When you have to change ball joints on a VAZ 2107 car, its owners begin to think: which ones are better to choose? This question arises for a reason, because there are several varieties of these automobile parts on sale. Let's consider the functional features of each type of ball joints for the VAZ 2107.

Ball joint overview

The production facility has an impressive fleet of modern technological equipment. It allows NGOs to fully ensure and control the production cycle. It includes developing the concept of the product itself. Ball joints are made of high-carbon alloys with high strength. This allows suspension components to function for a long period of time without replacement. The operating life is also affected by the conditions in which the vehicle is used.

The company carries out quality control at all stages. This is what ensures a low defect rate. Moreover, it is not released for sale. Over the entire period of its existence, the company has established itself on the positive side among consumers of its products. The company is the official supplier of the following enterprises:

- LADA AvtoVAZ;

- Renault concern;

- Nissan;

- Datsun;

- GAS;

- Ural.

Workmanship

All products undergo suitability testing. Several different model lines are presented:

- original;

- comfort;

- favorite;

- conveyor;

- Niva-Lux.

Each series has its own characteristics. The “original” version corresponds to class 9 in terms of surface finish quality. A liner made from newly invented polymers is used. It contains special anti-friction materials. The hinge works smoothly, the service life is more than several tens of thousands of kilometers, even in difficult conditions. Frost-resistant rubber is used.

The “comfort” series includes a list of products installed on AvtoVAZ products. The coating is made of zinc. This eliminates corrosion and premature aging of the material. At the time of packing into boxes, lubricant with fine metal dust is applied to the contact surface. This makes it possible to reduce the standard wear of the part several times.

"Favorite" has a warranty period:

- 2 years;

- 50 thousand km.

In practice, this part “runs” an order of magnitude longer. Reviews about the part are only positive. As in other series, the required amount of lubricant is already included. There is no need to use Litol or its analogues.

The “conveyor” series was developed specifically for the Niva Chevrolet car. An innovative, progressive design and assembly methodology was used. Due to the use of alloy metal, it became possible to achieve high strength. Due to this, the required minimum force for breaking was increased by 20%.

The continuation of the previous series is “Niva-Lux”. She received a rubber case based on durable components. They were developed by Bayer. Design features of the series:

- solid forged body;

- the liner is made of wear-resistant material of increased strength;

- The body is covered with impact-resistant polymer.

Difference from original auto parts

Despite all the advantages and high quality manufacturing, the products differ from the original parts:

- shorter resource - the maximum mileage on roads in the Russian Federation is from 50 to 60 thousand km;

- packaging and complete set.

It should be noted that each automaker produces parts under its own brand. In most cases, the quality of these is an order of magnitude higher than their analogues. Belmag uses modern materials (metals and polymers). But the period of continuous operation, as a rule, is an order of magnitude shorter than that of original components.

How to distinguish a fake?

The company has well established itself as a manufacturer of equipment. Therefore, it is important to remember: there are a large number of fakes on the market. It is not so easy to distinguish them. Nevertheless, there are a number of signs that characterize a fake:

- there is no special protective hologram on the packaging;

- The quality of the cardboard box is low, it is falling apart at the seams, there is no polyethylene on the support itself;

- the kit is not complete - there are no bolts for installation, there are no other components;

- low cost – the price in the store cannot be less than that stated on the company’s official website.

Using counterfeit products can lead to serious problems. In 100% of cases, the resource of parts is an order of magnitude less. A breakdown while driving can lead to a serious accident. It is advisable to carefully read the signs of counterfeit. This will avoid serious troubles in the future.

Reviews

In 2022, I purchased a new Niva Chevrolet. After 100 thousand km, knocking noises appeared in the area of the right wheel. After an inspection of the chassis, the need to replace the ball joint was identified. I immediately purchased a pair from the Niva-Lux series from Belmag. It should be noted that it is easy to install. The part corresponds 100% to the overall dimensions of the original. Therefore, it fell into place without any problems. Separately, it is necessary to note the quality of the rubber. Even in severe frost it remains soft and does not crack.

