| The engine cooling system (ECS) is one of the main systems of a car. Is cold air blowing from the stove or is the engine on the LADA Kalina overheating? Then the inspection should begin with this system. In this article you will find all the information on the operation of the Lada Kalina cooling system. |

Design of the LADA Kalina cooling system

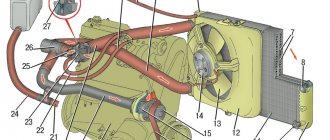

Cooling system: 1 — expansion tank;

2 — radiator outlet hose; 3 - inlet hose; 4 - radiator; 5 — steam exhaust hose; b — radiator supply hose; 7 — electric fan; 8 — electric fan casing; 9 — coolant temperature sensor; 10 — coolant temperature indicator sensor; 11 — throttle assembly; 12 — bracket for the coolant pump pipe; 13 — coolant pump; 14 — coolant pump pipe; 15 — heater radiator supply hose; 16 — heater radiator outlet hose; 17 — exhaust pipe; 18 — coolant pump pipe hose; 19 — thermostat housing Expansion tank. Coolant is poured into the system through the expansion tank. It is made of translucent polyethylene, which allows you to visually monitor the liquid level. To do this, the marks “MAX” and “MIN” are marked on the wall of the tank. In the upper part of the tank there is a pipe for connecting to the radiator steam exhaust hose, in the lower part there is a pipe for connecting to the inlet hose. Expansion tank viburnum

Expansion tank cap with valves. The tightness of the system is ensured by the inlet and outlet valves in the expansion tank cap. The exhaust valve maintains increased (compared to atmospheric) pressure in the system on a hot engine (due to this, the boiling point of the liquid becomes higher, steam losses are reduced}. It begins to open at a pressure of at least 1.1 bar. The intake valve opens when the pressure drops to system relative to atmospheric pressure by 0.03-0.13 bar (on a cooling engine).Expansion tank cap with valves

The coolant pump is a vane, centrifugal type, driven from the crankshaft pulley by a timing belt. The pump housing is aluminum. The roller rotates in a double-row bearing. The bearing is lubricated for its entire service life. The outer ring of the bearing is locked with a screw. A toothed pulley is pressed onto the front end of the roller, and an impeller is pressed onto the rear end. A thrust ring made of a graphite-containing composition is pressed to the end of the impeller, behind which there is an oil seal. The pump housing has a control hole to detect fluid leakage when the pump fails. It is recommended to replace the pump as an assembly. The redistribution of liquid flows is controlled by a thermostat. Coolant pump Kalina

The cooling system consists of two so-called circulation circles:

- The movement of liquid through the cooling jacket and radiator forms a large circulation circle.

- The movement of liquid through the engine cooling jacket, bypassing the radiator, is a small circle of circulation.

The cooling system also includes a heater radiator and a throttle body heating unit. Liquid circulates through them constantly and does not depend on the position of the thermostat valves.

Thermostat. It has a solid temperature-sensitive element and two valves that redistribute the flow of coolant. On a cold engine, the main thermostat valve blocks the flow of fluid from the radiator and the fluid circulates only in a small circle, bypassing the radiator. At a temperature of (85±2) °C, the thermostat valves begin to move, allowing liquid flow into the radiator and closing the bypass channel. At a temperature of about (100±2) °C, the main valve opens completely and the bypass valve closes. Almost all the fluid circulates in a large circle through the engine radiator. Thermostat viburnum

Coolant temperature sensor. To monitor the coolant temperature, a sensor is screwed into the engine cylinder head, connected to the temperature indicator in the instrument cluster. In the outlet pipe, next to the thermostat housing, there is a coolant temperature sensor that provides information to the controller. Coolant temperature sensor viburnum

The heater radiator is built into the engine cooling system and is designed to heat the passenger compartment by circulating hot coolant through it.

The radiator consists of two vertical plastic tanks (the left one is with

baffle) and two horizontal rows of round aluminum tubes passing through the cooling plates. The tubes are connected to the tanks through a rubber gasket. The liquid is supplied through the upper pipe and discharged through the lower. Next to the inlet pipe there is a thin pipe for the steam removal hose. The radiator has a casing with an electric fan. There is a drain plug at the bottom of the right tank. radiator viburnum The fan maintains the thermal operating mode of the engine and is switched on via a relay based on a signal from the controller.

Coolant

The main thing is to constantly check the fluid level in the expansion tank; it is installed under the hood. Coolant is added to the system through a plastic expansion tank. The expansion tank performs another important role, namely, it compensates for changes in volume and fluid pressure in the system when it heats up or cools down.

Antifreeze or antifreeze, depending on what is filled, evaporates over time during the operation of the machine, heating up to a high temperature. Do not allow the liquid to evaporate to a level below the “MIN” mark; however, do not fill above the “MAX” mark either, the excess will expand, then pour out through the valve of the expansion tank cap, and antifreeze or antifreeze, consisting of toxic chemicals, will evaporate from the burning engine into the passenger compartment the car further through our lungs into the blood, let’s not be distracted by this from the field of medicine.

Don't worry if you have to add fluid once every few months. If you have to constantly top up, then you need to start looking, wondering what the pump or radiator pipe is leaking.

Avoid overheating the engine in traffic jams or when driving at low speeds on a straight road, especially uphill; when you are skidding, monitor the temperature to prevent the engine from boiling. Just in case, you should keep at least one and a half liters of coolant in reserve. The operation of an overheated motor leads to deformation of its parts, and the consequences can be corrected only by having an expensive overhaul from a motor mechanic or by changing the engine.

Distilled water can be used as a cooling liquid in the summer. Before the onset of frost, the water must be drained immediately, then pour in antifreeze or antifreeze, depending on what is recommended in your instruction manual. As is known, water expands at subzero temperatures, which can cause irreparable damage to car parts. It is good to use coolant all year round.

Here we have looked at the main aspects of the cooling system that need to be monitored when operating the car. Let's move on to looking at photos of repair kits for coolant inlet and outlet pipes.

