The reasons why the spark disappears on a VAZ-2109 carburetor type car may be the following:

- faulty Hall sensor;

- the switch burned out;

- break in the ignition coil;

- high-voltage wires are worn out;

- the candles became unusable;

- The timing belt is worn.

From the very beginning, if the disappearance of the spark is detected, you should review all contacts and the condition of the electrical wiring. If you find oxidation on the connector, it must be cleaned with sandpaper and rechecked for the presence of a spark. High-voltage wires should be checked for integrity using a special device - a tester.

A breakdown in the ignition switch can be diagnosed using a standard automotive lamp. One of its contacts must be connected to the body body or carburetor engine 2109, and the second contact must be connected to wire “B+” from the ignition coil. If the light is on, this indicates that the ignition switch is working properly. In this case, you need to go to the ignition coil.

The serviceability of the Hall sensor can be checked using a voltmeter or, again, a light bulb. At the moment the distributor rotates, the filament in the light bulb should change the intensity of the glow.

The simplest way to check for proper ignition of carburetor VAZ-2109

If there is no spark in the car, you can find the reasons in another way. This technique does not require the use of a special device or tool. In this method, the entire ignition chain is tested, without taking into account the Hall sensor. To carry out this work, we need a small wire with insulated ends and a nail or paper clip.

First of all, we disconnect the high-voltage cable from the distributor. During checking, it must be positioned approximately 10 millimeters from the minus of the car. Next, turn on the ignition. Disconnect the connector from the Hall sensor and connect its end to the middle contact, to which the green wire is connected. We short the other end of our wire several times to ground. At the moment of short circuit, sparks should run between the ground and the end of the wire. If there is a spark in a carburetor VAZ-2109, we can conclude that the Hall sensor is faulty or there is no contact. Often, inside the distributor itself, the plate frays the wires or the connector simply becomes loose. In addition, there are cases when, when checking, we see the presence of a spark, but when connecting the wire to the spark plug caps, there is no spark. This indicates the need to replace the slider inside the distributor. Some carburetor-type VAZ-2109 are equipped with an ignition interlock circuit, which may also become unusable (or there is a malfunction in the switch).

Before performing the test, you need to prepare the following set of tools:

- figured and flat screwdrivers;

- insulated pliers;

- control with a wire or tester;

- spare spark plug.

To protect yourself from electric shock, you should wear dielectric gloves.

Verification process:

- We turn off the ignition, after which we check the high-voltage wires for breaks, and at the same time check for good contact in the connections with the distributor and the ignition coil.

- We carefully inspect the condition of the wires between the distributor and the switch, and also check the wires from the ignition coil to the switch.

- With the ignition switch on on a carburetor VAZ-2109, you need to check the presence of power in the system. To do this, take a test lamp, connect one end to ground, and the other to the “B+” contact of the coil. The glow of the control lamp indicates the presence of power.

- Using a rubber glove, disconnect the middle high-voltage wire from the distributor. We put a spark plug into its tip and touch the engine ground with the metal part. When cranking the starter, sparks should flow from the spark plug.

- Unscrew the screws of the distributor and remove its cover. We check for cracks and damage, and also check the condition of the coal. If the cover is damaged or cracked, it must be replaced.

- We inspect the condition of the slider in the distributor. Quite often it happens when there is no spark due to a breakdown of the interference suppression relay or breakdowns in the housing of the ground slider.

- We check the crankshaft by rotating the starter. If the slider is stationary, the reason for this is a broken timing belt or the drive itself is faulty.

- We check again for the presence of a spark.

- If once again there is no spark in a VAZ-2109 carburetor type car, you should check the high-voltage ignition wiring, as well as the spark plugs themselves. To do this, you must use a known good spark plug. If there is still no spark, change the high-voltage wire.

There is a special offer on our website. You can get a free consultation with our corporate lawyer by simply submitting your question in the form below.

How does the Hall sensor and centrifugal mechanism work?

