The automotive market does not stand still; manufacturers are constantly improving car engine power, fuel consumption, aerodynamic values, and coming up with options for changing overall comfort. The main and obvious improvement was the transition from the use of a carburetor method of power supply to a more efficient injection system.

How does the latter work? Regulates the quantitative supply of fuel according to a single dosage for the operation of the power plant in different formats of activity. This allows you to reduce the amount of air consumption and ensure maximum power output from the power structure.

However, mechanics argue that the design of the carburetor system is technologically simpler, because the carburetor operates mechanically, which means that the mechanism can be assumed to be highly reliable. The VAZ-2110 is equipped with such a system. The advantage of the device is that the fuel-air mass is formed in the carburetor and in the cylinders through vacuum, which is created by the pistons.

Mass air flow sensor VAZ 2110: replacement and installation instructions

After dismantling the old non-working sensor, before purchasing, you can ask a friend for a temporary air flow sensor from his car, and then check it in your 2110. If with another sensor the engine works without interruptions, the consumption does not increase, then it’s time to replace your flow meter. This is the simplest diagnosis that can be carried out when the first signs of a malfunction appear.

We have studied the malfunctions and symptoms, what a mass air flow sensor is is now clear. If we succeed in checking, and we know that the flow meter is faulty, all that remains is to replace it. To do this, you need to prepare a replacement unit (you can buy a non-standard model) and a screwdriver. Visual inspection implies analysis, but let’s repeat it again:

- You need to turn off the engine and remove the key from the ignition. Disconnect the plug. Finding it is quite easy.

- Pull out the sensor connector as shown in the photo.

Unscrewing the bolts with a child's wrench. - Now you can remove the hose on the inlet pipe. It is attached with clamps to the air filter. After removing the clamps, the hose can be dismantled.

The sensor is dismantled along with the filter - ready. - Now we can remove the mass flow sensor and perform the replacement.

Installing a new element is done in exactly the same way.

Cleaning the sensor

If you observe signs of a malfunction of the mass air flow sensor, then you can try cleaning the device.

By the way, this is the most expensive sensor of all in the line of front-wheel drive VAZ cars. But if yours is broken, don’t rush to change it. There is a small chance of restoring his “health”. For the cleaning process you will need a special liquid that is used to clean the carburetor. Star keys are also useful. Unscrew the clamp, as well as the two “10” bolts. Remove the pipe and take out the sensor. Spray the liquid onto the wire and tube. Work with extreme care, wait until this liquid has completely evaporated and leave the device to dry.

While the device is drying, remove the throttle assembly. You will see plaque inside the throttle assembly. It needs to be removed with liquid. This dirt causes problems with the entire system. Because of it, problems with the mass air flow sensor appear, signs of a malfunction of the VAZ 2115, which bother beginners on automobile forums.

Do not remove the throttle cable. Place the knot on a cloth and treat particularly dirty areas with the liquid. Don't forget to clean the idle air control valve and the space underneath it.

Carry out such preventive maintenance regularly, and your car will thank you.

Source

Principle of operation

What is a mass air flow sensor and what is its operating principle? Let’s say right away that you cannot confuse the mass air flow sensor with the outside air temperature controller, since these are two completely different devices. The primary purpose of the flow meter is to calculate the required volume of air flow that enters the engine cylinders. This air is one of the components in the formation of the air-fuel mixture. The mass air flow sensor itself in the “Ten” is located behind the air filter element.

In order for the engine to operate in normal mode, when forming a combustible mixture, the ratio of substances must be strictly observed - 1:14. If these proportions are not observed, the engine will not operate correctly, which will ultimately lead to excessive consumption of gasoline or a decrease in the dynamics and power of the vehicle. Thanks to the flow meter, the air flow is transferred to the engine cylinders in certain portions. Data on calculating the volume of air flow entering the engine is sent to the electronic control unit. In accordance with the data received, the ECU calculates the required amount of fuel.

When the driver presses the gas pedal, the volume of supplied air flow increases significantly, and accordingly, this leads to an increase in gasoline consumption. If the vehicle moves evenly, then the portions of fuel and air flow that enter the cylinders will also be the same at each cycle. When you press the gas pedal, the throttle opens, which ultimately leads to an increase in the supplied air, and this also contributes to an increase in the load on the power unit.

How the flow meter works

The first copies of the sensors worked on the principle of a pitot tube in an airplane. The incoming air mechanically deflected the petal connected to a variable resistor. The changing resistance provided approximate information about the intensity of air flow. The technology was subsequently improved, and today the vast majority of cars have thermal anemometric sensors.

Regardless of the car brand, they look approximately the same.

The housing is a hollow cylinder, the diameter of which corresponds to the air duct of the intake manifold. It contains an electronic group consisting of various sensors and a heating device. An electronic control and data reading circuit is made in a single housing.

- Two resistors in series are connected in a bridge circuit and should show the same resistance. One of them is variable, the second is reference. A variable resistor is made of platinum wire and changes resistance as the temperature changes.

- To synchronize with the reference, the wire is heated until the resistance values match. When blown with air flow, the platinum wire cools and the resistance changes. The resistor heats up (at the command of the control unit), for this purpose a certain voltage is applied to the contacts.

- The value of this voltage is recorded by the engine ECU controller with an accuracy of 1/1000 volt, and based on a calibration graph, it converts the data into air volume.

