07 October 2015 Lada.Online 130 173 22

Even at the stages of car development, it was known that the Vesta platform would be truly new, and not just another modernization of the VAZ 2108 suspension. Now that serial production of the sedan has already started, and the first samples have already been on test drives in various car magazines, more detailed details are being clarified about the chassis of the Lada Vesta.

The last adjustments to the suspension characteristics took place in winter in Spain, at the IDIADA training ground. Then a balance was found between comfort and car controllability. What happened?

What is hard and soft suspension?

The suspension is influenced by a large number of factors:

- This is the mass of the body

- Body shape, tall or, on the contrary, squat

- Dimensions, wheelbase

- Speed and power characteristics

- Settings

A little theory, let's start with the oscillation frequency. After all, even when walking, it is present, and a person gets used to certain indicators in the life cycle.

A car also has this parameter, only this is the vibration frequency of the body with cargo and passengers on the suspension.

In simple words, the more the body weighs, the more powerful and, accordingly, stiffer the springs should be.

However, one value remains practically unchanged - the static deflection of the elastic element (spring or spring) is 25 cm. This is the difference in the values of the free spring and the compressed one on the suspension (with passengers and cargo). When brought to the wheel, because in some suspensions the springs work directly, and in others through a lever

Accordingly, the lever must be taken into account

This is ideal!

However, now on modern cars the suspension is made a little stiffer than we would like, let’s go point by point:

With low hardness it is difficult to achieve high energy intensity. To prevent the soft suspension from breaking through an obstacle, you need to make a large compression stroke. BUT there are two problems here: you can’t make a big move due to restrictions on the body layout (spars or wings simply won’t allow it). And a limitation on the suspension kinematics itself. The suspension works along a radius and with a large compression stroke, unwanted movements of the levers increase, which reduces controllability and increases the load on the elements.

Compression buffers. Probably everyone has heard the concept of “rebound” suspension operation. Some manufacturers, to please the consumer, can install soft springs and shock absorbers with “high compression,” but as a rule, such suspensions easily break through sharp bumps. Therefore, they install so-called compression buffers, rubber elements that limit the stroke. Both springs and springs have them. BUT if the suspension reaches the “buffer” its comfort is lost significantly.

A smaller, taller and lighter passenger car. The more difficult it is to achieve a smooth ride and, accordingly, a soft suspension. After all, soft springs are required so that they give a comfortable oscillation frequency. BUT there is another problem here, loading the car. After all, if such a machine is heavily loaded, the drawdown will be severe. It is also worth taking into account the kinematics of the suspension, because a small car will have smaller operating radii. But sometimes the car needs to be loaded just as heavily (for example, 4 people + cargo). That's why small cars are often the stiffest, especially those tuned to high speeds.

- Anti-roll bar. It is needed to increase the angular stiffness of the suspension and resist body roll when cornering. Helps in kinematics, not to go beyond the maximum permissible points of suspension radius mixing. Also helps with driving.

- Air suspension. When installed, almost any car can be made comfortable and soft (from the driver’s point of view), but the cost of the system is prohibitive. And they don’t install it on budget brands

I would like to summarize briefly. On large cars it is easier to make the suspension comfortable. Because the body weight is greater, the wheelbase is longer, there is plenty of space for the suspension to work, and the settings are for high loads and speeds. ON a large car, even huge springs will work better.

ON small, and even tall cars. Often, making a soft and comfortable suspension heavier. For example, I had a FORD FUSION, it was really made of oak (due to the short wheelbase and high body). The manufacturer has nowhere to roam in such a car. That's why they make such cars a little tougher. This is not a whim of the manufacturer, but a necessity.

Now I want to talk about myths that, although on the Internet

Wear of stabilizer bushings

If, when driving over a speed bump, a dull knock or squeak is heard from the front, there is a high probability that the reason for this is premature wear, due to the poor quality of the material, of the standard anti-roll bar bushings of the Lada Vesta - a malfunction typical of the VAZ sedan. In this case, other signs corresponding to the assumption should be present:

- knocking of the chassis when the car rolls while moving;

- beating in the steering wheel when driving on a flat surface at speeds above 60 km/h;

- increased play in the steering mechanism during intensive maneuvering;

- involuntary deviation of the car from straight-line movement.

The final conclusion will be made by inspecting the car on a car lift - if the bushings are swollen, have lost their geometry and elasticity, then they need to be replaced.

When diagnosing stabilizer bushings, as a rule, all elements of the front suspension are inspected and, first of all, the vertical struts of the anti-roll bar (article no. 8450006750), which also often fail in Lada Vesta.