VAZ 2101 cars have never been famous for their high-quality suspension. Ball joints have to be constantly changed due to the vehicle being used on roads in rural areas. I transport watermelons, a large number of fruits and vegetables. On the highway it became difficult to keep the car in a straight line. Especially at high speed. After inspecting the chassis, the service technician and I determined the need to replace the ball joints. The choice fell on Belmag. The parts perform well under difficult operating conditions. I've already driven 40 thousand km on them - and they're still intact! Ball ones from others for 20 thousand km. The impressions are positive!

Malfunctions

During the operation of the car, especially on our roads, the suspension is subjected to significant load, most of which falls on the ball joints. Naturally, over time they wear out, which leads to an increase in the gap between the spherical surface of the finger and the bottom of the case. The reasons for premature failure of ball joints are:

damage to the anthers, resulting in moisture and dirt getting inside the structure;

- lack of lubrication inside the support;

- high dynamic loads when driving off-road.

You can determine that the ball joint has failed by the following signs:

- knocking in the front suspension while driving on rough roads;

- difficulty turning the steering wheel, accompanied by creaking;

- “wobble” of the steered wheels when driving, vibration in the steering rack, and as a result, uneven tire wear.

How to independently determine the malfunction

If your car shows signs of ball joint malfunctions, have them diagnosed. There are two ways to do this at home, but it is better to approach this issue comprehensively, using them in turn.

First, let's look at the most accurate method. The cover of the original VAZ ball has a technological hole at the bottom, through which you need to measure the distance between the surface of the cover and the edge of the spherical surface of the finger. This can be done using a special depth gauge or an ordinary thin rod and ruler. If the depth gauge enters the support more than 11.8 mm, it is time to change the support.

The next method is to determine the amount of play between the finger and the cover without any tools. You just need to touch the support body and your finger with your hand at the same time, and loosen the front part of the car. If there is play, you will definitely feel it.

Do I need to change ball joints and when to do it?

The average service life of ball joints for the VAZ 2107, depending on their quality and operating conditions, is 30-100 thousand kilometers. If the car has traveled 100 thousand km and the supports have not made themselves known, it is still better to replace them. Replacement is also necessary if any signs of malfunction appear.

Untimely diagnosis and replacement of these suspension elements will lead to the fact that at one point the wheel or wheels of the car will simply turn outward and lay the car on its “belly”. In this case, the entire suspension will have to be repaired.

How much do ball joints cost, and how much will it cost to replace them?

If one ball is faulty, it is recommended to replace all the others. Prices for a set of supports, depending on the manufacturer, can vary from 1100 to 3000 rubles

When choosing a kit, pay attention to the manufacturer, and do not skimp. Catalog number of the original upper ball joint for VAZ 2107 is 21012904192, for the lower one – 21012904082

The cost of replacing 4 balls at a service station is from 800 rubles.

Types of ball joints for VAZ 2107

Automotive repair specialists characterize ball joints for the VAZ 2107 according to several criteria.

- By place of use of the part:

- upper - specially designed for the upper chassis unit and work to compress the structure;

- lower - designed for placement in the lower unit of the front suspension and operate when a special spring is stretched.

- By type of construction:

- filler (for installation on the upper suspension arms) - the peculiarity lies in the manufacture of this part, in which the ball pin is filled with durable plastic, and the rotation fixes only a certain angle;

- with metal-ceramic bearings (for mounting on the lower arms of the chassis) - characterized by a rather large angle of rotation, because the pin is fixed in an oval hole made in the cover of the part.

Based on the above functional features of ball joints of various types, we can conclude: the main part in this design is the ball pin. It is he who is responsible for the quality of work of the entire design of the part and the stability of the car when cornering as a whole.

When to change

The wear of ball joints largely depends on the intensity of driving, the loads being transported and the quality of the road surface. In addition to regular technical inspection at a service center, experts recommend inspecting the mechanism before a long trip or when a third-party knock appears in the wheel area. There is no point in delaying repairs, since if the ball is completely worn out, it can fly out even while driving, which will lead to the wheel turning out and uncontrolled skidding.

Signs of replacing ball joints are:

- knocking while driving on an uneven surface at low speed;

- squeaking around the wheels when turning the steering wheel;

- unstable movement in a straight line;

- uneven tire wear.

Tip: If there is no special indicator for checking the play, you can rest your palm against the body. An increase in free space will be felt when the wheel rocks.

