Print this article Font size 16

It should be immediately noted that replacing the clutch on a VAZ 2110 is a drastic measure to repair the unit. In some situations, it is quite possible to get by with repairs that will extend the life of the existing clutch. Today we will look at these issues in more detail in our material.

Disk

Clutch diagnostics on a VAZ-2110

The VAZ-2110 received the mechanism from the eight and nine virtually unchanged, only the downforce was adjusted, which corresponds to the engine torque.

Nevertheless, every clutch has its time. The resource of the unit greatly depends on the driving style and operating conditions. And besides, from the kit manufacturer. By the way, it is not at all necessary to change the clutch assembly due to a failed driven disk or release bearing; it is expensive.

But replacing any element of the mechanism, as well as the entire clutch, at a service station will cost at least 3-5 thousand rubles , not counting the cost of materials. Therefore, it makes sense to do the repairs yourself. This is not the simplest operation, but it is quite accessible even for a novice driver.

Clutch kit: basket, disc, bearing and mandrel.

Symptoms of a problem

Before removing the clutch on a VAZ-2110, you need to find out its condition based on the following signs:

- The clutch is slipping. This means that when the engine speed changes, part of the torque is lost when the clutch of the driven disk slips - the speed increases, but there is no traction. There may be several options - either the friction linings of the driven disk are worn out, or the adjustment of the free play of the clutch pedal is impaired. In the first case, disk replacement is necessary.

- The clutch is driving. When the pedal is fully depressed, the clutch does not disengage. That is, part of the torque is still transmitted to the gearbox; the drive and driven disks do not open. In this case, either adjusting the same pedal free play will help, or replacing the release bearing or clutch basket if the adjustment does not produce results.

- The clutch vibrates. We observe vibrations in the gearbox area at certain speeds or constantly. In this case, the clutch needs to be replaced; most likely, the basket has failed.

- The clutch is noisy. Increased noise when pressing the pedal, extraneous sounds when changing gears. Most likely, either the entire clutch assembly, or the basket or release bearing has failed. The kit needs to be replaced.

If one of these symptoms appears and, having made sure that the adjustment does not produce results, we proceed to disassemble the clutch with our own hands, so as not to disturb the specialists, whose time and labor will cost us a lot of money. We ourselves can replace the clutch assembly in an hour, maximum two.

Choice

If you plan to simply replace the disk, purchasing a completely new node does not make sense from a financial point of view. But when the old clutch leaves much to be desired due to the quality of its work, it’s worth thinking about completely replacing the unit.

Today the market is represented by an extensive list of alternatives made in Europe and China. We strongly do not recommend using Chinese spare parts, but European analogues should be considered as a replacement for VIS.

According to a study conducted among VAZ 2110 owners, the five best kits for the domestic “ten” were determined:

- Kraft Tech.

- LUK.

- Valeo.

- Sachs.

- VIS.

As we have already noted, VIS is installed as standard and works quite well. An important advantage compared to European counterparts is financial accessibility. But if your wallet allows it, replace the old clutch with a better and more expensive one.

In defense of the VIS system, we note that repairs often require simply adjusting the pedal and tightening the cable. And if you are going to completely change VIS to VIS, it will not cost you a pretty penny.

Replacing the clutch on a VAZ-2110 without removing the gearbox

As a rule, tens of clutches, like other front-wheel drive VAZ cars, are carried out without removing the gearbox.

Complete dismantling of the gearbox is necessary in cases where we have problems with gear engagement or with the gearbox. By dismantling the box completely, the work is almost doubled; you have to drain the oil, remove the axle shafts and carry out a lot of other work . Therefore, if the checkpoint does not bother us, we will not remove it.

Conditions

It is most convenient to change the clutch on a lift, inspection pit or on an overpass. You can do it in the field, but it is naturally inconvenient and time-consuming.

To work, we will need a standard set of tools, a jack, several wooden spacers and a mandrel, without which it will not be possible to install the driven disk. This mandrel follows the shape of the gearbox input shaft and centers the disk in relation to the flywheel.

What you need to know

The release bearing is not the weakest link in the clutch system, but for some reason it is the one that causes problems and troubles.

coupling

Some car owners have gotten used to the whistle and simply ignore it. But this cannot continue for long, since untimely solution to the problem can lead to even more complex and expensive repairs. If the situation gets worse, then a simple replacement will not be enough for you.