Photos of a repair kit for pipes for VAZ cars

VAZ-1118

The repair kit for the radiator pipes of the VAZ-1118 cooling system consists of three hoses of different shapes and sizes (see photo).

They have design numbers:

- 1. 1118-1303025-00P send. “leading” (number-1) quantity 1 piece.

- 2. 1118-1303008-01P “discharge” connecting hose (number 2) quantity 1 piece.

- 3. 1118-1303093P connecting hose for thermostat and water pump (number 3) quantity 1 piece.

VAZ-2112 and for VAZ-2170 st/sample

The set of radiator pipes for the VAZ-2112 cooling system consists of three hoses of different shapes and sizes (see photo). Suitable for the first Prior 2170 released.

Their design numbers:

- 1. 2112-1303025Р supply hose (number 1) quantity 1 piece.

- 2. 2112-1303010R outlet hose (number 2) quantity 1 piece.

- 3. 2109-1303093-01P hose “corner” of the thermostat to the water pump (number 3) 1 piece.

VAZ-2170 new/model

The set of radiator pipes for the cooling system for the VAZ 2170 consists of three hoses, two of which inlet and outlet are almost identical in shape and size, there is still a difference between them (see photo). The third hose, number 3 “corner” from the thermostat to the water pump, comes from the VAZ-2112 (see photo above).

They have design numbers:

- 1. 2170-1303010-10 sh. “discharge” (number-1) quantity 1 piece.

- 2. 2170-1303025-10 sh. “leading” (number-2) quantity 1 piece.

- 3. 2109-1303093-01P sh. “corner” of the thermostat to the water pump (number 3) 1 piece.

Possible malfunctions of the ODS, diagnostics

Almost always, a breakdown of the cooling function of a car is caused by an antifreeze leak. You should inspect the car under the hood for possible leaks. The cause of the leak may be:

- or a leaky clamp;

- or a radiator failure.

Then in the first case the element is replaced; this is not difficult and does not take long. As for the radiator, it is better to have it repaired. There are also no particular difficulties here: often you just need to solder the holes.

The reasons for overheating of this car can also be:

- thermostat. Its suitability is checked using both pipes: the temperature of the latter should not be sharply different (this is determined on a warm engine). Otherwise, the thermostat is faulty and antifreeze circulates in a small circle;

- clogging of radiator honeycombs. You can solve the problem by cleaning the outside of this element. Often this is not always easy to do, but there are no other methods other than manually cleaning the honeycombs;

- Fan malfunction. When the heating level of the coolant increases, this part should begin to operate. If this does not happen, check the relay, wiring or t° sensor;

- air in the coolant system. Lada Kalina is not insured, among other things, against the so-called air lock inside the system. In general, previous types of breakdowns are eliminated quite quickly and almost everything is clear with them. In the latter case, it is necessary to understand in more detail. The question - how to remove air from the Kalina cooling system - is really very important for the optimal functioning of the totality of the elements of this car.

Airlock

If the cooling system becomes airy, you need to do the following: with the expansion tank cap open, start the power unit, squeezing the gas pedal from time to time, warm it up until the t° sensor “reaches” the red scale. After “starting” the ventilation device, “add up the gas” a little more and then you can turn off the ignition.

If the cooling system is still leaking air and the above measures have not led to anything, you should act more radically. What needs to be done to remove air from the cooling system?

First, remove the power motor screen (dismantling is done in an upward direction).

Loosen the clamp with a screwdriver and remove one of the tubes from the heating fitting of the throttle assembly.

Unscrew the cap of the expansion tank. Cover the neck of the opened container with a clean piece of cloth. Now blow into the tank: coolant should flow from the tube that was removed. If you fail to break through the above container, close the lid and place the tube in its place.

Next, warm up the engine again and turn off the ignition. Then the tube must be removed again, without removing the lid from the tank, and wait until the antifreeze flows.

Since this liquid is very poisonous and dangerous for people, drain the coolant with extreme caution. Remember about safety: get rubber gloves. Monitor the temperature of the tubes. Keep in mind that you only need to drain the coolant when the engine has cooled down.

Now the tube is put on the fitting, the clamps are tightened. At this stage, the problem of how to remove air from the cooling system of the car has been successfully solved. As you can see, it is possible to eliminate faults in the ODS without the participation of professionals.

SOD Lada Kalina in a certain sense requires improvement.

At the moment, there are the following methods to improve it:

- rework. The car is equipped with a new thermostat. Thus, the temperature of the antifreeze will become stable, and the activity of the interior heating elements will return to normal;

- to minimize coolant malfunction, the machine is equipped with a coolant filter;

- an additional pump in the above-mentioned power unit system. This will force the antifreeze to circulate through the appropriate channels faster, which will definitely reduce engine overheating. And a plus - in cold weather you will not freeze in the car.

Everything that may be important for a motorist on the above topics regarding the Kalina car: what the Lada Kalina heating system is, as well as airing the cooling system, why the cooling system will air, how to remove air from the cooling system, possible malfunctions, necessary alterations more clearly will tell the presented video.

Replacing the thermostat Lada Kalina

Selection and main parameters of wipers for the Lada Kalina car

Which car is right for you

If after reading the article you still cannot compare Kalina and Granta liftback and have not decided which car is best for you, pay attention to the most basic nuances:

- Exterior of the car. It is of no small importance, because every day it is you who drives the car, and not someone else.

- Price. Think carefully about what you are willing to pay for and what doesn't seem necessary. Based on this, choose the appropriate package

- Specifications. Decide what is more important to you - power and speed, or comfort and maneuverability on difficult roads? And perhaps the size of the trunk and the space in the cabin? Do you want to show off your car’s dynamic design to your friends and fly through the city at night, or just comfortably get from point A to point B? Only by thoughtfully and truthfully answering these questions can you choose the car that will completely satisfy you in all respects and will become a real “friend on wheels” for you!

