The VAZ-2107 steering linkage consists of tips and rods combined into one design. It is necessary in order to turn the front wheels - force is transmitted from the steering wheel to the gearbox, and from the latter to the rods. If the tip or rod fails, this leads not only to inconvenience while driving, but also to an accident - driving the car becomes unsafe.

You can replace the elements of the steering linkage yourself relatively quickly, but it is better to adjust the camber and toe using specialized equipment. And the accuracy of adjustment using “old-fashioned” methods leaves much to be desired.

Where is the trapezoid located?

The steering tips and rods are located in the lower part of the engine compartment, in close proximity to the interior partition. You can see them on a lift or overpass, or when turning the steering wheel to its extreme position. The design of the trapezoid consists of the following elements:

- Two lateral rods (left and right short).

- One medium pull.

- Tips – total quantity 6 pieces.

The design also contains a pendulum lever - it is installed on the right side in the engine compartment.

How to determine if a trapezoid is broken?

The main symptoms by which you can understand that the rod ends are out of order:

- Increased free play (play) of the steering wheel.

- There are knocks in the steering system.

- Tire wear is too fast (or uneven).

Rubber wears out quickly if the toe angles of the front wheels are violated. Also, similar symptoms appear when the steering rod itself is deformed. At the same time, the car leaves the trajectory, the camber and toe angles are quite difficult to adjust.

Replacing steering rods VAZ 2107

During vehicle operation, suspension parts and other systems are subjected to significant loads, which leads to their wear and failure. On the VAZ 2107 model, wear forms in the tie rod ends, and knocking noises appear when driving on a bad road. Ignoring them is fraught with destruction of the unit and loss of control of the car. The solution to the problem is to replace faulty mechanism parts.

To carry out repair work on a VAZ 2107 car, you will need the following spare parts:

- steering rods;

- protective covers;

- nuts with crown and fixing cotter pin.

Replacement of components is carried out on a vehicle installed above the inspection hole. To dismantle parts and install new ones, a special puller, socket wrench and extension are used.

Diagnostics of trapezoid elements

But before you replace the VAZ-2107 steering linkage, you need to make sure that it is faulty. To do this you need to do the following:

- Place the car on a viewing hole or overpass to make access to the steering control elements easier.

- Inspect the tie rod ends. Pay attention to the anthers - there should be no cracks or cuts on them. The play of the hinges should not exceed 1.5 mm.

- Twitch the tips and listen for sounds. If knocking noises are heard, then the tip must be replaced - it is useless to repair it, although such a service is available.

- Steering rods have virtually no wear - they only bend as a result of an accident or driving into large holes.

You should not try to straighten the rod - it is made of very durable metal; to do this, you need to make a huge effort. In addition, the strength of the metal is compromised after such “repairs”.

Maintenance and repair

The VAZ 2107 car has fairly reliable steering, the system has been tested over years of operation. The diameter of the steering wheel is chosen well; its size allows minimizing the load on the driver when driving. The equipment requires periodic inspection and maintenance:

- During maintenance, the mechanism is carefully inspected for increased play and increased wear of ball joints. The steering wheel, the optimal size, turns from side to side. Lack of reaction from the wheels when the wheel deviates from the initial position by more than 5 degrees indicates significant wear.

- The oil in the worm gear housing is changed every 60 thousand kilometers. The device is checked for no leaks of operating fluid through the seals.

- The pendulum steering lever of a VAZ 2107 car is inspected when the steering wheel is slowly turned from side to side. Movements of parts in the vertical plane are not allowed.

Any steering malfunctions must be immediately corrected: the mechanism and drive are partially dismantled. Defects of parts are carried out, the entire steering system is checked with special care. Units with signs of significant wear must be replaced.

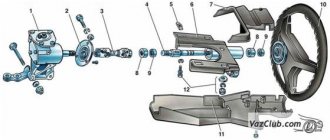

The steering mechanism is a worm pair consisting of a globoidal worm 1 (Fig.) and two ridge rollers 8, placed in the crankcase of a VAZ-2107 - 0.215 liters. A worm welded to the bottom of the steering shaft 10 is installed in the crankcase on two tapered roller bearings. Shaft 11 of the steering bipod is installed in two bronze bushings.

