It is extremely important to maintain the steering in good condition, since traffic safety directly depends on it. One of the problems that the driver runs the risk of encountering is the appearance of squeaking when turning the steering wheel. This symptom can occur both on cars with hydraulic power steering and on cars without power steering. The creaking can come either from the steering wheel itself or from under the front of the car. In this article, we will look at the main reasons why the steering wheel squeaks when turning and what to do in such a situation.

How to determine the cause of a squeak when turning the steering wheel

The steering mechanism of a car is quite complex, especially if it works in conjunction with a power steering. Because of this, there can be a lot of reasons that lead to squeaking when turning the steering wheel.

Carrying out diagnostic work that will allow you to determine the causes of the squeak should begin with identifying the specific place from which the squeak is heard when turning the steering wheel. To do this, you need to put the car in a hole and ask someone to turn the steering wheel, while listening to sounds from under the car to determine the location of the squeak. Having decided which element is creaking, you can move on to repairs.

When the shock absorber is faulty

Sometimes the cause of the noise is the creaking of the support bearing when turning the steering wheel. If creaking and howling noises occur no matter which way you turn, check the shock absorbers. Often the problem is in the bearings of this unit. It may be enough to remove any dirt that has clogged up under the boot. How to diagnose? Read on.

Try turning the steering wheel while standing still. Even better, ask an assistant to “steer”, while you listen and watch the movement of the shock absorber spring into the gap between the upper edge of the tire and the wing arch. If the part turns jerkily, as if something is interfering with it, it means that the support bearing creaks when turning the steering wheel. It's simple. There is no movement - neither the transmission nor the hubs can make noise - the shafts and wheels do not rotate. In this case, the only thing to suspect is the shock absorber struts.

Common causes of squeaking noise when turning the steering wheel

Here are the most common reasons why you hear a squeak when turning the steering wheel.

Wheel alignment performed incorrectly

If you hear squeaking noises from your tires, and it mostly happens when the car is stationary, there is a good chance that the problem is due to improper wheel alignment. In this case, it is necessary to perform a wheel alignment as quickly as possible to correct the problem.

Incorrect wheel alignment angles negatively affect the tires, which begin to wear unevenly and fail much faster than they should.

Silent blocks creak

A common problem that is often encountered in hot weather. If silent blocks begin to creak at high ambient temperatures, this is the first “bell” that they will soon fail.

The creaking of silent blocks in hot weather is due to their drying out. Since the main working material of silent blocks is rubber, at high temperatures it “dries out” and decreases in size, especially if we are talking about relatively old parts.

There is no danger in the creaking of silent blocks until the part breaks. Remove the silent blocks and carefully inspect them for cracks and various types of damage. If there are no visible problems, you can put them in place and continue driving, hoping that soon the air temperature will drop lower and the squeak will disappear.

Please note: For many modern cars you can find silent blocks made of polyurethane, which is not subject to the problem of “drying out” in the heat.

Bearings squeak

If you hear a squeaking, squeaking, or crackling sound from the steering knuckle when you turn the steering wheel, this most likely indicates a bearing problem. They behave in a similar way if there is not enough lubrication for their proper operation or if there is sand (or other foreign element) in the bearing.

Bearing creaking must be eliminated as quickly as possible so that the part does not fail completely. To do this, remove the bearing and inspect it for damage. If they are not found, then lubricate the part, install it in place and adjust.

Please note: When the squeaking of a bearing is caused by foreign elements entering it, be sure to find the reason for their entry into the part.

Steering rack or steering column creaks

It is quite simple to determine the creaking of the steering column by the characteristic vibration, which will also occur when the steering wheel rotates. Most often, the steering column clutch squeaks, and this problem is typical for cars that were unsuccessfully restored after a serious accident. This problem, if the noise is not strong, does not affect the quality of the steering mechanism, so you can continue to operate the car. The situation can only be corrected by replacing the steering column.

Front suspension repair

The cost of the parts themselves when eliminating the described reasons is most often small, but the price of replacing them in car services sometimes causes bewilderment. In such cases, it is better to repair the suspension yourself. This requires special devices and tools.

To remove the tips and ball joints of the steering wheel, pullers are needed that, during dismantling, preserve the integrity of these parts.

