Before considering the main topic of the article - which grenades are better for the VAZ 2114, you should first understand what this part is. A CV joint (otherwise called a grenade because of its characteristic shape) is an element of the front suspension of a car, extending from the hub of each wheel. It has an oblong shape with a thickening at the end. Its main purpose is to transmit torque at maximum rotation angles (reaching 70 degrees).

CV joint VAZ 2114

As for its service life, it can be noted that initially CV joints were created as elements with a very long service life (in some cases equal to the service life of the car itself). But, in practice, damage to the grenade occurs quite often, and the main reason for this is wear or cracks on the CV boot, allowing dust and dirt to get inside, violating the integrity of the structure and causing its damage.

Checking the damage to the grenade is quite simple - you just need to turn the car's wheels as far as possible in any direction and inspect the suspension. If the boots are damaged (that is, have cracks or tears), they should be replaced immediately. And in a situation where a grinding or other extraneous noise emanating from the suspension is heard while driving, conclusions can be drawn about the damage to the grenade and its failure.

In this case, it is categorically not recommended to continue driving - firstly, it is very dangerous and can lead to road accidents, and secondly, driving with a faulty CV joint can lead to the breakdown of a number of other parts and mechanisms, as a result of which the total cost of repairs is significantly will increase.

CV joint location

If the CV joint is damaged and noise is heard from the front suspension, it is absolutely forbidden to continue driving. This can not only lead to damage to other elements of the car, but is also very dangerous to life.

Which grenades are better for the VAZ 2114: choosing the best option

Before considering the main topic of the article - which grenades are better for the VAZ 2114, you should first understand what this part is.

A CV joint (otherwise called a grenade because of its characteristic shape) is an element of the front suspension of a car, extending from the hub of each wheel. It has an oblong shape with a thickening at the end. Its main purpose is to transmit torque at maximum rotation angles (reaching 70 degrees). As for its service life, it can be noted that initially CV joints were created as elements with a very long service life (in some cases equal to the service life of the car itself). But, in practice, damage to the grenade occurs quite often, and the main reason for this is wear or cracks on the CV boot, allowing dust and dirt to get inside, violating the integrity of the structure and causing its damage.

Checking the damage to the grenade is quite simple - you just need to turn the car's wheels as far as possible in any direction and inspect the suspension. If the boots are damaged (that is, have cracks or tears), they should be replaced immediately. And in a situation where a grinding or other extraneous noise emanating from the suspension is heard while driving, conclusions can be drawn about the damage to the grenade and its failure.

In this case, it is categorically not recommended to continue driving - firstly, it is very dangerous and can lead to road accidents, and secondly, driving with a faulty CV joint can lead to the breakdown of a number of other parts and mechanisms, as a result of which the total cost of repairs is significantly will increase.

If the CV joint is damaged and noise is heard from the front suspension, it is absolutely forbidden to continue driving. This can not only lead to damage to other elements of the car, but is also very dangerous to life.

Fault diagnosis

The VAZ 2114 has 2 external and 2 internal CV joints. First you need to determine which one is knocking. The optimal test would be on a suspension diagnostic stand. If this is not possible, diagnosis by ear is possible.

Two signs indicate a grenade malfunction in a VAZ 2114:

- the sound resembles a crunch;

- It usually appears when turning.

The simplest and most accurate way to do a garage check is as follows:

- Place the car on a flat surface;

- Turn the wheels to one side (to the middle position or a little further);

- Drive off with medium speed. It is worth remembering that starting too smoothly may not reveal a crunch due to insufficient load on the CV joint, and starting too abruptly may lead to the drive flying out of the wheel.

- Repeat the operation by turning the steering wheel in the other direction. The appearance of a crunch indicates a malfunction of the outer CV joint on the side in which the steering wheel is turned.

Replacing CV joints

In order to replace a failed grenade, it is not at all necessary to contact a service center. The motorist himself is quite capable of performing this procedure.

Tool

In order to replace CV joints, you will need the following set of tools and accessories:

- jack;

- shoes;

- set of socket heads;

- spanners;

- special lubricant for CV joints;

- a clean cloth or rags;

- new anthers.

To increase the service life of CV joints, you should regularly check the condition of their boots. Even a small crack on the boot can cause the CV joint to fail.