Rice. Steering mechanism VAZ-2105 VAZ-2107

1 - worm; 2 — adjusting nut; 3, 4 — locknuts; 5 — adjusting sleeve; 6 — oil filler plug; 7 — crankcase cover; 8 - roller; 9 — roller axis; 10 — steering shaft; 11 — steering bipod shaft; 12 — oil seal; 13 — steering bipod; 14 — adjusting shims; 15 — gasket of the adjusting screw; 16 — adjusting screw; 17 - crankcase

The design of the steering mechanism provides for adjusting the axial clearance of the worm using an adjusting nut 2 and the lateral clearance in the engagement of the worm with a double-ridge roller using an adjusting sleeve 5 (for the VAZ-2105 VAZ-2107 - screw 16).

When the worm and the double-ridge roller interact, the bipod shaft 11 rotates and the bipod itself 13, mounted on the shaft splines, moves.

The steering mechanism of the VAZ-2105 VAZ-2107 car (Fig.) consists of a steering wheel 7; upper 5, intermediate 4 and lower 2 parts - steering shaft; two cardan joints 3 of the facing casing 6 and a steering mechanism 1 mounted on the body spar 8.

Rice. Steering control of the VAZ-2105 VAZ-2107 car:

Tools for repair

In order to replace the elements of the VAZ-2107 steering linkage, you need to prepare the following tools:

- Socket and open-end wrenches.

- Pliers.

- Tip remover.

It is best to dismantle the VAZ-2107 steering linkage rod using a special device. Be sure to buy a puller - it is not very expensive, but the work will go well with it.

It is very difficult to remove the pins of the tips from the holes - they are conical in shape, and the metal often sticks. You can benefit if you buy a universal puller - you will also need it when repairing the suspension (for removing ball joints).

PROCEDURE FOR PERFORMANCE OF REPAIR WORK

Replacement of a faulty part of the steering mechanism is carried out in the following sequence:

- We clean the assembly from dirt using a brush, and apply a penetrating compound to the threaded connections.

- Using pliers, remove the fixing cotter pins and, using a spanner wrench or a “22” socket, unscrew the nut on the pin.

- The steering rods are detached from the steering knuckle using a special puller. The device is put on the assembly from above and using a bolt, the finger is squeezed out of the eye.

Helpful advice: if you first tap the joint using a copper or bronze drift, the dismantling process will be significantly accelerated.

The manufacturer of the VAZ 2107 recommends replacing worn steering rods as a set. The service life of these structural units from one batch installed on a vehicle is usually the same. Replacing only one of them does not fundamentally solve the problem; a little time will pass and the repair process will have to be repeated for the remaining elements of the system.

Carrying out replacement: step-by-step guide

You immediately need to decide how many rods and tips need to be replaced. Based on this, you can understand whether it is worth changing the VAZ-2107 steering linkage assembly, or its individual elements. Sometimes it turns out that completely replacing a trapezoid is much more effective - its service life is much longer than that of a restored one.

To replace you will need to perform the following manipulations:

- Place the car on a viewing hole or overpass. It is imperative to remove the wheel from which the repair will be carried out.

- Straighten and remove the cotter pin, after which you can unscrew the nut from the tip pin. You do this using the key at “22”.

- Install a puller on the tip and turn its bolt, squeezing the pin out of the hole.

It is advisable to treat all threaded connections with WD-40 penetrating lubricant before starting work. The price of the assembled VAZ-2107 steering linkage will be about 2000 rubles. And it is much easier to dismantle it than each rod separately.

After pulling out the first finger, proceed to the second - repeat the manipulations described in points 2 and 3. After this, the traction can be completely removed. To disrupt wheel alignment as little as possible, you will need to measure the length of the old rod and ensure that the new one has the same size. But this does not mean that after repair there is no need to adjust the camber and toe - this procedure is mandatory.

Replacing steering rods on a classic

Hello everyone!

The other day I was literally shopping and bought external tie rod assemblies, without a middle. The middle has either been replaced or is in very good condition, in any case the anthers are intact and I did not change it. For one thing, the old owner left the BZAK pendulum on bearings. And I replaced the remaining silent blocks on the lower arms, because without removing the rods, the puller cannot be installed on the silent blocks! Old pendulum with rubber bands

The most annoying thing is that to replace the rods I bought a puller that didn’t fit. As a result, I used a crowbar and a hammer to remove everything, breaking two fingers. I wasted 360 rubles in vain!