Silent blocks are replaced using a long threaded rod or bolt with a corresponding nut and a set of bushings and washers. The bushings should rest on the lever cage, and the washer should match the diameter of the rubber seal. Tightening the nut squeezes the silent blocks out of the lever, and then presses a new one in its place.

Dismantling the shock absorber strut is done with two ties that compress the spring. This makes it possible to unscrew the mounting bolts, remove the support bearing and remove the shock absorber and spring. The new spring is also completely compressed by the ties, then the entire assembly is assembled.

A knock when turning the steering wheel should not make the driver nervous. However, as soon as you have time, you should immediately start troubleshooting the problem. Today on the Internet you can find videos from professional craftsmen and amateurs about repairing suspensions of different car models and for various malfunctions. It is better to spend time studying their experience and then repair everything efficiently and quickly.

If the front suspension of your car is knocking, you have to go to a service center and look for the problem. But the issue is not always resolved during diagnosis. Firstly, the qualifications of the technicians may not be enough to detect the problem. Secondly, some elements of the chassis cannot be checked without disassembly. So you need to learn to look for problems based on the nature of the sound. A knock in the front suspension may occur when hitting bumps. We have already talked about such cases; they are not difficult to find. This type of problem can be found quite simply if you drive into a pit and ask an assistant to shake the car. At this time, it is enough to hold on to various suspension parts or release the silent blocks. This will help you find exactly the part that knocks when hitting obstacles.

If the knocking noise in the forward drive occurs on a flat road, the problem is more subtle. Finding it will not be easy, especially without experience and knowledge in this matter. It should be remembered that knocking can occur in different ways. It is by the nature of the sound that you can often understand what is knocking in your car. However, the concept of a smooth road in Russia is quite relative. So we will consider the issues of knocking of various parts, including sounds on small irregularities and smooth holes on the road. Knocks are also possible on a perfectly flat road. In this case, any rotation element may become unscrewed, which causes a knocking sound simply when turning the wheel. But it’s worth sorting everything out in order. There are a number of reasons that are worth checking if your car exhibits a clunking sound on relatively smooth roads in the suspension area.

Symptoms of Control Problems

As the wear of the car's steering parts increases, when turning the steering wheel in place, a creaking sound is heard, and various kinds of extraneous knocks occur, which become more intense over time. They entail incorrect operation or complete failure of operation. Signs of a malfunction of this control include knocking noises in the steering mechanism, rack, tip or rods. There is a creaking noise when turning the steering wheel in place and extraneous noises when driving.

Wear of crosspieces of cardan joints of rack drive shaft

If you hear clicks when turning the steering wheel, which can also be felt on the steering wheel, you should check the condition of the steering drive elements. The wear of the crosspieces is detected by probing the universal joint when turning the steering wheel to the right and left at a small angle.

The bite is clearly felt by the hand and allows you to accurately identify the worn part. It is necessary to take into account that there are several such parts and some may be located in hard-to-reach places. In some cases, it may be necessary to dismantle components to disassemble and inspect components, followed by replacement of the faulty part.

Sounds on cars with hydraulic booster

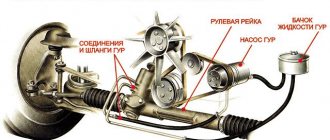

The power steering mechanism consists of the same parts and trapezoids, only the rack has special oil channels. Through them, oil under pressure acts on the steering rods, which makes it easier to turn the wheels.

— wear of the impeller of the power steering pump itself;

— jamming of the power steering pump;

— broken boots in the steering rack (it will start to leak);

— wear of the power pump drive pulley.

This kind of trouble happens even when the steering is working properly. In a strong eversion of the wheels, the load on the power steering pump becomes large. Especially when the car is loaded. The sound occurs due to increased wear on the drive pulley or belt.

Why do cables squeak?

Another nuisance is when creaks and clicks begin to appear when the clutch with mechanical drives is disengaged in the area of the cable. It’s more difficult to figure out here, because the cable can creak both in the cabin and under the hood. But in such cases it is better to coat the cable completely, especially since it will not take much time. To make it more convenient, the cable needs to be disconnected from the clutch fork and lubricated from under the hood. They do this in different ways, but if the cable is not yet old, then there is no point in removing it completely. You can lubricate it with a syringe and motor oil, methodically pushing the oil under the cable casing. Working areas, those places where the cable comes out of the casing, are lubricated with waterproof grease. Litol 24, for example.