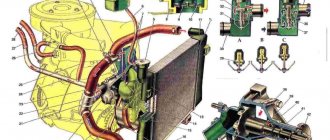

LADA Kalina engine cooling system diagram

diagram of the LADA Kalina cooling systemCooling system: 1 - coolant drain hose from the heater radiator; 2 — hose for supplying coolant to the heater radiator; 3 — coolant pump supply pipe hose; 4 — expansion tank hose; 5 - expansion tank; 6 — steam exhaust hose of the engine radiator; 7 — thermostat; 8 — hose for supplying fluid to the throttle assembly; 9 — hose for supplying fluid to the engine radiator; 10 hose for draining fluid from the engine radiator; 11 — engine radiator; 12 radiator drain plug; 13 electric radiator fan; 14 coolant pump; 15 supply pipe of the coolant pump; 16 coolant drain hose from the throttle body

Procedure for checking the Lada cooling system

1. Check the coolant level in the expansion tank; it should be between the “MIN” and “MAX” marks. If antifreeze has to be added periodically, then the system is not sealed (we check the integrity of: hoses, radiator drain holes, cylinder block, sensor installation locations, expansion tank housing, pump and its connections, engine and heater radiators).

2. Check the thermostat. We warm up the engine to 85-92C and check the lower radiator hose leading from the radiator (in diagram No. 10), if it is cold, it means the coolant is circulating only in a small circle, the thermostat is faulty and should be replaced.

3. Check the circulation of antifreeze in the cooling system. Open the cap of the expansion tank and monitor the flow of antifreeze into the tank. Attention, the cooling system is under pressure, and the antifreeze in the system may be hot; open the expansion tank cap very carefully. Poor circulation of antifreeze indicates a malfunction of the water pump (pump), or the cooling system is clogged (needs to be cleaned).

If the engine radiator fan does not turn on, then you should check: the fuse, additional resistance, relay, integrity of electrical circuits, temperature sensor and fan motor (more details).

Let us remind you that the formation of air in the cooling system may be due to a malfunction of the expansion tank cap. See also the solution to the problem of air in the cooling system.

AVTOVAZ recommends replacing the fluid in the cooling system of the Lada Kalina every 75 thousand km of the vehicle or after five years, whichever comes first. Our illustrated step-by-step instructions will help you complete this procedure yourself.

LADA > Kalina

It is more convenient to replace the coolant when the car is installed on an inspection ditch or overpass.

Kalina heater diagram

The Lada Kalina heater device is designed for heating and cooling the car interior. If the car does not heat up, the windows fog up, or you feel discomfort, then you need to test the performance of the heating system. Understand the functioning of the stove on Kalina.

General layout of the Kalina stove

The location of the stove was designed for easy installation of an air conditioner. The system is simple, but at the same time quite reliable.

- Left side flow outlet.

- Left air duct.

- Heated side window.

- Air flow splitter.

- Stove.

- Right ventilation duct.

- Right side flow exit.

- Bottom heating duct.

- Interior heating duct.

- Central outlet of ventilation flows.

The supply and exhaust principle is used. The air masses inside the car are heated using a special liquid, which simultaneously cools the engine. The operating principle of the Kalina stove is based on the fact that the liquid warms up the radiator, where heat exchange occurs, and the heated air passes into the cabin through the air ducts.

If we analyze Kalina’s heater, the operating principle and the heater circuit will differ in configuration. The first option has a simple and reliable design. And in the other - full electronic control. The air passes through the filter into the air intake, and then the fan blows further through the system. The engine is running and warmed up. Antifreeze moves through the system in which the heater radiator is involved.

The amount of air that is heated by the stove radiator is regulated by a damper. Controls the operation of the fan and dampers by a unit located on the central panel.

Heating device control unit

- Temperature regulator. We change the heating of the air flow by turning the knob. The blue zone produces cold air, the red zone produces warm air.

- Fan speed switch. By turning the knob clockwise, the intensity of the air flow is adjusted. Choose one of 4 fan speeds.

- Air flow separation selector. Distributed in specific areas:

The flows pass through the upper part of the cabin.

The air is directed downwards.

Air flows are directed onto the windshield and down.

Air flows are concentrated in the area of the windshield, as well as the side ones.

- The handle that controls the recirculation of cabin air. We turn on the mode when driving off-road or in a traffic jam. Used for a short time, the glass fogs up.

- Rear window heating mode switch.

We regulate the direction and saturation of air flows through aerodynamic devices. We turn the guide blades and change the position of the dampers to achieve the desired air direction.

Interior ventilation of Lada Kalina

The outlet pipes are located in the car body under the trunk. The heater is located under the dashboard. The air flow enters the car interior through an intake, which is designed in front of the windshield in the engine compartment. The air enters through the filter and is accelerated throughout the cabin under pressure created by the fan.

1.Pipes for supplying air to the rear of the cabin.

2.Side ventilation nozzles.

3.Blowing the side windows.

- Windshield blower nozzle.

5-6-7. Central deflectors for flows entering the car interior.

We direct the supply air through the deflectors by turning the handwheel. If we turn it up, the flap opens and vice versa. You already understand how the stove on Kalina works.

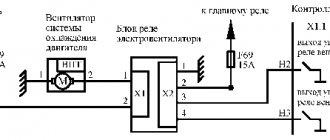

Electrical diagram of the Kalina stove

- Relay with fuse assembly.

- Mode switch.

- Resistor.

- Electric stove motor.

- Egnition lock.

A. To the power source.

Cooling system elements

The Lada Kalina cooling system has the following elements: water pump, thermostat, radiator, electric fan, pipes, expansion tank, water jacket and temperature sensor.

To fully understand the circulation pattern and operation of the cooling elements, it is worth considering them separately.

Radiator

One of the main elements of the cooling system, which provides direct cooling of the liquid that passes through the element. The part is cooled using a counter flow of air and an electric fan, which is located behind the radiator. Lada Kalina is equipped with 3-row radiators, which provide maximum cooling of the liquid.

