Many people replace the input shaft bearing themselves, without the help of specialists from a service station. To perform such work, you need to know the location of the element you are looking for and the signs of its malfunction. Plus we will tell you in detail how you can understand this bearing.

Element appearance

VESKO-TRANS.RU

AutoNews / Reviews / Tests

Replacing the Primary Bearing of a VAZ 2110 gearbox

Replacing the input shaft bearing on a VAZ 2114

Many people replace the input shaft bearing without outside help, without the help of professionals with 100. Algorithm for replacing a VAZ 2115 radiator. Replacing a VAZ 2110 clutch without removing the box, etc. To do this, you need to know the location of the required element and signs of its malfunction. Plus we will tell you carefully how you can understand it.

Element appearance

Location

Since we are talking about a VAZ 2114, we will first determine the location of the element.

In the fourteenth, the primary bearing is located on the shaft behind the seal.

Catch this on some gearboxes, this bearing additionally plays the role of an oil seal, bearing the load along with the output bearing.

To get to the deformed transmission component, you need to remove the transmission. When choosing a new product, be sure to read the operating instructions for the VAZ 2114 car to find out its overall dimensions.

Signs of failure

All bearings in a car show approximately the same signs of failure. Replacement of VAZ 2110 Transmission shaft bearing. But, as you understand, the location of the bearing Input shaft , discovering that the difficulties that arise specifically with it will not be so difficult.

There are several relevant signs of failure.

Sign

Characteristics

It howls when the clutch is released in a parking lot.

The item is defective and needs to be replaced. Howling is usually caused by the formation of chips, cracks, or the destruction of 1-2 rollers

Whistling while driving

The bearing is partially broken or lacks grease. A problem in the absence of lubrication can only be detected by disassembly and visual inspection. Sometimes it's easy to lubricate the item and put it back in place to solve the problem

Coupling not cut or disconnected

Most likely the bearing is stuck. If the damage is severe, it may be necessary to replace the Input Shaft

The bearing knocks only when the part is completely destroyed. Replacing the VAZ 2107 shaft bearing. Publication “Replacing VAZ 2110 transmission bearings”: Replacing a VAZ 2110 by replacing the main bearing. Replacing VAZ 2110 gearbox bearings If replacement does not help, the bearing will be welded to the shaft, so you will have to replace the shaft itself

If you notice the first signs of a bad input shaft bearing in your transmission, you should immediately check the condition of the element and, if necessary, replace it.

replacement

Many people replaced this bearing, turning it into 100. It’s nice that car services often allow you to do similar work. Of course, because the procedure is discreet and you cannot take a lot of money.

replacing the primary bearing, secondary shaft for the VAZ 2112rpr gearbox

The knock is lost when the clutch pedal is pressed.

knock the input shaft bearing Gearbox VAZ 2110

In this video I will carefully understand how to disassemble and reassemble the box on the front wheel.

Follow the instructions to do the job yourself.

- You can often find advice about the need to completely disassemble the box to replace the bearing. But that's not true. How to replace the input shaft bearing on a VAZ? Replacing the gearbox bearing. You can do without such complex manipulations.

- Either way, the box will need to be removed, so read this procedure.

- Before removing the gearbox, the negative terminal is removed from the car battery.

- All the chips are out of the box and there is a wire coming out of the speedometer.

- Next, the trousers of the car's exhaust system are dismantled.

- Then you can remove the box completely.

- In the next step, the bell is removed. You can try to do without it, but then it will most likely hinder you in the process.

- Thoroughly clean the box of any accumulated dirt.

- The bearing is secured with retaining rings. You will need a flathead screwdriver to remove them.

- The rings are clamped and slightly compressed, after this there will be no more problems with removal.

- To make it more convenient, equip yourself with ring tweezers.

- Use a flat blade screwdriver to lift the bearing off the ring groove and immediately push the input shaft forward lightly.

- Insert the fastener between the box and the bearing. You can hardly do without an assistant.

- You will operate with tools, and meanwhile your friend will hold the mountain.

- Your main task. press out the bearing. Replacing the bearing of the primary and secondary shaft on the VAZ 2112rr, VAZ 2110, 2112 gearbox. To do this, apply clear, strong, but very careful blows to the primary shaft.