Not only the cable in the casing can creak, but also the compensating mechanism. In some cars it is installed under the hood, near the clutch, and in some on the other side, near the pedal, like on the Lada Granta. While the cable is new, it will squeak and click. This is inevitable, but it still needs to be lubricated. It is better to lubricate the compensation mechanism when installing the cable. But if the moment is missed, then you will have to practice acrobatics in the salon. Using the same syringe, you need to get to the compensation mechanism and spray a couple of drops on it. The squeaks should disappear. Magic aerosols are best saved for other occasions.

Problems with electric power steering

Unlike hydraulic steering, the wheels are turned using an electric motor. It is connected to the steering mechanism by a belt drive. On VAZ-2127 cars, control with an electric amplifier is installed. Creaking when turning the steering wheel in place (Priora as well) is possible for the following reasons:

— wear of the electric motor pulley and steering mechanism;

— low voltage in the network;

— lack of “mass” of the car;

— malfunction of the electrical control unit.

Eliminating extraneous sound

To eliminate squeaking when turning the steering wheel in place, you first need to determine the cause of the extraneous sounds. On cars with power steering, if the system malfunctions, a “check” will light up on the instrument panel. Therefore, the driver should have his car diagnosed for errors. Special software at the service station will show exactly where the malfunction occurs and which sensor has failed. When the cause is found, repairs begin. If the problem is in the suspension, damaged and worn parts are replaced with new ones.

Steering knuckle bearings

If, when turning the steering wheel, the driver hears an uncharacteristic squeak, which can sometimes appear quite suddenly, it is worth listening to the steering knuckle.

When the sound comes from there, the cause most likely lies in worn bearings.

These bearings can squeak and make cracking noises if there is no lubricant inside or if sand or other abrasive contaminants have entered the housing.

Untimely replacement can have dangerous consequences. It is recommended to remove the bearing from the steering knuckle and check it for defects. If they are not there, lubricant is added and the part is returned to its place. If defects are detected, a new bearing similar to the previous one is used.

Service

In order for the steering to work properly, the driver must know how to properly maintain and operate it. To do this, you should carry out maintenance: change the oil in the power steering pump, if the tips or steering rods are worn, replace them with new ones, check the wheel alignment and adjust them if the angles do not match. Spare parts and oil must be from high-quality and original manufacturers. During operation, the driver must monitor the condition of the steering and the proper operation of the hydraulic or electric booster.

Causes of creaking rack and steering column

If the steering column is not working properly, you will hear a slight knock and noticeable vibration when driving. The cause of this malfunction is a strong mechanical impact on the steering wheel, during sudden braking or a collision during an accident. Such signs indicate deformation of the steering column. Also, strange sounds may come from the coupling.

Of course, the best way to eliminate a squeaking or knocking sound when moving and turning the steering column is to simply replace the non-functioning element with a new part. Unfortunately, the steering column is expensive, which means you need to look for ways to repair the old part. Vibration and noise can be eliminated using lubricant. Lubricating the driveshaft with a small amount of grease can eliminate unwanted noise, but this will only mask the symptoms. It is important to seek help from professionals who can fix the broken part before it completely fails.

Front stabilizer

If the stabilizer link partially fails, a dull knock is heard when the wheels turn while moving. Moreover, the wheels begin to knock if they are turned to one side or the other at approximately 50...60%. However, a faulty strut itself can creak not only when turning, but also when the car is moving on an uneven road. Often the car also “fidgets” on the road, that is, it is necessary to constantly control (twist) the steering wheel. Additional signs - the car body rolls too much when entering a turn and sways when braking.

Problems with the steering rack

The main reason for annoying squeaking noises when turning the steering wheel is a faulty steering rack. Such a squeak can be annoying, and untimely repairs can damage the parts. Unwanted squeaking can occur due to simple wear of the mechanisms, damage to the rack box or wear of the steering tips, which can rub against the rods. In addition, damaged anthers can accumulate dirt and debris, which makes a nasty sound when the mechanism operates.

Also, the cause of an unwanted squeak may be an incorrect setting between the steering rack and the column. It is extremely difficult to make such an adjustment, since all machines have an individual adjustment system, and it is better to trust a specialist.

Verdict

Substandard behavior of the Granta pedal assembly is a malfunction that should be eliminated as soon as possible. The issue may be either in the drive, which here is a cable drive, or directly in the unit connecting the engine and the gearbox.

