Causes of malfunction

The VAZ 2110 8 valve engine is not complex in its design features, and therefore it is quite easy to establish the reasons. But, beginners cannot cope with the task and are forced to contact a car service, which is not always necessary. In fact, the VAZ 2110 engine has 8 valves for several reasons. Let's look at where to look for reasons:

- Malfunctions of the injection system.

- Failure in the ignition system.

- Sensors and ECU.

- Throttle.

- Air filter element.

- Piston group.

Auto repair school - Do-it-yourself car repair

Best answers

Answers 8)

Shown. Total: 8. Roman 14 Oct. 2022 18:25 #

Check to see if there is any air leaking somewhere or bad contact on any of the sensor chips. Remove the chip from the phase sensor and start it cold. If the problem goes away, it means a chip or a sensor.

1 DmitriyB64 Sep 12 2022 21:33 #

But almost immediately after reassembling the internal combustion engine, a new problem appeared that did not exist before. When accelerating at about third or fourth speed at 1000 - 2000 rpm, jerking appears. Single and fast, as if there is a misfire on one of the cylinders. In this case, the computer does not detect misfires. Here are the versions:

— the old injector on the first cylinder produces a lean mixture compared to the other three;

— the crankshaft sensor provides incorrect information to the computer due to contamination;

— one of the cylinders has low compression after rebuilding;

— the crankshaft pulley has some play after the bulkhead (it was also removed to replace the oil seal);

— one of the explosive wires is damaged.

1 DmitriyB64 Sep 12 2022 21:20 #

She started having sex again. I removed the ramp with the injectors. The first one is black again. I installed a clean old one. Started it right away and without trouble. After that I freaked out and rebuilt the engine. Almost a major overhaul. The cylinder head gasket was leaking in the area of the first cylinder.

My version is that because of it, antifreeze got into the combustion chamber. During the night, due to the high residual pressure in the cooling system, antifreeze could enter the cylinder and, during the first crank of the engine, through the intake valve it could possibly reach the injectors and fill them. Then, during operation of the internal combustion engine, combustion products, on the contrary, entered the cooling system. This was visible from the air bubbles coming out of the hose into the tank. And it started just recently.

Since I opened the internal combustion engine, I decided to change everything that was possible. Valves, rings, caps, gaskets.

Additionally, I replaced the pump, timing belt and roller.

Two weeks after that it starts without problems. There are no more air bubbles from the hose into the cooling system reservoir. Apparently the problem has been resolved.

At the same time, the catalyst malfunction error no longer appeared (apparently it had previously caught fire due to antifreeze vapor entering the system).

2 DmitriyB64 July 9, 2022 23:03 #

The first photo shows spark plugs after 10,000 km

The second photo shows a new injector on the first cylinder after 300 km of driving around the city.

The third photo shows the old injectors. It's dirty on the first cylinder

1 Ivan July 10, 2022 11:24 pm #

It looks like you answered your own question))) Everything really points to a problem with the valve seals. Alternatively, we can also assume there is a problem with the valve guide. This could be a wear on the working surface of the bushing, or a microcrack. Not often, but it happens that microcracks form on the guide bushings. Through which oil can pass into the cylinder. But, in any case, in order to accurately determine and eliminate the cause, you will have to remove the cylinder head.

2 DmitriyB64 July 9, 2022 23:01 #

In the end, nothing changed after replacing the injectors. The first one also becomes clogged with oil. There is an assumption that the problem is in the valve stem seals. The first time I installed new injectors, it started up perfectly, that is, they were not yet dirty with oil, but over time the situation worsened.

Please comment on the version.

3 Igor June 24, 2018 17:10 #

It looks like a rich mixture, I would look at the injection time, and also pay attention to the operation of the lambda probe. Maybe he's acting up - he's not adjusting the mixture.

3 Nikolaevich June 24, 2022 19:40 #

Of course, the lambda probe acts up after starting a cold engine! Moreover, this bastard generally refuses to work when the engine is cold! But after about five minutes, when the engine warms up, it slowly starts working! And here it would be better to look at the operation of the DTOZH of a cold engine, maybe it shows 0 instead of +20.