Ball joint selection criteria

To choose high-quality ball joints for a VAZ 2107 car, you should take into account a number of characteristic features of this part and its design as a whole:

- all safety requirements are met so that the vehicle maintains course stability in all situations;

- corrosion resistance;

- the possibility of operating this part under extreme driving conditions is provided;

- it is impossible for moisture, dust, and various small objects to get into the support structure, which could damage the main mechanism of this part;

- integrity of the body and reliability of the entire structure;

- ball pin manufacturing material;

- warranty period of operation.

By paying attention to these main points, you can choose high-quality parts of this type for your car.

Market overview of manufacturers of ball joints for VAZ 2107

It turns out that on the Russian market there are about 35 brands of companies that produce ball joints specifically for the VAZ 2107. The most popular of the domestic ones are BelMag, BZAK, and Kedr. Let's look at the distinctive features of the parts they produce:

- "BelMag" - produces parts of several series ("Original", "Comfort", "Favorite"), their characteristics:

- the lubricant is included under the protective cover at the factory;

- The part is designed for use in difficult road conditions.

- "Cedar":

- have a solid forged body;

- labyrinth design of protective boot;

- cold landing of the ball pin;

- rolling the ball surface with diamond rollers;

- anti-friction liner to preserve lubricant;

- It is not equipped with factory lubricant, so before installing it on the car it must be placed under a protective cover.

- “Track” produces parts from several series – “Classic”, “Champion”, “Sport”, “Master”, “Style”. Their features:

- suitable for use in Russian off-road conditions;

- have a reinforced structure;

- with additional aluminum coating.

- "BZAK" has established itself as a high-quality and reliable manufacturer, product features:

- reinforced ball joint housing design – all-metal, forged;

- with a warranty period of 50 thousand kilometers;

- increased anti-friction and wear-resistant properties, thanks to the patented additive “Lugam”;

- the finger is made using the cold heading method, which gives it additional strength;

- the presence of a rubber cover to protect the structure.

As you can see by reading the descriptions of ball joints from various manufacturers, their quality largely depends on the production technology of the structural components. Therefore, try to also visually inspect the part: it should not contain sharp edges, especially on the ball pin. Be careful in your choice, as your safety depends on it.

What needs to be certified

Vladimir Volkov, director of the Information Center of the Federal State Unitary Enterprise “NAMI”:

A modern car is a complex structure, many components and assemblies of which directly affect the level of safety of the driver and passengers. Only certified components can provide it. The work on certification of motor vehicles and their units is carried out by the Testing Center for Automotive Products (ITsPA FSUE “NAMI”).

Our specialists, in particular, conduct certification tests of brake systems, steering systems, anti-toxic systems, transmissions and suspension systems, including ball joints or joints.

The center has a staff of highly qualified specialists with extensive experience in the automotive industry. The testing base of the Center includes 18 laboratories, 14 motor and specialized boxes, 21 aggregate boxes, a stand with brake drums and gas analyzers and other equipment. Over the 10 years of the Center’s operation, our specialists have carried out almost 4,700 certification tests, including tests of ball joints. The work of our experts in certifying them allows us to block the path to the Russian market for low-quality components that do not ensure not only the safety of passengers, but also the safety of the vehicle itself, the operation of which may be impaired due to their use.

I cannot help but note that in recent years, a powerful production base has been formed in Russia and the CIS countries, ensuring the production of a wide range of ball joints of very high quality, capable of competing with the best foreign models.

Choosing ball joints for VAZ 2107

The importance of ball joints for a passenger car cannot be overestimated. Without these important components, any passenger car will go very far, and the VAZ 2107 is no exception. Like any other highly loaded unit, ball joints wear out, and on the VAZ 2107 this happens much faster than the driver would like. There are two reasons: the mediocre quality of domestic roads, and the equally mediocre quality of the “native” ball joints installed on the “Seven” by the manufacturer. As a result, one day the driver will definitely be faced with the question: how to replace broken ball joints? Let's try to figure it out.

The main function of the ball joint on the VAZ 2107

The task of a ball joint on any passenger car comes down to selectively limiting the movement of the wheel. Under no circumstances should it swing in a vertical plane, but at the same time it should move freely in a horizontal plane.