- During the impact, the shaft necessarily rotates.

- This work will take you about 20 minutes. But if you have a dedicated shooter, you can speed up your work. Although the puller is really only useful in this case, if you decide to disassemble the box.

- Before installing a new input shaft bearing, be sure to lubricate the element with regular engine oil.

- Gently press the component into place using light, gentle hammer strokes. Replacing the input shaft bearing on a VAZ 2114. It is better to use a pipe with a diameter or a stand.

- As you press, strike around the inner cage in a circle as evenly as possible.

- When the bearing is pressed, make sure it is seated correctly. Scrolling should be quiet, without interference.

- Assemble the box in a straight line and place it on the car.

Location at the checkpoint

Question about lubrication

Many people do this work on their own and with high quality. But their main mistake is that it is not always necessary to replace the bearing. Replacing the primary and secondary shaft bearings on a VAZ gearbox. Sometimes just lubrication is enough.

- Make sure the bearing is dry. There is not enough lubrication and visible damage, then all extraneous sounds may be caused by a lack of oil;

- Treat the element with high quality oil. Publication “Replacing the input shaft bearing of a VAZ 2110”: 21 photos with a description on vaz-2110.net. Transmission replacements 2109, 2114, 2110 Plain motor oil is often used;

- Install the old lubricated bearing.

There are two methods of lubrication.

- Digestion in lithol. It is recommended to use a water bath for this procedure.

- Extrusion method is safer. To do this, inject lithol into the syringe and pour it into the element. The process is long but effective.

When choosing a lubricant, it is better to focus on safety rather than speed of repair.

The gearbox is a constantly working element of the car, which leads to inevitable failure. Try to identify the problem with the input shaft bearing as quickly as possible and take repair or preventive measures to prevent the situation from worsening.

Signs of failure

All bearings, of which there are quite a few in a car, have approximately the same signs of failure. But since you know the location of the input shaft bearing, it will not be so difficult to determine that the problem arose with it.

There are several characteristic signs of its breakdown.

| Sign | Peculiarities |

| Howling when the clutch is released in a parking lot | The element has failed and needs to be replaced. The howling is usually caused by the formation of chips, cracks, or the destruction of 1-2 rollers |

| Whistle when driving | The bearing is partially damaged or there is no lubrication. The problem in the absence of lubrication can only be determined by dismantling and visual inspection. To solve the problem, sometimes it is enough to simply lubricate the element and return it to its place |

| Clutch won't engage or disengage | Most likely the bearing is stuck. If the damage is serious, the input shaft may need to be replaced. |

| Knock in the area where the element is located | The bearing knocks only when the part is completely destroyed. If you do not replace it in time, the bearing will be welded to the shaft, so you will also have to replace the shaft itself |

If you notice the first signs of a malfunction of the input shaft bearing on your gearbox, you should immediately check the condition of the element and, if necessary, replace it.

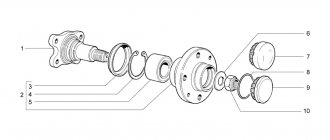

Transmission device diagram

The gearbox mechanism is a system of parts that has an independent structure and characteristic features determined by the model. Before you begin repairing the gearbox, you must familiarize yourself with the diagram of the transmission mechanism in the operating manual. The diagram contains the names of the parts and the structure of the relationship.

Transmission device: 1 - input shaft; 2 - secondary shaft; 3 — rod for shifting the third and fourth gears; 4 — fork for shifting third and fourth gears; 5 — differential; 6 — fork for switching first and second gears; 7 — fork rod for shifting first and second gears; 8 — gear shift rod; 9 — fifth gear shift fork rod; 10 — gear shift mechanism; 11 — reverse intermediate gear; 12 — clutch housing

Knowledge of the structure of the structure reduces the time spent on identifying mounting fasteners and dismantling components.

How the box works

It has features that entirely depend on the configuration of the machine. This could be a four- or five-stage vase model. The structure of a four-speed gearbox is as follows:

- 1. Primary shaft;

- 2. Reverse gears, to which the front shaft is attached;

- 3. Synchronizers, 2 pieces;

- 4. Bearings placed on the secondary shaft;

- 5. Driven gear. Attached to the differential flange.