The repair itself can be carried out anywhere, but it will be much better if the car can be placed on an overpass or placed above a sufficiently deep repair pit - this will greatly facilitate the efforts of the car enthusiast and make the process itself more accurate.

Process

The entire replacement of grenades occurs as follows:

- Turn off the engine and put the car on the handbrake.

- Stop the wheels with shoes (if necessary).

- Using a bolt remover, unscrew the wheel bolts.

- Raise the front of the car.

- Remove the retaining ring in the center of the grenade.

- Using a 13mm wrench, unscrew the fasteners of the ball joint in the upper part (it is not necessary to unscrew the fasteners of the lower part - they will not interfere with the process).

- Using a pry bar, slightly move the support out of the grooves.

- Knock the hub off the CV joint splines (use a soft hammer or spacer board!).

- Remove the broken CV joint.

- Check the mounting rod for damage.

- Remove old grease from the rod using a cloth.

- Install the new CV joint in place (namely, the CV joint itself, retaining rings, nuts, clamps and a new boot).

- During assembly, the assembly should be generously, but not excessively, lubricated with a special lubricant.

After the new CV joint is installed in its place, all that remains is to reassemble the entire assembly in the reverse order. At the same time, it is worth paying special attention to the installation and tightening of the hub lock nut - this should be done exclusively using a torque wrench and tightened strictly with the force specified in the car’s passport. But we’ll talk about which grenade is better to put on a VAZ 2114 below.

Features of the tripoid joint

Due to the use of needle bearings, tripoids are more resistant to wear, and friction losses of elements in the assembly are also reduced.

Characteristics of tripoid CV joints:

- Possible bending angle up to 18 degrees,

- Maximum axial movement up to 55 mm,

- Engine and gearbox vibration compensation more than 60%.

Also, the tripoid cannot immediately fail, immobilizing the car, which is important for lovers of off-road driving. Despite the sharp crunch and vibrations that arise, the emergency tripoid CV joint will allow you to get to the repair site under your own power.

What brand of grenade should I choose and what boots should I install?

Almost all motorists who are faced with a breakdown of this element are wondering - which CV joint is better for a VAZ 2114 - domestic or imported? The answer to this question can be completely unambiguous - the best CV joints are the original ones, produced by AvtoVAZ itself.

The only difficulty that exists here is that such grenades have not been and are not on sale, so it is very difficult to get them.

You can either try to look for them at auto repair shops (however, here you can unknowingly buy used ones, which is not very good - after all, the part may already be damaged) or go to an official AvtoVAZ service center (but the price will be very high). For these reasons, it would be best to look at products from other manufacturers.

So, the answer to the question which outer CV joint for the VAZ 2114 is better can be any of the following companies:

- Lobro;

- Hola;

- Kraft;

- GKN;

- GLO;

- FINWHALE;

- LPR;

- Mettelli.

The first three companies on this list are especially popular among domestic car enthusiasts, so if there is a choice in a car store, it would be better to give preference to them. Also, when buying new grenades, you should not forget about buying new boots (mounting new CV joints with old, albeit “working” boots, would be a very big mistake).

It’s not worth talking in detail about which CV joint boots are best for the VAZ 2114. All anthers can currently be divided into two types - ordinary, almost no different from the anthers installed at the factory, and the so-called “reinforced”.

When buying the latter, it is worth remembering that along with them you should also buy mounting clamps of an increased size, since clamps from ordinary boots will not fit. All of these anthers have approximately the same quality, regardless of the manufacturer (some believe that silicone anthers last a little longer, but, as practice and reviews from many motorists show, the difference between silicone anthers and conventional ones in terms of service life is minimal).

The most important thing to do when buying anther is to check its quality. It must not have cracks, tears or other damage. The CV joint boots should be replaced with new ones at the first signs of wear.

Useful video

You can get more information on this issue from the video below:

- Are you here:

- home

- Rating

The safe movement of the car depends on the quality of this part. If you do not pay attention to the symptoms of its defect, then the “grenade,” as a car service technician calls a CV joint, may explode: the wheel will fall off the suspension. In our review we will look at the best manufacturers of CV joints. Let's get acquainted with the pros and cons of these parts, and tell you about the rules for purchasing a CV joint.

Content:

- GKN

- NKN

- Stellox

- Hola

- GSP

Lubricant testing

The tests included the following checks:

- Rinse with water and protect the unit from penetration of this liquid into it.