The malfunction of this element may be due to contamination. Therefore, it is necessary to periodically clean the part. The most common method among motorists is cleaning using automotive chemicals. But, the most effective is to dismantle the radiator and clean it with steam or a special liquid under pressure.

Electric fan

The cooling system fan provides additional cooling of the radiator when there is not enough oncoming air flow. The most common malfunction associated with the fan is the failure of the fuse and coolant temperature sensor.

temperature sensor

This element ensures timely activation of the electric fan. The principle of operation of the sensor is very simple - I analyze the temperature of the coolant, it sends impulses to the electronic control unit, which, after analyzing the data received, decides whether it is necessary to use the electric fan. A malfunction of the meter can lead to overheating and even greater problems associated with deformation of the cylinder head.

Why does air get into the Kalina cooling system?

How much antifreeze is in the cooling system of a VAZ-2110 with 8 or 16 valves

One of the benefits of buying a new car is that from the very beginning you can see, feel and remember how the car works when everything is working properly.

While the car is new and unusual, it is difficult to say what works correctly in it and what does not. After three to four thousand kilometers, a picture of a normally working machine automatically forms in your head. If something suddenly changes, I notice it immediately. This change does not always indicate a malfunction, but often it indicates its approach.

Something like this happened after about two years of operation.

Visible signs of trouble Typically, the temperature gauge arrow on the instrument panel did not reach the “90 degrees” mark by about 2 mm. Of course, in traffic jams it rose even higher. But when driving, the norm is a little less than 90.

At some point, the picture changed and the arrow began to show a little more than 90. I noted this fact. But there were no other signs of any malfunction.

It was autumn, winter was approaching. Soon I started turning on the stove and made an unpleasant discovery: it was barely heating. And after a couple of days, the murmur of antifreeze in the heater radiator began to be clearly heard...

I spent several days studying the Internet and hardware and now I can tell you the solution to this little puzzle.

The cooling system on the Kalina (and similar ones) has two design defects, due to which at a certain stage of the car’s life air begins to be sucked into it. While there is still not too much air, it slightly disrupts the circulation of the coolant. In order to maintain the heating-cooling balance, the thermostat raises the temperature of the antifreeze.

If nothing is done, air will continue to accumulate in the system and the heater radiator will become air-filled. It stops heating normally. Since she is in the cabin, you can hear “streams babbling” in her radiator.

Design defects:

1. The expansion tank is located below the antifreeze level in the engine.

2. There is no air valve in the expansion tank plug (or it is always inoperative), there is only an emergency pressure valve.

After stopping the engine, the antifreeze begins to cool and compress - a vacuum forms in the cooling system.

While the car is new, all rubber pipes are tightly connected to their fittings. The rubber of the pipes is still fresh and elastic. Therefore, they slightly compress under the influence of the vacuum generated inside and compensate for the change in the volume of antifreeze during cooling.

After two years of operation, the rubber becomes tanned and at the same time the pipes are pressed under the clamps, the connections begin to lose their former tightness. As a result, when the engine cools down, air begins to be sucked through them. It gradually accumulates and - read above what happens.

The simplest "treatment"

1. Tighten all clamps.

2. After the trip, let the engine cool slightly and unscrew the expansion tank cap so that air can flow freely into the system.

You can park the car with the left wheels on the sidewalk a couple more times to help the air pockets escape into the expansion tank.

With an 80% probability, all air pockets will come out on their own and the temperature gauge will again show just under 90.

Try this trick. Just don’t forget to tighten the cork properly the next day!

Kalina engine cooling system

The engine cooling system of the Lada Kalina uses the main parts that are responsible for the correct operation of the ODS.

Heater radiator

A stove radiator is necessary to heat the car interior during the cold season. The coolant circulates through the stove radiator, thereby heating it, and the interior heater fan located in front of the radiator supplies air flow through it, thereby heating the air and entering the interior in a heated state.

Possible malfunctions:

- Radiator clogged inside and outside;

- Coolant leaking from the radiator at the joints;

Expansion tank cap

The lid has a pressure relief valve in its design, namely, during heating and cooling, the lid maintains optimal pressure in the SOD. The valve in the lid works both to increase pressure and to decrease it (vacuum).

Possible malfunctions:

- Damage to the lid and violation of its tightness;

- Locking the valve in the cover;

Expansion tank

The expansion tank is designed to compensate for the expansion and reduction of antifreeze particles, that is, when heated, the antifreeze expands, and when cooled, it decreases. This is why the expansion tank is used so that the hoses in the system do not swell from excess coolant pressure. Made of transparent heat-resistant plastic.

Possible malfunctions:

- Cracks due to overpressure;

- Broken fittings during work with SOD;

Thermostat

A thermostat is a housing containing a thermocouple with a valve that opens when a certain temperature is reached. Initially, the thermostat is in the closed position, and the coolant circulates in a small circle, bypassing the cooling radiator, but as soon as the coolant temperature rises to (85 ± 2) ° C, the thermostat begins to open and the liquid begins to circulate in a large circle through the cooling radiator. The thermostat valve opens completely at the coolant temperature (102±2)°C.

Possible malfunctions:

- Valve jammed in open or closed position;

Cooling radiator

This radiator serves to cool the engine; when the thermostat opens, when liquid begins to circulate through the cooling radiator, it passes through its tubes, which are cooled by the oncoming air flow when the car is moving. At the radiator outlet, the liquid already has a lower temperature than at the inlet, thereby cooling the engine.

Possible malfunctions:

- Coolant leak at the radiator joints;

- Radiator clogged inside and outside;

Water pump (pump)

The pump is responsible for circulating coolant through the system. Fluid circulation is driven by centrifugal force. The pump receives rotation from the crankshaft through the timing belt. The pump shaft on which the pulley is mounted rotates on bearings and has an oil seal that holds the coolant.