Most often, the problem lies in an unraveled cable or its limited mobility in the jacket. This problem can be eliminated by replacing the cable and/or lubricating it with oil, silicone or WD-40. The fork shaft often needs lubrication.

Less commonly, the problem is caused by a deformed or cracked fork. Wear on the leaf spring can radically change the amount of force required to release the pedal. A new clutch can also cause it to feel stiff.

Good day to you, dear friends. Today we will talk about how to remove extraneous sounds (crunches, squeaks, crackles) when working with the clutch pedal of a Lada Granta. Mechanics are generally a “sick” topic for domestic cars produced by VAZ. While making generally reliable and unpretentious gearboxes, assemblers sometimes make mistakes: they do not set the clutch pedals correctly, they spare lubricants on the working elements of the mechanisms, and they disrupt technological processes. As a result, the consumer is forced to deal with extraneous noise when working with the clutch pedal and the gearbox as a whole. Today I will tell you how to remove these annoying sounds.

Steering wheel creaks in place

Interestingly, squeaking when turning the steering wheel in place, just like with the steering rack, can occur due to damaged steering rod boots. It is the debris and dirt in the protection that can contribute to squeaking when turning the steering wheel. This sound can be heard both while driving and while parked. All you need to do is clean the components from dust and dirt with the familiar WD-40 product, and replace the worn boots with a new and high-quality product. But it’s better not to start everything up, and not to wait until the steering wheel squeaks again, but to periodically check the condition of the boots and, if necessary, replace them.

Important! If the steering wheel not only makes a grinding noise when turning, but also wobbles a little and vibrates, the problem is not only in the steering rod, but also in the steering joint. Such a hinge may wear out over time and require replacement. If you do not replace the part in time, the hinge itself may jam, and you need to be reminded what will happen if the steering wheel starts to jam while driving and turns poorly.

Another reason for squeaking when making turns is an insufficient amount of fluid in the power steering. Typically, such a squeak will only be heard when the steering wheel is turned while the car is stopped. The first thing to do is try to replenish the fluid in the power steering reservoir. If this method does not help, you need to carry out a full diagnosis and, if necessary, repair the pump and other power steering elements. These elements are quite complex to repair at home, so it is better to contact a service station.

Incorrect wheel alignment can also cause a crunching sound every time you turn the steering wheel. Diagnostics and debugging are carried out only in car services, using computer diagnostics. The service will set the exact angle of the wheels, which will not only get rid of squeaking, but also help avoid severe wear of the tire rubber.

Also, a crunching or rubbery squeak when turning the steering wheel may indicate that the ball joints are worn out. If such problems are detected, urgent diagnostics must be carried out. In the event of a breakdown, it is necessary to replace the broken part with a new support. If you can't find a new ball joint, you can use lubricant. This repair will be temporary and will need to be replaced in the future. If you do not replace the ball joint in time, there is a possibility that the wheel will come off at high speed. In this type of accident, it is rare for anyone to escape without injury.

Having learned about a malfunction in the steering part, there is no need to hesitate. It is important to remember under what circumstances the noise occurs and contact a car service center. With correct diagnostics and skillful hands, the car will be on the road again. The steering part is one of the most important parts of the car, so you should not carry out repair work yourself. Finding a quality car service is not easy, but the Uremont.com website makes the search much easier. You just need to submit a request for car diagnostics and select a suitable car service from the list. Thus, you can quickly and easily repair your car thanks to our service.

Replacing the ball joint

Tool for work:

- wrenches 17, 19;

- hammer;

- mount;

- puller;

- head for 12.

The ball joint is being replaced

The car is put on the handbrake, the bolts of the wheel from which the ball joint will be removed are loosened. Using a jack, the front part of the Lada Kalina car is raised, the bolts and wheel are removed. Use a 19 wrench to unscrew the ball pin nut. Insert the puller and twist to release the support pin.

The support fastening bolts are removed using a 12mm socket. The lever is pressed down, the support is released and removed. There is another way to dismantle the ball joint: the brake disc is placed on a rigged brick, the jack is lowered slightly to relieve the lever. At this moment the rack rises up, the ball is released.

A large amount of lubricant must be added to the new support. The pin is put in place, the nut is tightened with a torque of 66-82 Nm. If the holes of the steering knuckle and the support coincide, the bolts are tightened. The procedure requires patience and considerable effort.