- Fluidity when the temperature rises to 180 ○C.

- Lubricating properties.

- Resistance of the lubricating film to pressure.

- Wear of metals protected by lubricant.

Places during the testing process were not allocated to the competitors, they were simply graded, so you will have to determine which lubricant is better. Below are the results of testing of ball joint greases by one of the independent researchers.

- CV joint-4 manufactured by AZMOL JSC, Berdyansk. Rated "Good".

- CV joint-4M manufactured by Sibneft OJSC Omsk Oil Refinery. Rated "Good".

- LM 47 Langzeitfett manufactured by Liqui Moly GmbH (Germany). "Excellent" rating.

- Chevron Moly Grease EP 2 manufactured by Chevron Products Company, San Francisco (USA). "Excellent" rating.

- Castrol MS/3 Spezialfett manufactured by Castrol (Germany, Hamburg). "Excellent" rating.

- BP Energrease L21M manufacturer British Petroleum British oil and gas company.

The best CV joint manufacturers

Automotive stores have a large selection of similar products. They differ from each other in cost and manufacturer. We list the companies whose products are in high demand among car enthusiasts.

Description. The company's CV joints do not require balancing during installation, which reduces installation time. The signature feature of German manufacturers is the availability of lubricant “to capacity”. This makes the part maintenance-free until the end of its service life.

GKN joint devices provide an optimal balance of power and torque of the vehicle engine. The anthers of the product are made from high-quality plastic and neoprene, capable of operating at high temperatures.

Equipment. The kit includes: CV joint, boot, snap ring, gasket and fasteners.

Life time. With proper operation, it lasts about 80 thousand km.

- Long working life.

- Reliable components: clamps, boot, fastening.

- Plenty of lubrication.

- Metal quickly becomes covered with rust.

- High price.

Description. The reason for the Japanese success should be sought in the use of innovative technologies in the development of parts. So, during production, the cold forging method is used. The resulting parts are coated with a protective layer of molybdenum and impregnated with carbon at high temperatures, which ensures increased strength of the products.

The company also does a lot of work to protect its products from counterfeit goods. For this purpose, original packaging materials have been developed; the name of the part on the box is covered in gold. Inside the package there is a thank you note from the manufacturers for purchasing the product: “Thank you.”

Equipment. In addition to the part itself, the CV joint kit includes a boot with lubricant, two clamps, a retaining ring and fasteners.

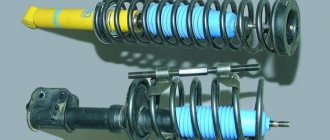

Tripod CV joint with needle bearings

A tripoid grenade design is often used as an internal hinge on modern cars:

In the body of such a hinge there is a three-beam fork, pressed onto the splines of the driven shaft. Three working rollers are attached to the ends of the fork, which can move along the guide grooves of the body when the unit is rotated or axially displaced.

To protect tripod joints from wear and metal scuffing, special synthetic compounds without solid additives are used.

Types of CV joints

There are two types of CV joints: external and internal. The first of them is located behind the drive wheel behind the hub and ensures rotation of the wheel (up to 70°) in different planes.

It is equipped with an elastic boot that protects the mechanism from the harmful effects of moisture, dirt, and dust. The failure of this rubber part means that it is time to change the CV joint itself.

The internal constant velocity joint is located next to the gearbox, connecting it to the axle shaft. Its operating range is much smaller - up to 20°. its purpose is to dampen suspension vibrations and engine vibration.

CV joints can be:

- Tripoid.

- Ball.

- Cam.

- Cardan-coupled.

The most popular type among car manufacturers is tripoid. It is distinguished by reliable operation and long service life. Such a hinge can ensure reliable operation when the vehicle is moving at high speed.

The ball version is also popular. It uses balls instead of rollers installed in the tripoid.

The cam type is installed on vehicles operating at low speeds. Trucks and commercial vehicles are equipped with cardan joints.

What are the differences between tripoid and ball

They differ from each other in that the ball type has balls, dividing grooves or levers, while the tripoid type has rollers with a spherical surface and a fork.

The joint where balls are used is usually:

- frame;

- clip with grooves;

- six balls in the grooves of the cage;

- a separator holding these balls;

- protective cover with CV joint lubricant.

This CV joint is connected to the drive shaft through splines.

