The mass air flow sensor is used to estimate and balance the air flow entering the engine. Signals from the device are sent to the motor control unit.

Based on data from the mass air flow sensor and other sensors, the required mixture composition is formed. To prevent the device from breaking down on the road, it is necessary to diagnose it.

There are several ways to check the mass air flow sensor on a VAZ 2114.

The overall design of the sensor consists of two filaments made of a platinum-based alloy. The threads are heated by electric current, with one being the working thread and the other being the control thread.

The working element is located in the air flow supplied to the engine, which cools the part. As the temperature of the filament changes, resistance increases or decreases.

The data is compared with the parameters of the control element, and based on this, the amount of air passed is automatically calculated.

On later VAZ 2114 models, thermistors began to be used, which have increased durability and measurement accuracy. This is exactly the sensor that is used on the VAZ 2114.

Sensor restoration

Before starting work on the car, it is necessary to deactivate the ignition and disconnect the plug with wires from the regulator.

What will you need?

To carry out the procedure you will need:

- rags;

- set of wrenches;

- cleanser;

- a screwdriver if its use requires dismantling the flow meter.

Selecting a cleaner

Products that can be purchased at the store to clean the controller:

- WD-40. A universal product that can also be used for cleaning.

- Liqui Moly. The use of such a composition is relevant for working sensors. The product is universal and can be used on both diesel and gasoline engines.

- Alcohol.

- Cleaning agent for carburetor engines.

- Liquid key. This product is sold as a spray.

- Air Senso Clean.

Good to know

Do not use cotton swabs or compressed air to clean the device.

It is important that the cleaning agent does not contain acetone or ether

| Image | Step |

| The user must remove the hose connected to the sensor; to do this, use a wrench to unscrew the screws securing the device to the air filter housing. The dismantling algorithm may differ depending on the design features of the car. | |

| |

|

Signs of a malfunctioning mass air flow sensor

Mass air flow sensor (MAF)

The performance of the mass air flow sensor plays a significant role in the correct formation of the air-fuel mixture. Therefore, its malfunctions lead to disruption of the installation or, in some cases, the inability to start the motor.

The failure and failure of this sensor can be identified by the following signs:

- the “Check engine” signal comes on;

- increase in gasoline consumption;

- power drop;

- decreased dynamics of speed gain;

- difficulty starting or inability to start;

- floating speed in idle mode.

But such signs are not only a signal that this sensor is broken; there may be other reasons. Therefore, you need to determine whether this sensor is really acting up.

What does a faulty air flow sensor cause?

Operating an engine with an inoperative/faulty flow meter causes detonation of the fuel mixture in the combustion chamber. This affects the operation of the crank mechanism (crank mechanism) and destroys the piston surface, which can cause a “wedge” in the engine.

What indications should a working mass air flow sensor give?

The voltage of the analog-to-digital converter (ADC) of the flow meter when the engine is not running should be 0.996 V. Indicators of 1.016 and 1.025 V are acceptable, but if they reach more than 1.035 volts, it means that the sensing element of the mass air flow sensor is clogged.

IT IS IMPORTANT TO KNOW . To accurately determine the degree of deviation of the operating flow meter values from normal values, it is necessary to evaluate the engine operation at different speeds.

For example, for an injection 1.5-liter VAZ 2111 engine, if it is in good condition, at idle (860–920 rpm) the correct readings are 9.5–10 kg/hour, and at 2 thousand rpm - 19 –21 kg/hour. If the flow meter at 2 thousand rpm shows about 17–18 kg, then the car will drive stably. If the values are from 22 to 24 kg/hour, then the vehicle will move steadily, but the fuel consumption per 100 km will be approximately 10–11 liters. In addition, the car will have difficulty starting in cold weather due to fuel overflow when the engine warms up.

Types and principle of operation of flow meters

How to rinse and clean the DMRV sensor of a VAZ 2110 with your own hands

The mass air flow sensor is a hot-wire device.

The main types that are used on cars:

- Film with analog and digital signal.

- Wire (thread) analog.

- Frequency mass air flow sensor. Already installed on most modern cars coming off the assembly line.