On a VAZ-2109 car, the distributor corrects the ignition timing during engine operation. This is possible due to the use of a centrifugal device in the design. It can affect the slider when the engine accelerates sharply. The centrifugal mechanism is similar in design to those devices that were installed on contact-type ignition systems. In addition, the breaker on the VAZ-2109 car is also equipped with a vacuum corrector. When a vacuum is created in the intake manifold, it is then transmitted through a special tube to the corrector chamber. There is a rubber diaphragm there. The latter is connected to a rod, which is fixed to the plate. This is where the Hall sensor is located. This element made it possible to remove the contact group from the distributor and make the operation of the ignition system more stable.

The Hall sensor, together with this plate, can move, thereby adjusting the ignition timing. In this case, the SOP increases or decreases. It depends on the number of revolutions and how intensely the engine picks them up.

Communities › VAZ: Repair and Modification › Forum › no spark VAZ 2109 carb

there is no spark on the VAZ 2109 carb, it all started with the fact that at speed the wires to the radio connected directly from the battery were shorted, I accidentally shorted it with my foot on the gas pedal, after which the car just immediately stalled and would not start again. found the reason there was no spark from the coil, bought a new switch with a check of the hall sensor, before that it was 6 pin and installed 7. so when you turn on the ignition, the light on it lights up, but as soon as you put it on the bolts (that is, on ground) there is a click in the sensor EPHH which is screwed into the carburetor on the right, and the light stops burning, when pressed from ground it lights up) what could it mean? And is it possible to remove the contact from this EPHH for now so as not to interfere?) the hall sensor is working, the switch is new, all that remains is to check whether the switch is providing power to a reel of which I simply didn’t have time because... The battery is dead. And by the way, I saw a video that on the classics, the spark is checked by twisting the distributor (the runner itself) manually, is it possible to check the spark on the nine this way, that is, take off the cover with the explosive wires and twist the distributor by hand?

Yes, everything is MUCH simpler my friend. The car has stalled, first you check the timing belt to make sure it is spinning and not standing still, check the + on the coil switch, then remove the chip from the Hall sensor on the ignition switch on the distributor and short the middle contact to ground, the central armored wire must be removed from the distributor so that a spark can be seen If there is a spark, then Hall is replaced. If there is no switch or wiring, the coils rarely die at all, and even then gradually. Good luck in finding

soooo. The middle contact is the contact that goes to the hall into the distributor to ground? Or to it?

Yes, everything is MUCH simpler my friend. The car has stalled, first you check the timing belt to make sure it is spinning and not standing still, check the + on the coil switch, then remove the chip from the Hall sensor on the ignition switch on the distributor and short the middle contact to ground, the central armored wire must be removed from the distributor so that a spark can be seen If there is a spark, then Hall is replaced. If there is no switch or wiring, the coils rarely die at all, and even then gradually. Good luck in finding

how to check the plus on the coil?

Check the power to the coil by connecting the wires from the carrier. If there isn’t one, then we sell MD-!, this is just for troubleshooting, there are three light bulbs - K-coil, P-power, D-sensor. connects to the bus connector instead of the switch. As for 6 and 7 contacts, they are all 6, because the 7th is simply free, and the price of a two-channel one is five times more expensive and will be larger in size!

Well, here’s the one that I bought when I checked the sensor, a new one with 7 contacts in it, it’s small in size, I couldn’t even put it back on the bolts, which was larger with 6 contacts) I still haven’t gotten there, what’s the difference between them... how much does the MD sensor cost?

MD-1 costs about 150 rubles. This is a box with a block for a bus connector and three diodes. They have it in stock just in case, they carry it in the glove compartment, like the emergency ignition, which will help you get to the place if the Hall sensor fails, AZ-1, everything is the same connection and price as for MD-1.

You bought a switch under a transparent cover, most likely “ASTRO” are test switches! In terms of fit, most likely the studs are slightly bent or a casting was missed in the mounting hole of the switch radiator (this is not a crime, you can forgive the manufacturer) the main thing is that the electronics are passable.