Possible malfunctions and ways to eliminate them

Now let’s look at the main symptoms of a malfunction that will help determine if the flow meter is broken:

- Increased gasoline consumption. In this case, the problem can be identified by the readings of the on-board computer, if the latter calculates the amount of fuel. If the mass air flow sensor breaks down, gasoline consumption may increase by one liter or more.

- Reduced engine power during operation.

- The car engine began to work less stably. The car takes longer to accelerate, and sometimes the engine picks up speed uncharacteristically quickly.

- The Tens power unit does not start or starts, but not immediately, after several attempts.

- Floating idle speed.

Of course, such symptoms of problems can also be associated with other malfunctions, for example, spark plugs, distributors and other components of the ignition system. Therefore, in order to accurately verify that the flow meter is not working, you will have to check the device. As for troubleshooting methods, the mass air flow sensor itself is usually not repairable, so in most cases, if there is a problem with its operation, the device is simply replaced. It happens that the reasons are due to poor contact of the device with the vehicle’s on-board network, so before replacing, we recommend checking the connection circuit, as well as the quality of contact of the device with the connector.

Types of mass air flow sensors, their design features and operating principle

Three types of VU meters are most widespread:

- Wire or thread.

- Film.

- Volumetric.

In the first two, the operating principle is based on obtaining information about the mass of the air flow by measuring its temperature. The latter may involve two accounting options:

- By changing the position of the slider, driven by a special blade, which is affected by the air flow passing through the device.

Considering the presence of rubbing mechanisms, the level of reliability of such structures is quite low. This was the main reason for the refusal of car manufacturers from sensors of this type. For reference, here is a simplified example of the design of a volumetric flow meter. Volumetric air flow sensor device - By counting Karman vortices. They are formed if a laminar air flow washes over an obstacle whose edges are quite sharp. The frequency of the vortices breaking off from them is directly related to the speed of air flow passing through the device.

Vortex sensor design (widely used by Mitsubishi Motors)

Legend:

- A – pressure measurement sensor to record the passage of the vortex. That is, the frequency of pressure and vortex formation will be the same, which makes it possible to measure the flow of the air mixture. At the output, using an ADC, the analog signal is converted to digital and transmitted to the ECU.

- B - special tubes that form an air flow similar in properties to laminar.

- C – bypass air ducts.

- D – column with sharp edges on which Karman vortices are formed.

- E – holes used to measure pressure.

- F – direction of air flow.

Symptoms of malfunction

There are several signs by which you can determine a malfunction of the mass air flow sensor:

- The check engine light comes on on the instrument panel;

- Fuel consumption increases noticeably;

- The car loses dynamics and power, failures occur when trying to increase engine speed;

- Difficulties arise when starting on a hot engine.

But what exactly causes these symptoms? The causes of sensor malfunction are as follows.

- The connector has lost contact.

- The air filter, grilles or sensor temperature detectors are dirty.

- Mechanical damage to sensor elements has occurred.

When the first signs of a malfunction occur, you should definitely check the mass air flow sensor, and then, depending on the situation, clean or replace the device.

Examination

Now let's talk about how to check our sensor. Today, two main methods of checking the mass air flow sensor are used.

- The engine is tested in operation with the mass air flow sensor disconnected. Simply turn off the power from the regulator and start the motor. When the mass air flow sensor is not present during startup, the electronic control unit turns on the power unit in emergency mode. The speed is adjusted to 1500 rpm. After disconnecting the sensor, drive a few kilometers and evaluate the dynamics and power. If the engine is running normally, then the sensor is the cause of the symptoms.

- The second method will require the use of a car tester or voltmeter. After starting the ignition, do not start the engine. The voltage threshold is set on the tester to 2V. The positive probe connects to the yellow wire on the sensor connector, and the black probe connects to the green wire. Next, refer to the table.

| Index | Air flow sensor condition |

| 0,99-1,02 | The sensor is functioning normally |

| 1,02-1,03 | Not ideal, but still acceptable voltage readings |

| 1,04-1,05 | Maximum permissible values that indicate imminent sensor failure |

| 1.05 or more | The air flow sensor has failed and needs to be replaced |

In what situations is it necessary to check the control device?

The following signs indicate that the controller has failed:

- Check is on, errors appear during system self-test;

- fuel consumption increased;

- the car began to slowly pick up speed;

- problems with hot starting of the engine;

- reduction in engine power.

Most often, the breakdown of the mass air flow sensor occurs after mechanical damage to the sensor or due to the negligence of the owner of the VAZ-2110. In particular, you need to check the condition of the rubber seal. If it is worn out, air mixed with foreign particles will enter the sensor. As a result, the wire will become dirty and the readings of the device will be distorted. The easiest way to test this device is to use a multimeter.

Methods for checking sensor functionality

How to check the flow meter yourself? There are several diagnostic options, we suggest you familiarize yourself with each of them (the author of the video is the Bezdelnik TV channel).

Shutdown

First you need to try disconnecting the flow meter from the power supply. To do this, you need to start the engine and let it run for a while. Next, you will need to disconnect the plug from the flow meter - after this, the emergency mode of operation of the motor should be activated. In this case, the volume of required air flow will be calculated in accordance with the throttle position. If, after switching off, you notice that the engine began to work more correctly and at the same time it became more dynamic, then the mass air flow sensor definitely needs to be replaced.

Diagnostics using a multimeter

Diagnostics can be performed using a multimeter; for this we recommend that you read the operating instructions for the tester. The device must be configured in the DC voltage measurement mode; it is usually marked with the symbols DCV or V.