The element is controlled by a drive, rod, rod and ball joint. Only complete interaction of these parts can ensure full operation of the box.

Gearbox device

To determine the type of gear, there is an additional lever, which is attached to the inner end of the rod.

There are also axles in the body; a three-arm lever is attached to one of them. Its main purpose is to lock the bracket and bushing, which is necessary to ensure the strength and immobility of the mechanism.

The second axis is designed to fix the locking brackets from their rotation, passing through the center. In addition, there is a lock that prevents the box from loosening. The other axle also has a fork, which is necessary to engage the VAZ 2114 in reverse.

The five-stage type differs in the size of the shaft and the absence of a bushing in the element. Usually this is what is installed in the VAZ 2114, since the other one is not entirely practical to use. Like any spare part, a gearbox can also break down and fail.

The most common problems are:

Unknown noise: it may be caused by bearing failure or gear wear. In addition, you should play it safe and check the oil level;

The solution to the problem is to completely replace failed spare parts and add oil.

Difficulty shifting the VAZ 2115 gearbox: the drive rod may have become deformed. It would be a good idea to check how firmly all the screws are screwed on and how the box drive is adjusted correctly. There is a possibility of failure of plastic parts in the drive;

Solution: Strengthen the screws, adjust the drive, replace worn and failed parts, replace or correct the deformation of the rod.

Turning off the gearbox without the driver's participation: the cause may be damage to the teeth on the synchronizer, an incorrectly adjusted drive, or poor installation of the traction cover, which provokes incomplete engagement of the traction;

Solution: Adjust the drive and replace the covers, replace the failed spare parts.

Oil leak. The reason is still the same - wear of spare parts, which this time are oil seals, seals and hinge bodies

In addition, you need to pay attention to the strength of the fastening. If it becomes loose, it is necessary to tighten all the bolts and check the seals for damage;

Solution: Purchase new spare parts and replace them.

Where and how is it more profitable to buy a gearbox in case of its complete failure? Since the performance of the vehicle and safety depend on the VAZ 2114 gearbox, its technical condition must be taken very seriously.

That is why it is worth recalling that, like any element of the machine, the gearbox needs regular technical inspection. Saving on oil changes, untimely detection and replacement of breakdowns, complete ignorance of troubles with the machine’s mechanisms - all this leads to failure of the gearbox.

Don’t think that if you have a domestic car, that means you are lucky. The rise in prices for spare parts is indicated by the price of the box, which today ranges from 16 thousand rubles. up to 18 thousand rubles Add in fees for removal, installation and maintenance - the cost will be impressive.

Used manual transmission for Lada 2114

An easier option would be to purchase a used item. No one will give a guarantee that there are no defects in it, but the purchase will cost half as much.

The best option is to carry out timely maintenance and repair of the box. This approach will not only save the budget, but will extend the life of the parts.

When do you need to change the gearbox input shaft bearing?

Replacing the input shaft bearing on a VAZ 2110

Surely, many car enthusiasts are asking the question “when do you need to change bearings?” In fact, there is no definite answer, since the resource of this mechanism directly depends on:

- bearing quality;

- vehicle operating conditions;

- driving style;

- regularity of technical inspection.

Typically, problems that occur due to a worn bearing are detected during the next technical inspection. Diagnostics of the gearbox can be carried out in specialized technical centers, and it becomes possible to evaluate the resource of the components of the unit that remains. The same applies to PV bearings. In certain situations, you can get by with simply lubricating the bearing. Such measures will help normalize operation and eliminate noise in the gearbox. When undergoing vehicle maintenance, experts strongly recommend doing a clutch diagnostic (see: Repairing the VAZ 2110 clutch - we do it ourselves).

Repair of VAZ 2114 gearbox

According to the source of this article, provaz2114.ru, the most reliable method of keeping the mechanism in good condition is prevention of malfunctions (systematic maintenance) and proper operation. But even so, situations are possible that require prompt repairs. When the gearbox cannot be repaired, information becomes relevant about how much a new VAZ 2114 gearbox costs? Estimated price in stores is 16 thousand rubles, used: 4000-10000 rubles. When the gear knob is loose on a VAZ 2114, it is possible that the solution to the problem is to install a new one. The VAZ 2114 gearbox linkage also needs to be replaced.

