talk about what to do in such a situation, as well as how to find the reason why the engine stalls after starting.

Read in this article

Signs and solutions to problems

Below we will look at the most common signs when a car stalls at idle.

The car starts and stalls immediately after the starter is turned off.

- When a car suddenly stalls at idle, the most common reason is that the throttle valve is dirty, causing it to become clogged and sticky.

This problem is solved by simply cleaning it, using a carburetor cleaner from a bottle. This happens due to the use of low-quality fuel and the presence of large contaminants entering through the air filter (for example, oil). This is what a dirty damper looks like. - It is also worth paying attention to the presence of contaminants in the oil trap system in the engine crankcase. Because if this filter is dirty, the engine will simply stall from excess crankcase gases.

The car starts and immediately stalls

Checking the MAF sensor readings

The cause of a malfunction with such symptoms is most often the above-mentioned sensors: IAC (idle air control), MAF (mass air flow sensor). Before purchasing new parts, you need to disassemble them and check for contamination. Also check the mass air flow sensor for the main signs of malfunction. However, if you have the opportunity to check the malfunction using diagnostic equipment, then do not deny yourself this. Read more about replacing the IAC here, and about replacing the mass air flow sensor here.

The functionality of all sensors should be checked in order, starting from the least structurally complex to the most.

Checking relays and ECUs and other sensors

- It may be necessary to remove the fuel pump to check. You will need to remove the rear seat and check the voltage at the pump terminals. The device should show + 12 volts. Then crank the engine using the starter. When it is triggered, they proceed to subsequent actions. It may happen that when you turn the ignition key, the starter does not turn. Then you need to check the reliability of all wires on it. The cause may be a problem in the contact group in the ignition switch.

- If it is determined that everything is in order, check the spark on the spark plugs. To do this you will need to open the hood. First, you need to unscrew the spark plug from the first cylinder. It is necessary to throw an armored wire over it and press it against the mass. In this case, the candle must be held with pliers and not with your hands. Otherwise you will get an electric shock. At this time, the assistant starts the engine. All other candles are checked in the same way. If there is a spark on each cylinder, it is necessary to look for ignition problems.

- The situations may be different, for example, a spark is present on cylinders 1 and 4, but not on cylinders 2 and 3. The ignition module should be replaced. If the replacement does not give a positive result, you should look for the reason in the output transistor switches to the ignition module from the ECU. The ECU may need to be repaired.

- It may happen that there is no spark on any cylinder. VAZ 2110 does not start because there is no spark. Often the reason for this lies in the crankshaft position sensor. The DPKV ECU gives a signal through which pulses are sent to the ignition module so that a spark is formed. The cause of the malfunction may be the lack of connection between the gear and the generator wheel. This can occur even if the DPKV is in full working order. At the same time, the crankshaft rotates, but the sensor will not process these rotations. Many are frightened by the fact that the VAZ 2110 injector has a large number of sensors. Indeed, there are a lot of them, but the reason that the VAZ 2110 does not start the first time is only one thing - the DPKV sensor is faulty.

- It is necessary to unscrew the spark plug from the cylinder and check its moisture content. A dry spark plug indicates that the injector is not spraying fuel. Then check the pressure in the fuel rail. It has a special bolt on the side. It must be unscrewed and a pressure gauge inserted in its place. It will show the presence or absence of pressure in the ramp. But it may not be at hand. Then the bolt is unscrewed and the pump starts. If there is pressure in the ramp, a good stream will flow out of the hole.

- If there is no pressure, the fuel filter must be replaced. The reason may also be that the line on the way from the fuel tank to the ramp is clogged. If the unscrewed candle turns out to be wet, then they all need to be unscrewed, wiped and dried thoroughly.

- Sometimes the reason is that the injectors are clogged and need to be cleaned. Clogged injectors may cause the spark plugs to be flooded with fuel. Dirty injectors are often the reason why a car engine has difficulty starting.

- Sometimes the reasons that the VAZ 2110 16 valves does not start may be of a deeper nature. They are very difficult to diagnose. But for the VAZ 2110 this is the exception rather than the rule.

Causes

Why doesn't the VAZ 2110 start? This may be due to a malfunction:

- Fuel pump

- Crankshaft and camshaft sensors

- Spark plugs

- Ignition coils.

The reasons have been discussed, but how to eliminate them? More on this below.

Fuel pump

If the battery is charged and in good condition, but the engine is difficult to start, then you should start checking with the fuel pump. If it stops working, then the engine does not receive gasoline in the required quantity, so starting is impossible.