Pitot tube (vane type) flowmeters are not considered due to their outdated design.

The operating principle of the first two types of devices is similar to each other and is based on changing the voltage readings supplied to the heating elements (threads or film). The ECU monitors these changes and performs calculations to form the fuel-air mixture. More details below.

Wire mass air flow sensor

Used on most modern cars. In such devices, the key role is played by thermistors - two tungsten or platinum filaments with a diameter of 0.07 mm, to which voltage is applied with a certain current strength, as a result they heat up, as well as a thermistor (temperature sensor), but it is not provided everywhere.

One thread is closed from the air flow, and the second, with the throttle valve open, on the contrary, is shoeed and actively cooled.

To equalize the temperature readings of thermistors, more current is supplied to the open thread.

The ECU takes into account the difference in voltage readings between the threads, the intensity of their cooling and, based on them, calculates the volume of incoming air and, in accordance with this, calculates the required amount of fuel supplied to the cylinders.

Wire mass air flow sensors have several significant disadvantages: over time they become dirty or wear out.

To solve the first problem, the designers developed a self-cleaning mode. It provides for a short-term (so as not to discharge the battery) heating of the filament to 1000-1100C with the engine turned off. At this temperature, all deposits burn out.

When the thermistors wear out, the sensor is replaced.

Film flowmeters

Structurally, such sensors differ from the first ones, although the principle of their operation is largely the same.

Instead of a sensitive thread thermistor, a platinum-coated ceramic heating element or semiconductor film is installed here.

The location of the film device remains the same, and the ceramic element itself has several resistor layers, each of which performs its own function: a temperature sensor, a heating one, two thermistors.

An important advantage of such a sensor is that it measures the temperature of not only the incoming air, but also the reflecting air. The device is also less susceptible to contamination.

It is worth noting that in modern devices, the output signal U is transmitted not only in analog mode, but also in digital mode, this speeds up data processing.

Frequency mass air flow sensor

The General Motors product was installed on the first VAZ 2109 and worked in tandem with the January 4 ECU. It is characterized by reliability and a long service life.

The principle of operation is not based on a change in direct voltage, but on a change in the frequency of the output signal of an alternating signal U. When the frequency is high, this indicates high air flow, low frequency indicates low air flow.

The main advantage of a frequency flow meter is stable data transmission to the ECU when the voltage in the circuit drops (poor contact, oxidation, etc.).

Let's imagine that the contacts in the connectors have oxidized. Then the output signal of 1.02V will decrease and, for example, 0.9V will come to the controller. This is not critical, but it will increase fuel consumption.

In the frequency sensor, voltage surges do not affect the operation of the ECU in any way. Oxidation of the contacts will not change the signal frequency in any way, which means 100% of the output data will reach the recipient, i.e. controller (ECU).

What happens if the mass air flow sensor is faulty

The ECU controller will stop receiving or receive distorted air mass data, resulting in the fuel-air mixture being formed incorrectly. The result is a loss of power and torque (in VAZ cars these parameters are not too high anyway), as well as an increase in fuel consumption.

Signs of a malfunction of the mass air flow sensor - absence or incorrect value of the information signal from contact No. 5 of the sensor connector. If the sensors break down, an overestimation of indicators is first observed (up to 25%), then a complete cessation of information output. This leads to the following symptoms:

- on a cold internal combustion engine, the speed is increased by at least a third;

- with a sharp release of gas, the speed first remains at the same level, then slowly decreases;

- fuel consumption increases significantly;

- the car may stall immediately after starting;

- lacks acceleration dynamics and traction under load.

Detailed repair instructions

In practice, with the help of cleaning, the functionality of most sensors can be restored. At the same time, the car owner saves money. If, when checking the mass air flow sensor, it turns out that the voltage readings do not correspond to the norm, then you need to dismantle the device and wash it.

It should be remembered that you cannot use a toothbrush or cotton swabs for cleaning, since mechanical contact with the sensitive elements of the sensor can cause serious harm. Alcohol must be diluted with water in a ratio of 5 to 1. In addition to the listed means, in some cases you may need a 10-20 cc syringe with a needle.