If this principle is not followed, the driver will have serious problems with driving the car. And if one of the ball joints is damaged too much, an extremely dangerous situation can arise: the wheel at full speed turns out at a right angle to the engine.

After this, the car almost always skids, and the driver will be very lucky if at that moment he is alone on the road and does not collide with other cars.

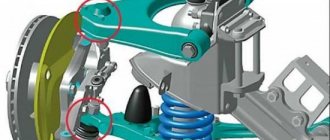

Design of ball joints for passenger cars

As you can easily guess from the name, a ball joint is a regular joint installed behind a car wheel. The main element of any ball joint is the ball rod. There is a thread at one end of the rod and a ball at the other. It is pressed into another important part of the support - the eye. It has a hemispherical recess, ideally adjusted to the size of the ball on the rod. The resulting structure is covered with a so-called boot. In modern supports, this is the name given to plastic caps that protect the hinge joint from dust and dirt. Today, more and more often, boots are made of translucent plastic, which is quite convenient: the car owner does not have to remove the boot to assess the degree of damage to the hinge. Supports with an opaque boot often have another design feature: a technological hole near the ball rod. It allows you to assess the wear of this part without removing it.

It should also be noted here that on the very first VAZ 2107 models, the ball joints were equipped with pressure springs designed to increase the reliability of the articulated joint. But in later models of the “seven” it was decided to abandon springs.

Replacement instructions

It is most convenient to carry out repairs in an inspection pit or on a lift. This will ensure that you have a good overview for inspection and will have the necessary access to the mechanisms.

What tool will you need?

From the tool you will need:

- metal brush;

- solvent;

- a set of keys;

- puller for supports;

- adjustable wrench;

- medical syringe;

- lubricants.

Step-by-step description with photos

Before starting the replacement, make sure that the car is on the handbrake and the protective flaps under the wheels are installed correctly.

- We remove the wheel.

- Clean the ball joints with a metal brush.

- To prepare connections for disassembly, we use a solvent that will remove coked dirt and rust.

It will be much easier to remove nuts if you pre-treat the joints with WD-40.

Using a 22 wrench, remove the nut from the lower ball joint

We install the puller in a certain position and press out the support with it

Using a wrench, unscrew the nut on the upper ball joint

We use a socket wrench to remove the fastening bolt.

After unscrewing the bolt, the ball joint can be easily removed

Video of replacing ball joints on a VAZ 2107

Ball joints from various manufacturers

First of all, it should be said that the ball joint is a very important part. During operation, it is subjected to severe shock loads, so the technical requirements for it are very high. There are very few enterprises capable of meeting these requirements. Let's list the most popular companies.

Ball joints "Track"

Track supports are very popular among VAZ 2107 owners.

The reason is simple: these supports are good value for money. Here are the main features of Track ball joints:

- the ball rod in all Track supports is manufactured using cold heading technology, after which it is subjected to heat treatment;

- the ball on the “Track” support rod is always carefully processed, surface roughness class - 10;

- threads on the ball rod are applied only by rolling;

- liners on the “Track” supports are made of a special wear-resistant polymer, which significantly extends the service life of the supports;

- the bearings in the “Track” supports are made of cermets and are thoroughly lubricated, so there are no problems with the sliding of the ball rods;

- The body of the “Track” support is obtained by cold stamping. Then its parts are fastened to each other using spot welding, and between the fastened halves of the body there is always a layer of industrial sealant;

- The support boot is very durable, and what is especially important for our country, is frost-resistant. Due to this, the service life of the boot almost always exceeds the service life of the support itself;

- The body of the Track support is coated with a special coating that reliably protects the support from corrosion.

The manufacturer claims that the Track supports are guaranteed to cover 40 thousand km, and the actual mileage of the supports can reach 100 thousand km or more. The cost of a set of four “Track Champion” supports starts from 1,500 rubles.

Ball joints "Cedar"

In the Kedr ball joints, which are the second most popular among VAZ 2107 owners after the Trek, the manufacturer has implemented several technical innovations that should definitely be mentioned.