The clutch serves to act on the leaf spring of the clutch basket. It is also called diaphragm, so don't be confused if you hear this designation. Due to this impact, the driven disk is disconnected from the flywheel and the pressure plate of the basket. This disengages the clutch.

If the squeezer is faulty, this can lead to various consequences:

- The clutch fork will be damaged;

- The integrity of the clutch spring petals will be compromised;

- The guide bushings are deformed.

In order not to pay twice, or even three times, promptly react to the appearance of a whistle in the clutch and try to quickly take action.

When is it necessary to install a new clutch on a VAZ 2110 car and why?

Restoring a car on your own has always required not only some effort, but also financial investment. It is precisely because of the last factor that car owners try to carry out repairs themselves, thus saving on payments to service station workers. Clutch repair, of course, is not comparable in labor intensity to changing the working cylinder , but even if you have basic skills, it is quite doable in a garage.

To prevent replacing a VAZ 2110 clutch disc from becoming a waste of time and money, it’s a good idea to find out the symptoms indicating the need for repairs; experienced car enthusiasts already know them, but it will be useful for beginners:

- Loss of engine power.

- Vibrations when pressed or a “cotton” pedal.

- Switching on gears occurs with slipping or is accompanied by crunching and jerking.

- Spontaneous gear shutdown.

- Difficulty switching on speeds.

- Friction lining smell.

It is important to clearly identify the source of the problem; for example, a “stuck” pedal may also indicate that drive cable . Experienced motorists regularly check the condition of the friction mechanism every 80,000 km so that the installation of the VAZ 2110 clutch is fully justified.

Is noise a sign that replacement is needed?

Not really. If noise occurs, this does not mean that you should immediately replace the element. But it is strongly not recommended to delay repairs. Let's just say this is a signal for certain actions, which you will have some time to complete before the consequences become catastrophic.

In some cases, the noise occurs when the engine is started, and it persists until the car warms up, after which it disappears. In other cases, the noise returns every time you try to disengage the clutch.

The worst option is a grinding sound. This sound indicates that the element is rubbing against the leaf spring, and wear will form on the petals. If you are “lucky enough” to encounter such a situation, there is no time. Replacement needs to be done quickly.

By the way, there is no point in repairing it. Release bearings cannot be repaired, so the only solution is replacement.

Technology for replacing the clutch disc on a VAZ 2110 car on your own

Some zealous car owners are starting to look for an accessible solution, for example, in the form of welding a layer of metal onto the legs of the basket. However, it is difficult to increase the same thickness; misalignment occurs, which again leads to uneven wear of the unit. Therefore, it is more reasonable to immediately install a new part, for which we will consider the procedure for implementing the repair:

- To prevent a short circuit, remove the negative terminal from the battery.

- Disconnect the mass air flow sensor connector, loosen the clamp securing the corrugated pipe and remove the air filter housing to gain access to the gearbox mounting bolts.

- Loosen the left wheel mounting bolts and lift the car on a lift or jack up the front part and install supports.

- Remove the front left wheel and remove the engine protection (if equipped).

- Using two 19mm wrenches, loosen the two cable fastening nuts and remove the cable from the bracket to the gearbox.

- Unscrew the top bolt securing the autostarter to the box using a 17mm wrench, then use a 19mm wrench to unscrew the nearby gearbox mounting bolt.

- Remove the speed sensor connector and disconnect the speedometer drive cable.

- Remove the torque rod of the gearbox drive, having previously made marks at the place where the clamps are attached, so as not to have to adjust the gear shift lever later.

- Unscrew the second starter mounting bolt and remove it.

- Unscrew the lower bolts securing the left ball joint.

Gearbox installation

We install the gearbox in the reverse order of removing it. Please note that our illustrated instructions will help you both change the VAZ 2110 clutch and repair it by replacing only individual parts. Of course, it would be nice to do all this in the pit, but we had to do without it. We carried out the work as follows: 1. Lowered the jack under the engine; 2. We inserted the left drive into place and tightened the nut; 3. We installed a homemade lever under the gearbox, made of two bricks and a piece of board (60–70 cm); 4. My assistant stepped on the lever, lifting the box, and I pushed it into place. Now all we have to do is assemble everything, adjust the rocker, as well as the clutch itself.