Removal and cleaning of the mass air flow sensor must be carried out in the following order:

First, disconnect the block with the power wires. To do this, you need to press the release button, which is located at the bottom of the device. Unscrew the screws securing the unit to the air filter housing. Unscrew the connecting elements of the protective casing, screws, and remove the sensor itself. The most sensitive parts of the device are the temperature sensor wire, contacts

They need to be washed with extreme caution. To wash the resistor, the aerosol tube must be inserted into the upper channel of the sensor to a depth of approximately 10 millimeters

The procedure itself is carried out several times with short breaks of a few seconds. Penetrating lubricant WD-40, “Hado” is applied for cleaning several times with breaks of 30-40 seconds. At the last stage, you need to let the device dry thoroughly. After this, the sensor is installed in place, and its voltage is checked using a tester. If all indications are normal, then the procedures performed can be considered successful. Otherwise, you will have to change the mass air flow sensor.

Thus, if the air flow sensor partially loses its functionality, you should not rush to purchase a new device. It is advisable to spend 15-20 minutes dismantling and cleaning the old device. This will restore its functions and help save money.

Purchasing a new and replacing the mass air flow sensor

Purchasing and replacing a mass air flow sensor is not a problem. The market is teeming with offers. Prices also vary from 2500 to 9000 rubles. For VAZ and GAZ, look for Bosch products with article number 0280218037.

To replace you will need:

- Cross-shaped or flat decoction.

- Key head 10 (for Lada Kalina).

Procedure:

- Loosen the air duct clamp bolt and move the latter to the side.

- Press the button under the plug and pull the latter out of the connector.

- Using a 10mm wrench, unscrew the two bolts (one on top, the other on bottom).

- Remove the sensor.

- Installation in reverse order.

Before buying a new flow meter, pay attention to the markings of the old one. It is advisable to purchase a product with the same marking so that it is guaranteed to be compatible with the car’s ECU

The main thing after replacement is not to forget to adapt the new flow meter. To do this, remove the negative terminal of the battery for a few minutes to expose the data in the ECU.

In some car models, this cannot be done in a garage; you will have to go to a service center where there is special diagnostic equipment.

Operating principle of the air flow sensor

The sensor is based on a platinum wire only 70 micrometers thick. It is hidden in a special tube located in front of the throttle valve. When air hits it, the wire cools. To restore normal temperature, a certain charge of electricity passes through it, according to the size of its ECU, and finds out exactly how much fuel the engine needs at the moment.

Due to the fact that air comes directly from the atmosphere, dirt regularly settles on the wire. It is this that, for the most part, contributes to the fact that the sensor becomes unusable. The latest models of mass air flow sensors, however, have an automatic cleaning system.

A significant drawback of the described design is its inability to repair. As a result, sooner or later, the expense of money becomes inevitable.

Cleaning the air flow sensor

As noted earlier, the mass air flow sensor cannot be repaired. But some craftsmen manage to clean it, thus extending the service life of the monitoring device in question. Moreover, some claim that they have done this more than once.

In reality, it is worth recognizing that the chance of repair is quite low. However, if you take into account that the cost of a new sensor is quite high, and an attempt to revive the old one generally requires nothing but time, then you should try.

To clean the air flow sensor you will need:

- composition for cleaning carburetors;

- soft brush;

- Phillips screwdriver.

The sensor is disassembled and the inside of the tube and the platinum wire itself are carefully cleaned. Next, all parts must be left to dry. During this time, remove the throttle entirely and also clean it of any plaque inside. Do not remove the cable from the gas pedal. The assembly is placed on a clean rag and washed with carburetor fluid. You will also need to clean the idle speed regulator and the surrounding area from dirt. If you managed not to damage the wire in the mass air flow sensor, then eventually the problem will become less acute for some time

It is important that the sensor is not damaged mechanically

Finally, it is worth noting that to increase the service life of the sensor, first of all, it is necessary to replace the air filter on time.

Diagnostics of mass air flow sensor

If there is no similar sensor, then there are other ways to check the performance of the flow meter:

- visual diagnostics;

- checking while driving;

- determining firmware compliance;

- diagnostics with a tester.