This is interesting: How does the hidden patrol work in Moscow?

Well, yes, I heard the astro test)) with which I checked the hall sensor and that’s it! I looked at the coil, it doesn’t provide power, thanks to my friend for his wonderful switch that solved all the problems, look, the hall sensor is working, we checked the switch, it gives power to the coil, but the coil flatly refuses to accept this situation and does not give us a spark, all that remains is that replacing the coil, right?

that is, on the MD-1 you can calmly check everything, start it and drive away? how long can you ride it? I just have an idea to plug it in instead of a switch and that’s it

NO! Not the right decision. MD is an abbreviation, M-instant D-Diagnostics. T, E, this is a device for checking a malfunction in the power system.

AZ-A-emergency Z-ignition, i.e. In order not to change the Hall sensor, put it in the block and go!

It’s interesting that you write about the coil. Your spark is gone. The switch is wonderful - it shows the presence of power, then it doesn’t. What's next ? Next you need to check the power to the coil. pulses from the Hall sensor.

Only then make a decision to replace something. But you can start changing something right away. The method of scientific poking, this one is also applicable, however. The current coil costs 550 rubles. Yes, and change the sensor - remove the distributor. and on the Tauride motor the lower nut is not very conveniently located. Although, you can smear it on the spot without removing the distributor, summer is warm, however))))

yeah it's warm))) I used a lot of Russian language to unscrew the rusted nuts on the coil: DD but still I replaced it with a new one, it costs 650 rubles. the impulse goes to the coil, checked with a light bulb, it seems like it should start, I don’t know, I just sneezed, and this is a sign, there’s just no gasoline in the tank)) I’ll see if it doesn’t start and I’ll report back)) thanks for the advice!

If it doesn’t start, then you need to lubricate the place where you start it with Vaseline))))) Engine - starts Electric engine - gets excited

Stage one

Usually the symptoms of difficulty are the following: the starter rotates regularly in its own standard mode, but the engine does not want to start. One of the most possible circumstances is a fuel pump that does not start. When on injection “tens” it is submersible and is located directly in the tank.

There is an option to check the element by the presence of operating sound. Turn on the ignition - there should be a rumble in the area of the rear seats. He is absent from time to time. In our version, you should check the fuses. The VAZ-2110 is a fuel-injected car, and the fuse box is located on the side of the center console of the unfamiliar front passenger. You need to unscrew the fasteners, then remove the cover, check the fuses for functionality and change them as necessary. In this case, the elements are 100% serviceable, then you need to check whether the relay will turn on, both the main one and the fuel pump. Of course, you can feel the moment of switching on with your finger. A corresponding click will also be heard.

If the fuel pump is operational, use a pressure gauge to check the presence of fuel there. If there is no pressure gauge, then press on the spool at the bottom of the fuel rail. myth element may be in a protective cap. The pressure will be completely tangible, although its power cannot be found. A running pump and no pressure indicates an obstruction in the fuel line. This is caused by a clogged fuel filter.

How to determine that there is no spark on a VAZ 2109 (carburetor)

If an attempt to start the engine fails, you may suspect an ignition problem. not try to start the engine more than 3 times , as the battery will be discharged and the malfunction will not go away on its own . We need to start looking for the reason for this state of affairs. The search for a possible malfunction is done with an assistant who could turn on the ignition switch at the right time. A simple household multimeter will be useful for this work.

The first step is to check the performance of the coil, since it produces a high-voltage discharge. The simplest test is this:

- remove the high-voltage wire from the distributor cover;

- wearing gloves (to prevent electric shock) or taking the wire with pliers with insulated handles, bring its contact to the ground at a distance of about 1 cm;

- the assistant turns on the ignition (starter);

- A large blue spark should appear.

If there is an electrical discharge, the search for the cause is directed towards the distributor and spark plugs; if not, the coil, switch, Hall sensor, and ignition switch are checked. Let's consider how to independently check the serviceability of the listed devices.