3 DmitriyB64 June 19, 2022 20:02 #

An interesting version, but it doesn’t look like it yet. What could have changed in the car that caused air to begin to form in the ramp? I always park the car level. I didn't change the gas station. And with the new injectors it starts much better now. It started to vomit a couple of times, so I thought that nothing had changed. But the next day everything is fine. While I'm watching. This weekend I'll see if deposits form on the new injector in the first cylinder. And I'll check the old injector on the stand. But it was time to change them anyway.

2 Nikolaevich June 16, 2022 08:23 #

The first injector on the ramp is the farthest from the gasoline entrance. Perhaps in your version air accumulates in the ramp. Or gasoline vapors. And this is a question of the amount of gasoline in the tank, the position of the car while parked. Try parking the car so that the left side is higher than the right.

And before replacing injectors, it would be good to check the old ones for atomization and performance on a bench.

4

Solution methods

Now that the main causes have been identified, you can proceed directly to troubleshooting methods . Before we begin, it is worth noting that not all faults can be identified independently, much less eliminated. Let's look at what needs to be done to eliminate engine tripping.

Fuel rail and injectors

The most common cause of engine tripping is a malfunction of the injectors and fuel rail. To eliminate the cause, it is necessary to disassemble this element. The fuel rail is inspected for cracks and deformations. But with candles, not everything is as simple as it seems at first glance.

To determine the performance of the elements, they need to be run through a special stand, which will show whether the injector will work. If they become clogged, they must be cleaned at a nozzle cleaning stand, and if the element is completely faulty, then replace it with a new one.

Spark plugs and wires

Another reason why the power unit fails is the spark plugs and high-voltage wires. So, it is worth removing the elements from the engine and conducting diagnostics. Spark plugs, first of all, are inspected for integrity, and then checked on a special spark plug stand. If everything is in order with the spark plugs, then it is necessary to set the contact gap before installation.

High-voltage wires are checked with a conventional resistance tester. So, a good quality wire will have a resistance of 5 ohms. Deviation from this indicator is considered to indicate that the wires are not suitable for further use and must be replaced with new ones.

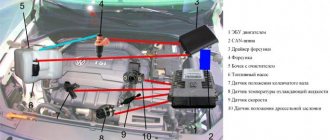

Sensors

Failure of several sensors can lead to the motor becoming unstable and tripping. This could be a failure of the TPS, IAC, camshaft sensor, or DMVR. When all these components fail, they signal the electronic engine control unit, which in turn outputs information to the driver. The malfunction can be eliminated by replacing the corresponding sensor.

There are two ways to determine the performance of the sensor - measuring each sensor one by one with a tester, or connecting to the on-board computer, where an error will pop up, decoding which you can determine the location of the problem.

Throttle valve

A faulty throttle valve can cause the engine to shake. To cure the malfunction, you need to dismantle the element and clean it. Today, there are a sufficient number of products on the auto chemical market that can be used to clean this unit.

But the most popular folk method remains carburetor cleaner, or VD-40. Both products clean out accumulated dirt and dust quite well.

What are the consequences of engine tripping?

In this case, there will be a significant drop in power, the car will “shudder” and shake, increased gasoline consumption - but these are all flowers.

When operating such an engine, its resource quickly ends for the following reason: during engine operation, gasoline enters the non-working cylinder, which does not burn and settles on the cylinder walls, and then enters the crankcase. Gasoline begins to gradually dissolve and dilute the oil, which, in turn, loses its lubricating properties and harms the engine: compression drops (there should be at least 10 points in each cylinder), pistons and rings wear out (scores appear), the engine begins to overheat. And then it’s almost a major and unnecessary engine repair.

Conclusion

The main reasons for the VAZ 2110 8-valve engine tripping are identified, and methods for solving the problem are described. So, the main problems arise due to an incorrect air-fuel mixture, the formation of a spark or in the piston mechanism. There are different ways to solve the problem.