To ensure that connecting the device does not cause difficulties, you need to know exactly the pinout of the device:

- black-red or pink contact is a connection to the control module;

- green is ground (grounding, ground), connected to the body or battery;

- gray-white contact - output voltage;

- yellow - used to supply current to the input.

Diagnostics with a multimeter is performed as follows:

- To begin with, the tester should be turned on and the voltage value set on it to 20 volts, and then the probes from the device are connected to the corresponding contacts on the plug.

- To make the connection more convenient, you can use pins; you will need two of them. Each of them is installed in a hole with green and yellow contacts. Then you will need to connect the probes of the device to these pins.

- The next step is to activate the ignition and measure the voltage. Read more about the test results below (the author of the video is the IZO channel)))LENTA).

On a working device, the voltage level will be around 1.01-1.04. If the readings are between 1.02 and 1.05 volts, this indicates that the device will need to be changed in the near future. If the readings obtained are higher, then the flow meter must be replaced because it is faulty.

It should be noted that during operation, the voltage parameter will only increase, since the resistor components of the device wear out, and the resistance value, accordingly, decreases. You can also accurately determine the voltage using the on-board computer, if it has the appropriate function. To search, go to the flowmeter voltage section and find the U value.

Visual inspection

As for visual diagnostics, first of all it is necessary to check the condition of the corrugation in which the flow meter is installed, as well as the device itself. If, as a result of the check, you see traces of motor fluid or condensation, then it is possible that the device does not work for this reason. In some cases, cleaning the device from contaminants allows the flowmeter to resume operation and prevent possible replacement. It should be taken into account that contaminants usually accumulate as a result of infrequent replacement of the air filter element (the author of the video about the regulator malfunction is the channel In Sandro’s Garage).

If you notice traces of engine fluid, then there is a possibility that the reason lies in a clogged oil seal, or the problem may lie in exceeding the permissible level of lubricant in the crankcase. When cleaning is complete, you will need to make a visual inspection of the regulator - on the front of it you can see the rubber seal that is used for sealing. The seal is necessary to prevent uncleaned air flow and it may be that the rubber band moves a little - this will lead to the accumulation of dust on the flowmeter grid.

How to check a sensor with a multimeter

The easiest way to check the mass air flow sensor is to disconnect it from the power supply and then try to start the car. If it accelerates quickly, then the controller is not working properly. In this case, it is worth checking it with an electronic multimeter. The testing device is switched to voltage detection mode up to 2 V. Then you need to take measurements. Be guided by the location of the wires, as their color may vary depending on the year of manufacture of the car. You need to find wires to measure:

- yellow – incoming signal;

- gray-white – power supply;

- green with black ground;

- black and pink, going to the main relay.

The conductors are located in the same order as in the list, if you move from the windshield. You need to connect the red (positive) probe of the device to the input signal wire, and the black (negative) to ground. After this, pay attention to the instrument readings. They can be:

- up to 1.02 – the sensor is absolutely working;

- up to 1.03 – mass air flow sensor is functioning, but contamination is possible;

- up to 1.04 – the device is operating at the limit;

- up to 1.05 – breakdown is possible in the near future;

- over 1.05 – the controller has failed.

In the latter case, it is worth replacing it or trying to restore it. Since the sensor is expensive (up to 3,500 rubles), it can be additionally checked by a motor test. This can only be done at a service station that has the appropriate equipment.

Causes of failure

Most often, the sensor fails due to contamination or age; on many VAZ 2110 cars, the sensor has not been changed from the factory, which, of course, seriously affects its operation and the operation of the entire car as a whole.

The most common causes of failure of the mass air flow sensor:

- Filter contamination;

- Aging factor;

- Mechanical damage;

- Damage to the power supply circuit;

- Oily thread contamination;

Let's briefly consider each of the reasons and how to extend the service life of the mass air flow sensor.

Filter dirty

In order for the mass air flow sensor to last much longer, change the air filter in a timely manner, since a dirty filter can damage the sensor by preventing its filament from cooling, and dust deposits may also appear on the sensor.

Aging

On older cars, the sensor loses its properties; the thread changes the resistance from its nominal parameters, which leads to incorrect determination of the amount of air and, consequently, incorrect operation of the internal combustion engine.

Mechanical damage

Quite often, when repairing a car, the sensor is subjected to mechanical stress, which can damage it.

Power circuit

A connector of several wires is connected to the mass air flow sensor; due to corrosion, some wires may be damaged, which will lead to the sensor being inoperable.

Oil contamination of the thread

With a high mileage on a VAZ 2110, oil begins to flow from the low crankcase ventilation hose into the intake tract and, in some cases, settles on the air flow sensor thread. Sometimes cleaning the air flow sensor helps solve this problem.

Let's sum it up

As you can see, the VAZ 2110 mass air flow sensor is a fairly important component of the car in the ECM device. This sensor closely interacts with the computer and determines the degree of enrichment of the fuel mixture with air.

It is quite obvious that any malfunction of the sensor will sharply reduce the efficiency of the engine. At the same time, selecting and replacing the sensor is not difficult. The main thing is to choose the right device and follow the instructions above.

We also recommend reading the article on how to replace the cabin filter on a Lada Granta. From this article you will learn when to change the cabin filter on a Grant, as well as how to change the cabin filter on a Grant with your own hands.