The tripoid joint has a housing that houses the three-arm fork. It is pressed onto the splines of the output shaft. Three rollers with a hemispherical surface, rotating on needle bearings, are mounted on the fork arms. Under them, grooves are cut out in the tripoid body, thanks to which the desired angle of rotation of the hinge is created and the possibility of longitudinal displacement is created. The functions it performs differ depending on whether the CV joint is internal or external.

Thus, the main difference between CV joints is that the first rotates with the help of balls, and the second - thanks to needle bearings.

Which CV joint to buy

To purchase the hinge device you need for your car, you need to know the following.

1. Tell the seller the VIN code of the car, by which he can easily find the required part in his catalog. As a last resort, it is necessary to indicate to him the make and model of the car, the year of manufacture, as well as the characteristics of the power unit.

2. Specify the type of product: internal or external CV joint, as well as its installation location.

3. Compatibility of the CV joint with the ABS system. Parts that interact with the anti-lock braking system have design differences from products installed on cars without ABS.

4. Check the compatibility with the replacement part in terms of dimensions to exclude an error in the part chosen by the seller.

5. Conduct a visual inspection of the product to determine whether it is of poor quality. A hinge device with burrs and poor polishing indicates a fake.

6. Inspect the packaging. Manufacturers of counterfeit goods do not bother to produce high-quality packaging.

You should also pay attention to the manufacturer of the product.

CV joint with ball bearings

In general, the part is a housing with a driven shaft (trunnion), into which a holder (knuckle) is inserted. On the inner surface of the body and the outer side of the cage there are guide grooves along which six balls move, held by the separator. The splined part of the drive shaft is inserted into the central hole of the knuckle. To ensure stable operation, the installed hinge is filled with lubricant and sealed with a rubber or silicone boot. For ball CV joints, thick lubricants with molybdenum disulfide are used.

Which CV joints should I choose for VAZ (Lada) 2113/2114/2115?

Last month, PartReview users gave preference to GKN. 17% of positive votes belong to this manufacturer.

In second place were PILENGA CV joints - 5%.

TRIALLI closes the top three with a result of 5% of the votes.

In the general rating of CV joints, which takes into account the opinions of owners of different brands and models of cars, these brands occupy the following positions:

- GKN received 1st place, PR score - 75. Data from 84 reviews and 273 votes are taken into account.

- PILENGA has not yet managed to collect the required number of reviews to participate in the rating. If you add a review and indicate this brand and model of your car, you will help fix this.

- TRIALLI - 9th place, and the PR score was 68. Data from 51 reviews and 161 votes are taken into account.

Other spare parts for VAZ (Lada) 2113/2114/2115

Having found out which CV joints owners of VAZ (Lada) 2113/2114/2115 prefer to install, you can look at other popular spare parts for this car. In October 2022, the leaders on PartReview were:

- #1 KYB shock absorbers - 19% of votes.

- #1 ATE Brake Discs - 10% of votes.

- #1 ATE Brake Pads - 6% of votes.

- #1 Shell Motor Oil - 10% of votes.

- #1 BRIDGESTONE tires - 8% of votes.

You can also find out what the owners of VAZ (Lada) 2113/2114/2115 chose among manufacturers of such spare parts as: Engine mounting, Timing belt, Cooling radiator, Pump, Thermostat, and others.

Which CV joint to choose VAZ 2114

CV joint on VAZ 2114 : replacement without problems

The CV joint on a VAZ 2114 is replaced after diagnosing its malfunction. As a rule, this unit confidently covers more than 100 thousand kilometers. CV joint service can fail early if the car owner does not monitor the integrity of his saws and change them in a timely manner. Large amounts of dirt then enter the hinge mechanism through cracks or gaps, making the assembly unusable very quickly. Symptoms of a bad workpiece include a knocking sound and a clear sound when the front wheels turn in any direction.

An operation such as replacing a constant speed connection on a VAZ 2110-14 does not take much time. You need to place the car on an inspection hole or overpass to perform. Under the rear wheel, diagonally removed from the removed one, it is necessary to put on the pads. If the ditch has poor lighting, you can use an LED flashlight that can be mounted on your head. This will free both hands to work. Here is a list of other replacement tools:

- a set of keys or heads;

- pliers;

- hammer;

- ball rod extrusion puller;

- pressure;

- ball wrench and jack;

- screwdriver;

- Grease CV joint-4;

- rags.