How to modify the cooling system of the Lada Kalina

Traditionally, modification of the cooling system on the Lada Kalina involves the installation of a new thermostat with 6 recesses, a filter through which antifreeze passes, and a faucet for the furnace mechanism. Service station workers also recommend installing another pump. This amount of work requires repair skills and knowledge. The average driver does not have them.

Therefore, craftsmen came up with another way to improve the cooling system. Follow the step by step instructions:

- The cooling system should be looped with a hose that was previously used to warm up the throttle assembly.

- Take an extra hose, a tee and enough clamps, and then install a connection with a smaller diameter. This will help ventilate the cooling system and bring it back to life.

- It is preferable to place the air vent closer to the thermostat; a prepared tee will help with this. It should be cut into the supply hose to the radiator unit.

- Now start processing the second end of the air outlet component, attach it to the steam outlet passing near the RB fitting.

The proposed modification to the cooling system of the Lada Kalina will make it possible to maintain the temperature when moving the car at a constant level of 90 to 95 degrees. At the start, the stove warms up to 50 degrees. How expensive is this method of improving a cooling system prone to air pollution? When purchasing the missing coolant, tees and clamps, 1 m of hose, 600 rubles were spent. Those who have already tried the modification note a noticeable decrease in engine temperature, but before that it heated up to 100 degrees, and cold air flowed into the cabin from the furnace mechanism.

Refinement of the cooling system on the Lada Kalina

Refining the cooling system on the Lada Kalina will help solve the problem of airing and the formation of traffic jams. There are several ways to eliminate this defect. The ineffective operation of the unit is associated with its design features. The operation of the engine cooling system (ECS) is associated with the interaction of various elements. The temperature of the power unit determines the passage of coolant through the large and small circles. At the first stage, the coolant circulates without passing through the radiator; after reaching the required temperature and the thermostat is activated, the liquid passes through the radiator. The normal functioning of the engine and stove depends on the correct operation of the system.

Causes of ODS malfunction

Refinement of the cooling system on the Lada Kalina

can be produced either in-house or at a car service center. However, in the latter option, experts usually recommend replacing or repairing the thermostat, which is not always practical or effective. The main causes of problems in the cooling system:

- Coolant leak. It is recommended to check the clamps and integrity of the radiator. If necessary, elements are replaced or repaired. You can check the circulation of refrigerant in the system by making sure that liquid enters the tank. If this does not happen, you should replace the pump or clean the SOD with special means;

- Failure of the thermostat or its elements;

- Contamination of radiator honeycombs;

- Fan malfunction;

- Presence of air pockets in the system.

Traditional Troubleshooting Methods

To solve the problem of airing, you should open the expansion tank, start the engine, press the gas pedal several times until the sensor arrow reaches the red zone. If the fan turns on, you need to squeeze the gas all the way several times and turn off the ignition. If this method is ineffective, the following procedure is used. The plastic motor protection is removed, the clamp is lowered and one of the fitting tubes is dismantled. The expansion tank cap is opened and the system is purged until coolant begins to pour out of the removed tube.

Let's sum it up

So we figured out why there is pressure in the engine cooling system, why it can be excessively high or, conversely, low. There is often nothing complicated about checking it yourself, although a lot depends on the car. For example, it happens that the coolant temperature sensor fails. It can provide incorrect data to control devices, thereby misleading the driver. It can show both a high temperature of the power unit and, conversely, a low one. But this will not mean that the system is not working correctly.

If there are any breakdowns in the cooling system, they must be repaired as soon as possible. It is advisable not to operate a vehicle with a stuck cover or thermostat. After all, for some engines overheating is fatal, and major repairs are not cheap at all. In general, it is worth regularly checking the coolant level in the system to ensure that there are no leaks or other defects. It is also recommended to periodically clean the radiators from dirt, as this can cause increased engine temperature.

Cooling system pipe

What is a pipe? There are often several of them in a cooling system; they connect individual parts into one sleeve and are the basis for cooling.

Pipes can be divided into two types:

- diverting;

- leading

From the names it becomes clear that the outlet pipe is designed to drain coolant, and the inlet pipe is designed to supply it. To cool the engine, antifreeze or antifreeze is most often used, since at very low temperatures they tend not to freeze.

It is worth recalling that two pipes of different types should not be confused or swapped, since their operating temperature conditions are different.

Most often, the supply pipe fails, since the load on it is maximum, which leads to the rubber drying out, as a result it can leak or even burst.

Basic data for monitoring, adjusting and maintaining the cooling system

| Temperature at which the main thermostat valve begins to open, °C | 85-89 |

| Full opening temperature of the main thermostat valve, °C | 102 |

| Opening pressure of the outlet valve of the expansion tank plug, kPa (bar) | 110-150 (1,1-1,5) |

| Opening pressure of the inlet valve of the expansion tank plug, kPa (bar) | 3-13 (0,1) |

| Coolant temperature in a warm engine at an ambient temperature of 20–30 °C and a fully loaded vehicle moving at a constant speed of 80 km/h, no more, °C | 95 |

| Resistance of additional resistor, Ohm | 0,23 |

| Volume of liquid in the engine cooling system, l | 7,8 |

| Coolant (mixing liquids of different brands is not allowed) | OZhK-KHT; OZh-40-ХТ; OZh-65-ХТ; OZH-K Antifreeze; OZh-40 Antifreeze; OZh-65 Antifreeze; OZh-40; OZh-65; OJK-KSK; OZh-40SK; OZh-65SK; Lada-A40; OZH-K Tosol-TS; OZh-40 Tosol-TS; OZh-65 Tosol-TS; Antifreeze G-48; AGIP Antifreeze Extra; GlysantinG03; GlysantinG913 |

Procedure for checking the Lada cooling system

1. Check the coolant level in the expansion tank; it should be between the “MIN” and “MAX” marks. If antifreeze has to be added periodically, then the system is not sealed (we check the integrity of: hoses, radiator drain holes, cylinder block, sensor installation locations, expansion tank housing, pump and its connections, engine and heater radiators).