Lada Vesta produces standard stabilizer bars. These parts are of fairly high quality, but they also have their own resource, which depends on many factors. The degree of wear of the vertical struts is determined by the presence of play in their hinges - if the struts knock when the stabilizer is suddenly manually moved, they need to be replaced. Knowing the length of the struts (283 mm), you can select even better parts for replacement, for example, from Toyota or Hyundai.

- socket wrench “16” - unscrewing the nut;

- Torx key 30 – pin locking.

Front suspension Lada Vesta

In the car's operating instructions, the manufacturer indicates that the front suspension of the Lada Vesta is independent and equipped with shock absorber struts (gas-filled). They are hydraulic, with a double-acting telescopic design. These struts consist of shock absorbers and coil springs (barrel-shaped), and the suspension kit, in addition to them, includes lower wishbones and anti-roll bars, this entire structure is mounted on a subframe.

The originality of the Lada Vesta suspension is due to a completely new approach to the problem of driving on domestic roads and creating a competitive car. Engineers tried to implement the most optimal technical solutions in the front suspension of the car.

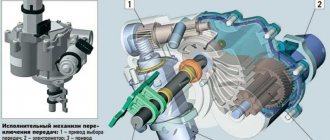

A subframe was added, on which the motor support points (two) were located. It was decided to leave the MacPherson struts, since they are considered the most popular in the world. But the main feature of the new “West” suspension, the designers believe, is that, in contrast to the longitudinal extension of the “eight” and its wishbone, the manufacturer began to install an L-shaped lever with a caster angle of 5°. It bears all the main loads (longitudinal as well as transverse).

This decision helped to significantly improve the handling characteristics of the Lada Vesta. This was also facilitated by the fact that the engineers installed structurally new steering knuckles on the front suspension. The suspension arm of the Lada Vesta only benefited from this.

All these engineering innovations have led to excellent results:

- Driving on straight sections of roads has become noticeably more confident, and steering sensitivity has increased significantly. It has now become much easier to determine what position the front wheels are in;

- When cornering, when you “play” with the brake or gas pedal, you no longer feel wobbling, shaking, etc. Previous Lada car models were “sinful” of this;

- If, when cornering, you encounter a washboard-type section or worse, vibrations are almost not felt, and the steering wheel does not jump out of your hands.

1 – additional subframe spar; 2 – front suspension subframe; 3 – lower front suspension arm; 4 – steering knuckle with hub assembly; 5 – telescopic front suspension strut assembly; 6 – stabilizer bar with struts assembly

Vesta front suspension diagram: 1 - ball joint; 2 — lever; 3 — steering knuckle; 4 — stabilizer bar; 5 — shock absorber strut; 6 - spring; 7 — front subframe; 8 — longitudinal beam of the front subframe.

The front suspension of Vesta is completely original. A subframe appeared on which two engine support points (stretch) were placed. The other two support points of the power unit are located on the side members. MacPherson struts remain. The main feature of the Vesta’s front suspension is that instead of the “eight” longitudinal brace and wishbone, one L-shaped lever with a castor of 5 degrees appeared (see.

From the point of view of handling, the mutual understanding between the driver and the car turned out to be successful. Driving in a straight line is confident, with a clear sense of zero steering position. When turning corners when increasing the gas or braking, there are no familiar wobbles or shaking (as was the case on Lada cars of previous years). When turning on uneven roads, vibrations practically do not come to the steering wheel. The steering wheel does not break out of your hands, and reliable feedback is maintained.

Question to AvtoVAZ: Why was the subframe fixed rigidly (without damper cushions)?

Answer: The introduction of dampers worsens key indicators of comfort and handling.

List of reliable online stores

*prices are valid for

Conclusion

The manufacturer has installed an improved suspension, but it has not yet been possible to achieve ideal results. Perhaps, when creating the next new product, all the shortcomings will be corrected, and the suspension will be able to compete with foreign cars.

In general, the car drives smoothly, noise during fast driving has been reduced as much as possible, and the sensitivity of the suspension has decreased.