Coil

Before checking the coil, it is worth checking the integrity of the central high-voltage wire, since its malfunction may also be the cause of the lack of a spark. To do this, the tester switch is set to the 20 kOhm position, and its probes are connected to the opposite contacts of the armor wire. If the multimeter shows values between 3.5 and 9 kOhm, the high voltage wire is OK. For other values, the wire is replaced with a serviceable one.

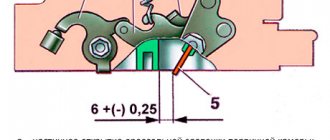

If the armored wire is working properly, the coil is tested. We check the integrity of the primary winding. The multimeter probes are connected to the “B” and “K” terminals of the coil. The switch is in the 20 Ohm position. Normal resistance for a device installed on the “nine” will be in the range of 0.4–0.5 Ohms.

To check the resistance of the secondary winding, connect the probes to terminal “B” and the high-voltage output. Tester switch in position 20 kOhm. The normal resistance value is within 4–5 kOhm. If the resistance readings are very different from normal, the coil is replaced with a new (good) one.

Switch

If the coil showed normal resistance figures, it is not the reason for the disappearance of the spark. Next along the chain is a switch. The tester will not be able to “ring” it. The functionality of an electronic device is checked by replacing it with a known good one. If the “live” switch has not changed the situation, you need to move further along the chain.

Hall Sensor

This device is treated in the same way as a switch (replaced with a functional one). The difference is that the Hall sensor is more difficult to reach. To do this, you need to disassemble the distributor.

Egnition lock

If the coil, commutator and Hall sensor are working properly (do not forget to check the integrity of the contacts between these devices), but the spark does not appear, the reason may lie in the ignition switch. When the lock is turned on, power is supplied to the coil. It is checked like this:

- the tester switches to 20 volts;

- one multimeter probe to terminal “B”, the other to ground;

- When the battery is charged, the device will show 12 V.

You can use a control light. When its wires are connected to the mentioned contacts, the lamp will light up. If the lamp does not light or the tester does not “detect” voltage, you should look for the cause of the missing spark in an open circuit (fuse, wire).

Rarely, there are situations when when you turn the key in the lock to the first position, voltage flows to the coil, but disappears in the second position (engine start). To eliminate this option, terminal “B” of the coil is connected to the battery positive directly. If there is a spark in this situation, there is a problem with the lock. It is better to replace it or have it repaired by an experienced auto mechanic. If you have the skills to work with this mechanism, we can offer information to help.

Now let's look at what causes the spark to disappear in the direction of the circuit other than the coil.

Distributor

A distributor malfunction is suspected if there is a full spark on the central armored wire, but there is none on any of the spark plugs. The reason is that the contacts on the distributor or slider cover burn out. To determine problems, an inspection after removing the cover is sufficient (the contacts are oxidized or covered with black soot). The malfunction is eliminated by cleaning the contacts. If the integrity of the distributor cap is damaged, it should be replaced.

Remember that the cover of the distributor, armored wire, and spark plugs should be kept as clean as possible. Oil stains, dirt, and moisture significantly impair the quality of the spark.

High-voltage wires (VV, armored wires)

If you conduct a full test of the ignition system, you cannot do without checking the armored wires connecting the distributor cover and the spark plugs. They are “tested” with a multimeter in the same way and with the same desired result as the central wire (described above). During active use of the VAZ 2109, it is better to replace the armored wires approximately once a year, since their service life is designed for approximately this period.

Changing such parts every year is not a cheap pleasure.

Is it because of the candles?

Often the cause of the disappearance of the spark is the spark plugs themselves. If they have not been changed for a long time, then even with a high-quality high-voltage pulse the spark will be weak or disappear altogether. Problems also arise with “fresh” candles. When the fuel mixture is highly enriched, they quickly become covered with a thick layer of soot, which is a dielectric and therefore reduces the quality of contact between the electrodes. In this case, you should adjust the carburetor (reduce the gasoline content in the mixture), and clean the spark plugs with a special brush with metal bristles.