To make sure of this, you need to check the spark at the spark plugs. If there is a spark, then the problem should be resolved after replacing the fuel pump.

The fuel pump is replaced as follows:

- You need to disconnect the negative terminal of the battery.

2. Then unscrew the fuel pump cap.

3. The next step is to remove the connectors from the pump.

4. Now there is free access to the device. It is necessary to loosen the fuel line clamp.

5. At this stage you will need a key. Here you need to unscrew the lines, but before doing this, release the pressure. After dismantling, it is also recommended to replace the O-rings on the fuel lines

6. Unscrew the 8 screws of the sealing cover and then remove it.

7. Now you need to remove the faulty fuel pump and install a new one in the reverse order.

Doesn't start when the engine is warm

If the VAZ 2110 doesn’t start well when it’s hot, then the problem is most likely related to the injectors. To check, you must try to start the engine. If the starter turns, the fuel pump is working properly, and the spark plugs are flooded, then the injectors are clogged. They need to be washed. However, you need to remove the injectors first. Here are the instructions:

- First you need to remove the injectors. To do this, wait until the engine cools down, then disconnect the fuel pump connectors;

- Start the engine and repeat until there is no reaction to turning the key. This way you can reduce the pressure in the power system;

- Remove the negative terminal from the battery, and you also need to disconnect the pipes and connectors from the ramp;

- Remove the intake manifold along with the throttle valve and pipe;

- Now you can begin to remove the fuel rail along with the injectors;

- You need to disconnect the mounting brackets from it and remove the injectors.

- The first step is to remove the rubber rings. Then it is best to install new ones in their place;

- Now you need to clean the nozzles, as well as the funnel-shaped surfaces;

- Next, you need to simulate the operation of the injectors in the engine by connecting 2 wires from the battery to them, as well as a button;

- To wash the injectors, you need to prepare a cleaning liquid that can be poured into a carburetor cleaning bottle. It must be connected to the nozzles as tightly and hermetically as possible;

- Now you need to apply the cleaning agent and at the same time press the button. This should be continued until the liquid comes out evenly from the sprayer. After this, the process can be considered complete.

A cold engine will not start

What to do if a cold VAZ 2110 has trouble starting? If at the same time the starter turns, the battery is in good condition, but starting still does not occur, then you need to pay attention to the spark plugs.

What to do? The spark plugs need to be unscrewed, and then new ones need to be heated and installed. After this, start the engine. If it starts, the problem was faulty spark plugs. If the problem does not go away, then you need to contact a service station, since such a malfunction cannot be eliminated on your own. Need diagnostics.

The engine starts and stalls

Some owners of the VAZ 2110 8-valve injector also encounter such a problem that the engine starts and immediately stalls. In this case, as a rule, a light on the instrument panel with an exclamation mark lights up. This indicates that the starter needs to be replaced as it has become unusable.

- For ease of dismantling, it is best to remove the air filter housing, and you must also disconnect the negative terminal from the battery;

- Now there is free access to the starter. On it you need to disconnect the traction relay connector

- Using a 13mm wrench, you need to unscrew the wire from the positive terminal of the starter, and then disconnect the wire

Sources:

https://www.lada-forum.ru/index.php?showtopic=20067 https://korchim.ru/biblioteka/dvigatel/vaz-2110-zagloxla-2.html https://rus-avtomir.ru/ remont/mashina-zaglohla-na-hodu https://wroom.ru/forum/topic/21437 https://zen.yandex.ru/media/id/5a7d84fa7ddde831ad801200/5ae2adb400b3dd64a60eb4f8

The car stalled - procedure

First of all, don't waste your battery trying to start your car. It may still be useful if you manage to start the engine. Next you should check:

- Is the fuel pump working?

- availability of gasoline;

- correct ignition.

Sometimes the injectors become clogged. However, usually the problem is their:

- gaskets;

- seals;

- vacuum hoses.

It is extremely rare for the ECU to fail.

The serviceability of the fuel pump is checked by ear - during operation it makes a characteristic sound. You need to listen in the back seats.

Next, you need to make sure that the wiring is working properly. The pump is supplied with 12 volts. The normal pressure for it during fuel supply is up to 3 bar. When the engine is turned off, it gradually decreases - an instantaneous drop indicates a breakdown of the regulator or a leak. It is imperative to check the reliability of the connections of the wires and their connectors - the latter often come loose due to vibration.