Visual inspection

Before checking the device using this method, it must be removed from its mounting location. To do this, the pipes are disconnected from the housing of the air filter element. The inside of the controller must be dry; traces of motor fluid and condensation are not allowed. Often the device breaks down due to non-compliance with the air filter replacement intervals, as a result of which dirt remains on the sensitive component. This leads to the controller giving incorrect readings.

If there are traces of motor fluid on the internal cavity of the controller, this indicates a high level of lubricant pressure in the power unit. The reason may be a clogged crankcase ventilation. When checking, you need to make sure that the sealing element is located in the right place where the corrugation is installed. This part may have become stuck in the air filter housing. With this problem, air leaks into the engine, which gets inside with dust and contaminates the regulator.

Diagnostics on the move

It is necessary to disconnect the plug with the power circuit from the sensor and start the engine, and then disconnect the block. The Check Engine indicator will appear on the dashboard. The minimum engine speed should increase to 1500 per minute. If the engine begins to operate more stably after turning off the device, this indicates a malfunction. The sensor needs to be replaced.

User Igor Belov spoke about several methods for diagnosing the flow meter, including checking while driving.

https://youtube.com/watch?v=HO6ITsSSoDY

Compliance of the mass flow sensor with the ECU firmware

To check the firmware compliance, you need to take a 1 mm thick plate and place it under the damper stop, this will lead to a change in engine speed. Then the block with wires is disconnected from the controller. If the car engine does not stop, then the reason is the firmware of the microprocessor module, idle speed controller without a flow meter in emergency mode.

Checking the mass air flow sensor with a multimeter

For diagnostics, the ignition is activated, but the power unit does not need to be started. Use the contact of the red probe on the tester to touch the first cable (yellow), and the black one goes to ground (green contact). It is not recommended to use sharp objects for connection, as this will lead to errors in the readings. This diagnostic method will allow you to determine the voltage level between the conductors.

The status of the sensor will be determined by the following readings:

- from 0.99 to 1.01 V - parameters of the new controller;

- 1.01 - 1.02 V - the regulator is in excellent condition, no need to change;

- 1.02 - 1.03 V - generally satisfactory condition of the device;

- 1.03 - 1.04 V - the controller’s service life is almost exhausted, replacement will soon be required;

- 1.04 - 1.05 V - the sensor is in unsatisfactory condition, it’s time to change the device.

Diagnostics by the tester may not be performed on all types of flow meters. The pre-diagnostic mode of the multimeter must be configured to measure the value of direct current and set the maximum parameter to 2 V. Four cables are connected to the controller, each of which is designated by a specific color.

Starting from the near conductor to the windshield:

- the yellow contact is intended for input of a flow meter pulse;

- a white or gray cable is used as the supply voltage output channel;

- green contact is ground or ground;

- The black cable, equipped with a pink stripe, is responsible for the output to the main relay.

The colors of the contacts on the mass air flow sensor may be different, but the arrangement of the wires is always identical.

The “Simple Opinion” channel talked about performing diagnostics on a flow meter using a tester.

When cleaning doesn't help

The cleaners listed above can only help if the mass air flow sensor, firstly, is in working order, and secondly, its clogging is not critical. On average, according to statistics, the service life of an air flow meter is about 150 thousand kilometers. Typically, a wire sensor fails due to the fact that a coating of precious metals simply falls off on the sensitive elements: from time, dirt and high temperature. In this case, only replacing the sensor with a new one will help.

You can extend the service life using different methods. First of all, you need to regularly monitor the condition of the engine air filter, since dust and dirt (motor oil, process fluids, sand, midges) pass through it, which contaminate the mass air flow sensor. The second thing you need to monitor to extend the life of the sensor is the condition of the engine. In particular, oil vapors, brake fluid, antifreeze, or simply dust can get on the sensor. Therefore, it is worth monitoring the condition of the engine as a whole.

How to check the mass air flow sensor

In modern vehicles, the only way to check the MAF sensor is to use a scan tool.

Auto mechanics measure the amount of air (mass air flow sensor readings) at different speeds. They compare the readings to the manufacturer's specifications or to readings from a known-good sensor.