Source: emex52.ru

Results

If there is an overpass or lift, the operation is carried out quickly and efficiently, and when there is a reliable assistant, it is also fun. However, not everyone has such capabilities, and this is where engineering ingenuity comes into play.

Some car enthusiasts practice repairing the clutch without removing the gearbox; for this purpose, instead of the upper standard mounting bolts, they screw in longer bolts. For this, for example, two bolts from the upper arm of the front suspension of the “VAZ classic” are suitable. By screwing them into the upper holes, the box can be moved back by 14-15 cm with a pry bar. In this case, the transverse rod should not be unscrewed, because the rear part of the gearbox will lie on it. These conditions are quite enough to replace faulty parts.

If repairs are necessary, experts recommend doing a complete replacement of the entire assembly along with the release bearing, especially since the choice of clutch kits is quite wide. This position is explained simply - an old part left behind threatens to fail at any moment. The procedure, as you yourself saw in the video, is quite labor-intensive, and repeating it over and over again is not a pleasant pleasure, except for real “homemade people.”

1200 rub. for the photo report

We pay for photo reports on car repairs. Earnings from 10,000 rubles/month.

Write:

Are there signs of clutch wear on your 2110? Hence? You need to purchase a new set and make repairs, or rather replace the clutch on the VAZ Top Ten.

Without a garage with a pit, you can make do with improvised means. To change clutches on a VAZ 2110 you will need : a set of keys, a jack and wooden stumps. And for proper alignment of the clutch disc, you will also need a guide, which is also a simulator of the gearbox input shaft.

Preparation

There are 2 ways to replace the clutch. Instructions for replacing the VAZ 2110 clutch with your own hands without removing the box and without the need to drain the oil + informative photo report + video. With the replacement of the clutch, replacement without removal, replacement of the Priora stove gearbox without. One method involves completely removing the gearbox, the other does not. In any case, the following available tools are needed:

See:

- jack;

- an overpass, without which it will be problematic to replace the clutch ;

- logs or bricks;

- a set of keys and sockets of sizes from 8 to 19, you may need a 15 socket, which is rarely required;

- extension cords for keys will not be superfluous, since sometimes a situation arises in which it will be impossible to reach the part by hand;

- mandrel 10-12 cm for centering the driven disk .

Method for removing the gearbox:

- Drive the car onto the overpass.

- Remove the battery.

- Disconnect the cable going to the speedometer.

- Now you have to remove the gearbox. Moreover, if you put back the old pressure plate, you need to note the relative position of the flywheel and the casing of the above-mentioned disc to maintain balance.

- Next, insert the mandrel into the hole in the disk. You can do without this procedure, but then you need to hold the driven disk, otherwise it will fall out.

- While holding the flywheel, unscrew all 6 mounting bolts. Lada Kalina station wagon luxury › logbook › replacing the clutch without removing the box and without draining. Contents of the article: replacing the clutch on a VAZ 2112 without removing the CV joints; replacing the clutch on a VAZ 2110, 2111, 2112; replacing the clutch. Replacing the ball joint for Renault Logan, Sandero, Lada Largus, Logan2, Sandero2 Replacing the ball joint for Renault Logan, Sandero, Lada Largus Nissan Almera g15 without removing the suspension arm - replacing. In this case, this must be done gradually, one turn from each bolt, so that the disk does not warp.

- Now you can remove the casing that will contain the pressure plate.

- Next, the driven disk with the mandrel is removed.

- Now comes one of the crucial moments in the entire replacement process, namely the inspection of the driven disk. It is necessary to check it for wear, check the surface of the friction linings and the reliability of the damper springs in the hub sockets.

- We must not forget about checking for its “beating”. In other words, how smooth its surface is.

- If there are any signs of wear, the necessary parts must be replaced.

- If there are obvious signs of wear on the pressure plate, it should be replaced completely as an assembly.

- Before installing the clutch, it doesn’t hurt to check the parts for ease of interaction. Replacing a Priora clutch without removing the box

. Replacing the clutch on a Lada Priora is possible without the input shaft of the box. Any nicks or defects should also be addressed.

- When installing the driven disk into the housing, the protruding part of the hub must be in contact with the spring.

- Next, assembling the clutch proceeds in the reverse order.

What kind of clutch should I put on a VAZ 2110 and when should I change it?

Original number 21100-1601000-00, average price about 2615 rubles.