Finally, we note that if the sensor is dirty, it is not necessary to immediately resort to replacement. At the initial stage, it is cleaned, as well as the pipes are treated to remove accumulated debris, dust and dirt, and at the same time, all components of the sensor are inspected. However, if there is no positive result, it is necessary to purchase and replace the device.

Is the air flow sensor covered? Don't rush to buy a new one

A new sensor costs from 2 to 3.2 thousand rubles. But before we run to the nearest store or car market, let’s try to bring the old one back to life. This method of resuscitation does not provide a 100% guarantee of restoration of functionality. But it's worth a try.

First, disconnect the negative terminal on the battery. Remove the sensor from the vehicle. Remove it from the air filter housing. Disassemble the device using a Phillips screwdriver. Be careful with platinum threads, do not touch them with your hands or other objects. Clean with carburetor cleaner. Spray the liquid 3-4 times onto the areas indicated by arrows in the photo. Assemble the mass air flow sensor and install it on the car.

Accompanying photos to the process

Do not touch the platinum threads in the mass air flow sensor, as this can damage the working sensor. The mass air flow sensor can be disassembled using a Phillips screwdriver and pliers. You can try to revive the mass air flow sensor using carburetor fluid.

If you are a little lucky and act carefully, you will be able to save a couple of thousand rubles

In conclusion, I would like to note that a drop in power and an increase in fuel consumption do not always indicate a malfunction of the mass air flow sensor. But if such symptoms appear, check the air flow sensor first. Its initial diagnosis can be performed independently. An accurate check is carried out using special equipment at a service station. Be careful with your car - it will save your money and time.

What to do if the device fails

If tests show that the sensor is faulty, then you should first try to restore it. To do this you need to follow the instructions:

- Remove the negative terminal from the battery.

- Get to the air filter and remove the sensor from it.

- Disassemble the controller, being careful not to touch the platinum wire. It is forbidden to touch it, as this will disrupt the operation of the sensor.

- Wipe the remaining parts of the mass air flow sensor with battery cleaning fluid.

- Reassemble the sensor and reinstall it.

Even if you fail to restore the device, you will not lose anything. Test the restored device using a multimeter. If it shows a normal value, then you can do without replacement. When installing the sensor, inspect the air filter and seal. If the rubber gasket is worn out, you need to install a new one in its place. The need to install a new air filter is indicated by contamination of the old one.

A new mass air flow sensor is quite expensive. On the other hand, the technology for repairing it is quite simple, so almost every car owner can save a lot of money. Even a beginner can repair this device. The main thing is to adhere to the correct algorithm and use the appropriate means.

We check the mass air flow sensor on a VAZ-2110 with a multimeter

The sensor block, the first wire may not be there - this is normal.

To do this, we need to understand the pinout and the sensor connection diagram. As you can see, the block has only five wires:

- + 12 Volt.

- + 5 Volts.

- Total ground (green wire).

- Air temperature output signal.

- Air flow signal output (yellow wire).

Electrical diagram for connecting the mass air flow sensor.

The pinout may differ in different firmware versions and on different sensors. Everything is clear with the first two contacts - take a multimeter and check the presence of voltage when the ignition is on. If there is no signal, we look for the cause either in broken wires or in poor contact. Now we check the main indicator - the accuracy and magnitude of the air flow signal. By the way, this can be checked without a multimeter, using the on-board computer, if one is installed:

- We go to the menu, look for sensor parameters.

- Find the voltage Udmrv.

- The rating for all of the above modifications is from 0.996 to 1.01 V.

The platinum thread gets tired over time and distorts the impulse upward. A change of even one hundredth of a Volt is unacceptable. If the computer is not installed, we use a multimeter. We check the voltage between 3 and 5 (minus) contacts, setting the measurement limits on the multimeter to 2 V. Turn on the ignition, but do not start the engine.

The scale shows 1.00 - the sensor is in excellent condition.

On a scale of 1.26 – the sensor is “dead”.

Check table

We evaluate the result using this table:

| 0.99-1.02 V | The condition of the air flow sensor is excellent, close to new |

| 1.02-1.03 V | Sensor in good condition |

| 1.04-1.05 V | The platinum thread is worn out, you need to think about replacing the sensor |

| More than 1.05 V | The sensor does not work, urgent replacement is necessary |

Checking and repairing at home

There are eight ways to independently check amplitude and frequency mass flow sensors.

Method No. 1 - disabling the air flow meter

The method consists of disconnecting the sensor from the fuel system of the car and checking the functionality of the system without it. To do this, you need to disconnect the device from the connector and start the engine. Without a mass air flow sensor, the controller receives a signal to switch to emergency operation mode. It prepares the air-fuel mixture only based on the throttle position. If the car moves faster and does not stall, it means that the device is faulty and requires repair or replacement.

Method No. 2 - flashing the electronic control unit

If the standard firmware has been changed, then it is unknown what reaction of the controller is programmed in it in case of an emergency. In this case, you should try to insert a 1mm thick plate under the throttle stop. The turnover should increase. Now you need to pull out the chip from the air flow meter. If the power unit continues to work, then the cause of the malfunction is the firmware.

Method No. 3 - installing a working sensor

Install a known good part and start the engine. If after replacement it begins to work better, the motor does not stall, then replacement or repair of the device is required.

Method No. 4 - visual inspection

To do this, use a Phillips screwdriver to unscrew the clamp holding the air collector corrugation. Then you need to disconnect the corrugation and inspect the internal surfaces of the air collector corrugation and the sensor.