- https://VestaXray.ru/model/lada-vesta/podveska.html: 4 blocks out of 7 were used, number of characters 3176 (12%)

- https://xn--80aal0a.xn--80asehdb/car-description/photo/lada-vesta-photo/707-osobennosti-podveski-lada-vesta.html: 1 blocks out of 3 used, number of characters 2034 ( 8%)

- https://remont-avtovaz.ru/kak-modernizirovat-podvesky-na-lada-vesta/: 6 blocks out of 9 used, number of characters 6702 (25%)

- https://podveska-avtomobilya.ru/nadezhnost-i-resurs-podveski-lada-vesta-sw-cross.html: 2 blocks out of 6 used, number of characters 4209 (16%)

- https://olade.ru/v-chem-sekret-preimushhestva-novoj-podveski-lada-vesta-pered-starymi: 3 blocks out of 5 were used, number of characters 2843 (11%)

- https://Lada-Vesta-SW.ru/podveska-lada-vesta-cross-obzor-perednej-i-zadnej-video-i-resurs/: 4 blocks out of 9 were used, number of characters 3274 (12%)

- https://xn—-21-43dabppn4d4dn.xn--p1ai/tormoza-i-podveska-lady-vesty/: 5 blocks out of 6 used, number of characters 4568 (17%)

Trim or install other springs

To cut this at all is some kind of game!

Firstly, there is no 25 cm in a loaded car, which is necessary for comfortable work. Secondly, the work of the suspension will be, on the contrary, torn, and the spring will become a little softer, it simply won’t have enough coils to hold the body normally. The center of gravity of the body will be mixed, which has an extremely negative effect on handling. If you cut off more turns, you will hit the bottom on the road, because again there is not enough spring (let’s say power) to hold the body. YES, the spring can simply fly out of its place.

Install other springs. Hypothetically, this is possible, but they are selected together with shock absorbers (more on this below). But if you make it more powerful, the car will become stiffer, but we need comfort. And if you install it softer than what you had, then the body simply won’t hold up, there will always be breakdowns.

Loose wheel bolts

The situation when the fastening bolts of one or several wheels have become loose is typical not only for Lada Vesta, but occurs frequently. There can be many reasons - from inattention during tire fitting to an unsuccessful attempt to steal a wheel.

If a knocking sound occurs while driving, the first step is to perform the most accessible action - stop the car and check the tightness of the wheel bolts, since a tire that falls off while turning can cause the car to roll over with unpredictable consequences. In this case, diagnostics is inseparable from troubleshooting.

After tightening the bolts or making sure that the reason for the knocking is not their tightening, you can continue driving. If the problem is not solved, you should not put off diagnosis for a long time. In order not to aggravate the situation when one malfunction causes another, it is strongly recommended to contact an authorized dealer as soon as possible for qualified diagnosis and elimination of the causes of knocking or other abnormal suspension noises performed on a car raised by a lift.

Rear suspension device

The rear suspension of the Lada Vesta is the same as on Renault Megane cars. This diagram is provided by the Renault-Nissan concern. At the rear, the Lada has barrel-shaped coil springs on a transverse beam with spaced shock absorbers and brake drums.

Rear suspension

A photo of the Vesta pendant gives an idea of the changes:

- The designers were the first to use a new arrangement of springs and struts with spaced mounting;

- The tuning was carried out using original technology at Renault's European factories;

- The rear track has been increased to 1510 mm, as a result of which the rear wheel arches have also been enlarged.

We can conclude that Vesta received a new suspension device capable of ensuring passenger comfort and, most importantly, a smooth ride. The suspension device is shown in the photo and consists of:

- Rear suspension beam;

- Barrel springs;

- Double-acting gas-filled shock absorbers

In addition to the described features, the suspension on the Lada Vesta has a number of other equally important innovations.

Changes in a number of systems and innovations in stabilization

Not only are the previously listed innovations more than enough to designate Vesta as a significantly modified car, but other improvements and modifications can also be noted. For example, these are ESP, EBD, ABS. The power steering, for example, is used the same as in Nissan designs, the braking system contains parts from Renault (Logan and Megan). All together, this specificity provides Vesta with well-deserved status and reliability.

The car also contains a stabilization and traction control system. The new product is designed to help the car suggest how to behave without much difficulty during drifts and skids while driving.

A vehicle's cross-country ability can be considered good when a well-configured electronic unit is able to simulate differential locking. "Vesta" contains just such a feature, and it is configured simply superbly. Snow, rain and poor road terrain are no longer dangerous for the car - as are driving off the edge of the road. When the system is turned on, the car switches to a special mode that allows the car to operate with increased cross-country ability for driving in difficult conditions.

It should be clarified that this new product is being used for the first time, however, according to the existing feedback from car enthusiasts, it has proven itself very well.

Front suspension struts ASOMI Comfort PRO (without lowering) for LADA VESTA and LADA VESTA SW

Description of Asomi series

Hydraulic struts and shock absorbers are an excellent option for replacing the stock shock absorbers installed by the manufacturer. The choice of car owners who prefer a quiet and comfortable ride.