A dirty or faulty mass air flow sensor, in most cases, will show lower air flow than a known good one. In some rare cases, a faulty sensor may show higher readings.

Of course, different engines will have different readings. Air consumption depends on engine size, so the readings of a V6 or V8 engine will be higher.

Low MAF readings do not mean the sensor is faulty. A clogged air filter or clogged catalytic converter can also cause low airflow sensor readings.

Air leaks also affect the sensor readings. This is why mechanics use a known good sensor to compare readings.

Is there a way to check the mass air flow sensor readings at home? Of course, for example, here we used the Torque application to measure the mass air flow sensor readings at different speeds.

This sensor is OK.

To use any smartphone diagnostic app, you will need a Bluetooth or Wi-Fi adapter that plugs into the OBD port.

Sometimes a poor electrical connection at the sensor connector can also cause the airflow reading to be out of range. For this reason, the connector terminals, as well as the wiring, must be carefully inspected.

Often, if the air filter is not installed properly, or the air filter housing is not closed, some debris can get sucked into the MAF sensor and cause problems.

Sometimes debris can get in while replacing the air filter. In this case, the repair is simple. The mass air flow sensor must be cleaned and the air filter must be properly installed or replaced.

Checking the mass air flow sensor with a multimeter

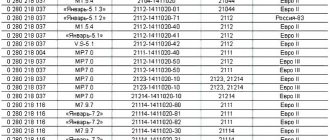

This method works on Bosch sensors with numbers: 0 280 218 116, 0 280 218 004, 0 280 218 037.

We turn the multimeter into DC voltage measurement mode and set the limit to 2 volts.

DMRV pinout:

- Yellow (closest to the windshield) – sensor signal input;

- Gray-white—sensor supply voltage output;

- Green - grounding;

- Pink-black - to the main relay.

The colors of the wires may change, but their location remains the same.

We turn on the ignition, but do not start the engine. We connect the multimeter with the red probe to the yellow wire, and the black probe to the green (to ground). Thus, we measure the voltage between the specified terminals.

It is not recommended to use needles and other additional connections, as they introduce an error in the measurements. We look at the multimeter readings.

During operation, it gradually changes and, as a rule, increases. The greater the value of this voltage, the greater the wear of the mass air flow sensor.

Mass air flow sensor voltage:

- from 1.01 to 1.02 - good condition of the sensor;

- from 1.02 to 1.03 - good condition;

- from 1.03 to 1.04 - the mass air flow sensor resource is running out;

- from 1.04 to 1.05 - a dying state, if there are no negative symptoms, then we continue to exploit;

- 1.05 and above - it’s time to replace the mass air flow sensor.

The same readings can be obtained without a multimeter, using, for example, the OpenDiag mobile application.

Characteristic

On VAZ cars, the mass air flow sensor is mounted between the air filter element and the throttle hose. Today, products from the manufacturer Bosch are very popular among compatriots. Regardless of whether it is a universal Bosch sensor or, for example, spark plugs, quality from a German manufacturer can always give a head start to domestic products. Let's look at the main characteristics of regulators models 116 and 037.

DMRV 116 is designed to control and convert the air flow that enters the motor into voltage. The data transmitted by the regulator makes it possible to determine the operating mode of the power unit and calculate the cyclic filling of the cylinders with air flow. This filling is carried out in steady-state operating modes of the motor, which last no more than 0.1 seconds.

Let's look at the technical features that Bosch 0 280 218 116 has:

- the regulator operates on the principle of measuring air flow;

- the device provides accurate data, which ensures optimal fuel consumption;

- operating range varies from 8 to 550 kg/h;

- the output pulse level when measuring the range from 0 to 100% will be about 0.05-5 volts;

- As for power supply, the controller is powered from the vehicle’s electrical network, that is, 12 volts is enough for it;

- current consumption is about 0.5 ampere;

- the regulator can function normally in the operating range from 45 degrees below zero to 120 degrees;

- The service life of the Bosch 116 mass air flow sensor is about 3 thousand hours.

Bosch 116 device

As for the mass air flow sensor 037 from Bosch, the technical features will be similar. The controller consists of two main elements - working and control, as well as a heating resistor device. The air that enters the engine cools one of the controllers, while the electronic module converts the temperature differences between the controllers. In the event that sensor 280 218 037 fails, its options will be performed by TPS.