Inspection of duct corrugation

There should be no traces of oil or condensation on them, the surfaces should be dry and clean. If you do not take care of the air filter and change it rarely, then dirt can get on the sensitive element of the sensor and cause it to break. This is the most common malfunction. Traces of oil may appear in the flow meter if the oil level in the crankcase is high, or if the oil sump of the crankcase ventilation system is clogged. If necessary, you need to clean the surfaces using special cleaning products.

Method No. 5 - checking the mass air flow sensor with a multimeter

To do this, you need to turn on the tester in a mode in which constant voltage is checked. The limit value for measurements should be set to 2V.

DMRV operation diagram

- The yellow wire is located closer to the windshield. It serves as an input for a signal from the flow meter.

- The white-gray wire is the sensor voltage output.

- The black and pink wire leads to the main relay.

- The green wire is used to ground the sensors, that is, it goes to ground.

The wires may have different colors, but their location is unchanged. To check, you need to turn on the ignition, but do not start the car. The red probe from the multimeter must be connected to the yellow wire, and the black one must be connected to ground, that is, to the green wire. We measure the voltage between these two outputs. Multimeter probes make it possible to connect without disturbing the insulation of the wires.

On the new device, the output voltage ranges from 0.996 to 1.01 V.

During operation, this voltage gradually increases and by its value one can judge the wear of the flow meter:

if the sensor is in good condition, the voltage is from 1.01 to 1.02 V; in satisfactory condition - from 1.02 to 1.03 V; the sensor resource ends if the voltage is in the range from 1.03 to 1.04 V; a value in the range from 1.04 to 1.05 indicates a near-death state; if there are no contraindications, then you can continue to use the sensor; if the voltage exceeds 1.05 V, the mass air flow sensor requires replacement.

Checking the mass air flow sensor with a multimeter

- Set your multimeter to voltage measurement mode with a limit of two volts.

- Connect the positive probe to the fifth contact on the mass air flow sensor connector. The fifth pin produces an ADC signal. To make contact when the connector is connected, insert a pin without damaging the wire.

- Connect the second probe to the negative on the battery.

- Turn the key in the lock to the ignition position.

- Place the positive probe on the pin and record the reading.

In our case, the multimeter showed a voltage of 1.02V. The table below shows data on the ADC in volts and the state of the sensor.

| ADC (V) | Air flow sensor condition |

| 0.0996-1.01 | New sensor. |

| 1.01-1.02 | A working sensor with a large remaining life. |

| 1.02-1.03 | Acceptable condition, but the sensor is far from new. |

| 1.03-1.04 | Most of the resource has been exhausted, collect money to buy a new sensor. |

| 1.04-1.05 | The sensor has served its purpose and it is time to replace it. |

| 1.05 and higher | The sensor is the source of problems in engine operation. |

After checking with a multimeter, we decided to double-check this method and perform computer diagnostics at a service station. After the diagnostics were performed, we obtained an ADC value of 1.016V.

It is worth noting that for self-diagnosis you need a laptop with the OpenDiag program installed and a diagnostic cable.

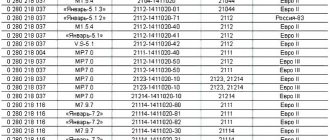

Please note that the above-described check can only be done with a mass air flow sensor from the manufacturer Bosch with catalog numbers 0280218004, 0280218037, 0280218116.

Characteristic

On VAZ cars, the mass air flow sensor is mounted between the air filter element and the throttle hose. Today, products from the manufacturer Bosch are very popular among compatriots. Regardless of whether it is a universal Bosch sensor or, for example, spark plugs, quality from a German manufacturer can always give a head start to domestic products. Let's look at the main characteristics of regulators models 116 and 037.

116

DMRV 116 is designed to control and convert the air flow that enters the motor into voltage. The data transmitted by the regulator makes it possible to determine the operating mode of the power unit and calculate the cyclic filling of the cylinders with air flow. This filling is carried out in steady-state operating modes of the motor, which last no more than 0.1 seconds.

Let's look at the technical features that Bosch 0 280 218 116 has:

- the regulator operates on the principle of measuring air flow;

- the device provides accurate data, which ensures optimal fuel consumption;

- operating range varies from 8 to 550 kg/h;

- the output pulse level when measuring the range from 0 to 100% will be about 0.05-5 volts;

- As for power supply, the controller is powered from the vehicle’s electrical network, that is, 12 volts is enough for it;

- current consumption is about 0.5 ampere;

- the regulator can function normally in the operating range from 45 degrees below zero to 120 degrees;

- The service life of the Bosch 116 mass air flow sensor is about 3 thousand hours.

Bosch 116 device

037

As for the mass air flow sensor 037 from Bosch, the technical features will be similar. The controller consists of two main elements - working and control, as well as a heating resistor device. The air that enters the engine cools one of the controllers, while the electronic module converts the temperature differences between the controllers. In the event that sensor 280 218 037 fails, its options will be performed by TPS.

As mentioned above, the technical features of the models are the same:

- the operating range for normal operation varies in the region of 8-550 kg/h;

- when operating correctly, the controller will provide accurate data, making it possible to achieve optimal gas mileage (of course, if the engine is running in normal mode);

- since the element is used in a car, it is logical that it should be powered by 12 volts;

- the controller consumes about 0.5 ampere of current;

- the part can operate normally both at 45 degrees below zero and at 120 degrees of heat, this is its operating range;

- service life is at least 3 thousand hours;

- Unlike model 116, the new one in calculations can produce an error of 2.5 percent (both down and up).