New

I changed the silent blocks quickly, it’s good that I had a puller. I did half the repairs in the dark and started late, around 3 p.m.

I exposed the alignment by eye. The steering wheel turns much easier, but I haven’t figured it out yet. Tomorrow I'll go for a wheel alignment and we'll see.

Manufacturers of steering linkages

And now a question that interests many motorists - which is the best steering linkage for the VAZ-2107? There are many manufacturers on the market, it is quite difficult to choose a decent one. Here are just a few of the most popular manufacturers:

- "VIS" - have high reliability, their cost is relatively low. According to reviews from motorists, this is one of the high-quality manufacturers of elements.

- "TRACK" - the highest quality elements from this manufacturer. Rubber boots last quite a long time - there are practically no equal ones in terms of service life.

- "BELMAG" - good quality products at a relatively low cost.

- "CEDAR" - low cost and very poor quality.

This is a list of the most popular manufacturers that can be found on the market.

Motorists praise TRACK very much - these are very high-quality VAZ-2107 steering linkages. Its price is approximately 1700-2000 rubles. Its resource is very high, it cannot be compared with KEDR products. Most of them are of very poor quality - it gets to the point that they last 2000-5000 kilometers, after which terrible knocking noises appear. Therefore, it is better to purchase quality products.

Steering rods are responsible for turning the front wheels, so for safety reasons they should always be kept in working order. The VAZ 2107 is equipped with an outdated rod system with hinges, which is called a trapezoid. It has a small resource, so it has to be changed often. Knowing the device and following the instructions for dismantling and reassembling, you can replace the steering rods with your own hands.

Design and principle of operation of a trapezoid

Steering rods turn the wheels in the direction in which the driver turned the steering wheel. It is located at the level of the bottom of the car under the power unit, attached from below to the side members. Consists of three rods: right, middle and left. The middle link has two hinges, the other two are prefabricated parts from a long and short part.

Repair and maintenance

Over the years of operation it has been proven that the steering on VAZ 2107 vehicles has impressive reliability. However, this does not take away the fact that the machine requires periodic inspection and repair.

- When performing maintenance, it is important to check for increased play as well as increased wear on the ball joints. To do this, you need to turn the steering wheel from one side to the other. If the wheels do not respond when the steering wheel is turned 5 degrees from its original position, this indicates severe wear. Here you will need to repair the steering column on a VAZ 2107.

- To avoid the need for urgent and rather expensive repairs of the steering gear on a VAZ 2107, it is necessary to change the oil in the worm gear housing. This is done at intervals of 60 thousand kilometers. Leaks may occur through the seals, so they are carefully checked 2-3 times a year. This is one of the weak points of the system.

- The swing arm should be inspected by slowly rotating the steering wheel from side to side. If the parts move in a vertical plane, then surgical intervention is required.

To do this, the drive and steering mechanism are dismantled completely or partially. Everything depends directly on the nature of the breakdown.

Check which parts have defects and what has failed. Inspection is required for each component of the mechanism. If parts are worn out, there is no point in trying to repair them. There is only one way out - a complete replacement of worn-out components of the steering system on a car from a Volga company.

If problems arise with the steering, it is advisable to contact a professional service station.

Photo of the VAZ 2107 steering gearbox

You can replace the gearbox yourself, but the process is complicated and requires at least minimal experience and skills.

The VAZ "Seven" is a true classic of the domestic automotive industry. Unlike modern LADAs, they are more reliable and durable, which is proven by the huge presence of these cars on our roads.

Of course, the VAZ 2107 has long been outdated, it does not have a hydraulic booster, and you have to apply sufficient force to turn and maneuver. But for connoisseurs this is not a problem.

Purpose and operation scheme of the trapezoid

The rod system serves as an intermediary between the steering shaft and the steering knuckles of the front hubs. The task of the mechanism is to synchronously turn the wheels in one direction or another, obeying the rotation of the steering wheel. The trapezoid is located under the engine at the level of the bottom of the car, attached to the body stiffening elements - the lower side members.