There will be no spark even in the situation if the candles are “flooded”. This happens when a cold engine is started with the air damper closed (on choke). In this case, the fuel mixture is very rich, and after the first unsuccessful attempt to start the engine, the spark plugs become wet. The situation is corrected by calcination and subsequent cleaning of the candles, after which they become suitable for use.

Video: Why there is no spark on the carburetor “nine”

Malfunctions of the ignition system of cars, including the VAZ carburetor “nine”, throw many car enthusiasts into a stupor. Although, if you understand the scheme, it turns out that it is not at all complicated. It is important to consistently approach the diagnosis of possible causes, eliminating one after another, in order to achieve success in the test.

This is interesting: Myths regarding ground clearance: advertising and real figures

High voltage wires

It doesn’t often happen that all the wires fail at once, but they still need to be checked. The functionality is determined by disconnecting each one in turn and measuring the resistance. In good condition, the resistance value, including on the main conductor, should be within the range of 2.7-9 kOhm. If deviations are detected, faulty elements must be replaced.

It will not be superfluous to check the so-called “coal”, that is, the graphite contact of the wire. If it is damaged, no voltage is supplied to the slider and all spark plugs will be de-energized.

Based on the list of common problems that cause the “nine” to lose spark, it is clear that this car is not very complex in terms of effort and time. It is enough to have a basic set of knowledge and a set of tools - and the car is ready to travel again.

Device Features

Structurally, the VAZ 2109 coil consists of a pair of windings - secondary and primary.

- The primary winding has fewer turns, but wires with a larger cross-section;

- The secondary winding of a coil with a large number of turns, but a smaller wire cross-section.

Windings

Signs of breakdown

Often the spark at the carburetor disappears unexpectedly when the driver is not prepared for such a turn of events. But if you have enough experience and pay close attention to the behavior of your car, you can detect signs of a malfunction before the spark disappears and the engine does not start.

So, why does the spark disappear, what are the reasons and what signs may indicate a failure of the ignition coil?

- Approximately 500 kilometers before the coil’s life is over, on a cold engine the device normally starts working only after a couple of minutes of warming up. The engine starts with difficulty, but some people think that the problem is in the idle system. At the same time, the engine begins to behave unstably at low speeds. This phenomenon occurs within 10-30 seconds, so you don’t always have time to pay attention to it.

- Another short-term symptom is the engine actively shaking when starting a cold engine and holding down the gas pedal. This will happen literally for 3-5 seconds, and after pressing the pedal again, everything will return to normal.

- When accelerating or changing gears at the gearbox, the engine may produce jerks, vibrations, and the dynamics deteriorate for a short time. The downside is that such a symptom may appear for a few moments, but disappears just as quickly.

- The most obvious sign is the complete failure of the engine to try to start. The spark disappears, and therefore the chances of starting are zero.

Bringing the car back to life

As for why a spark disappears, everything is probably very clear. Now, it would not be amiss to consider the order of her return. The reality is that in most cases, getting the spark back is a simple matter and just involves carefully checking the broken car. To be more precise, to normalize sparking it is required:

- Firstly, check the spark on the injector using the method described above, make sure that it has disappeared, and, at least indirectly, try to determine the cause of the malfunction;

- Next, it is enough to assess the current circumstances and act based on them. As typical situations, we suggest considering solutions to the following problems:

- the spark plug is wet, the presence and strength of the spark are unimportant, the carbon deposits are correct (brick color) - wipe the part and screw it back in;

- the spark plug is wet (not always) and the carbon deposits are incorrect (white or black) - clean, dry the part and try to start the engine, if there is no result, change the spark plug and deal with problems in the fuel system (cleaning the injector, checking the ECU, etc.);

- the spark plug is wet, there is no spark at all, the color of the soot is not important - we try to change the part, if there is no result, we check the ignition system and the operation of the injector.