These are the features:

- All Kedr ball joints are equipped with a compensator. The manufacturer claims that this part allows you to increase the service life of the support by 30%;

- all “Kedr” support bodies are protected with a special cataphoresis coating, which has increased adhesive properties;

- Before applying the cataphoresis coating, the support bodies are subjected to shot blasting, which guarantees the complete absence of surface defects and dirt on the surface of these parts;

- The material for the liners of all Kedr supports is graphite-filled polyamide. This material is able to halve the friction in the support and thereby increase the service life of the part;

- The anthers on the Kedr supports are made of rubber used in the aviation industry. Rubber has increased oil and gasoline resistance, and is practically immune to sudden temperature changes;

- the rod of the ball joints “Kedr” is coated with a special material “Nilbor-20”, which several times increases the anti-friction characteristics of the rod and reliably protects it from corrosion;

- All Kedr ball rods are monitored using ultrasound for internal defects. Thus, the possibility of marriage is practically excluded.

The manufacturer provides a 18-month warranty on “Kedr” supports (for comparison: the “Trek” supports have a 12-month warranty). The guaranteed mileage of the supports is 40 thousand km. The cost of a set of four “Cedar” supports on the market starts from 1,400 rubles.

Malfunctions

During the operation of the car, especially on our roads, the suspension is subjected to significant load, most of which falls on the ball joints. Naturally, over time they wear out, which leads to an increase in the gap between the spherical surface of the finger and the bottom of the case. The reasons for premature failure of ball joints are:

damage to the anthers, resulting in moisture and dirt getting inside the structure;

- lack of lubrication inside the support;

- high dynamic loads when driving off-road.

You can determine that the ball joint has failed by the following signs:

- knocking in the front suspension while driving on rough roads;

- difficulty turning the steering wheel, accompanied by creaking;

- “wobble” of the steered wheels when driving, vibration in the steering rack, and as a result, uneven tire wear.

How to independently determine the malfunction

If your car shows signs of ball joint malfunctions, have them diagnosed. There are two ways to do this at home, but it is better to approach this issue comprehensively, using them in turn.

First, let's look at the most accurate method. The cover of the original VAZ ball has a technological hole at the bottom, through which you need to measure the distance between the surface of the cover and the edge of the spherical surface of the finger. This can be done using a special depth gauge or an ordinary thin rod and ruler. If the depth gauge enters the support more than 11.8 mm, it is time to change the support.

The next method is to determine the amount of play between the finger and the cover without any tools. You just need to touch the support body and your finger with your hand at the same time, and loosen the front part of the car. If there is play, you will definitely feel it.

Do I need to change ball joints and when to do it?

The average service life of ball joints for the VAZ 2107, depending on their quality and operating conditions, is 30-100 thousand kilometers. If the car has traveled 100 thousand km and the supports have not made themselves known, it is still better to replace them. Replacement is also necessary if any signs of malfunction appear.

Untimely diagnosis and replacement of these suspension elements will lead to the fact that at one point the wheel or wheels of the car will simply turn outward and lay the car on its “belly”. In this case, the entire suspension will have to be repaired.

How much do ball joints cost, and how much will it cost to replace them?

If one ball is faulty, it is recommended to replace all the others. Prices for a set of supports, depending on the manufacturer, can vary from 1100 to 3000 rubles

When choosing a kit, pay attention to the manufacturer, and do not skimp. Catalog number of the original upper ball joint for VAZ 2107 is 21012904192, for the lower one – 21012904082

The cost of replacing 4 balls at a service station is from 800 rubles.

About other manufacturers

As mentioned above, the production of high-quality ball joints requires serious costs. And this cannot but affect the final cost of the product. Therefore, there are only four large manufacturers of supports for the VAZ 2107, and all of them are listed above. Of course, there are smaller companies that offer car enthusiasts ball joints at almost half the price. But any sane person understands: if a ball joint costs half as much, it means that the manufacturer saved on something during its manufacture. Most often, savings are made either on ultrasonic analysis of rod blanks or on heat treatment. Neither the first nor the second bodes well for the buyer of the support.

And if the car owner is of sound mind, then he will not react to a temptingly low price and save on a detail on which his life literally depends. It is for this reason that little-known manufacturers of cheap supports will not be considered in this article.