The part of the steering mechanism in question consists of 3 main parts:

- the middle link is screwed to two bipods - a pendulum lever and a worm steering gear;

- the right link is attached to the swing arm of the pendulum and the steering knuckle of the front right wheel (in the direction of travel of the car);

- The left rod is connected to the gearbox bipod and the left front hub knuckle.

The method of connecting the swivel brackets to the trapezoid parts is a conical pin, inserted into the counter hole of the bipod and secured with a nut. The pendulum arm and gearbox are rigidly attached to the side members with long bolts.

The middle link is a hollow metal rod with two hinges. Two side rods are prefabricated elements consisting of 2 tips - long and short. The parts are connected to each other by a threaded clamp, tightened with two bolts.

How does a trapezoid work:

- The driver turns the steering wheel, rotating the shaft and shank of the gearbox. The worm mechanism transmits fewer revolutions to the bipod, but increases torque (force).

- The bipod begins to turn in the right direction, dragging the left and middle rods with it. The latter transmits force to the right rod through the pendulum bracket.

- All 3 elements move to one side, causing the front wheels to turn synchronously.

- The pendulum arm, mounted on the second spar, acts as an additional hinged suspension for the system. In older versions of pendulums, the bipod rotates on a bushing, in new elements - on a rolling bearing.

- Ball pins at the ends of all rods allow the trapezoid to move in one horizontal plane, regardless of the compression of the front suspension springs.

Increasing torque with a worm gear makes it possible to do without hydraulic and electric power steering. On the other hand, the driver physically feels problems with the chassis - as soon as the ball joint or rod end becomes sour, it becomes much more difficult to rotate the steering wheel.

How to change steering rods on a VAZ 2107

VAZ cars, which are classic models, are distinguished by pleasant reliability. This also applies to the steering mechanism.

It is quite complex, but its design allows you to maneuver and ensure reliable vehicle control even in the most difficult road conditions.

The modernization process led to the installation of a composite shaft and a safety column. Due to the size of the steering wheel, the driver makes the necessary maneuvers without any problems. From lock to lock, it takes 3.5 turns to turn the steering wheel completely. The force from the steering column is transmitted to the drive via a composite shaft.

The current steering mechanism on the VAZ 2107, a product of the Volga Automobile Company, is quite informative and does not allow the driver to get tired during long trips. There are certain difficulties when turning in a parking lot, but as soon as the car begins to move, the resistance weakens and turning the steering wheel becomes easier.

There is one more nuance - when the steering mechanism is working properly, there is a slight play. But its limit value complies with the traffic rules. This is due to the fact that there are steering rods on the VAZ 2107 and an impressive number of elements in the gearbox.

In general, the steering of the 7 can be considered reliable.

Arrangement of rods and tips

The middle solid element of the trapezoid has the simplest design - an iron rod with two hinges at the ends. The rod fingers are inserted into the second holes of the bipod (counting from the end of the lever), screwed with 22 mm castle nuts and secured with cotter pins.

Please note: the mid-link rod is bent forward slightly to bypass the gearbox. If you insert the part the other way around, problems are inevitable - the bend will begin to rub against the gearbox housing, making it very difficult to control the car.

Not all service station mechanics know about the correct installation of the middle trapezoid rod. My friend, who came to the service to change a set of steering rods on a VAZ 2107, was convinced of this. The inexperienced master placed the middle section in a backward bend, so it was not possible to go far - exactly until the first turn.

Side rods consist of the following parts:

- short (outer) tip with ball pin;

- long (inner) tip with hinge;

- connecting clamp with 2 bolts and nuts M8 for a 13 mm spanner.

The element is made detachable to adjust the toe angle of the front wheels. The length of the lever can be changed by rotating the threaded clamp and thus adjusting the position of the wheel for straight-line movement. The threads of the tips and inside the clamp are different - right and left, so when rotated, the rod lengthens or shortens.

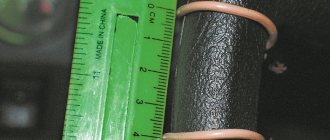

The design of all hinge ends is the same and includes the following parts (the numbering coincides with the diagram):

- Ball pin with M14 x 1.5 thread for a 22 mm castle nut. The radius of the sphere is 11 mm; a hole is made in the threaded part for a cotter pin.