But, it is recommended to turn to professionals in solving such problems who can do everything quickly and efficiently. Because improper repairs can lead to even bigger problems, which will entail additional costs.

Source

How to restore the performance of a VAZ-2114 engine: expert advice

Automotive repair experts recommend that motorists use several tips to restore the functioning of a VAZ-2114 engine that is tripping.

First tip: check and replace the electronic control unit.

Second tip: check and replace the oxygen sensor.

Third tip: check the functionality of the crankshaft position sensor. This can be done using the electronic control unit. This device will generate an error if the crankshaft position sensor is faulty. This means you will have to replace it with a new one.

Fourth tip: check and replace the ignition coil.

Fifth tip: check and replace the air filter.

Sixth tip: check the correct placement of the timing belt.

As you can see, almost every piece of advice contains two stages - checking and replacing some part related to the proper functioning of the VAZ-2114 engine. Therefore, the easiest way would be to immediately allocate a few hours of your time in order to come to grips with the search for the problem of its tripling. Although the best option, but more expensive, is to entrust the inspection to qualified service center specialists, who will find a solution to the existing problem much faster.

VAZ 2110 troits when cold, but after warming up it works fine

The operation of the motor can be accompanied by various problems. All of them must be immediately eliminated. For example, a VAZ 2110 engine with an 8-valve injector shakes at idle, but after the car warms up enough, everything comes back to order. Many car owners try not to focus on this and continue to operate the car. Meanwhile, they do this in vain, since the existing problem requires a solution.

How can you tell if the engine is leaking?

Signs that the VAZ 2114 engine is malfunctioning:

- jerks when driving or accelerating a car - the car does not develop the necessary power;

- increase in fuel consumption - due to malfunction of the injection system;

- uneven exhaust - you can hear popping noises and smell unburnt gasoline;

- vibrating, uneven sound of the engine - due to malfunction of the valves and all rotating parts of the engine;

- feeling of vibration and “shaking” at idle.

The origin of the phrase dates back to the days of four-cylinder engines. If one of the cylinders failed, three remained operational. Now the engine design has changed, but the common expression remains.

Troubles the VAZ 2114 engine

Reasons for needing an engine check

The operation of the engine should be like a clockwork. It should not twitch, but work smoothly. Sometimes there are suspicions that the engine is unstable. VAZ 2110 troits when cold, but after warming up it works fine. It’s better to immediately put emphasis on this and open the hood. After this, you should listen carefully to how the engine operates. If the engine “troubles”, it means that some cylinders are not involved in the work. This is due to conditions that are absent for the normal course of processes in the combustion chambers.

How to identify a bad cylinder

To find out the reason for the engine tripping, first identify the faulty cylinder. This is easy to do even without experience and special tools. To do this, start the engine and disconnect the high-voltage wires from the spark plugs one by one. If, after disconnecting the wire, the sound of the engine has changed, this indicates that the cylinder is working properly. When the faulty cylinder is disconnected from the ignition system, no changes will occur in the operation of the internal combustion engine, and it will operate in the same mode.

Before testing the motor, you must take safety precautions, since there is a high probability of receiving an electric shock from high-voltage wires. When pulling out a high-voltage wire, you need to hold on to the cap where it contacts the wire.

What is the reason for engine instability?

The situation in which the VAZ 2110 troits when cold and then works normally can be due to a number of reasons:

- In all likelihood, the spark plug is faulty. She might just get wet.

- In some place there is a breakdown of the high-voltage wire.

- Extremely low quality of gasoline poured into the tank.

- The operation of the vacuum brake booster is accompanied by air leaks.

- The exhaust manifold has lost its seal.

- The valves need to be adjusted.

- The valve or piston is burnt.

- The piston rings have failed.

- The valve levers have exhausted their service life.

- The cylinder head gasket is broken.

- The valve stem seals have become unusable.

