If you want your vehicle to always be on the move, you must comply with certain operating conditions for certain elements. For example, if the coolant temperature sensor on a VAZ 2110 fails, the car owner may face serious problems. In this article we will tell motorists everything they need to know about this device.

Device Description

If you need to know where the coolant temperature sensor is located and how it works on 16- or 8-valve VAZ 2110 engines, first read the basic information on the device. The operating principle of the regulator and typical problems with this element are described below.

DTOZH for VAZ 2110

Principle of operation

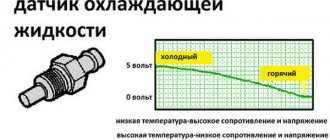

The coolant temperature regulator on a 16- or 8-valve VAZ 2110 car is a simple thermistor device. A thermistor is a resistor that has the ability to change resistance values depending on the temperature conditions in which it operates. On an injector with 8 or 16 valves, the device is installed directly in the cylinder head. Antifreeze circulates through the hose in which the regulator is installed.

The purpose of the coolant temperature sensor on the carburetor or injector of 16 valves of the VAZ 2110 is to monitor this temperature. If the indicator exceeds the normalized one, the device reports this to the control unit, as a result of which the fan is turned on. It should be noted that the fan is turned on forcibly. Without turning on the fan, the motor may overheat.

There is an opinion that in the entire design of the VAZ 2110 16-valve injector, this element is the most reliable. However, breakdowns still occur. On the dashboard there is a regulator with a pointer, which receives a signal from the device. If the element is working correctly, the signal indicator will always show the exact temperature.

Two knobs for "ten"

Typical problems

There are quite a lot of problems associated with the failure of the sensor on the engine injector 16 valves of the VAZ 2110. As a rule, the essence of the malfunction lies in the lack of contact on the internal components of the device. The malfunction may also be due to problems with the insulation of the cables around the regulator itself, in particular if the gas pedal cable is hanging loose. If the regulator does not work correctly, it will not be able to provide the correct information to the control unit, and accordingly, over time, problems with starting the internal combustion engine may appear. In addition, if the device on the 16-valve injector of the VAZ 2110 does not work correctly, fuel consumption may increase.

If the device sends incorrect signals, turning on the fan will be impossible, and without turning on the fan, as mentioned above, it will not be possible to cool the motor. Sometimes it happens that the fan is turned on constantly - if the regulator registers an increased temperature, but in fact it is normal. Then the fan is turned on constantly, in principle, this does not threaten the car enthusiast in any way, but this can cause high energy consumption of the battery (the author of the video is Vasily Kalugin).

The thermistor, which is installed inside the coolant temperature control device on the 16-valve injector of the VAZ 2110, is an electronic system. This system is characterized by negative temperature indicators. If the element heats up, the resistance level begins to decrease, and vice versa, if the device cools, the resistance increases. By the way, the resistance indicator is considered quite important. The optimal operating temperature of the VAZ 2110 injector is up to 130 degrees, in this case the resistance level drops to 70 Ohms.

The lowest temperature limit, which is 40 degrees below zero, will increase the resistance to the highest value - 107 Ohms. When the controller is operating, it passes a voltage of about five volts to the regulator according to the circuit. The coolant temperature in this case is determined by the ECU. The control unit calculates this parameter based on the voltage difference across the device. Always take into account the fact that temperature levels affect the functioning of many vehicle mechanisms.

Idle speed control

Today, in urban environments, drivers simply cannot do without idling. Therefore, every car, including the VAZ 2110, is equipped with an idle speed sensor. Incorrect operation or failure of this regulator will significantly complicate driving, because it will cause the engine to stop even during the shortest stops. So if the controller fails, and this is not uncommon in VAZ 2110 cars, it needs to be changed as quickly as possible.

Removing the idle air control

The main purpose of this type of regulator is to support the speed required for normal operation of the power unit. Thanks to the device, the driver can always make a short stop as a result of changing the incoming air volume. As for the location, this controller is installed on the throttle line. In particular, we are talking about an anchor stepper motor, which is equipped with two windings.

When a corresponding signal is received on one of the windings, a special needle moves forward one step and backwards one step. Thanks to the worm gear, the device rotates, which is produced using a stepper motor, thus converting this movement into translational. The rod itself, namely its conical part, is located in the line through which the air flow is supplied.