Regulator model 0280218037

DIY replacement and installation instructions

How to replace the regulator in a garage:

- First, turn off the engine and ignition.

- Next, open the hood and find the location where the mass air flow sensor is installed. You need to disconnect the plug and wiring from the regulator.

- After this, unscrew the bolts that secure the clamps, and then disconnect the intake manifold pipe. This line is connected to the air filter housing.

- After completing these steps, you must remove the flow meter from its installation location. Before installing a new mass air flow sensor, it is necessary to clean or rinse the installation site. Further installation and assembly is carried out in reverse order.

Photo gallery “Changing the flow meter”

DESCRIPTION

The MAF sensor (mass air flow sensor) measures the volume of air passing through the throttle body. The ECM uses this information to determine the duration of fuel injection and generate the appropriate air-fuel ratio. Inside the MAF sensor there is a heated platinum wire that is exposed to the incoming air flow. By passing a specified amount of current through the wire, the ECM heats it to the desired temperature. The flow of incoming air cools the wire and the internal thermistor, changing their resistance. To keep the current constant, the ECM varies the voltage applied to specified devices in the MAF sensor. The voltage level appears to be proportional to the air flow rate passing through the sensor, and the ECM uses this level to calculate the intake air volume. This circuit is designed in such a way that the heated platinum wire and the temperature sensor form a bridge circuit, and the power transistor is controlled so that the potentials of A and B remain unchanged, thereby maintaining the set temperature.

- Open or short circuit in the mass air flow sensor circuit

- Mass air flow sensor

- ECM

- Open or short circuit in the mass air flow sensor circuit

- Mass air flow sensor

- ECM

- Open or short circuit in the mass air flow sensor circuit

- Mass air flow sensor

- ECM

HINT: If one of these DTCs is set, check the air flow by accessing the following menus on the handheld scan tool: Powertrain / Engine and ECT / Data List / MAF.

- Open circuit in the power supply circuit of the mass air flow (MAF) sensor

- Open or short circuit in VG circuit

- Open circuit E2G

Features of cleaning the regulator

How to clean the regulator by washing? In some cases, cleaning actually helps to extend the life of the flow meter; this process can be called a component of repair. For cleaning, you can use specialized products designed for this specific purpose. You can also use WD-40 liquid or carburetor cleaner.

How to wash the flow meter yourself:

- First, you need to dismantle the mass air flow sensor, we talked about this in more detail above.

- Once you have the device in your hands, you will need to use a cleaning agent to wash all sensitive components of the regulator. In particular, we are talking about wire mesh, thermal sensor, and contacts. When cleaning, be as careful as possible and regularly monitor the level of pressure of the jet from the cylinder. Please note that the stream itself should not be too strong; it is best to keep the balloon at a distance of approximately 5-10 cm from the device.

- Wait a few minutes, then apply the cleanser again, wait a little again. The cleaning procedure must be carried out several times, but as practice shows, usually three times is enough to obtain the desired result.

- Then, you need to pour distillate with alcohol into a medical syringe (you can find it in any pharmacy). Using a syringe, treat all sensitive components of the device, as well as contacts, this will allow them to be thoroughly cleaned.

Main malfunctions in the sensor operation

If the sensor does not display the fuel level correctly, you can judge that a certain breakdown has occurred and needs to be repaired. Modern sensors that record the fuel level, like all vehicle parts, fail from time to time. In this case, it is necessary to repair the fuel level sensor.

Malfunction in indicators

The main sign of a sensor failure is the display of false data displayed on the pointer. Based on its “behavior,” certain conclusions can be drawn regarding the resulting breakdown. Here are the most basic types of breakdowns and their causes:

The indicator is at zero, regardless of the fuel level. The problem is that the float stop is broken. The pointer moves, but still drops to the zero mark. In this case, you need to pay attention to the general condition of the device winding, as well as the reliability of the contact between the sensor and the current collector. Fluctuations in fuel quantity indicators. This malfunction indicates sufficient wear on the contacts. When starting the engine, the fuel gauge does not rise above the zero mark. Such a malfunction is directly related to the electronics of the vehicle

Here it is important to check the wires for possible breaks and the degree of reliability of the connection. It is important to ensure the overall integrity of the fuse. Low fuel light does not light up

This problem is often associated with device failure. The fuel level sensor is lying. In such a situation, it will be necessary to check the float for the level of tightness.

According to modern traffic regulations, operating a car with a faulty indicator is strictly prohibited. Problems that arise with sensors must be eliminated as promptly as possible.

Mechanical and functional malfunction

Along with problems that are expressed in incorrect indicators, sensor failure can manifest itself in the following malfunctions:

- loss of tightness of the built-in float;

- strong bending of the wire holder;

- violation of the general tightness of the housing and the resulting decrease in the level of resistance;

- mechanical break of the variable resistor;

- loss of tightness at the point where the device is attached to the fuel tank.

After the float loses proper tightness, the control device, with a full tank, will indicate an incomplete fuel level. If there is a sufficiently strong loss of tightness, the indicator will immediately show the minimum fuel level. In this case, the actual quantity will not matter. To fix this problem, you will need to remove the sensor and replace the float. If it is not possible to purchase a float, you will need to completely replace the entire device.

Quite often, the sensor fails due to long-term movement over rough or uneven terrain. Repeated impacts on the tank will cause serious damage to the wire holder of the built-in float.