Gas-filled shock absorbers and struts are ideal for those who prefer a more active driving style. Original settings of shock absorbers and struts ensure their reliable operation, significantly improve vehicle handling and guarantee comfortable vehicle movement both at low speeds on roads with significant unevenness and at high speeds on roads with good surfaces.

Gas-filled struts and shock absorbers with stiffer damping parameters. They are ideal for lovers of an aggressive driving style. Automotive suspension components of the SPORT series reduce vehicle roll when making sharp turns, ensure its stability and controllability at high speeds, and guarantee safety when driving quickly.

Gas-filled struts and shock absorbers that provide lift (lift) of the front and rear suspension of the car up to 15 mm. This is the choice of those drivers who would like to improve the vehicle’s off-road capability and driving on non-paved roads, as well as increase the vehicle’s carrying capacity.

ASOMI struts for LADA Vesta cars improve the driving performance of the car, significantly increase its handling and guarantee comfort.

ASOMI struts on the Lada Vesta have a reliable two-pipe gas-filled design and original settings. The use of “gas boost” in the reservoir significantly improves the performance of shock absorbers in “transition” modes during rapid changes in the quality and type of road surface, and as a result, ensures effective traction of tires to the road, reducing roll and swaying of the car at high speeds and when making sharp turns. In addition, low pressure gas guarantees comfort and prevents knocking in the initial stages of vehicle movement in the cold season and guarantees comfort when driving over uneven surfaces.

When designing struts and shock absorbers for the Lada Vesta, design solutions were used that took into account the characteristics of vehicle operation on Russian, far from ideal roads, climatic conditions (low temperatures in winter and high temperatures in summer) and consumer preferences. Thus, ASOMI struts and shock absorbers for LADA Vesta have a larger diameter of working cylinders and rods compared to the original struts and shock absorbers. As a result of the increased size of the cylinders and specially selected resistance forces, ASOMI struts and shock absorbers have increased energy intensity, which improves the car's behavior on the road without reducing the smoothness of the ride.

IMPORTANT:

Racks for Lada Vesta TM ASOMI are suitable for installation with standard springs and supports, however, it is necessary to replace the standard compression buffer with a protective casing with a buffer A110.2902.816 (2110-2902816) with a casing 2170-2902814.

Advantages of ASOMI racks:

- high quality and attractive price,

— original characteristics providing increased comfort and high controllability,

— provide effective traction of tires to the road, reducing roll and swaying of the car at high speeds and when making sharp turns,

— prevent knocking and guarantee comfort in the cold season, when driving over uneven surfaces, potholes and holes,

— have a larger diameter of the working cylinders and rod (compared to the original struts), which guarantees an increased service life,

— stability of operation both at low temperatures in winter and at high temperatures in summer,

— 100% check of racks at the stand,

- original protection.

APPLICABILITY:

LADA Vesta

Guarantee period:

12 months (unlimited mileage)

Buy or make it yourself?

This question worries many who have decided to install spacers under the supports of the rear shock absorbers of the Lada Vesta. Some people buy parts to save time, while others make them themselves if they can't find the material they need on the market or just want to work on the machine. You can choose any path.

Purchase

Those who want to buy spacers for the rear shock absorber supports of Lada Vesta can do this not only in a store or market, but also order it online. The most popular products are presented in the table.

Online store

Price, rub.)

An example of purchased metal spacers.

Self-production

If you decide to make spacers yourself, you first need to decide on the material. Of course, it’s unlikely that anyone will cut them out of steel, so most likely it will be paranit, fluoroplastic or polyurethane.

Self-made components.

First, you need to make patterns on paper so that you can then cut out the elements using them. Thanks to one of the owners of Lada Vesta, known on Drive under the nickname “LLlau6a”, and his car “Lada Vesta Crimean”, it is by no means necessary to crawl under the car and take measurements yourself - he has already done everything.

Parameters of shock absorbers for which the gasket is cut:

- Length – 13.1 cm;

- Width – 6.3 cm;

- The diameter of the central hole is 5.0 cm;

- The distance between the holes for the bolts (their center) is 10 cm.

- Length – 13.4 cm;

- Width – 6.8 cm;

- The diameter of the central hole is 5.3 cm;

- The distance between the holes for the bolts (their center) is 10 cm.

Naturally, there may be a slight error, because everything was done independently, but this is not critical. When the patterns are ready, all that remains is to cut out the elements.