Thanks to the functioning of the rod, the system adjusts the idle speed of the power unit. The rod from the device, as mentioned above, can be retracted or extended. In this case, it all depends on what kind of pulse will be supplied from the regulator. The controller itself allows you to adjust the frequency at which the engine crankshaft will rotate when the machine is stopped for a short time.

In addition, the controller controls the incoming air flow, which bypasses the throttle in the closed position. When the engine is warmed up, the regulator, by controlling the movement of the rod itself, at idle speed allows you to maintain the required crankshaft speed. In this case, the load and condition of the power unit do not play a role.

Loading …

Mass air flow sensor

If everything is clear with the coolant sensor, then let's move on to the mass air flow device. Unlike the fluid regulator, this sensor is designed to analyze the volume of air that the motor consumes during normal operation. It is this indicator that directly affects the fuel consumption of the VAZ 2110 engine.

MAF for VAZ 2110

The engine air flow sensor itself is a device in the form of a film on which the regulator itself, as well as a heating resistor, are located. In the middle of the element there is a special section, the heating level of which is monitored by the regulator. On the back of the film surface there are several more thermal sensors. In the event that there is no air flow, these regulators, including the air flow sensor, will display the same parameters using the signal indicator.

When there is air flow, the first device will be cooled, but as for the second, its performance will be the same, since the air will heat up in any case when the engine is running. The signal level from both regulators will be proportional to the mass of the air flow, and the electrical circuit, in turn, will convert this parameter into voltage. The engine air flow sensor must always be clean, otherwise the readings that the device will produce will be incorrect. Accordingly, problems may arise in the operation of certain machine engine mechanisms, so it is necessary to periodically check and monitor the cleanliness of the film itself. The author of the video on how to diagnose a faulty mass air flow sensor regulator at home is in Sandro’s garage.

Mass air flow sensor

The power unit of the "tens" is controlled using the ECM - an electronic system. This system must always know how much air needs to be supplied for a certain volume of gasoline. These two parameters are closely related to each other, since with their help a combustible mixture with the required density is formed in the engine power unit. After the system determines the required volume of air, it begins to select the appropriate amount of gasoline. As for the regulator, it is responsible for the suction volumes.

Air controller for "ten"

This controller has certain disadvantages, in particular:

- its performance may be impaired if the controller is exposed to moisture;

- if the car is moving at lower speeds, the controller can produce higher readings;

- as practice shows, at idle the air regulator does not work entirely correctly;

- when starting the power unit, certain difficulties may arise;

- the power unit may stop abruptly for no reason after an increased power mode;

- Gasoline consumption during vehicle operation may increase.

We've dealt with the shortcomings, now let's talk about how the device functions:

- The controller design consists of several sensitive elements installed directly in the line itself through which the air flow passes. One of these components is designed to fix the temperature of the air flow, and the other two are always heated to the required parameters.

- To correctly determine the air flow rate, the principle of measuring electrical power is used to maintain the desired temperature level.

- The air regulator controller has a special mesh installed in the line, designed to filter the air flow.

- Thanks to this, the sensor can transmit the necessary data to other regulators designed to activate certain modes. Subsequently, these regulators either change or support the loads.

Checking work

How to check the device at home? To check an element, it is necessary to measure its voltage level only if it does not work. The voltage check is carried out with the engine turned off; the indicators for checking can be measured using a multimeter. It is necessary to pierce the circuit as carefully as possible next to the regulator connectors and measure the voltage level between the third and fifth contacts.

If the component is working and does not require replacement, the voltage reading will be about 0.996 volts. Of course, if the element is not working, it will show incorrect readings, which will be more than 1.7 volts. If this is indeed the case and during diagnostics you identified such a parameter, the part needs to be replaced. To replace a component you do not need any knowledge or experience, everything is quite simple.

Selection of DTOZH

When making repairs, it is recommended to use original components or spare parts manufactured by reputable factories. Products manufactured at the AvtoVAZ parent plant cost about 400–500 rubles and have catalog number 21120–3851010–00. The last two digits may be different provided that the parts are manufactured by partner factories that are part of the AvtoVAZ group of companies. Among the possible replacement options, it is recommended to consider products from well-known brands:

- Vemo V40-72-0322 (900 – 1100 rubles).

- Hella 6PT 009 107-271 (800 – 950 RUR).

- Facet 7.3098 (700 – 800 rub.).

- Vernet WS2586 (400 – 500 rubles).