As mentioned above, the technical features of the models are the same:

- the operating range for normal operation varies in the region of 8-550 kg/h;

- when operating correctly, the controller will provide accurate data, making it possible to achieve optimal gas mileage (of course, if the engine is running in normal mode);

- since the element is used in a car, it is logical that it should be powered by 12 volts;

- the controller consumes about 0.5 ampere of current;

- the part can operate normally both at 45 degrees below zero and at 120 degrees of heat, this is its operating range;

- service life is at least 3 thousand hours;

- unlike model 116, the new mass air flow sensor 037 during calculations can produce an error of 2.5 percent (both downward and upward).

Regulator model 0280218037

How to check the mass air flow sensor for serviceability

There are several basic methods for checking the mass air flow sensor, which allow you to verify its malfunction.

Checking the mass air flow sensor in motion

The easiest way to diagnose a flow meter is to analyze the operation of the engine when the sensor is forcibly turned off. The check proceeds as follows:

It is necessary to open the hood and disconnect the connector from the mass air flow sensor. After this, close the hood; Next, get behind the wheel of the car and start the engine. The car should start to operate in limp mode, in which the Check Engine light will be on.

In such a situation, the amount of air in the fuel mixture will be determined depending on the throttle position; Try driving the car and pay attention to its dynamics in comparison with how the car worked before the mass air flow sensor was turned off. With the sensor turned off, the car should become “more lively”, that is, accelerate faster

If this is the case, then we can confidently talk about problems with the mass air flow sensor.

It is highly not recommended to operate a car for a long time with the mass air flow sensor turned off.

Checking the mass air flow sensor with a multimeter

You can diagnose a problem with the sensor using a multimeter. To do this, you must first understand the design of the device and its “pinout,” that is, the wiring of the wires on the board. There are 4 wires coming out of the mass air flow sensor. Depending on the MAF model and manufacturer, their colors may vary, but in most cases they are as follows:

- Pink (or pink-black): wire to main relay;

- Green: wire to ground;

- Gray: wire to power;

- Yellow: signal input.

To check the mass air flow sensor, the multimeter must be set to constant voltage measurement mode and set the limit to 2 Volts. Next, you need to turn on the ignition, but do not start the engine. Once this is done, connect the multimeter's red lead to the sensor's signal input (yellow wire) and the black lead to ground (green wire). This can be done without “exposing” the wires by inserting the probes of the diagnostic device through the rubber seal of the connector.

Based on the measurement results, conclusions can be drawn about the state of the sensor:

- Fully serviceable device (new): 0.996 - 1.01 Volts;

- The sensor is in good condition, but has already worked: 1.01 - 1.02 Volts;

- The sensor has been working for a long time, but is still working: 1.02 - 1.03 Volts;

- The mass air flow sensor will soon need to be replaced: 1-03 - 1.04 Volts;

- The flow meter is close to failure, but continues to cope with the tasks: 1.04 - 1.05 Volts;

- The sensor needs to be changed: 1.05 Volts and above.

Some modern on-board computers allow you to view the voltage on the mass air flow sensor. In such situations, you can do without a multimeter.

What is a mass air flow sensor, why is it important and how to diagnose its malfunction

Over the past three decades, engines with distributed and direct fuel injection have finally supplanted all other types of designs. It would seem that this is a considerable period of time, but engineers have not been able to overcome the “childhood diseases” of important electronic components, including the mass air flow sensor (MAF), which is responsible for the composition of the air-fuel mixture. Let's remember how the mass air flow sensor works, why it is so important and how to diagnose its malfunction.

What is DMRV

Modern engines use two types of power supply systems: with distributed injection, the nozzle supplies fuel to the intake pipe, with direct injection, it supplies fuel to the combustion chamber. For both systems, the correct operation of the mass air flow sensor, which was once mechanical (vane type), but is now devoid of moving mechanical parts and made hot-wire (from “anemo” - wind), is important.