2. Check the thermostat. We warm up the engine to 85-92C and check the lower radiator hose leading from the radiator (in diagram No. 10), if it is cold, it means the coolant is circulating only in a small circle, the thermostat is faulty and should be replaced.

3. Check the circulation of antifreeze in the cooling system. Open the cap of the expansion tank and monitor the flow of antifreeze into the tank. Attention, the cooling system is under pressure, and the antifreeze in the system may be hot; open the expansion tank cap very carefully. Poor circulation of antifreeze indicates a malfunction of the water pump (pump), or the cooling system is clogged (needs to be cleaned).

If the engine radiator fan does not turn on, then you should check: the fuse, additional resistance, relay, integrity of electrical circuits, temperature sensor and fan motor (more details).

Let us remind you that the formation of air in the cooling system may be due to a malfunction of the expansion tank cap. See also the solution to the problem of air in the cooling system.

Keywords: cooling system Lada Kalina | cooling system for Lada Granta | cooling system for Lada Priora | 4x4 cooling system | cooling system for Lada Largus | cooling system for Lada Vesta | cooling system lada xray | Niva cooling system | universal article

Found an error? Select it and press Ctrl+Enter..

- (AEB) Car sales statistics in the Russian Federation for April 2022 (-72.4%) - the largest drop

- How to install skins on standard MMC Lada Vesta

- Which gearbox is better: automatic robot, CVT or DSG

- Test drive Lada XRAY Cross with Jatco CVT and Renault-Nissan engine

Symptoms of problems

There are a number of symptoms that indicate a malfunction of the cooling system; if at least one of them is detected, it is worth taking corrective action.

- When the engine is not started and has cooled down (more than 8 hours of inactivity), a residual pressure remains in the cooling lines (this can be understood when the rubber pipes are pressed, they will be hard).

- The release of coolant when the engine is running can be either a small amount or a significant column of steam.

- Coolant leakage from lines or radiators is accompanied by a decrease in the coolant level in the tank.

- When the engine is fully warmed up, cold air blows from the deflectors coming from the cabin heater. The effect may disappear when the crankshaft speed increases.

And if with the first three points everything is more or less clear, then with the last it’s not so simple. You can change radiators, thermostats and coolant as much as you like, but you still won’t achieve a positive result. The problem is the formation of an air lock that cannot be seen. The air in the lines prevents the normal removal of heat from highly heated parts, which can lead to serious damage to the power plant.

Problems and methods for solving them

There are few actual reasons for failures and deviations in the functioning of the cooling system in LADA Kalina. Liquid leaks are the most common. They can arise from loose clamps on the pipes, through the gasket or seal of the pump, a broken radiator (also in the heating circuit), etc. Copper radiators used to be subject to repair, but it is unlikely that it will be possible to successfully restore a modern aluminum product. The clamps can be tightened, and if it doesn’t help, they can be replaced, fortunately this is a cheap idea. The radiator is much more expensive, so replacement may be burdensome, but there is no other way.

How to change the running light bulb on a Grant

Granta gearbox with cable drive

Installation of alarm system on Lada Granta

Sometimes the engine cooling system can become clogged. This will require cleaning followed by a complete fluid replacement.

We will also consider other problems that arise in the cooling circuit of the Lada Kalina.

- Thermostat. An effective diagnostic measure would be to manually touch the pipes connected to the radiator. If the lower radiator hose does not warm up on a warm engine, then we can safely state that the thermostat has failed. The valve stopped opening, preventing the liquid from circulating in a large circle. The only way out is to change the part.

- The radiator honeycombs are clogged. Here you also need to resort to cleaning. In spring and summer, debris clogs the honeycombs, making the radiator ineffective in terms of cooling.

- The fan has failed. The first step is to check the integrity of the wiring and the serviceability of the relay in the Lada Kalina with an 8 or 16 valve engine. Most breakdowns point to these components.

- Airing of the system, the so-called air lock. Often air can get inside the circuit, forming plugs. Airing of the system can often be observed after replacing antifreeze. To combat this phenomenon, open the reservoir cap and raise the engine speed (accelerate). If the traffic jam cannot be removed, we try to raise it in front of the car (as high as possible) and continue to practice with the accelerator. Blowing out the tank until liquid appears from the fitting also helps.

Improved cooling of VAZ-1118 “Kalina”

To reduce the likelihood of airing of the SOD due to jamming of the compensation valve of the expansion tank cap, readers suggested removing the valve from it as a temporary measure. We cannot recommend this method, because the risk of boiling and overheating of the engine increases. But if you decide to go this route, in order to prevent the antifreeze from boiling away at atmospheric pressure, we lower the fan start temperature to 98 degrees programmatically, or we cut an adapter into the radiator inlet pipe for sensor .

A more correct upgrade option has been tested several times and has shown its performance on cars with a cable-operated throttle. We put a plug in the pipe connecting the large cooling circle to the expansion tank;

- We connect the freed fitting to the lower heater hose through the tee from 2110;

- We plug the thin outlet hose (distant, if you look from the front of the car) of the throttle heating.

- We connect the free fitting through a tube of the appropriate diameter to the expansion tank. To do this, we cut an additional nipple into the upper plane, or connect through a tee to a thin input. Thus, we transfer the steam outlet to a small circle, while taking the liquid with air bubbles at the top point of the system.

Thus, we transfer the steam outlet to a small circle, while taking the liquid with air bubbles at the top point of the system. On a car with an electronic pedal (e-gas), we do the same.

- We connect the thin fitting of the thermostat to the upper part of the expansion tank (via a tee or an additional fitting). We turn off the standard thin tube from the thermostat.

- Disconnect and turn off the lower extension hose. tank, in the vacant space we connect a homemade line from a tee embedded in the “return” of the heater.

Engine cooling system: SOD Kalina and modification

Let us note right away that correct modification begins with the fact that it is necessary to slightly change the distribution of antifreeze flows in the cooling system of the VAZ-1118 Kalina. This will reduce the intensity of airing due to the jamming of the compensation valve of the expansion tank cap.