Failure of the sensors leads to incorrect operation of the ECU. However, if there is a red light on the panel indicating problems with the engine, most likely the computer is fine.

The battery is working properly and produces 12.5 volts at the terminals. When the engine starts, its voltage drops to 8. If these values are lower, then the battery needs to be charged or replaced.

The most common causes of engine starting problems

Faulty spark plugs and glow plugs - like the battery, have an indefinite shelf life, but must be replaced after a certain period of use. They often fail either one at a time or in groups. Efficient spark plugs are a very important element in diesel engines, where they are a key element in starting the car.

Electrical malfunction - problems with starting the car can be caused by damage to the electrical wiring, such as incorrect connection of the battery, a malfunction of the connector on the cable that supplies current from the battery to the starter, or even a failure of the starter. First of all, you also need to check the idle air control system for corrosion on the wires. If corrosion is found, then it is time to replace the wiring. Another option to solve the problem is to check that the wires are connected correctly, especially if there has been any interference.

Damaged fuel system - the fuel pump located in the tank affects the engine starting. There is no indication that the fuel pump is about to fail, and failure of this element (due to overheating, for example) means that you will not move. A working fuel pump can be identified by a characteristic slight buzzing sound when the engine starts. If you don't hear a similar sound when you try to start your car, it's likely that the pump has failed. It could also be due to a dirty or faulty relay that starts the fuel pump. Then it is necessary to restore it properly or replace it altogether.

Poor quality fuel - as a rule, the problem concerns diesel cars that are not adapted to low temperatures in winter. The fuel begins to thicken and paraffin settles, which clogs the system, causing the car to immobilize. A tow awaits you.

The next possible case is that gasoline contains too much moisture , then such a mixture, entering the combustion chamber, does not work efficiently and the engine does not work correctly. If you recently refueled, and before that the car was working fine, then the problem is most likely in the fuel.

What to do? Drain gasoline from the fuel tank and fill with quality fuel. Or drive as is, which is worse, but next time fill up at another gas station.

Low fuel pressure

If your car stalls when driving on hills, downhill or uphill, the problem may be low fuel pressure. With such a malfunction, the car will not operate reliably.

Source

Why does it start and stall?

If you turn on the logic, there may be several main reasons why the engine stalled after starting:

- insufficient amount of fuel;

- exhaust system malfunctions;

- failures in the formation of the air-fuel mixture and its supply to the injectors.

It can be assumed that the cause is faulty spark plugs or a clogged air filter. But spark plugs do not all fail at once. If one spark plug does not work, the engine starts to stall, but this will not cause it to stall. To clog the filter to such an extent that it is unable to pass air through itself requires a lot of effort. When there is no air supply, the engine will not start at all, and even if it does start, the thrust will drop significantly. Traveling would be difficult, if not impossible.

Insufficient fuel supply

The symptom is simple: after starting, the engine runs for 5–10 seconds and stalls. In most cases, the cause is the fuel pump located in the fuel tank. To be precise, the problem is a clogged fine filter or mesh. This detail, insignificant at first glance, does not allow dirt particles to enter the fuel line, which, like water in the gas tank, is abundant (especially on cars with a mileage of 50,000 or more).

In summer, the water and other substances in the tank are liquid and can pass into the main line, but in winter they often turn into ice on the mesh filter. This causes the fuel pump to be unable to pump enough fuel to run the engine. Therefore, it turns out that the pump manages to pump a little fuel, and this is just enough to start the engine, but no more. To eliminate this problem, it is enough to replace or clean the fuel pump mesh.

Occurrence of a problem

Engine problems in the VAZ-2110 arise for various reasons. The result of a malfunction of one of the nodes associated with the engine will be unstable operation of the entire node.

Not everyone can independently identify the reason why the car stalled, so it’s worth paying attention to some little things.

One of the main problems with cars with high mileage is contamination of the system with fuel combustion products, so a simple lack of cleaning can eventually cause the engine to stall.

If the pipes are clogged, fuel enters the combustion chamber in small quantities; it is not enough for normal engine operation. The solution to this problem is simple - check all the fuel channels, clean them, replace the fuel nozzles. For carburetor types of VAZ, this will not only solve the problem, but also improve engine performance.

The second reason why the engine may stall is low-quality gasoline. An incorrectly selected brand of gasoline can have a very detrimental effect on many vehicle systems, including the engine. You need to replace the fuel, this will help solve the problem.