Factory air flow sensor made in Germany for a VAZ engine

The mass air flow sensor can be installed not only on a gasoline engine, but also on a diesel engine, where the operation of the EGR valve (exhaust gas recirculation system) is “tied” to it.

As old-school drivers used to say, an internal combustion engine does not work in two cases: there is nothing to burn or there is nothing to set it on fire. The mass air flow sensor precisely informs the electronic control unit about the amount of incoming air, the oxygen of which becomes the “fuel” for the working mixture. Having received such a signal, the ECU can ensure the most complete combustion possible. The device, located in the intake tract, consists of two resistors, which can be designed in various designs. In the first case, the resistor is exposed to passing air: when the flow intensity changes, it cools and its internal resistance changes. In the second case, it is not blown - based on the difference in readings from two resistors, the volume of air that needs to be supplied to the cylinders is calculated.

The sensor is supplied to the aftermarket with protective caps to prevent contamination during transportation.

This is what the sensor looks like on a regular VAZ engine. It will not be possible to remove it from the case without a special key.

The removed sensor is in its “bare” state. The sensitive element is clearly visible

Based on the data on the mass and temperature of the incoming air, the ECU determines its density, and also calculates the duration of opening of the injectors and the amount of fuel supplied to the combustion chamber. In general, the mass air flow sensor is important for achieving maximum engine power, for more complete combustion (environmentally friendly), and for economical driving. The failure of this sensor, like most others, causes the Check Engine warning light to go off.

The check engine light can come on for any reason. If there is no on-board computer with a diagnostic function, you will have to go to a service station where there is a scanner

However, the owner does not always associate the triggered “check” with the mass air flow sensor - especially if the engine runs without any interruptions, and the dynamic characteristics of the car have not deteriorated at all. Therefore, it is important not to leave the illuminated engine malfunction indicator unattended, but to consider errors with the diagnostic computer.

MAF or DBP?

The absolute pressure sensor (MAP), together with the temperature sensor (DTS), also controls how much air enters the intake manifold. Based on these readings, the controller generates a pulse command to the injectors. An important difference between DBP and MAF is the absence of air in the housing, since this sensor works based on measuring the difference in inlet pressure and pressure in the vacuum chamber. A design feature of the DBP is a highly sensitive diaphragm, which expands under the influence of pressure in the intake manifold. This process affects the resistance of the strain gauges, as a result of which the voltage changes.

The absolute pressure sensor (pictured) and the mass air flow sensor operate on different principles

DBP is much cheaper than a mass air flow sensor, but its operating algorithm is less advanced. And in general, not all control units can work correctly with DBP. Moreover, when switching to an absolute pressure sensor, the engine may respond to opening the throttle with a much greater delay than with the original mass air flow sensor. And, of course, simply replacing the mass air flow sensor with a DBP without serious modifications will not work due to the difference in their design and even location.

There are engines where there is no choice between DBP and MAF, because both of these sensors are present on the engine at once!

Usually, thoughts about installing a DBP instead of a standard mass air flow sensor appear when the latter fails, as well as during engine tuning - especially if the aspirated system is converted to turbocharging. However, some owners deliberately refuse the mass air flow sensor because of its high cost and not the greatest resource. Indeed, in an unfortunate combination of circumstances, the sensor can fail after 60-70 thousand kilometers, and by the figure of 120-130 thousand on the odometer of many budget cars, it is almost guaranteed to “die”.

But those who don’t bother with engine modifications usually drive with a standard mass air flow sensor, rather than replacing it with a DBP+DTV (air temperature sensor) combination. Moreover, not all engine control units work better with an absolute pressure sensor than with the original mass air flow sensor. It is difficult to answer unequivocally which sensor is more advanced in design, especially if we are talking about an attempt to replace one (and often already faulty) flow meter with another. After all, history knows many examples when happy owners clocked up several hundred thousand kilometers both on an engine with a native flow meter and on an engine with an absolute pressure sensor, especially if the latter was standardly installed at the factory.

Is it possible to do without it?

Failure of the mass air flow sensor causes the check to be triggered, but the engine will continue to operate. True, depending on the newness of the ECU firmware, the “emergency” program, without seeing a signal, can raise the idle speed to approximately 1,500 rpm. On relatively new software versions, a sensor malfunction only leads to an increase in fuel consumption or a drop in dynamics. In any case, an error in the mass air flow sensor is an important reason to check it, at least by measuring the voltage.