Here we should mention another unpleasant thing: fakes. Recently, ball joints from well-known brands have begun to appear on the shelves of car dealerships, costing suspiciously cheaply. Upon closer examination, the vast majority of them turn out to be fake, and often the fakes are made so well that only a specialist can recognize them. For an ordinary car enthusiast, the criterion for selecting supports is still the same: price. It should be approximately the same as indicated above. And if a ball joint from a well-known brand costs half as much, then buying such a part is categorically not recommended.

Video: about fake ball joints

How can I replace the puller?

Not every car enthusiast has a ball joint remover in their garage. In its absence, you can use a sledgehammer and a soft metal attachment. In this case, you will need to apply physical force to unpress the “finger”. You need to hit in a certain place, as indicated in the photo.

The blow must be applied to the ball joint journal

But it is worth considering that if the car is used for a long time, problems may arise with removing the “finger” in this way.

You should not delay the repair of ball joints, since the destruction of this mechanism while driving can lead to a serious accident. For replacement, you should choose components from a reliable manufacturer. Chinese fakes should not even be considered, despite the low price.

If when driving over bumps you are haunted by an unpleasant sound in the front of the car, then there is no need to bring the matter to a critical moment. To find the cause of the knocking, you need to understand the structure of the suspension, both as a whole and its individual parts. In this article I will talk about one of the causes of knocking and how to replace ball joints on a VAZ 2107.

Ball joint device for VAZ 2107.

The ball joint consists of a pin inserted into the body. Between them there is a plastic liner, which wears out over time. A rubber cover placed on the body and fits tightly to the finger protects against dust getting inside the insert. The ball joint housing has a hole for lubrication and checking the condition of the part. But not all manufacturers do this.

Diagnostics of ball joints of VAZ 2107.

If there is a knocking sound on bumps in the front part of the car and a beating in the steering wheel, as well as increased sensitivity of the car to the ruts, you should check the condition of the suspension and one of the points will be checking the ball joint of the VAZ 2107. How to check the ball joint on the VAZ 2107? Very easy! There are several ways to check ball joints.

If you have an inspection hole or overpass, then we go there and begin inspecting the car. First of all, you should pay attention to the condition of the ball joint boots. From them you can determine the first signs of a malfunction of the ball joint of the VAZ 2107. If they are torn, then most likely this was the reason for the abrasive getting into the body and increased wear of the part. If the boot is intact, and you have a ball with a technological hole in the body, as in the diagram above, then cut a piece of thin straight wire, mark 11.8 mm on it and insert it into this hole. If the tag is immersed in the ball, then it’s time to change it.

If you do not have access to the overpass, simply turn the steering wheel and hang the wheels on the jack one by one. Next, we hold one hand at the junction of the body with the finger, and with the other we shake the wheel. To check the upper ball joint, you should rock the wheel while holding its upper part, and to check the lower ball joint, you should apply force to the very bottom part of the wheel. You can also simply rock the upper and lower parts of the wheel toward and away from you, but this may not give accurate results, since in this case the silent blocks of the levers may still make a sound.

Reinforced ball joints

Any serious manufacturer offers customers a wide range of ball joints: from regular to sports, or reinforced. For example, “Track” supports have a reinforced “Track-Sport” modification.

The “Cedar” supports have a reinforced modification “Cedar-trial-sport”, etc.

All of these products, designed for extreme loads, have a number of common features. Let's look at them using the example of Track-Sport supports:

- universal design. This means that reinforced mounts can be installed on both the upper and lower control arms. Moreover, reinforced supports can be installed on other cars (in particular, Track-Sport supports can be installed in the suspension of a Niva car without any problems);

- increased pullout force of the ball rod. In order to tear the rod out of the suspension, a force of 7 thousand kgf must be applied to the Track-Sport support (while on conventional Track supports the force is 5 thousand kgf);

- The mileage guaranteed by the manufacturer for sports ball joints starts from 60 thousand km (for conventional bearings - from 40 thousand km);

- Sports support inserts have a special design. They are stiffer and have special grooves designed to remove excess lubricant and wear products. This technical solution allows you to double the service life of the reinforced support.