Please note that simply removing the valve from the cover, as many suggest, is strongly not recommended, as the engine may overheat. It would be better to lower the fan switch-on temperature in the firmware to 98 degrees.

In general terms, you need to do the following:

- you need to drain the coolant, and then put a plug in the pipe that connects the large cooling circle and the expansion tank;

- then the free fitting is connected to the lower heater hose through a tee. The VAZ 2110 tee is suitable for these purposes;

- the next step is to plug the distant hose (thin outlet hose) designed to heat the throttle assembly;

- then the released fitting must be connected through a suitable tube to the expansion tank. To do this, you need to cut another “nipple” into the upper cavity. You can also connect via a tee to connect to a thin input;

- then you should fill in the coolant, a little higher than that, start the engine and warm up the unit until the fan turns on. The final stage will be to de-air the system and adjust the level of antifreeze or antifreeze.

This modernization allows for steam removal through a small circle, and aired liquid can be collected at the highest point of the cooling system. By the way, as for the version with an electronic gas pedal, in this case the thin thermostat fitting is connected to the top of the expansion tank.

The result of such actions will be active de-airing of the cooling system, the stove will heat normally at different speeds, and the engine temperature will always remain at a normal level, regardless of the mode and load on the engine.

At the same time, it is quite obvious that if the thermostat on the Lada Kalina is working properly, it is not necessary to change it. In other words, it is not the cause of overheating or a cold stove. In turn, a more comprehensive improvement of the cooling system of the Lada Kalina allows us to solve a number of problems.

So where should you start?

The first thing you need to do is check the antifreeze level in the system. To do this, open the hood and look at the expansion tank. Ideally, it should be filled to ½ of the total volume. If necessary, add coolant to this level.

If you find an antifreeze leak, then inspect the engine compartment of the car - there may be leaks here.

Signs of a broken cooling system pipe

The first and most common sign of a cooling system failure under the hood or under the car is wet and slightly greasy spots of coolant. These are the first signs that a pipe has burst somewhere. Also in the cabin on the instrument panel, there is a special indicator that will show the low fluid level in the expansion tank.

If the sensor fails, the engine temperature will rise rapidly, which may result in the engine boiling. It also happens that you can smell antifreeze in the cabin; this is an indicator that the pipe may burst not under the hood, but under the front panel or in the area of the interior partition and engine.

Many experienced car enthusiasts advise, from time to time, to simply check the level of antifreeze in the expansion tank. Inspect the pipes for greasy, oily stains and do not delay repairs if this is detected.

How to find a coolant leak in the system. First of all, it is worth inspecting the expansion tank for leaks. Next we move on to the radiator, since it is most often damaged. When inspecting, special attention should be paid to the joints of pipes (nozzles) and honeycombs, which are easily damaged.

Next, we inspect the pipes and hoses themselves along their entire length, since it is through them that the coolant circulates. Do not forget about the clamps at the connection points; due to engine vibration, the clamps may become loose, which means the pipe may come off the mounting point and leak.

The last and most unpleasant failure of the cooling system is liquid getting into the oil jacket. As a result, checking the oil level with a dipstick or opening the filler cap to fill the oil, you can see how it foams. This is the first sign that coolant has gotten into the oil.

Functional range of elements of a car cooling system

The standard cooling system consists of the following elements:

- sensors – determine t° in certain auto mechanisms; one of the management elements of the system;

- pump – makes it possible to circulate liquid in the SOD; operates in a forced mode;

- pipes – coolant moves through them;

- expansion tank - compensates for the volume of antifreeze, since due to temperature fluctuations it narrows and expands;

- radiator - a device that discharges excess heat into the environment;

- fan – activates the cooling process by forcing air; With its help, the cooling intensity increases;

- Thermostat - although small, is a very important element that regulates the amount of antifreeze; provides a “comfortable” temperature regime throughout the entire system.

Operating principle

The cooling system operates in a self-regulating mode, which is aimed at maintaining optimal temperature in the power unit. If the oil temperature rises significantly, the system does everything to ensure that the temperature inside the engine decreases.

Thus, with the close interaction of the above elements, the system functions. It automatically sets the necessary conditions for the inclusion and operation of structural parts, which ensures effective cooling of the power unit.

And if any problems arise with the functionality of the components of this system, it is necessary to carefully examine the safety of its main components. If the driver is qualified and experienced enough, he can cope with the task independently. Otherwise, it is better for an owner who is not very knowledgeable about cars to seek help from a service station.

Cooling system elements

The Lada Kalina cooling system has the following elements: water pump, thermostat, radiator, electric fan, pipes, expansion tank, water jacket and temperature sensor.

To fully understand the circulation pattern and operation of the cooling elements, it is worth considering them separately.

Radiator

One of the main elements of the cooling system, which provides direct cooling of the liquid that passes through the element. The part is cooled using a counter flow of air and an electric fan, which is located behind the radiator. Lada Kalina is equipped with 3-row radiators, which provide maximum cooling of the liquid.

Replacing the pipes of the Kalina stove

In my case, the heater pipes were in the worst condition. In addition, unscrewing the clamps on the heater radiator itself was very problematic, since they are located immediately under the steering rack. To do this job I used a small ratchet with an 8mm head. It was simply impossible to get through with a screwdriver.

Before removing the pipes, be careful - the liquid remaining in the heater radiator will flow from them, so prepare small dishes in advance. Do not allow liquid to get on the speed sensor, which is installed exactly under the heater pipe.

The process of replacing the pipe

The first thing to do before replacing the pipe is to completely drain the coolant from the system. If the liquid is clean and drained into a clean container, it can be reused. Now it’s time to remove the clamps on the missing pipe. It happens that they rust, so you should prepare all the necessary tools and WD40 in advance to facilitate the removal process.