- A rubber (or silicone) dirt-proof cover, also known as a boot;

- Metal body welded to a rod with M16 x 1 thread.

- The support liner is made of a composite material, otherwise - a cracker.

- Spring.

- A cover pressed into the body.

Some lever manufacturers cut into the cover a small fitting for periodic lubrication - a grease fitting.

The short outer ends of the side rods are the same, but the long ones are different. You can tell which part belongs to it by its bend—a lever curved to the right is installed on the right side. The ball pins of the side rods are attached to the first holes of the bipod of the pendulum and gearbox.

A car mechanic I know suggests distinguishing between long tips like this: take the part in your right hand by the hinge, pointing the ball pin downward, as if you were holding a gun. If the “barrel” is curved to the left, you have a left-hand rod tip in front of you.

Video: design of the rod end for VAZ 2101—2107

Mechanism design

To repair the steering column on a VAZ 2107, you first need to understand its structure, as well as the principle of operation.

The seven is in many ways similar to the “penny”. Therefore, the device and design received minor changes. The structure includes:

- A mechanism that transmits the driver’s force to the executive components;

- A steering drive that turns at an angle specified by the driver.

In turn, the steering mechanism consists of:

- Composite shaft with cardan transmission;

- Steering wheel (steering column together with a steering wheel with a diameter of 520 mm);

- Worm gearbox of the VAZ 2107 steering mechanism.

The control system has the following components:

- Bipod;

- Pendulum arm;

- Swivel arms;

- Steering rods for VAZ 2107 (one middle, two side).

The outer rods include two parts, which allows you to change their size by adjusting the toe angle.

Tie rod/end set for VAZ 2107

The operating principle of the steering mechanism looks like this:

- The driver begins to rotate the steering wheel, the wheel size of which ensures that this task can be performed quite simply;

- By means of a composite shaft, a worm gear is activated, which reduces the speed;

- The steering mechanism is lubricated with special oil (TAD 17) poured into the gearbox;

- The worm gears rotate, which causes the double ridge roller to move;

- This, in turn, causes the secondary shaft to rotate;

- The tray mounted on the secondary shaft makes a turn and pulls the rod system behind it;

- These components influence the levers that synchronously rotate the wheels to the required angle specified by the driver.

Parts of the steering gear housing: 1 - housing; 2 - bipod; 3 — lower crankcase cover; 4 — adjusting shims; 5 — outer ring of the worm shaft bearing; 6 — separator with balls; 7 — bipod shaft; 8 - adjusting screw; 9 — adjusting plate; 10 — lock washer; 11 - worm shaft; 12 — upper crankcase cover; 13 - sealing gasket; 14 — bipod shaft sleeve; 15 — worm shaft seal; 16 — bipod shaft seal.

Details: 1 — steering gear housing; 2 - shaft seal; 3 - intermediate shaft; 4 - upper shaft; 5 — fixing plate of the front part of the bracket; 6 — bracket for fastening the steering shaft; 7 - upper part of the facing casing; 8 — bearing sleeve; 9 — bearing; 10 — steering wheel; 11 — lower part of the facing casing; 12 — bracket fastening parts

Troubleshooting

As the car moves, the ball pins rotate in different planes and gradually wear out the crackers, which causes backlash. The following signs indicate critical wear of a tip (or several):

- a distinct dull tapping sound when driving over any uneven surfaces;

- vibration from the play of the ball pins is transmitted to the steering wheel;

- on a flat section of the road the car spontaneously leaves the straight path;

- The rotation of the steering wheel is difficult, and a creaking sound is heard from below.

When a lot of force is required to turn the steering wheel, the worn tip must be replaced immediately. The symptom indicates that the ball pin is jammed inside the housing. If measures are not taken in time, the hinge may jump out of its socket and the car will become uncontrollable.

A similar story happened to my relative. When there was literally half a kilometer left to drive to the garage, the right steering tip on the “seven” broke off. The driver showed ingenuity: he tied the end of the dropped rod to the suspension arm, leveled the wheel with his hands and slowly continued driving. When it was necessary to turn, he stopped, got out of the car and manually adjusted the wheel in the right direction. The 500 m long path was covered in 40 minutes (including the entrance to the garage).