REPLACING THE INPUT SHAFT SEAL

To replace the gearbox seals, especially the input shaft, the gearbox must be removed from the engine. Having removed the gearbox, carefully inspect the installation locations of the cuffs. And first of all, you need to dismantle the release bearing and remove its guide. Under it you will find the input shaft oil seal.

To remove the seals we need a flat-head screwdriver. By prying it from the inside, you can remove the cuff from its seat. The input shaft oil seal has dimensions 25x45x9. Catalog number 2110-2301043Р. It is better to install it with sealant. The outer race of the oil seal must first be degreased, and then a thin layer of sealant must be applied.

When installing, you must ensure that the inner race of the oil seal does not turn outward and the cuff spring does not jump out of its place. We install it in its place and carefully, using a pipe, lightly tapping, hammer the cuff into place. In this case, it is necessary to ensure that the plane of the input shaft oil seal lies exactly in relation to its seat.

Then we install the release bearing guide in place. It is secured with three bolts, which should be tightened evenly so that it fits into place without distortion.

Next, we immediately install the release bearing. When installing it, you must immediately put on the wire springs, which are placed on the legs of the release bearing and fix it in place.

Now it's time for the drive seals. There are two of these seals, the left one is red and the right one is black. They also differ in the direction of rotation. This direction is shown by arrows on the seal housing. These arrows are located on the inside of the oil seals, on the right oil seal the arrow points to the left, and on the left oil seal the arrow points to the right. This can also be determined by the oil removal notches applied to the inside of the cuff.

Instructions for removing, disassembling and assembling the VAZ 2114 gearbox

Removing the gearbox is required when troubleshooting parts and the mechanism of the gearbox itself; when replacing the clutch.

Repair work may require one business day, so the instructions below must be started in the morning. Hiring a partner with experience in this type of repair will reduce time costs and improve the quality of repairs.

Preparation

The preparation process consists of the following steps:

- to warm up the oil to be drained, we drive a vehicle for a distance of 5 km;

- we install the vehicle on an inspection ditch (pit) or drive it onto an overpass;

- We put the car on the handbrake;

- raise the hood;

- fix the raised hood;

- we install the hoist, or use improvised means, or a special device, which is a crossbar to support the engine in a suspended position.

Removing and disassembling the gearbox. Procedure for cleaning gearbox parts

We perform the following steps sequentially:

- We remove the terminals.

- We remove the battery.

- We remove the battery to the side.

- We unscrew the three bolts that secure the crankcase protection.

- We remove the protection.

- If the model is before 2003, then remove the oil level dipstick.

- Using a 17 key, unscrew the plug (plug) of the drain hole.

- Place a five-liter container under the drain hole.

- Drain the existing oil from the gearbox into a container.

- We are waiting for the oil to be completely removed from the gearbox.

- We unscrew the two locking nuts of the starter protective jacket, located below in relation to the pit, and one locking nut on top of the starter.

- Remove the protective jacket of the engine starter.

- Disconnect the power wires to the engine starter.

- We remove the engine starter from below, that is, by descending into the pit.

- Remove the clutch cable.

- Compress the spring holding the block.

- From below, disconnect the block with the wires of the speed sensor under the hood.

- Disconnect the reverse sensor wire connector.

- We unscrew the bolts under the hood connecting the ignition module bracket to the gearbox housing.

- Disconnect the torque rod bracket.

- Loosen the gear shift rod clamps.

- We remove it by pulling the torque rod from the hinge intended for changing gears.

- We take out the gear shift rod.

- Unscrew the fastening bolts to the steering knuckle of the left ball joint.

- We carry out dismantling by disconnecting the lower mounting of the gearbox to the engine (sometimes it is enough to loosen the tightening).

- Unscrew the bots.

- Removing the transmission housing

- We unscrew the bot from the lower left part of the gearbox.

- Using a board, we hang the motor.

- We remove the fixation of the left and rear (attachment to the body) engine mount by unscrewing the corresponding nuts.

- We unscrew the pair of bots that secure the rear engine mount to the transmission, holding the nuts against spinning with a second wrench.

- We dismantle the support.

- We insert a screwdriver into the hole between the engine cylinder block and the clutch housing.