Spare parts for every taste and budget are available for sale.

Video “Procedure for replacing the MPV sensor on a VAZ car”

How to replace the regulator on the “ten” yourself at home - find out from the video (the author of the video is In Sandro’s garage).

The VAZ 2110 temperature sensor is an important element of the system; it informs the computer about the engine temperature. A lot depends on the engine temperature. For example, the lower it is, the richer the fuel mixture is supplied to the injector or carburetor.

Sometimes on the road you can see cars standing on the side of the road with steam pouring out of their open hoods. This is a fairly common situation when the engine temperature exceeds the permissible limits and the engine overheats.

The coolant sensor in the car failed or the car owner was distracted and did not notice that the temperature of the VAZ 2110 engine was going through the roof. Due to engine overheating, the liquid in the cooling system exceeded its boiling point and turned into steam. To somehow help the car cool down, the driver opens the cap on the radiator and releases steam, which comes out under pressure.

You shouldn't do that. This carries certain risks: you can get serious burns. To avoid such problems, the motorist needs to be extremely careful during the trip and promptly respond to information from sensors and instruments on the console. It is also important to ensure that the VAZ 2110 coolant sensor is in working order and its readings are accurate.

What functions does the cooling system of the VAZ-2110 car perform?

During engine operation, thermal energy is generated, which is eliminated by the cooling system. If it fails, serious consequences for the power unit can occur. In addition, the cooling system provides a number of other options:

- ensures prompt heating of the engine to the required, optimal temperature;

- cools the engine lubrication system;

- provides heating of the air in the cabin;

- cools the products of oxidation and incomplete combustion of fuel.

The 2110 model has a liquid cooling system. Antifreeze or antifreeze is used as a coolant. The vehicles also use an air and combined OS system. In the latter case, we are talking about cooling the system by blowing air and liquid.

Operation and possible device malfunctions

The VAZ 2110 temperature sensor is nothing more than an ordinary thermistor. This is a resistor that has the property of changing its resistance parameters depending on the temperature in which it is located. It is integrated into the cylinder head. Coolant circulates through the pipe in which the sensor is located.

The sensor must ensure that the operating temperature of the VAZ engine does not exceed the norm. If the temperature readings are outside the normal range, the device supplies the corresponding information to the ECU, and then a command is generated to force the fan to start.

If the sensor is faulty, it will provide incorrect information, which may result in certain difficulties when starting the engine, and will also increase fuel consumption. The thermistor located inside the sensor is an electronic system with negative temperature indicators. As the device heats up, the resistance decreases. If it cools, the resistance indicators increase.

The operating temperature of the VAZ engine is up to 130 °C, the resistance of the device can drop to 70 Ohms. The lowest temperature limit of -40 °C will increase the resistance of the thermistor to 107 ohms.

The controller, also known as a detector, allows a voltage of 5 V to be passed to the temperature sensor with a constant resistance inside. The electronic control unit determines the coolant temperature values by the voltage difference across the temperature sensor. When using the device, you need to remember that the temperature of the coolant affects the operation of many vehicle components.

Causes of DTOZh malfunction on the VAZ 2110 and ways to eliminate them

To ensure that reliable information is transmitted to the computer, the coolant regulator must be installed correctly. The tips of the device must be in contact with the coolant.

Practice shows that the VAZ 2110 DTOZH quite often demonstrates incorrect operation as a result of improper installation.

Even an unprofessional motorist, using a number of “symptoms,” will be able to independently determine that the controller has failed. The following signs indicate this:

- fuel consumption has increased;

- the power unit is not working correctly;

- there are difficulties starting the engine;

- a sensor on the panel indicates overheating of the power unit;

- the quality of exhaust gases deteriorates;

- The panel displays an error code.

Usually in such situations, drivers immediately begin to replace the controller. But quite often on the VAZ 2110 the signs of the listed problems are caused by poor contacts and damaged wiring.

The need to replace the device is indicated by deposits and rust on its surface. Therefore, even a visual inspection allows you to determine the relevance of the replacement. The best option is to check the resistance using a measuring device. The motorist will need a voltmeter. The data must meet the following values:

- with a hot engine - 0.5 V;

- cold - 2 V.

Mass air flow sensor

This device analyzes the amount of air that the engine consumes during operation. Fuel consumption directly depends on its readings. The device is a sensitive element in the form of a thin film. It contains temperature sensors and a heating resistor.