With such bends, the behavior of the indicator will directly depend on where the holder was bent. If the bend is directed upward, the parameters will always be increased, if downward, the parameters will be underestimated. If the breakdown involves such a bend, you just need to straighten the wire holder and give it its original shape.

Often the seal of the sensor housing is broken. This happens after an accident has occurred, as well as after long-term use of low quality fuel. If gasoline gets into the device, it will malfunction and, as a result, cause incorrect sensor readings. These malfunctions can only be eliminated by completely replacing the device.

If the variable resistor breaks, this will cause the sensor to always show a full or completely empty tank. Similar signs can be observed in the process of a break in the signal wire running from the sensor to the display unit. Before removing the sensor, you will need to connect a variable resistor with a resistance level of 100 - 200 Ohms to the car body and to the signal contact. As you rotate the knob, you need to make sure that the sensor readings change. In this case, the malfunction can only be eliminated by completely replacing the device.

This is interesting: Updated Subaru Forester

The main sign of a complete loss of tightness at the installation site of the device is the appearance of the smell of gasoline in the cabin.

When you need to change the DFID sensor 2110: symptoms of sensor malfunction and check

During the operation of a vehicle, the mass air flow sensor 2110 can fail for various reasons, one of which is the long period of use of the device. When a sensor fails, it is usually not repaired; it is simply replaced with a new one. The following symptoms may indicate that the sensor is not working properly:

- “Check Engine” lights up on the car’s dashboard (you need to check the engine);

- fuel consumption increased, acceleration dynamics decreased;

- the car engine does not start;

- at idle, the car’s internal combustion engine operates jerkily (change in idle speed down or up).

All of the listed signs of sensor malfunction indicate that air is not being supplied to the mixture in the volume required. Taking into account the fact that this problem may be associated not only with a malfunction of the mass air flow sensor, before proceeding with dismantling the sensor, it is necessary to make sure that it is faulty.

In fact, the VAZ 2110 mass air flow sensor can be checked for performance using three methods: in motion, with a multimeter, visually. Checking the mass air flow sensor 2110 experimentally (in motion) is the easiest and fastest way. It consists of analyzing the operation of the vehicle’s internal combustion engine when the sensor is forcibly turned off.

Algorithm of actions:

- opening the hood, disconnect the mass air flow sensor connector;

- start the car engine;

- since the car will operate in emergency mode, the “Check Engine” light will come on and the amount of air in the fuel mixture will be determined depending on the throttle position;

- Having driven a car operating in emergency mode, you need to pay attention to its dynamics and compare them with the dynamics before the sensor was turned off;

- If the car accelerates faster with the sensor turned off, the air flow sensor is faulty.

The next stage of diagnosis may be checking the mass air flow sensor 2110 with a multimeter. This method of checking the sensor for functionality involves the use of a measuring device (multimeter).

Before checking, you need to understand the design of the device and find out its “pinout” (soldering of wires on the board). There are four wires coming out of the MAF. Typically these are the wire to the main relay (pink/black or pink), ground (green), power (gray), and signal input (yellow).

To check you need:

- set the multimeter to constant voltage measurement mode, setting the limit to 2 Volts;

- without starting the engine, turn on the ignition;

- connect the black multimeter probe to the ground wire, the red one to the signal input of the multimeter sensor, inserting the multimeter probes through the rubber seal of the connector;

- take measurements and use the results to determine the state of the sensor.

Based on multimeter readings:

- voltage 0.996-1.01 Volts (new sensor);

- voltage 1.01-1.02 Volts (working sensor in good condition);

- voltage 1.02-1.03 Volts (sensor working, with long-term operation);

- voltage 1.03-1.05 Volts (sensor is worn out and may fail);

- voltage from 1.05 Volts and above (the sensor is faulty and requires replacement).

If the device is not at hand, the faulty sensor can often be determined by its appearance, that is, by visual inspection. In this case, it is necessary to dismantle the device and carefully inspect it for mechanical damage or for the presence of liquid in the sensor and air pipe.

The reasons for liquid and dirt getting into the sensor can be different (for example, the oil level in the crankcase is increased, dust gets on the hot-wire anemometer due to untimely replacement of the air filter, the oil sump of the crankcase ventilation system is clogged, etc.).

What does a DMRV failure lead to?

Faulty mass air flow sensor

may lead to the following manifestations of vehicle operation.

- The engine does not start (this is very rare and on VAZ

cars the mass air flow sensor is not capable of affecting the engine’s operation so much; moreover, if you turn it off completely, the on-board computer will set the default value) - Changes in idle speed - they may increase or, on the contrary, decrease

- Increased fuel consumption with decreased acceleration dynamics. (incorrect readings from the mass air flow sensor interfere with the correct preparation of the fuel-air mixture).

- Check Engine

light on the dashboard.

In general, monitor the technical condition of your car and carry out all possible scheduled work on time to prevent engine breakdowns, including timely oil and filter changes.

- 219 11 151k

This photo report shows in detail how to do it yourself using the folk method to check the mass air flow sensor (MAF) on a VAZ 2110 car.

The procedure is very simple, a beginner can easily handle it. You will need a multimeter and a couple of metal pins. If the results of checking the air flow meter also show that it is not functioning correctly, then cleaning it is unlikely to help - the mass air flow sensor will have to be replaced.

We plug the + and – wires into the multimeter. Set the voltage to 20V.