The frequency of replacement depends on your driving style. On average, factory ones last about 50 thousand km, so car owners often replace them with imported ones, since they last more than 100 thousand km.

Loosen the wheel bolts, jack up the car and place the sawhorses.

Remove the left wheel and unscrew the two bolts securing the lower ball joint.

We remove the “negative” terminal from the battery, remove the connector from the mass air flow sensor, loosen the clamp securing the corrugation to the mass air flow sensor, and remove the air filter housing from the car.

Remove the clutch cable from the clutch fork. Loosen the two nuts securing the cable to the bracket on the gearbox (hereinafter referred to as “Gearbox”).

- Unscrew the bolt securing the MZ to the gearbox housing.

- Unscrew the first gearbox mounting bolt.

You will need a good wrench with a 19 mm head and possibly a pipe wrench. There is another gearbox mounting bolt nearby.

You must remember to loosen this nut.

Unscrew the upper starter mounting bolt.

Remove the connector from the speed sensor and unscrew the speedometer cable.

We remove the longitudinal extension along with the lever.

Unscrew the lower starter mounting bolt.

Unscrew the third gearbox mounting bolt. There is another gearbox mounting nut in the area of the right inner CV joint.

On a VAZ 2110, unscrew the two bolts securing the jet thrust.

- Loosen the nut on the clamp of the gearbox control drive rod and remove this rod from the gearbox.

- Unscrew the two rear cushion nuts.

You must first place a block under the engine, otherwise it may drop too low and tear off the interior heater hoses.

Carefully remove the gearbox from the engine and place it on the floor.

The gearbox hangs on the axle shafts. The advantage of this method is that there is no need to drain the oil from the box . But there is also one big problem - the risk that after such a load the seals will leak .

- It is better to replace the clutch release bearing.

- If the springs are loose in their place, then definitely change the disc.

- The linings are worn down to the rivets.

- There is little wear on the surface of the basket and will survive another disc.

There is slight wear on the petals, where the release bearing touches. Petals are normal.

The flywheel surface is not very worn. We perform assembly in reverse order. To install the clutch basket and disc, you must use a gearbox input shaft simulator.

First stage

The first question is: is it possible to replace the clutch on a VAZ 2109 without removing the gearbox? You can look through so many materials, videos and photos, but nowhere will you find a specific answer to this question. As a result, of course, you will come across some review in which the person directly points out that it is quite possible to do such a thing. And it will even give the basic requirements for carrying out such repairs. Then it will become clear that it’s enough to climb around in search of theory, it’s time to start practicing and repair or replace the clutch on a VAZ 2109 with your own hands. To do this, find two massive stumps, the height of which should be about 40 cm, as well as several bars. Of course, it’s scary that the car will fall during the repair process. Therefore, install two wheels nearby under the bottom for insurance.

Clutch disc VAZ 2109

Until the last moment, you can doubt whether it is possible to replace the clutch without completely removing the box, because you don’t want the massive gearbox to fall to the ground. But lifting it is problematic, since it is impossible to crawl under the car with it. First, disconnect the battery by de-energizing the system. So the whole story begins - start preparing the car for repairs, removing all unnecessary elements. Namely:

- Twist the wheels and move them to the side so they don't get in the way.

- Remove the tie rod ends to free up the struts.

- Remove the two bolts that secure the ball joint.

- Remove the engine protection.

- Drain the oil from the box.

- Loosen the nut on the rocker and remove it.

- Remove all nuts from the bolts on the two pads.

- Place a support or jack under the engine.

- Disable the reverse sensor.

- Disconnect the wires from the starter and remove it by unscrewing the three nuts.

- Unscrew the nuts from the flywheel protection.

- Remove the inner CV joint on the right side, do not touch the left one.

- Unscrew the three bolts securing the gearbox to the block.

- Unscrew the nut above the right CV joint.

labavto.com

The clutch is an important and integral element of the transmission system. Therefore, if you have suspicions about the inoperability of this mechanism, then it is better to replace it immediately. Today you will learn how to replace a VAZ 2110 clutch, how much it costs at a service station and what needs to be taken into account when changing this mechanism.

Popular problems and their solutions

There are several characteristic faults that occur on the VAZ 2110. Let's try to understand the reasons for their occurrence, and also consider ways to solve the problem.