In the middle part of this film there is a special area, the heating level of which is controlled by a temperature sensor. On the film on the side where the device controls the air flow, there are two more thermal sensors. If there are no air flows, they produce the same temperature.

If there is air flow, then the first sensor will cool, and the second will not change its indicators, since the air heats up. The signal from both devices will be equal to the proportional mass of air that passes through them. The electrical circuit converts this indicator into voltage.

It is very important to keep this element clean, otherwise the indicators may be distorted and, as a result, errors or malfunction of some parts of the car may occur. It is also necessary to monitor the cleanliness of the air that passes through the film.

Where can I buy a new sensor?

The acquisition of a sensor is carried out by contacting stores that provide them for domestically produced cars. Their prices may vary. It depends on the place of purchase/sale and a number of other indicators. Particular attention should be paid to fluid leaks. If, when starting the engine, coolant continues to ooze from the connecting holes, use a heat-resistant sealant.

Note. An alternative to sealant can be a copper washer, which will help hold the parts of the mechanism together and prevent the driver from leaking.

Also, you should pay attention to the voltage measurement. After completing this procedure, the car ignition should be turned off.

Checking operation and replacing the sensor

Checking the sensor for serviceability when diagnosing problems with a car comes down to measuring its voltage when it is at rest. Measurements are taken with the engine not yet running. You can take readings using a regular multimeter. You need to pierce the wires near the connectors of the sensor being tested as carefully as possible and record the voltage between pins 3 and 5.

For a working sensor, the readings will be 0.996 V, and if it is faulty or its readings are incorrect, then the voltage value will be more than 1.7 V. With such readings, it is better to replace the mass air flow sensor as soon as possible. To replace it on a VAZ 2110 car, you do not need special knowledge or skills.

The replacement procedure is a set of simple steps that even novice car enthusiasts can easily handle. You need to remove the negative cable from the battery, then drain the radiator. Next, you can proceed to dismantling the air filter.

It must be removed to make it more comfortable to replace the sensor. Then you need to squeeze out the plastic clip that holds the wire block from the sensor. Now all that remains is to dismantle the sensor itself, and then install a new one in its place and carry out all the steps in the reverse order.

It is advisable to purchase a coolant and mass air flow sensor of those models that are recommended by the manufacturer for the VAZ 2110. Their price is low, and a lot depends on the quality of these devices. It is necessary to carefully monitor the serviceability of the sensors and the veracity of their readings. Then it will be possible to avoid engine overheating and other problems with the “ten”.

1200 rub. for the photo report

We pay for photo reports on car repairs. Earnings from 10,000 rubles/month.

Write:

Checking the temperature sensor is a simple procedure that even a novice car enthusiast can handle. The coolant temperature sensor (abbreviated as DTOZH) is a thermistor, that is, a resistor that changes the value of its internal resistance in accordance with the temperature where its actuator is placed. Most often, a multimeter is used for this (another name is a tester, “tseshka”), which is able to measure the value of electrical resistance in a circuit.

Replacement

The check showed that the sensor was to blame. Therefore, you have no choice but to replace it with a new one. For this:

- The coolant is drained. It is better to drain the maximum amount. Especially if the coolant has long been due for replacement;

- Disconnect the terminals from the battery;

- To make it more convenient to work, remove the air filter from its seat;

- Turn off the ignition and remove the sensor connector;

- Use a 19mm wrench to remove the sensor. The sealing ring must be removed along with it;

- A new seal ring is taken and a new, high-quality coolant sensor, suitable for the VAZ 2110 model, is mounted in place of the old one;

- The entire assembly process is performed in reverse order.

How does the coolant temperature sensor work?

Before we move on to discussing how to check the coolant temperature sensor, it is necessary to briefly look at the signs of its malfunction and understand how it works. This will help determine the diagnosis. As mentioned above, the coolant temperature sensor (sometimes simply called the engine temperature sensor) is a thermistor - a resistor that changes its resistance depending on changes in temperature, in particular the coolant of the engine cooling system. The corresponding resistance value and its change are recorded by the electronic engine control unit (abbreviated as ECU), on the basis of which it issues the appropriate commands.

Signs of failure of the coolant sensor

A number of signs will indicate the need to check the coolant temperature sensor. However, it is worth noting that the situations listed below may be signs of other breakdowns in the car’s engine, therefore, to obtain an accurate result, it is necessary to perform additional diagnostics. So, signs of a faulty coolant temperature sensor include:

- Activation of the warning lamp on the Check Engine panel. However, it can also be activated during other failures, so it is necessary to perform an additional scan of the error code.