Video: review of Track-Sport ball joints

As you can see, there are few reliable manufacturers of ball joints, and the only criterion for choosing these parts is the thickness of the car owner’s wallet. If a person is not short of money, you can immediately purchase LEMFORDER supports and forget about problems with the suspension for several years. In second place is Trek, but here the situation is seriously complicated by the abundance of fakes of this brand. Automotive store shelves are now literally littered with fake Trek. Well, if the issue of price is critical for the driver, then you can pay attention to Belmag products.

Repair

Replacing ball joints on VAZ 2101, 2102, 2103, 2104, 2105, 2106 and 2107

Now these critical parts are considered consumables. But even relatively recently, during times of total shortage, balls were dismountable and craftsmen restored them for reuse. Such balls on classics lasted up to 40-45 thousand. Restored parts are slightly smaller. Modern ball bearings can last up to 60-65 thousand km, but this is in the factory version and on relatively good roads. But if you come across the wrong product, you will have to change the supports much more often. And in the worst case, you have every chance of standing in the middle of the road with a twisted wheel.

We bought products made by BelMag.

The company has been well known for a long time, and the packaging box with details and a security hologram gives hope for their authenticity. The standard tool for the job is quite enough: a jack, a hammer (weighing at least 0.8 kg) and a reliable stand. Those who oppose sledgehammer methods will also need a special puller (see below).

The main thing is to choose the most suitable replacement method for you.

When pressing out ball joints on a VAZ 2101-2107, it is possible to use the three most common methods.

Using an x22 open-end wrench, unscrew the nut securing the ball joint pin.

Then, we apply several blows to the body of the steering knuckle, as a result of which the finger should jump out of the socket.

For safety reasons, the rationalization shown in this photo is unacceptable! Pieces of hardening from an anvil hammer can riddled your face like bullets!

It is possible that working in the second way with a puller is easier than swinging a sledgehammer. But we didn’t like this option - it’s very inconvenient to turn the screws in a tight space.

But with such a device it’s both easy and pleasant. The third method turned out to be the most successful!

And the result was not long in coming.

All that remains is to unscrew the fasteners using two x13 keys.

and remove the ball joint.

Attention! Do not forget to remove the additional plate from the upper support and put it back in place when reassembling, otherwise there will be a gap between the cover and the support body. We remove the lower support in the same way. But the pin nut cannot be unscrewed completely, since the rotary lever is in the way

Therefore, all remaining turns will have to be done after pressing out the finger. Remember that in a worn body, nothing holds the finger and, if the nut is screwed together with resistance (for example, the thread was not cleaned of dirt and rust before this work), the finger will rotate in the body, and it will be very difficult to hold it with anything. Now, even if you decide to clean the thread, you will face the problem of how to screw the nut back on? WD-40 won’t always help here either! In such a situation, it is most reasonable to hit the cone of the finger into the hole of the steering knuckle. Now you can return the nut to its original place. Do not tighten too tightly! And then a thorough cleaning of the thread, after which the nut can usually be unscrewed.

But the pin nut cannot be unscrewed completely, since the rotary lever is in the way. Therefore, all remaining turns will have to be done after pressing out the finger. Remember that in a worn body, nothing holds the finger and, if the nut is screwed together with resistance (for example, the thread was not cleaned of dirt and rust before this work), the finger will rotate in the body, and it will be very difficult to hold it with anything. Now, even if you decide to clean the thread, you will face the problem of how to screw the nut back on? WD-40 won’t always help here either! In such a situation, it is most reasonable to hit the cone of the finger into the hole of the steering knuckle. Now you can return the nut to its original place. Do not tighten too tightly! And then a thorough cleaning of the thread, after which the nut can usually be unscrewed.

We carry out assembly in reverse order. And do not forget to put grease in the case before installing the ball. The mileage will be longer.

Sources

- https://www.avtorem.info/stati/vaz-2101-vaz-2106-vaz-2107/zamena-nizhnej-sharovoj-opory-na-avtomobilyah-vaz-2101-vaz-2102-vaz-2104-vaz- 2105-vaz-2106-vaz-2107-zhiguli-klassika.html

- https://spike.su/index.php/Ball-joints-VAZ-2101-2106-2107.html

- https://remontysvoimirukami.ru/remont-vaz-svoimi-rukami/remont-sharovyh-opor-vaz-2101-svoimi-rukami.html