The extractor puller is a metal cup with a side groove and a threaded rod for extrusion. A fairly common device, it can be found among many car enthusiasts.

Assembly Guide

Before removing the wheel from the faulty device, it must be loosened with a 30 mm cap by first pulling the metal cover out of its socket. Follow the instructions below:

- Unscrew the wheel bolts with a wrench, lift the car with a jack and remove the wheel. the hub nut completely and remove the washer using a screwdriver. If the engine oil pan is installed in the car, it will need to be removed. Some experts recommend draining some of the oil before removing the drive. Gearboxes (1.5-2 l), so that when the unit is removed it does not start to flow through the slot hole.

- Loosen and unscrew the steering wheel ball nut and remove the pin from the socket in the front suspension. Returning for convenience the entire assembly by hand unscrew the 2 bolts securing the ball. Holding the brake rotor with both hands, carefully pull the CV shaft out of the hub spindle and move it to the side.

- The other end of the VAZ 14 articulated joint must be removed from the twisted part in the gearbox, while being in the inspection ditch. To do this, you will need to install a mounting knife between the box body and the grenade, and then sharply pull the assembly out of the socket, using the mount as a lever. If the part cannot be used, it can be torn out of place by light blows of a hammer on the mounting blade. Before removing it, it is recommended to replace the tank under the transmission, as it may leak oil. The entire collection is then manually deleted. Further disassembly requires whiskey.

CV joint VAZ. Lada grenade. Comparison of different manufacturers

Consideration of CV connection

(grenades) for

VAZ

2108-2115.

CV connection for VAZ 2108-2115

Everything related to the AvtoVAZ conveyor has been forged. Any item purchased at a car dealership can be counter-offensive.

Disassembling the CV connection VAZ 2114

The block shaft is securely clamped in a vice, closer to the outer grenade if the outer joint is connected. Here you should check the condition of the saw. If there are no cracks or damage, and the rubber continues to be elastic, then only one collar should be opened to hold the trunk to the grenade body.

Then it is turned outward or simply shifted so as not to interfere. Then, holding part of the grenade with one hand, apply a light blow with a hammer from inside its edge. If the grenade needs to be replaced there is no need to worry, it can be beaten until it comes off the splined shafts. The pillow with defects is turned over, the second clamp is loosened and the part is removed from the shaft. The interior CV connection is disassembled in the same way as the exterior, you only need to clamp the shaft in the handle next to the grenade itself.

Installation of new parts and assembly

First of all, the CV connection is loaded when necessary. This is done in reverse. The sequence is: first clamp the shaft, put on the new shoe, and then slide the clamp and tighten it. Do not try to place the barrel on the shaft using a clamp, this is very inconvenient. For these purposes, it is better to take new clamps. The next step is to install a new grenade on the shaft so that the cracks line up.

Then, through a wooden spacer, with a light blow the hammer is pushed towards the shaft until it stops. Warning! Before assembly, make sure there is no grease inside the ball joint, usually there is not enough oil there. According to the documentation for the VAZ 2114 car, the cavity of the internal grenade must contain at least 80 cm³ of oil, and at least 40 cm³ of external oil. As a lubricant, it is necessary to use special thick oil “CV joint-4”.

FakeHeader

Comments 31

How are the grenades going?

How are the grenades going?

I have a tripoid, I’m not complaining, before this it was simple. Today a salesman came into our store and said that tripoid is better!

A tripod is an internal CV joint. And a ball CV joint is an external CV joint. They have a different operating principle and purpose of work! WHAT IS THE ESSENCE OF THIS?

ahh I understand everything. Internal one, old model or new! Of course, a tripod is more reliable. It won’t crunch, but the backlash is less with a ball-type one. YOU CHOOSING IT, BUT I WOULD PUT A BALL-BOARD

The ball one was also internal, but I already changed it today to a tripod. As I understand it, this type of CV joint is more reliable on all foreign cars; I trust gas tank engineers more than ours.

The only difference is that ours are sitting over the hill)))

I think the first type of CV joint is better in design, because internal CV joints are installed exactly like this on modern foreign cars.

It doesn’t matter whether it’s the first or the second CV joint. I tried both in my field. As the practice of “raping” CV joints has shown, they always broke in the wrong part. The most important thing is that the CV joint must be original, properly hardened, and not a Chinese basement raw material!