- Increased fuel consumption . This is due to the fact that incorrect information is supplied to the electronic control unit, and accordingly, it is also unable to determine exactly how much fuel is needed not only to create an optimal air-fuel mixture, but also to maintain the engine temperature in the normal (non-emergency) range.

- Unstable motor operation . In particular, its unstable operation at idle, difficulty starting (especially in the cold season), spontaneous stopping at low speeds.

- The engine stalls when hot . That is, it may suddenly stall when the critical coolant temperature is reached. Moreover, this does not depend on what kind of coolant was poured into the system (in particular, factory-made antifreeze or ordinary water).

- Problems with the cooling fan on the radiator . This can manifest itself in different ways. In some cases, the fan does not turn on at all, in others it does not turn on in emergency modes, in others it does not turn off even when the engine cools down. When the coolant temperature sensor is disconnected, the electronic control unit perceives this as an open circuit in the sensor and forcibly turns on the fan. In any case, to obtain an accurate picture, it is necessary to perform additional diagnostics of the sensor and/or thermostat.

Due to the fact that this sensor has a fairly simple device and most often a non-separable housing, if it fails it must be replaced. This applies to almost all machines on which this device is installed.

Causes and symptoms of malfunction

Service workshop technicians say that in 90% of cases, the breakdown of the temperature sensor on a VAZ and other brands of cars occurs due to natural causes. Most often, a break in the internal contacts of the resistor occurs. As a result, the DTOZh sends incorrect parameters to the ECU, for example, engine starting t° within 0 °C. The control unit considers the engine cold and gives a command to another sensor - the mass air flow sensor - to reduce the air supply, that is, to enrich the mixture. Therefore, a warmed-up engine begins to work strangely, “excitedly” with failures. Here are 3 more most common reasons for the incorrect operation of the DTOZH:

- The seal of the sensor housing is broken.

- There was a break in the electrical wires.

- The power supply has fallen off.

In the above cases, the ECU does not see the DTS system, so it attracts the driver’s attention with a “Check Engine” signal on the dashboard. In this case, the operation of the car becomes unusual:

- the engine starts with difficulty and tends to stall;

- the speed fluctuates even on a warm engine;

- strong detonation is felt;

- the former power is lost.

In addition, fuel consumption increases, and dark smoke comes out of the exhaust pipe. It is necessary to make a diagnosis. To do this, you can go to a car service center, or install a special application on your smartphone and buy a Bluetooth adapter.

Sensor location on the engine

In order to check the coolant temperature sensor, you need to know where it is located. Naturally, this information will vary for cars of different brands and models. However, there are several typical signs by which you can find the place where the sensor is directly attached. So, in most cases it is located on the exhaust pipe of the cylinder head. Structurally, it has a metal thread, with which it is screwed into the corresponding hole. The main requirement in this case is to ensure direct contact between its sensitive element and the coolant. It is this contact that ensures the accuracy of the sensor readings.

Please note that some vehicles may be designed to have two temperature sensors installed. In this case, the first of them records the temperature of the coolant at the outlet of the engine (cylinders), and the second - at the outlet of the radiator. This approach makes it possible to more accurately monitor the condition of both the engine as a whole and its cooling system in particular. However, two sensors are usually installed on powerful and/or expensive cars, where this parameter is critically important, and the ECU contains special programs for engine operation. You can find additional information about the design of a particular car in the corresponding manual or technical documentation.

Replacing diesel fuel assemblies

Removal of diesel fuel assemblies in VAZ 2110

The VAZ 2110 interior temperature sensor is used to monitor temperature parameters in the car. This controller is also a transmitter connected to the ECM. In cold weather, the VAZ air controller transmits information to the ECU, which promotes optimal air flow throughout the car interior. As in the previous case, the malfunction of the device may be due to problems in the operation of the electrical circuit, so it would be a good idea to check the wiring if the controller does not turn on.

To replace the interior air temperature sensor, you need to perform the following steps:

- The car must be set to the parking brake. Disconnect the battery.

- Using a flat-tip screwdriver, you need to move the device body away from the installation site.