If the problem is a non-working spark plug, then it simply needs to be replaced. This fully applies to a broken wire. If sparking is noticeable in the dark, this may indicate damage to the high-voltage wire.

VAZ cars have always suffered from problems related to valves. You should always remember that after every 20 thousand mileage, the valves must be adjusted. It is necessary to ensure that they are completely closed and opened.

Situations in which valves and even piston burn out do not happen often. But to determine this, compression measurements in the cylinders are required. You can determine when the piston rings have reached the end of their service life and their destruction by pouring a small amount of motor oil into the cylinder. Increasing compression indicates a problem in the rings.

SIGNS AND REASONS OF “ADJUSTMENT”

Engine trouble: what is it, and what are the signs to identify this malfunction? You can understand that the internal combustion engine is malfunctioning by the following signs:

- At idle speed, the engine operates unevenly, jerking periodically;

- The car does not develop the required power when driving;

- The car drives jerkily, when you press the gas pedal, there are gaps in operation;

- The exhaust from the muffler is uneven, with interruptions, pops and shots are possible;

- Fuel consumption increases.

Increased fuel consumption hurts your pocket Reasons:

There are many reasons why the engine misfires. There are such nuances that even experienced technicians do not immediately determine the nature of the malfunction. But the most common cylinder failures are the following (starting with the elementary ones):

- The candle does not work;

- The high-voltage wire is broken;

- The ignition coil has failed;

- The control unit is faulty;

- There is an air leak in the intake manifold;

- Exhaust valve burnt out;

- The cylinder head gasket is broken;

- The compression rings on the piston are broken,

- The piston itself has burned out, or the bridge on the piston between the compression rings has burst.

This article is about the VAZ 2114 car, so carburetor malfunctions are not considered, since this device was not installed on the 2114 model. This brand of car has a fuel system with distributed injection (injector), and the answer to the question of why the engine stalls may be hidden in this system.

Problems with injection

Certain specific problems can cause tripping when the engine is running in a car:

- malfunction of the regulator responsible for idle speed;

- blockage in the injection nozzle;

- the fuel pump, air or fuel filter is clogged;

- the sensor responsible for the throttle position has failed;

- the ventilation system providing air to the engine crankcase is clogged;

- ECU is faulty.

Separately, it is necessary to note the problems of the “tens” with sensors. Although their cost is insignificant, problems with them arise quite often. They often require replacement. First of all, this applies to the sensor responsible for mass fuel consumption. The second most common problem is the sensor that is responsible for the throttle position. The risk zone is not complete without an idle air regulator. All these elements require constant monitoring of their condition.

The motor may not operate correctly if the firmware of the electronic control part is poor. This can happen if tuning is used unwisely. At high speeds the car operates normally, but at idle it starts to shake. Sometimes the ECU may have defects that cannot be corrected. In this case, the only way out of this situation is to completely replace the electronic unit.

Why does a car run on gas?

Quite often a problem arises when a car idles on gas with a cold engine, but when switching to gasoline everything works fine. There are few reasons for such a malfunction. The most common of them:

Damaged diaphragm in the gearbox

- clogging of gas filters;

- loose or loose connections of gas installation pipes;

- malfunctions of the gas reducer - damaged or contaminated membrane, poor-quality or used seals;

- partially or completely inoperative gas injectors. As a rule, the main reason for their malfunction is contamination;

- Incorrect setting of HBO.

Valves and piston

These systems are tested together. First you need to remove the breather hose from the manifold. If white smoke comes from it, then the cause of the cylinder failure is definitely the piston. You should disassemble the engine and see what happened.

Most often, the rings are stuck; to eliminate them, you will have to remove the pistons. If there is no smoke, or it is almost colorless, then the problem is in the valves. First, let's measure the compression. If it is less than 11, then the diagnosis is a burnt valve. You will have to remove the head, change the valve and grind it in. If everything is fine with compression, remove the engine cover and check the valve adjustment. The engine can fail either because the valve is tight or because it is too loose. In any case, they need to be adjusted.