A similar, new pipe must already be prepared in advance. The old pipe should be removed slowly and without much effort, since the radiator necks are not strong enough and break easily. If it cannot be removed, it is recommended to twist it from side to side, but not bend it in any way.

As a last resort, you can cut it to length, this way you can remove the old pipe. Taking it off is often not a problem, but putting on a new one is much more interesting. If the new pipe does not lend itself to the procedure, then its inside should be lubricated with a solution of soapy water. But in order to soften it, you need to lower the desired part into hot water.

The last step is to put the clamps on the pipe, and only then put it on the radiator neck and water jacket. Make sure that the pipe is correctly positioned and not twisted. Now we tighten the clamps on the necks and begin to fill in the coolant.

After filling, make sure once again that there are no leaks in the places of replacement and repair. It is worth remembering that when draining, there may be some coolant in the heater radiator. Now we start the engine and check the serviceability of the system. After filling in the new one, you need to turn on the stove, then add liquid to the expansion tank.

If you manage to break one of the necks, you should immediately solder it using argon welding.

Replacing the thermostat on Kalina 8 valves

The thermostat on Kalina consists of 2 parts - the so-called thermostat cover and housing. The cover is the part in which the thermocouple is located, and the housing is the part that is attached to the engine. Housings are not sold separately, unlike covers, at least I haven’t seen them. Therefore, you can either replace the cover or buy a completely assembled thermostat.

It is attached to the engine with 2 nuts along with the ground wire from the battery. We unscrew them and remove the thermostat. In most cases, the remaining gasket will stick to the engine. They will need to be removed with a knife or blade.

The coolant temperature sensor is screwed into the thermostat housing. You need to unscrew it from the old one and screw it into the new thermostat, or just buy a new one. It is attached under a copper gasket, which seems to need to be replaced with a new one, but practice shows that a used one also holds up normally. The thread of the sensor itself, closer to the gasket, can be lightly coated with sealant.

To be sure, I additionally applied a thin layer of sealant to the new thermostat gasket and installed it in the prepared place. According to reviews on the Internet, it is best to buy an original thermostat from AvtoVAZ. He will last the longest. In second place, this is exactly what I bought, since I simply couldn’t find the original one. Some samples may open not at 85 degrees, but at 90-95º. Not sure if this is normal. It should also be noted that the PRAMO thermostat cover will not fit into the AvtoVAZ body; the side will interfere, which the craftsmen successfully saw off with a grinder.

Replacing the pipes of the Kalina cooling system can be divided into replacing the heater pipes and replacing the radiator pipes. There are 2 pipes suitable for the stove - inlet (1) and outlet (2). There is also an inlet (3) and outlet (4) to the radiator. There is also a small connecting pipe (5) from the thermostat to the siphon.

Radiator pipes Kalina 8 valves

Lada "Kalina" became a breakthrough project of the Volzhsky Automobile Plant, aimed at producing a modern car, which, on the one hand, should remain relatively affordable for most citizens, and on the other, be closer to world analogues of this class of cars in terms of quality and the introduction of modern innovations and technologies.

The production and operation of this brand of car for more than five years revealed the traditional problem of the Volzhsky Automobile Plant, which is the insufficient quality of assembly of the units. In addition, the use of a full-fledged on-board computer in the model, the introduction of climate control and the installation of ABS, led to an expansion of the range of spare parts required for repairing the VAZ-1117.

The interior of the car has undergone quite a lot of changes compared to traditional “classic” models. However, the insufficiently high quality of plastic still forces the owners of this car to look for an alternative replacement for factory parts. Also very popular are the parts used for tuning the model and often allowing you to change the car beyond recognition.

Many car enthusiasts know that the car is equipped with a cooling system that prevents the engine from overheating. So, Lada Kalina has a standard, closed cooling system, which is no different from other devices of the same nature.

Filling with new coolant Kalina

The installation of new pipes is complete. Now the most interesting part is that you need to fill in new antifreeze. Don't forget to tighten the bolts from the drain holes back. I use Felix Green G11. To avoid the occurrence of a large number of air pockets, before filling in the coolant, I removed one hose from the throttle heating - the highest point of the cooling system. During the process of filling the system, air could be heard escaping. Out of 10 kg of antifreeze, about 2 liters remain in the canister.

I filled it up to the MAX mark on the expansion tank and put the hose from the throttle back in place. Now you can try to start the engine and see what happens. Before this, of course, you need to put in place the ignition module and the air filter along with the mass air flow sensor and the adsorber valve.

After the first start, the engine heated up to 120 degrees, but the radiator remained cold. I waited about 10 minutes until the engine cooled down and SLOWLY unscrewed the cap from the expansion tank, releasing the pressure, and then unscrewed it completely. At that moment I heard a gurgling sound - excess air was coming out. Some fluid has leaked into the system. I added new fluid to the reservoir and started the engine again. This time everything worked as it should - the radiator warmed up, the fan turned on, the stove was heating, the temperature stayed around 90º.

Sources

- https://avtonomnaya-gazifikaciya.ru/kalina/sistema-ohlazhdeniya-1.html

- https://gil-service.ru/dvigatel/dorabotka-termostata-kalina.html

- https://krutigayki.ru/sistema-ohlazhdeniya-kalina-vse-o-tom-chto-delat-chtoby-dvs-avtomobilya-ne-peregrevalsya/

- https://na-vi.ru/sistema-ohlazdenia-kalina/

- https://TrueScooters.ru/vidy-dvigatelej/sistema-ohlazhdeniya-lada-kalina.html

- https://CdmService.ru/salon/ohlazhdenie-dvigatelya-lada-kalina.html

- https://Vaz-Lada-Granta.com/kalina/motor-i-korobka/sistema-ohlazhdeniya.html

- https://topdetal.ru/stati/boremsya_s_peregrevom_i_kholodnoy_pechkoy_na_kaline/

- https://autobryansk.info/sistema-ohlazhdenija-dvigatelja-kalina-8-klapanov.html

- https://vaz.today/sistema-ohlazhdeniya-kalina

[collapse]