Maintenance and repair

The VAZ 2107 car has fairly reliable steering, the system has been tested over years of operation. The diameter of the steering wheel is chosen well; its size allows minimizing the load on the driver when driving. The equipment requires periodic inspection and maintenance:

- During maintenance, the mechanism is carefully inspected for increased play and increased wear of ball joints. The steering wheel, the optimal size, turns from side to side. Lack of reaction from the wheels when the wheel deviates from the initial position by more than 5 degrees indicates significant wear.

- The oil in the worm gear housing is changed every 60 thousand kilometers. The device is checked for no leaks of operating fluid through the seals.

- The pendulum steering lever of a VAZ 2107 car is inspected when the steering wheel is slowly turned from side to side. Movements of parts in the vertical plane are not allowed.

Any steering malfunctions must be immediately corrected: the mechanism and drive are partially dismantled. Defects of parts are carried out, the entire steering system is checked with special care. Units with signs of significant wear must be replaced.

Selecting new trapezoid parts

Since the VAZ 2107 car has been discontinued, finding original spare parts is becoming increasingly difficult. On the roads of the CIS countries, steering rods fall into disrepair quite often, so the supply of “original” parts has long been exhausted. In recent years, trapezoid kits have been supplied to the market by several well-known manufacturers:

A special feature of repairing a steering linkage is that worn tips can be replaced one by one. Few Zhiguli owners install complete sets because of one broken ball pin. As a result, the “seven” trapezoid is often assembled from spare parts from different manufacturers.

The quality of steering rods from these manufacturers is approximately the same, as evidenced by reviews from car enthusiasts on the forums. Therefore, choosing a new spare part comes down to following 3 rules:

- Beware of fakes and do not buy parts from dubious outlets.

- Avoid tie rods from unknown brands sold at bargain prices.

- Do not confuse the left long tip with the right one if you are changing part of the trapezoid.

INSTALLATION OF PARTS AND ADJUSTMENT

Installation of steering rods on a car of the classic VAZ 2107 model is not particularly difficult and is performed as follows:

- We measure the length of the old assembly using a steel ruler as accurately as possible.

- We adjust the new unit using a threaded connection to the desired size and lock it with locknuts.

- Installing the part in place is carried out by inserting a finger into the seat and screwing the nut with a certain torque.

Timely replacement of faulty components of the VAZ 2107 steering mechanism will allow you to avoid serious troubles and emergency situations on the road.

Replacing the outer short tip

Since the outer part of the trapezoid can be approached from the wheel side, disassembly can be performed without an inspection ditch. What tools and materials will be needed:

- ring wrenches size 13 and 22 mm;

- pliers;

- hammer;

- puller - a “glass” type extruder;

- a ruler at least 20 cm long or a tape measure;

- devices for removing the wheel - jack, wheel wrench, wheel chock;

- rags, fabric gloves.

Also, prepare a new cotter pin, WD-40 spray lubricant, and a wire brush in advance to remove any stubborn dirt from the rod before starting work.

Why is it customary to replace tips rather than repair them:

- High-quality factory parts are made non-separable; in a garage it is impossible to remove a worn-out cracker - the hinge cover is tightly pressed into the body.

- Collapsible rods made at home using a lathe are considered unreliable. The reason is the “licked” thread profile inside the housing; under load, the ball pin is able to squeeze out the lid and jump out.

Preparatory stage

Before removing the tip, perform a number of preparatory operations:

- Secure the car on the platform and unscrew the desired wheel. To provide maximum access to the tip, turn the steering wheel to the right or left as far as it will go.

Take this opportunity to examine the condition of the anthers on other tips. If you notice any breakthroughs, disassemble the trapezoid completely and install new silicone covers.

Disassembly instructions

Dismantling the old part and installing a new tip is carried out in the following order:

- Using a 13 mm wrench, loosen one nut of the tie rod, located closer to the wheel. Do not touch the second nut.

Some car enthusiasts, instead of measuring the length, count the revolutions when unscrewing the tip. This method is not suitable - the length of the threaded part on parts from different manufacturers may differ by 2-3 mm. I had to face this problem personally - after the replacement, the car began to pull to the right and “eat up” the edge of the tire. The issue was resolved at a car service - the master adjusted the toe angle of the wheels.