These solutions to the problem are simple and require minimal skill and expense from the driver.

Incorrect engine operation at idle

More questions arise if the engine suddenly stalls at idle. There are several possible faults that could cause this type of problem. You can check all of them yourself in your garage.

The first thing to check is the idle speed sensor. Since it is connected to the engine, its incorrect readings can disrupt the system. It is worth checking that it is connected correctly and is working properly. The device must be replaced if there is damage to the housing.

It is very easy to check the functionality of the sensor:

- Turn on the ignition; if the starter is unable to accelerate the engine, press the gas several times.

- If the engine starts after pressing the pedal, release it and observe the operation of the motor.

- If it stalls, you can be sure that the idle air control valve needs to be replaced.

No less problematic is the throttle valve assembly. If it is clogged, similar problems arise as when the fuel channels are clogged, and the engine sometimes stalls. Clean the throttle valve.

If this does not solve the problem, check the condition of the throttle sensor. Its malfunction also leads to incorrect operation of the engine unit, so replacement or repair will help solve the problem.

Problems on the go

Now it’s time to deal with the problems that arise on the road. It happens that the engine stalls while driving. In this case, it is best to call a tow truck or enlist the help of other drivers to deliver the car to a garage or the nearest service station.

If you have some skills in handling cars, then you can check several suspected problem components and parts yourself:

- Spark plugs - they are almost always checked. If they are not working, replace them with new ones.

- A dirty fuel filter blocks the flow of fluid, resulting in a lack of fuel causing the engine to stop working. Check the filter, clean or replace it.

- The air filter may also become clogged. If this is the problem, you will notice not only unstable operation of the engine unit, but also a significant decrease in engine power, which occurs due to the fact that there is not enough air to create a high-quality combustible mixture.

- Serious problems can arise if the fuel pump is faulty. Insufficient pressure appears in the system, and the car begins to stall due to poor fuel flow into the combustion chamber. Check, repair or replace the part.

- The battery is another element that is very rarely checked after the engine is stopped. The operation of electronic devices rests on it; as soon as it is discharged, the machine will stop. The contacts of the device may also be oxidized, but they can be easily cleaned.

- After the battery, it is worth checking the generator. This could be the reason why the battery is discharged. The battery will have to be charged, and the generator will have to be repaired or replaced with a new one.

Conclusion

The last and not the most obvious problems can arise in the carburetor and starter. Even a warm engine can stall if the temperature of the operating unit is very high. This happens especially often in the summer. Just press the gas pedal a few times and the engine will start. Updating the cooling system should help.

The last possible culprit is the starter. Its malfunction causes the engine to stop and not start. You need to check the connection and contacts of the device. If they are ok, replace the device with another one.

The most unobvious culprits for problems may be various sensors that are disconnected from the system.

A small glitch occurs, which ultimately leads to various breakdowns. The easiest way to identify problems with sensors is to send the car to a car service center.

Source: https://korchim.ru/biblioteka/dvigatel/vaz-2110-zagloxla-2.html

What other breakdowns of the VAZ 2107 can occur?

Another common problem that causes the engine of VAZ 2107 cars to start and stall is excess air getting into the carburetor. In this case, the fuel mixture cannot keep the engine running for a long time, and although the car starts, it stalls after a few seconds. It is necessary to determine the location of the air leak and eliminate the gap.

It happens that the jets and pipes of the dosing system become clogged. This also affects the drop in engine speed, so that the VAZ 2107 stalls after a few seconds. What to do in this case? You need to unscrew the jets and pipes under the carburetor cover and clean them. After this, blow out the wells and jets with compressed air. If you have a Solex carburetor, then you also need to clean and blow out the fuel jets located at the bottom of the wells.

Cleaning or replacing IAC on a VAZ-2110

Initially, buy a carburetor cleaner and you can get to work.

- Disconnect the wire block from the sensor.

- Unscrew the two fasteners to remove the assembly.

- If necessary, completely clean the device from any dirt on the cone needle and spring.

- Do not bypass the seat on the throttle assembly; it also needs to be cleaned. Upon completion of the procedure, put everything in its place.

- If after the cleaning measures nothing has changed, all the symptoms of breakdowns remain, then the best solution would be to simply replace the regulator.

The process of replacing the sensor is also quite simple:

- Disconnect power from the battery.

- Disconnect the power supply from the regulator.

- Unscrew the fastening screws and remove the sensor.

- Installing a new device occurs in the reverse order.