In principle, in theory there are no particular difficulties in repairs of this kind. Despite this, it often causes difficulties in implementation for inexperienced motorists. To solve these, you need to act in the order described above, but if something doesn’t work out, it’s better to turn to professionals at a service station. This approach to repairs will not only save time, but also guarantee trouble-free operation of the car in the future.

Perhaps this concludes the most important information on today’s issue. We hope that the material presented was useful to you and provided answers to your questions. Good luck in operating and maintaining your car!

Examination

If you notice signs of a problem with the ignition coil, or have to deal with a situation where the engine “died,” be sure to check the condition of this element.

As you test, you will be able to determine what caused the coil to fail and how the problems can be corrected.

How to check the device? The instructions are not complicated, even a beginner can handle it.

First, let's check the condition of the unit, and then check for correctness of the resistance of the coil itself.

- If the engine cannot be started, make sure that the coil itself is producing a spark at all. To do this, the central wire is removed from the distributor and a spare spark plug is connected to it.

- Now take the spark plug with pliers and place the metal casing on the breaker or motor.

- If a spark does not appear when the engine starter is turned, there is a malfunction in the ignition system.

- So check the power to the coil, or rather its presence. For this you will need a multimeter. One terminal is connected to contact B on the coil, and the second goes to ground. Turn on the ignition. If there is no voltage, the culprit is the ignition switch.

- You can start the engine in emergency mode. To do this, the plus from the battery is thrown onto contact B of the coil.

If there is voltage but there is no spark, check whether the primary winding is intact. To do this, the side low-voltage wires are disconnected from the coil and resistance measurements are taken with a multimeter. Then the secondary winding is checked.

We will tell you about this procedure in more detail.

Multimeter for testing

Low voltage circuit

Using a 12V lamp, you can check the low voltage circuit. The lamp must be connected with the first contact to the low voltage terminal, and the second to the car body. Next, you need to close the distributor contacts and start the ignition. If the circuit is OK, the lamp will light when the contacts open and go out when the contacts close.

If the lamp does not light up when the contacts are opened, this means that the problem is in the low voltage wiring or in the ignition coil, or rather, in its winding.

VAZ 2109 carburetor has no spark - search for reasons

The carburetor "nine" does not produce a spark. Why does this happen and what to do? If there is no spark in the VAZ 2109 carburetor, the reasons lie either in the malfunction of one of the elements or in the wiring that connects them. You can independently identify the cause of the unit failure. To troubleshoot, you will need an assistant to turn on the ignition. You will need a multimeter, as well as spare parts (switch, Hall sensor). To find a breakdown, you need to understand the sequence of connecting the circuit elements and at least in general know the principle of the appearance of a spark on the spark plugs. Let's look at it and check all the devices for functionality.

Why is car diagnostics necessary?

Judging by everything written above, we can conclude that searching for a problem takes a huge amount of time and spends a lot of effort. In order not to let this happen and to save on possible repairs in advance, it is necessary to carry out regular diagnostics of the vehicle.

Unfortunately, this cannot always be done through a service station, since:

- They ask a lot of money for standard diagnostics.

- You need to go to professionals if a serious problem arises.

- Finding workers who have experience in solving the problems that arise is quite difficult.

It also happens that after diagnostics are carried out at an unverified service station, additional repairs are required.

A good way to solve the problem of inspecting a car is to purchase an ELM327 auto scanner. The device can connect to any car, and the test is carried out using a mobile phone. This will not only allow you to identify the fault in time, but will also save money.

How a spark is formed on a candle

By turning the key in the ignition, you turn the starter. Its function is to engage the gear with the flywheel to transmit torque to the flywheel. As soon as the parts are engaged, the moment is transferred - the key returns to its place. And during this time, while the key was turned, a number of processes should occur, as a result of which a spark appears on the candles.