If you are unable to find the puller, try knocking the pin out of the eye by hitting the pin with a hammer. Method two: lower the wheel hub onto the block, screw a nut onto the thread of the pin and hit it with a hammer through a wooden spacer.

Knocking out is not the best way to disassemble a connection. You can accidentally rivet the threads, in addition, shocks are transmitted to the hub bearing. It’s better to buy an inexpensive puller - it will be useful for replacing other hinges.

Video: how to change the tie rod end

Set

The steering rod kit includes the rod itself and the tip (hinge). There are also several other main components.

- The main one is the housing; the axle shaft is installed in it.

- There is a ball pin on which a thread is cut for tightening.

- The third component is considered to be a Teflon limiter; it prevents the ball pin from moving and fixes it in place.

In order to protect the tip from debris and early breakage, a cover is provided that closes the housing. The kit includes several more protective devices and a nut for securing.

The kit also includes a ball joint; it is installed on the steered wheels and maintains a tight grip and limits the mobility of the steering arms. The ball joint is more of a part of the suspension because it helps keep the car on the road when cornering, keeps the wheels level, and helps steer the car.

Complete disassembly of the trapezoid

Removing all rods is practiced in two cases - when replacing assembled levers or a complete set of anthers on hinges. The technology for carrying out the work is similar to dismantling the outer tip, but is done in a different order:

- Complete the preparatory stage - place the car in the pit, clean the hinges, apply lubricant and remove the cotter pins. There is no need to turn or remove the wheels.

- Using a 22 mm spanner, unscrew the nuts securing the two side link ball pins; do not touch the clamp bolts.

Don't forget to position the middle section correctly - bending forward. After replacement, it is worth driving out onto a flat section of the road and observing the behavior of the car. If the car pulls to the side, go to a service station to straighten the camber angles of the front wheels.

Steering problems

The steering mechanism, like any other vehicle component, wears out and requires repair over time. To simplify the troubleshooting, there are certain signs that allow you to find out the nature of the breakdown and fix it in a short time.

Oil leak

On a classic, the problem of a “wet” steering gear is quite common. There can be many reasons for this:

- oil seal wear;

- leakage from under the gasket;

- loosening of the fasteners that secure the mechanism cover;

- Corrosion of the input shaft.

If the oil seal and gaskets can be replaced and the bolts tightened, then if the shaft is damaged, the part will have to be ground.

Tight steering wheel

Sometimes it happens that to turn the steering wheel it is necessary to apply noticeably more effort than usual. Several reasons can lead to this malfunction:

- incorrect wheel alignment;

- failure of one of the elements in the steering mechanism;

- the gap between the worm and the roller is broken;

- The pendulum axis fasteners are too tight.

Steering play

One of the reasons for free play in the steering mechanism is wear on the shaft crosspieces. In addition to them, play appears in the gearbox itself. If the unit has a high mileage, then it is advisable to disassemble it, inspect the condition of all the elements, replace parts with high wear, and then carry out adjustments.

Knock and vibration

If you feel feedback on the steering wheel while driving, there can be many reasons for this phenomenon. Driving a vehicle in such a technical condition leads to rapid fatigue and reduces the level of safety. Therefore, the steering mechanism needs diagnostics.

Table: causes of vibrations and knocking on the steering wheel and ways to eliminate them

| Cause of steering failure | Troubleshooting method |

| Increased clearance in front wheel hub bearings | Adjust the front wheel hub clearance |

| Loosening the tie rod ball pin nuts | Tighten the tie rod ball stud nuts |

| Increased clearance between the pendulum arm axis and the bushings | Replace the swingarm bushings or bracket assembly |

| The adjusting nut of the pendulum arm axis is loose | Adjust the tightness of the swingarm nut |

| The clearance in the engagement of the roller with the worm or in the worm bearings is broken | Adjust the gap |

| Increased clearance in steering rod ball joints | Replace tie rod ends or tie rods |

| Loosening the bolts securing the steering gear housing or the pendulum arm bracket | Tighten the bolt nuts |

| Loosening the swing arm nuts | Tighten the nuts |