- The clutch drives. The reasons may be: The pedal has insufficient travel, the tension is too tight. To eliminate this, you need to adjust the drive;

- The driven disk is deformed. Only replacement will help here;

- The driven disc hub sometimes gets stuck. If so, try washing it and lubricating the input shaft splines. If the element or the shaft itself is worn out, then replace them;

- The friction linings are broken and the rivets are loose. The best solution is a complete replacement of the casing, which includes a spring and a disk;

- The pressure plate is warped or warped. Replace the linings, but first make sure that there are no deviations in the end runout of the disk;

- There were problems with the cable. Pull it up. If there is no result, replace with a new one.

- The friction linings on the driven disk often burn or wear out. There is only one solution - replacement;

- Oil has reached the surface. We have already described how to solve the problem above;

The nuances of changing the release bearing

The release bearing of the VAZ 2110 is noisy

Note! If the release bearing is not replaced in a timely manner, it will jam in any case, and subsequent operation of the machine will be impossible.

To change the release bearing, you don’t have to go to a service station; you can do the steps yourself at home.

Quick release bearing removal

So:

- First, it is recommended to drive the car into a pit for inspection. Using a standard set of tools, the gearbox is removed.

- The clamps are pressed off the bearing.

- The part required for replacement is removed from the gearbox shaft.

- The paws are wrung out and the spring principle holder is removed.

- Now the bearing can be easily removed from the coupling.

Upon completion of the above steps, the bearing dismantling process is considered complete.

Installing a purchased release bearing

As a rule, after dismantling the old part, it is replaced. Before fixing the purchased release bearing, it should be carefully checked. It should rotate freely, and there should be no jamming or clicking. So:

- To install the bearing, it is necessary to fix it directly on the coupling in such a way that its protruding parts are directed towards the coupling.

- Next, you need to secure the bearing using a holder.

Release bearing VAZ 2110

- The release bearing is pre-lubricated with oil and installed on the shaft.

- The part is secured using a spring clamp.

- The gearbox is installed in its place.

At this stage, the process of attaching a new element is completed. All that remains is to adjust the clutch correctly, otherwise the bearing will not last as long as we would like. If you have the necessary tools, repair work can be easily done with your own hands; in any case, the price will be much cheaper than repairs at a service station. Detailed instructions for replacing the gearbox bearing can be seen in the video. In addition, it is recommended to use photographs and pictures as visual aids.

Add a commentAdd a comment We recommend reading VAZ 2109: replacing the release bearing on your ownReplacing the clutch bearing on a VAZ 2109 on your own

Owners of the domestic VAZ 2110 car often encounter a whistling noise in the clutch , which is caused by the release bearing of the unit. Moreover, this is a problem not only of the “tens”, but also of other cars from different manufacturers, the clutch design of which involves the use of this element. Therefore, replacing the release valve on a VAZ 2110 is not at all an exceptional problem. But it needs to be solved.

Release

How it works and what it consists of

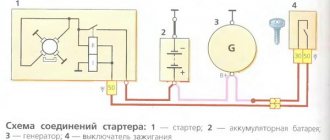

The VAZ 2110 has a single-plate clutch with a central pressure spring. The drive operates via a cable. The casing is attached simultaneously to the pressure plate and flywheel. The design also provides for a driven disk.

Device diagram

The factory clutch system for the VAZ 2110 is called VIS. Many people complain about it because it doesn’t work very effectively, although others are sure that there is no more worthy alternative for the “ten”. So opinions differ on this matter.

The main components of the system include:

- casing;

- Crankcase with a cover and supporting planes with which the unit is attached to the frame;

- Driven and pressure plate;

- Release bearing. It disengages the clutch;

- Flywheel;

- Shutdown plug;

- The cable wire that goes to the pedal (far left in the car interior).

How to renew?

The main factor influencing clutch life is driving style. To save the disk, you need to avoid high loads. Do not start driving at high speeds (with slipping) and do not overload the vehicle itself. The last factor also applies to those who like to drive with a trailer. Remember that every kilogram from the trailer loads the gearbox and clutch components. Do not tow vehicles that exceed your curb weight. These factors directly affect the life of the clutch disc. Using a careful driving style, you can increase the capabilities of this element to 150 thousand kilometers or more. In sports driving mode and other loads, even the highest quality VAZ 2110 clutch, the price of which is quite high, will not last even 40 thousand kilometers.