If the mass air flow sensor does not operate correctly, the electronics may begin to over-enrich the working mixture.

The malfunction should not be ignored, since even on relatively simple cars (the front-wheel drive Lada line of the first generations), failure of the mass air flow sensor threatens a noticeable excess consumption of gasoline or a weakening of the engine’s output characteristics. That is why the answer to the popular question “Is it possible to do without a mass air flow sensor if it is included in the design of the car?” is unambiguous and sounds like this: no, you can’t.

How to diagnose a malfunction?

In addition to the indirect signs that we mentioned above, there is a completely objective parameter that indicates the condition of the sensor and its resource - this is the operating voltage when the ignition is on. Let's study it using the example of the VAZ sensor as one of the most common.

Connection diagram for mass air flow sensor on a VAZ engine

By connecting the multimeter in DC voltage measurement mode and turning on the ignition, you can take readings of the mass air flow sensor output voltage. For a new or “reference” part it is 0.996 V.

This voltage indicates that the sensor is working like new.

One of the options for measuring voltage is directly through the sensor connection connector

Then the parameters are evaluated as follows:

1.010-1.019 V - good condition, you don’t need to think about replacing yet 1.020-1.029 V - the sensor is operational, this is about half of the remaining life 1.030-1.039 V - still in good condition, but its life is coming to an end 1.040-1.049 V - mass air flow sensor is on the verge of breaking down building, will soon require replacement 1,050 V and above - the flow meter requires immediate replacement

With a parameter of 1.016 V (first photo), the sensor is in good condition, but 1.035 V is already a reason to think about buying a new one

The sensor produces this parameter on the verge of serviceability, but you need to make sure that the data corresponds to reality and is not related to the error of the multimeter

It should be taken into account that many testers overestimate readings, so there is a risk of “sentencing” a completely serviceable sensor. In addition, its parameters largely depend on the purity of the “mass” in the circuit.

Poor crimping of wires or a rotten “braid” can affect the correct operation of both the mass flow sensor and the DBP, which is especially typical for engines of old cars.

It is best to first install a known-good “used” one before purchasing a sensor that is not the cheapest, borrowing it for testing for a while from a work colleague, a neighbor in the parking lot, a friend from a forum with the same car, etc. You should also trust the readings of a diagnostic scanner connected to the OBD-2 connector more than a cheap multimeter.

To rinse or not?

Many mechanics with many years of experience and ordinary car owners are confident that a “tired” mass air flow sensor can be revived by simply washing it - that is, remove it from the body and thoroughly “spill” it with some “carb cleaner” or alcohol in about the same way as 20-30 years ago they did this with carburetor jets. In fact, there are specialized sensor cleaning compounds that have nothing in common with the deposit solvents used to flush carburetors. Therefore, the price of such “narrowly sharpened” air flow sensor cleaners is completely different - and, as one can easily assume, higher. In addition, the manufacturers of such liquids directly indicate that they will not do miracles and will not turn a “half-dead” sensor into a completely new one, but are intended for preventive flushing of working mass air flow sensors - to remove contaminants associated with dust and oil mist that has entered the intake tract from the ventilation system crankcase

Please note: for flushing, a specialized composition is used specifically for cleaning the air flow sensor, and not a universal carburetor or fuel system cleaner

Practical experience in using such “miracle remedies” shows that they can indeed slightly reduce the readings of a still working sensor, but for those that go beyond 1.05 V, such manipulations will be like a poultice for the dead.

The main thing is not to damage the removed sensor, which is afraid even of dust, not to mention mechanical impact.

Many drivers, due to inexperience, themselves destroy still living sensors when washing. Sensitive elements should not be touched with hands or wiped with a rag, and strong pressure of liquid will do nothing but harm. Therefore, cleaning the mass flow sensor in a garage should be treated with great caution and remember: if the sensor has already “died”, then this is harmless and will no longer help it, but even if it is still in good working order, this procedure may not bring a noticeable result.