>>>CV joint must be original, properly hardened, and not Chinese-basement raw material! Well, you yourself wrote that the tripod should be original, and not some kind of sticky one, so you can’t see the difference.

Slightly different operating modes provide their own corrections for the condition of components and assemblies. Everything can be broken. I install CV joints of the highest quality that I can find in the city. Not a single grenade has yet broken in the moving part - that’s what I’m talking about. It makes no difference whether it is tripoid or not, both will perform their functions. If the moment is extremely high, then it occurs in the area of the spline part. But in this case, if the grenade is of high quality, then it will be extremely difficult to break it, regardless of its design.

If you are interested in how grenades break on all-wheel drive with a locked differential, I can show you in pictures

NO, why bother showing it). It’s understandable, you have a field, and he has a chisel, he will be much better off with a tripod than with an ordinary grenade, the tripod will withstand much greater loads than an ordinary CV joint, this is a fact, and a proven one, but as I told someone here - then, if you want something good, then fork out for it, or take the usual, but good one. I myself have internal tripods, the previous owner did not cheapen and installed parts of very good quality, but the external ones are ordinary, one of them is GLO, I know for sure, because I installed it myself).

Today I changed the ball grenade to a tripod, I took the LGR company, it costs 200 rubles more than the ball one

the very first picture, this CV joint is better... I had a GLO (the same manufacturer) and it’s an example of reliability - one bad guy knocked my boot off and I drove for a week (it’s a pity I didn’t know about that), and then I drove 1600 km in a couple of days, and while inspecting the car I saw the remains of the boot, took it apart and was surprised - only two of the 3 bearings were alive, everything was covered in drying mud, and the drive did not jerk when turning and accelerating, and there were no clicks... but a cage-type CV joint would have eaten its brains out long ago with a bang

Thank you all very much for your advice. Tomorrow I’ll go change the grenade to a tripoid type.

When I installed it for myself quite recently, the master told me that a grenade with 3 balls will live longer and is somehow better, but at high speeds it seems to give vibration... that is, if you have a terribly charged car and you don’t drive, but fly, then yours option 2, and if you are for everyday driving then option 1 will last longer! This is approximately how I understood his words!

Well, you didn’t quite understand his words correctly. It’s better to put a tripod on a charged car, it’s stronger and more reliable, but you have to pay a lot for a good tripod...

I installed the 1st version of the Indycar company, drove 20 thousand so far it’s holding up...

I also have a tripoid on the left, it’s better either way)

a little wrong, the one with 3 “balls” holds more torque but doesn’t like a large angle very much, so as a rule the tokae is installed as an internal CV joint, but with 5 balls it bends better, so these are installed as external grenades, but in fact it all depends on the quality of the manufacturer

I can’t answer which one is better, but I know for sure that the first option is on an old Mazda like 626. I think that Mazda has better engineers than ours. PS Of course, it depends on the manufacturer.

Fords also have one like this, a tripoid, there’s only one problem with it: there are three bearings in it and the bearing needles tend to fall apart

The first is tripoid type. It is believed that they hold more torque and, most importantly, are less critical at large angles. But in the end it all depends on the manufacturer of the part and the quality of the lubricant. The Chinese tripod is worse than the real stock one.

Which manufacturer do you recommend? I'll go change the grenade tomorrow anyway

About two years ago I focused on manufacturers, as I worked in this field. I don’t know how it is now. The good ones were GLO and GKN (not tripoid), but among the tripoid ones there were only Chinese ones. I only saw non-Chinese ones in price lists, it makes sense to look through online tuning stores, you could come across such CV joints there.

+100! I support! the main thing is not to buy a fake

A little theory

CV joints (constant velocity joints) perform one single, but very important task, namely the transmission of torque at rotation angles of up to 70 degrees relative to the axis.

CV joints are used only in all-wheel drive and front-wheel drive vehicles to ensure the front wheels turn and rotate under load.

CV joints are divided into:

- Internal

-

transmit torque from the gearbox to the drive shaft. - External

-

transmit torque directly to the wheels.

I will not analyze in detail the structure of CV joints, since the article will turn out to be too long and tedious, and you decided to read it only in order to find out how to carry out a quick and effective diagnosis. Therefore, I will simply advise you to check the CV boots more often, since some manufacturers themselves say that generally CV joints only have to be changed when the boot breaks.

Well, now let's get straight to the point.