- First, the upper part of the diesel fuel assembly is removed, this will allow for more convenient dismantling of the controller. When the device is removed from the latches, proceed carefully, since you will still need to disconnect it from the wiring (two connectors). First, the wiring is disconnected, then the combustion engine itself is removed.

- As for installation, the procedure looks similar, but is done in reverse order. After installation, it is necessary to diagnose the functionality of the device.

Causes of failure of the coolant temperature sensor

Structurally, the coolant sensor is quite simple, and accordingly, it rarely fails. Usually this happens simply due to its old age or mechanical damage. For example, corrosion of contacts and metal parts of the case may occur due to the fact that instead of antifreeze or antifreeze, ordinary water was poured into the cooling system (and even more so if this water is “hard”, that is, with a high content of metal salts). Also, the reasons for the failure of this device may be:

- Hull damage . This can be expressed in various aspects. Often, leaks of coolant are visible, which flows from the threads of the sensor or its housing. Also, the electrical contacts and/or the thermistor itself may be damaged, which will produce an incorrect signal.

- Oxidation of contacts . Sometimes situations arise when, under the influence of fumes or simply from old age, the contacts on the sensor oxidize, so the electrical signal does not pass through them.

- Damage to the chip . In some cases, due to mechanical damage, the so-called “chip” may fail, that is, a group of contacts that is connected to the coolant temperature sensor. Simply put, the wires at the base of the connector fray. According to statistics from reviews found on the Internet, this is one of the most common malfunctions that occurs with the sensor and the corresponding system.

- Lost electrical contact inside the sensor . In this case, unfortunately, repair is hardly possible, since usually its body is sealed and does not allow access to the insides of the DTOZH. Accordingly, in this case the sensor only needs to be replaced with a new one.

- Violation of wire insulation . In particular, we are talking about the power and signal wires that go to the sensor from the electronic control unit and back. The insulation can be damaged due to mechanical stress, abrasion, or even simply from old age, when it “peeles” in pieces. This is especially true for those machines that are operated in conditions of high humidity and sudden changes in ambient temperature.

If it is possible to simply clean the body/threads/contacts of the sensor, then to restore its normal operation it is enough to carry out the appropriate measures. However, if the housing is damaged and/or the internal thermistor is damaged, then repair is hardly possible. In this case, you just need to replace the sensor with a new one. Its price is low, and the replacement process is simple and will not take much time and effort even for novice car owners.

CO functions

The cooling system is responsible for removing excess heat that is generated during operation of the power unit. If the engine overheats, the consequences can be catastrophic.

Cooling system diagram

In addition to heat removal, CO additionally performs several other functions:

- Helps accelerate engine warming up to optimal operating temperature;

- Warms the air inside the cabin;

- Cools the lubrication system;

- Cools exhaust gases.

In total, three types of cooling systems can be used on cars:

- Air. The cooling process is carried out by blowing air over the units;

- Liquid. The coolant is a special liquid - water, antifreeze or antifreeze;

- Combined. Both types of cooling are mixed in one system.

antifreeze or antifreeze acts as a cooler .

How to check the functionality of the coolant sensor

There are two main methods for checking the health of the coolant temperature sensor. The first - with its dismantling, the second - directly on the seat in the car engine. In turn, the first method can also be divided into two more. The first is with the use of a thermometer, the second is without it. Removing the sensor can usually be done using an ordinary wrench of a suitable size, after first disconnecting the contact terminals from it. But before dismantling the sensor, you need to make sure that power is supplied to the DTOZH. Typically it is equal to 5 Volts DC voltage. This can be easily found out by disconnecting its chip from the sensor, and using a multimeter set to DC voltage measurement mode (with the appropriate range) using probes to check the voltage value. If voltage is present and at the specified value, then further testing of the coolant sensor can be performed.

Examination

Diagnostics should only be carried out if you have the skills to use measuring instruments. Acting in strict sequence, it is necessary:

- Make sure the wires are connected to the connector.

- Perform a visual inspection to detect damage to the sensor and wiring.

- After disconnecting the wiring and turning on the ignition, use a multimeter to measure the voltage at the current-carrying terminals. It should be about 5 volts.

- With a cold engine, measure the resistance at the terminals of DTOZH No. 2. If the ambient temperature is within +23… +25 °C, the device readings should be in the region of 2870 Ohms.

- Connect the sensor, start the engine and wait until the cooling system fan turns on, turn off the car and take repeated measurements. At this point the resistance should be approximately 180 ohms.