The flywheel itself is mounted on the crankshaft and rotates it. From the crankshaft through the timing belt, rotational motion is transmitted to the camshaft. Simultaneously with the camshaft and at the same frequency, the shaft on which the distributor slider (ignition distributor) is located rotates. The cylindrical screen rotates and an electromagnetic field (EMF) is generated, the voltage value of which is read by a Hall sensor. Next, the switch comes into operation. This device converts the voltage to the required value and transmits it to the primary winding of the ignition coil.

An electromotive force is generated inside the coil and exits through the central electrode. From here the pulse is supplied to the central wire of the distributor, to which 4 spark plugs are connected. The distributor rotates, making contact with each of the spark plugs in turn. The spark plugs are screwed into the cylinder head, their electrodes are located in the combustion chamber.

As a result of a short circuit on the spark plugs, a voltage of 10–15 kV is achieved. This is enough for a spark to occur between the central and side electrodes of the spark plug.

Coil

The VAZ 2109 ignition coil itself fails quite rarely, but it is necessary to check it. This can be done using a multimeter turned on in ohmmeter mode. We connect one of its probes to terminal “B”, and the second to terminal “K”. These are the ends of the primary winding. The resistance value should be 0.4-0.5 Ohm.

After this, we check the secondary coil by connecting the probes of the device to terminal “B” and the high-voltage terminal. Here the resistance should be about 4-5 kOhm. For any other indicators, the VAZ 2109 ignition coil must be replaced.

The VAZ 2109 ignition coil itself fails quite rarely, but it is necessary to check it. This can be done using a multimeter turned on in ohmmeter mode. We connect one of its probes to terminal “B”, and the second to terminal “K”. These are the ends of the primary winding. The resistance value should be 0.4-0.5 Ohm.

The main reasons for the lack of ignition

The principle of operation is clear. All malfunctions of the VAZ 2109 ignition system are associated with the failure of one of the above elements. If there is no spark on the VAZ 2109 carburetor, it means there is a malfunction:

- switch;

- Hall sensor;

- timing belt;

- ignition coils;

- ignition switch contact groups;

- distributor cover contacts;

- candles (“drenched”, burnt);

- circuit wiring.

If the commutator is faulty, then the voltage value to the coil is not converted. A failed Hall sensor does not supply current to the switch. If the timing belt breaks, the operation of the system is disrupted and EMF is not generated. A broken coil stops the chain moving on itself, the distributor contact does not receive voltage. Damaged distributor cover contacts prevent voltage from being applied to the spark plug.

The spark plug electrodes may not produce a spark due to carbon deposits or moisture on them. It happens that the culprit is the first element of the circuit: the ignition switch. A breakdown in its contact group does not start the starter. It is also possible that a banal damage to the wiring has occurred, causing the connection of the elements to disappear.

If there is no spark in the VAZ 2109 injector, the process of finding a breakdown is much more difficult. After all, the design of the system requires the presence of a separate ignition module controlled by the ECU.

Possible errors in VAZ injectors

Codes, of course, indicate defects in all parts and components in the car. In most cases this is due to sensors. Temperature sensors suffer in particular - they overheat. Car owners also complain about the injectors. Problems arise due to breaks in the circuit. Once completed, they do not have the basis to work properly. This also includes the popular breakdown on the VAZ-2110 - no spark. The 8 valve injector cannot start normally due to this.

Now about errors related to the engine. The most common one is overheating. The spark plugs also overheat, causing the spark . And therefore the engine does not show any signs of life. Next it’s worth looking at the valves. These parts are usually very dirty, which in the process will lead to their complete closure. They do not allow the required mixture of air and fuel to pass through. And finally, the fans - if they don’t work, then the unit will constantly overheat.

Determining the area

If the VAZ 2109 (carburetor) does not start at all, it is better to start checking in the area from the battery to the distributor. This way we will understand whether the battery, the lock contact group, the switch and the coil are working.

- Raise the hood.

- We disconnect the “cradle” of the central armored wire from the distributor cover.

- We insert the spark plug into the cradle, press it with its “skirt” against the valve cover (an unpainted area of the body) and ask an assistant to start the starter. Never hold a candle with your bare hands! You will receive an electric shock. Although not fatal, it is quite unpleasant. It is best to hold the candle with dielectric pliers.