- Using an inserted screwdriver, we move the box along the guides so that the rear part of its body passes over the backlight extension, and the input shaft is disconnected from the clutch.

- We remove the gearbox unit from under the car.

- We clean the gearbox parts, removing deposits with a brush.

- We clean the holes and slots from dirt.

- We wash and blow off the parts and bearings with a stream of compressed air.

- We examine the details of the gearbox.

- If necessary, we replace worn or damaged parts.

- We carry out the assembly, focusing on the procedure indicated above.

ABOUT THE DEVICE AND PRINCIPLE OF OPERATION

It is a regular roller bearing of a specific design.

In the clutch mechanism, it is destined to serve as a stop for transmitting the forces that will come from the pressed pedal. The bearing then transmits this movement to the pressure plate to break the connection between the basket and the flywheel. Without this, it is impossible to turn on the speed and start moving. Its structure can also be judged from the photograph.

Release bearing disassembled

From the photo you can see that it consists of three main parts:

- Clip with guide bushing;

- Roller bearing;

- Fixing washer.

Which wheel bearing to choose for replacement

The front wheel bearing is of both domestic and foreign production. As they say, there will be something to find for such a car. But it’s better not to buy Chinese spare parts to replace the front wheel bearing on a VAZ 2114. They are inexpensive, but hence the quality is not very good, and you won’t go far with them.

Which wheel bearing to choose for replacement

It is better to pay attention to imported spare parts, especially from Europe. Although they are more expensive, their quality speaks for itself. When purchasing, be careful not to confuse them with Chinese counterfeits, there are many of them now.

It is also worth looking at domestic manufacturers, such as those from Vologda or Samara. Excellent quality at a reasonable price. They also include instructions for installing the bearing, which makes the task even easier.

How to buy original bearings

In order to distinguish an original bearing from a fake, look at the box; it must have proper presentation. The rotation of the bearing is tight, but the fake bearing rotates very easily, no effort is required. The inner holder of the original has all the necessary numbers and inscriptions. But on fakes they are located both inside and outside. The differences between them are minimal, there may be a different brightness of color on the bearing, or a slight difference in shape.

- Wheel bolt wrench;

- Two jacks;

- Car stands;

- Power wrench;

- Thirteen two head;

- Wheel chocks;

- Open-end wrench for ten, seventeen (2 pieces), nineteen;

- Ratchet driver;

- Socket head for eight, thirteen, fifteen, seventeen, nineteen;

- Head with E12 profile;

- Extension;

- Phillips and slotted screwdrivers;

- Penetrating lubricant;

- Hammer;

- Extension;

- Oil collection container;

- Lithium grease.

- Place wheel chocks and loosen the wheel nuts on the right and left. Thirty-two head nuts.

- Loosen the wheel bolts, jack up and remove the front wheels. After removing the wheels, place stands under the sills and lower the car on them.

- Loosen the fastening nut and remove the negative terminal of the battery.

- Remove the air filter housing. To remove, unscrew the two bolts securing the front panel, disconnect the power connector for the mass air flow sensor and loosen the clamp securing the pipe to the body. Next, remove the pipe fitting to the filter housing and then lift the housing and disconnect the air intake pipe. After completing the procedures described above, the case no longer holds anything, remove it. The mounting bolts are for a thirteen head, and the clamp is for a Phillips screwdriver.

Apply penetrating lubricant, loosen the clutch cable to the box and remove it from the bracket. In order to loosen you need two seventeen keys.

Remove the clutch cable from the fork and place it to the side.

Remove the small terminal from the starter and unscrew the nut securing the positive wire. Head nut for thirteen.

Unscrew the ignition coil bracket mounting bolt. Thirteen head bolt.

Unscrew the upper starter mounting nut. Fifteen head nut.

Unscrew the two upper bolts securing the box to the engine. Nineteen head bolts. The location of the first bolt is in the photo below, and the second bolt is located under the thermostat.

Replacement

Many people turn to a service station to replace this bearing. It is noteworthy that car services often refuse to perform such work. It’s understandable, because the procedure is painstaking, and you can’t get a lot of money for it.

Dismantling works

To do the job yourself, follow the instructions.