We take 2 pins and stick them into the MAF wires, one on the yellow wire, and the second on ground, the green wire.

We stick the negative and positive wires into the pins. Plus yellow, minus green.

Turn on the ignition and the multimeter takes a measurement. The result is a voltage of 1.05V.

Some articles measure voltage in a slightly different way, which is not entirely accurate.

The positive wire was also inserted into the yellow wire.

But minus, for the weight of the body. We stick it between the hood lock springs.

The result changed a little, the multimeter showed 1.06V.

If the sensor is completely live, then the measurement should range from 0.99 to 1.00.

The mass air flow sensor is a mass air flow sensor. It is an electronic device that serves to count the amount of air entering the cylinders from the air filter.

Depending on the volume of air passing through the sensor over a certain time period, the corresponding information is transmitted to the electronic control unit via a pulse signal. Based on the pulse frequency, the ECU determines the ratio of fuel and air in the air-fuel mixture, and controls the operation of the injector injection.

On a VAZ 2110, this sensor is located on the outlet pipe of the air filter, connecting it to the corrugation.

Searched element

Replacing the air flow sensor

To replace the VAZ 2110 mass air flow sensor, you need a part suitable for this model (the new sensor must have the same markings as the old one). In terms of selection, there are three price categories:

- Chinese-made sensors (relatively inexpensive);

- mid-price sensors from the manufacturer AvtoVAZ and some foreign manufacturers;

- high-quality and reliable, but quite expensive imported sensors;

When choosing a new sensor, you should focus on both the price and the manufacturer (Siemens, Bosch, etc.). In any case, you can buy a VAZ mass air flow sensor at any auto supply store, taking into account financial capabilities and personal preferences. Replacing the mass air flow sensor itself involves dismantling the old device and installing a new one. The procedure is quite simple, accessible to every car owner and can be done with your own hands. Before replacing the sensor, it is necessary to carry out a number of preparatory work:

- buy a mass air flow sensor with the same markings as on the body of the old sensor;

- prepare the necessary set of tools, screwdrivers of different sizes, wrenches or socket wrenches or wrenches with socket heads;

- multimeter (if necessary).

General procedure:

- Place the car on a level surface, lift the hood, remove the negative terminal from the battery;

- disconnect the mass air flow sensor connector;

- loosen the fastening screw of the corrugated hose with the mass air flow sensor housing;

- using a “10” wrench, disconnecting the hose, unscrew the two mounting bolts of the sensor with the air filter housing;

- Remove the old sensor housing and replace it with a new one, installing it in the reverse order of removal.

Please note that after the repair it is necessary to make a test drive to check the dynamics and power. You may also need to replace the air filter if the existing filter element is too dirty. It is also recommended to blow out the air filter housing with a compressor before assembly.

Interchangeability

This issue is quite relevant, especially taking into account the cost of original products from the imported automobile industry. But it’s not so simple here, let’s give an example

In the first production models of the Gorky Automobile Plant, the injection Volgas were equipped with a BOSCH air flow sensor. Somewhat later, imported sensors and controllers replaced domestic products.

A – imported filament air flow sensor manufactured by Bosh (pbt-gf30) and its domestic analogues B – JSCB “Impuls” and C – APZ

Structurally, these products were practically no different with the exception of several design features, namely:

- The diameter of the wire used in a wirewound thermistor. Bosch products have a diameter of 0.07 mm, and domestic products have a diameter of 0.10 mm.

- The method of fastening the wire differs in the type of welding. For imported sensors this is resistance welding, for domestic products it is laser welding.

- Shape of a thread thermistor. Bosh has a U-shaped geometry, APZ produces devices with a V-shaped thread, and products from JSC Impulse are distinguished by the square shape of the thread suspension.

All the sensors given as an example were interchangeable until the Gorky Automobile Plant switched to film analogues. The reasons for the transition were described above.

Film air flow sensor Siemens for GAZ 31105It makes no sense to give a domestic analogue to the sensor shown in the figure, since outwardly it is practically no different.

It should be noted that when switching from filament devices to film devices, most likely, it will be necessary to change the entire system, namely: the sensor itself, the connecting wire from it to the ECU, and, in fact, the controller itself. In some cases, the control can be adapted (reflashed) to work with another sensor. This problem is due to the fact that most filament flowmeters send analog signals, while film flowmeters send digital signals.

Where is the VAZ MAF sensor located?

If you do not know where your mass air flow sensor is located, then read the text carefully. On any car, be it a VAZ series 2110, 2111, 2112 or any other brand, the installation location of the mass air flow sensor DMRV is the same. The manufacturer installs this sensor after the air filter. Having found the wires going to the sensor installed after the air filter, in 99% it will be the mass air flow sensor. We look at the photo below of the owner of AvtoVAZ.

Where is the mass air flow sensor installed VAZ 2110, 2111, 2112 DMRV

Let's summarize

From the above, we can conclude that you can check the VAZ 2110 mass air flow sensor using a multimeter yourself. By comparing the ADC readings with computer diagnostics, we can say that the test with a multimeter is correct.

It is also worth noting that if you want to maximize the life of the air flow sensor, change the air filter more often. The manufacturer recommends replacement every 30 thousand kilometers. We recommend reducing this interval to 20 thousand kilometers, and if you mainly travel on dusty roads to 15 thousand km. mileage

The process of replacing the MAF VAZ 2110, 2111, 2112 is clearly shown in this video:

Source