- While the starter is operating, we look at the interelectrode space. If there is no spark, the VAZ 2109, naturally, will not start.

Now we have to install the faulty element in the battery-coil section. This is not difficult to do.

Switch

With a switch the situation is somewhat more complicated. The fact is that it is impossible to check it yourself. The best solution here would be to replace the device with a known good one.

Having determined that the spark on the VAZ 2109 (carburetor) has disappeared in the area before the distributor, we can immediately conclude that the switch is the reason for this. This is the most capricious device in the entire ignition system. It can “burn out” due to the slightest voltage drop caused by a malfunction of the generator, faulty spark plugs or high-voltage wires. This is why some experienced Samar drivers carry a spare device with them.

No need to guess too much - you need to use the following devices

The first device – A3-1 – emergency ignition. You can use it in the rain or when driving through puddles (to warm up or dry the spark plugs) to check the electronic switch or when the hall sensor fails. In other words, emergency ignition is a substitute for a hall sensor, but with a speed limit of up to 90 km/h.

The second device - MD-1 - instant diagnostics. Used to check the functionality of the hall sensor, ignition coil and ignition switch. To begin with, it is better to use MD-1. We connect it instead of the switch and turn on the ignition, but we don’t start the car!

- if the LED “P” is on, the ignition switch and ignition relay are operational

- LED “K” is on - the ignition coil is working

- turn on the starter: if the “D” LED blinks, it means the hall sensor is working

If it were not blinking, then we would have to use the AZ-1 device and connect it instead of the hall sensor - this would check the wiring and the serviceability of the sensor itself.

After the cold weather I can’t start the car. Dying Path: At first the car started, but stalled. Warming up with the accelerator pedal pressed did not solve the problem.

Symptoms: No spark.

Dear friends! Thanks to everyone who helped in finding the problem.

The reason has been found. I was mistaken in that: - I have not a 4-pin, but a 3-pin chip on paired coils.

What happened after our questions: — Replacement of the camshaft position sensor; — disabling the alarm for interaction with the ignition system; — the main relays were checked.

What was the reason: 1. Having tried all the options, which lasted long enough for me to miss driving)), the car was taken for diagnostics and to a professional electrician. 2. I got into a tow truck and rushed through the streets of Sevastopol. Admiring your swallow in the rearview mirror. I caught myself thinking that the situation was unusual for both of us)) 3. Diagnostics showed that impulses come to all possible connectors, chips, injectors. It's not a matter of signal wires here. And everything was fine with the mass. The signal from the ignition switch does not go directly to the relay, as we discussed. The wire goes to the ECU, from it through the main relay to the coil. 4. As I described, the twin coil that distributes the spark plugs was replaced. It caused damage to the ECU. This was confirmed visually (melting of board elements).

VAZ-2110 malfunctions: no spark. 8-valve injector: probable causes of problems

Our client is left with possible breakdowns of VAZ-2110 cars, which are conventionally divided into three types. These are problems in the fuel supply system, various failures in electronics and electrical systems, and also more global problems (ICE, gearbox). If there are problems with the ignition system in the car, then a diagnosis is immediately made - the spark has disappeared. It is necessary to consider why there is no spark on the VAZ-2110 (injector, 8 valves). What is needed, what are the prerequisites for such a malfunction?

Battery and ignition switch contact group

If you have determined that the spark on the VAZ 2109 (carburetor) has disappeared in the area from the battery to the high-voltage terminal of the coil, the culprit may be either a discharged battery or a faulty ignition switch. Let's check if electricity is supplied to the coil. To do this, using a voltmeter (multimeter), with the ignition on, measure the voltage between the “+B” terminal of the coil and “ground”. If it is, its value should be at least 11 V.

The absence of voltage indicates a failure of the contact group. The most common cause of malfunction is oxidation or burning of the leads. This problem can be resolved by cleaning the contacts.