- You can often find advice about the need to completely disassemble the gearbox to replace the bearing. But this is optional. You can do without such complex manipulations.

- In any case, you will have to remove the box, so familiarize yourself with this procedure.

- Before removing the gearbox, remove the negative terminal from the car battery.

- All the chips are removed from the box, the wire from the speedometer is unscrewed.

- Next, the trousers of the vehicle exhaust system are dismantled.

- After this, you can completely remove the gearbox.

- At the next stage, the bell is dismantled. You can try to do without it, but then it will definitely constantly interfere with your work.

- Thoroughly clean the box from accumulated dirt.

- The bearing is secured using retaining rings. To remove them you will need a flathead screwdriver.

- The rings are pryed off and loosened a little, after which there will be no more problems with removal.

- To make it more convenient, arm yourself with tweezers that can be used to remove the ring.

- Using a flat-head screwdriver, pry the bearing by the ring groove, and at the same time move the input shaft slightly forward.

- Insert a pry bar between the gearbox and the bearing. It is unlikely that you will be able to do this without an assistant.

- You will operate the tools, while your friend will hold the pry bar.

- Your main task is to press out the bearing. To do this, precise, strong, but most accurate blows are applied to the input shaft.

- In the process of striking, the shaft must rotate.

- This work will take you about 20 minutes. But if you have a special puller at your disposal, you can speed up the work. Although it is really convenient to work with a puller only if you decide to disassemble the gearbox.

- Before installing a new input shaft bearing, be sure to lubricate the element with regular engine oil.

- Carefully press the component into place using gentle, light blows with a hammer. It is better to use a pipe of diameter or a stand.

- When pressing, apply blows to the inner race, in a circle, as evenly as possible.

- Once the bearing is pressed in, make sure it is seated properly. Scrolling should be calm, without obstacles.

- Reassemble the box in reverse order and install it on the car.

Location at checkpoint

POSSIBLE FAULTS

Despite the imperfect operation, the VAZ 2114 gearbox, when used correctly, is distinguished by good endurance and durability. If you do not hesitate to prevent and promptly eliminate breakdowns, repairing it is not expensive.

Let's consider the main gearbox malfunctions that the owner of the fourteenth may encounter:

- Lack of speed fixation when switching. If the speeds are out of whack, the cause is most likely worn teeth on the gears and clutch. Accelerated wear of these parts is caused by incorrect gear shifting and non-compliance with the speed limit. The problem is resolved by replacing the gears.

- The gear shift lever is tight. The reasons are mechanical damage to the teeth of the lever fixing on the hinge or wear of the reaction rod; it’s also a good idea to check the integrity of the plastic parts of the gearbox drive;

- The VAZ 2114 gearbox is humming. Most often, the gearbox is humming in neutral gear. First of all, you need to check and, if necessary, add oil (in general, the box may hum due to the use of low-quality lubricants). If the oil is normal, the problem is wear of the bearing on the input shaft, which can only be determined through diagnostics or by disassembling the gearbox;

- Crunching sound when changing speed. Here it is necessary to change the worn out synchronizer, and it must be changed immediately after the problem has been discovered, because if you tighten it, the gear unit will completely fly off;

- Knock. The gearbox on a VAZ 2114 can knock both under load and without it, and in any gear. The cause of the knocking noise is a damaged drive gear of the problematic transmission.

One of the key factors for the trouble-free operation of gearbox number fourteen is the use of high-quality lubricants. The most suitable option is GL-4 mineral oil. It is not cheap, but it does its job at 5+; when using mineral oil, VAZ gearbox repairs are usually required extremely rarely.

Most VAZ 2114 owners agree that the best gearbox oil is 75W90. It is distinguished by greater fluidity than typical gearbox oils, due to which the lubricant better gets into those places of the gearbox, the lubrication of which is provided exclusively by splashing. Good options for 75W90 are Hypoid-Getriebeoil TDL and Liqui Moly Vollsynthetisches Getriebeoil (GL-5).

Checking the oil level should be carried out every three weeks. In the gearbox, the fourteenth gear is placed vertically, the topmost is the fifth, it is the one that is most susceptible to failure due to lack of lubrication, so it is always necessary to fill in oil to the maximum mark, and best of all - 200-250 ml. more than the required norm.