Tuning modification Lada Vesta Cross SW

Vesta Cross is the most interesting option from the entire line. Tuning will improve ride quality, comfort, appearance and generally remake the car to suit you, making it truly unique

But it is important to remember that during modifications the machine may suffer a little, the warranty will be voided and reliability will be lost. For example, when chipping an engine, up to 10% of its service life can be lost

And the work itself can cost up to 150 thousand rubles.

In the “cross” version it is possible to increase the ground clearance. If 203 mm of ground clearance is not enough for you, then you need to make some minor modifications. You can install special spacers – metal plates – under the racks. This will give you a few extra centimeters. It should be noted that different spacers are used for the front and rear struts. You can also reduce the ground clearance using a shortened suspension, in which shock absorbers and springs have been developed. But you won’t be able to cut the springs yourself, since a different suspension design is used.

One of the most popular types of tuning is the development of the “brains” and the engine. Often, reflashing is resorted to due to many shortcomings in the program, however, in more recent models, many of them have been eliminated by the manufacturer. But even after reprogramming such cars, they drive completely differently. Replacing the manifold also helps improve performance. Instead of the standard one, a “spider” is installed, but the Euro compliance indicators drop from the fifth level to the second. In addition, ringing often occurs due to the thin metal of the part, so it is wrapped with thermal tape, but this does not completely solve the problem. As a result, the car starts easier, performs better and becomes more dynamic.

Price difference

Station wagon cost:

- Lada Vesta SW from 639,900 to 804,900 rubles.

- Lada Vesta SW Cross from 755,900 to 847,900 rubles.

Having an amount of about 760 thousand rubles, the buyer begins to think about which of the two station wagons is better to buy:

- Lada Vesta SW 1.8L with manual transmission in the Luxe Multimedia package for 761,900 rubles.

- Lada Vesta SW Cross 1.6l with manual transmission in Luxe configuration for 755,900 rubles.

A regular station wagon will have:

- More powerful engine.

- Multimedia system with navigation 7".

- Rear view camera.

A regular station wagon will not have:

- Original body kit.

- Body color "Mars".

- Orange interior trim.

- Exhaust pipe nozzle.

- Increased ground clearance.

- A different suspension (different from the sedan).

- Alloy wheels R17 (will be R16).

Lada Vesta

A steel protective screen 0.8 mm thick with zinc coating is installed at the bottom. As in the case of Granta, it has technological holes for draining oil and monitoring the tightness of the box. It is attached at 12 points along the perimeter.

The Vesta suspension is technically more advanced with modern solutions at a fundamentally different level compared to the Granta. A huge advantage of the Vesta suspension is the subframe.

It is composite, the spars come separately. A subframe is a cool thing because it gives the car a number of beneficial advantages. For example, it contributes to the structural rigidity of the entire vehicle, allows it to more evenly distribute the load from the suspension onto the supporting body and prevent local overloads of the power elements. This also simplifies the process of installing the front suspension and steering. The subframe also guarantees the accuracy of the location of the suspension elements.

Advantages of a subframe

Firstly, due to the subframe, or rather the steering rack mounted on it, in the Lada Vesta we get informative and clear “steering”.

Secondly, at Vesta’s wheel alignment post, only one parameter will be adjusted – wheel alignment. The camber is determined by the geometry of the subframe and levers.

Thirdly, when driving on an uneven road in Vesta, shocks will not be transmitted to the steering wheel. The Granta will have this because the steering rack is mounted on the front panel. Accordingly, the impacts go to the body, through direct communication they are transmitted to the rack and directly to the steering wheel. In general, I think that the subframe has a lot of advantages.

Front suspension

L-shaped levers are used, the design of which replaces the longitudinal brace and wishbone of the Granta.

The lever comes complete with a ball, but if desired, it can be replaced separately. This is somewhat more difficult, since it is secured with rivets. But it will be much cheaper. The ball joint costs about 1,000 rubles, and the lever assembly costs more than 3,000.

In front of the lever there is a rigid silent block, which provides the lateral rigidity necessary for precise response to steering inputs. At the rear there is a rubber-metal joint, which allows the wheel to move slightly backward, which has a beneficial effect on the smoothness of the ride.

For Lada Vesta cars of the first years of production, there were several characteristic defects regarding the suspension. The first and most basic thing that 99% of owners of these cars have encountered is the creaking of stabilizer bushings. The point was that with large suspension strokes, the stabilizer bar began to rotate in the bushings, and a creaking sound appeared. There were many complaints; AvtoVAZ sent dealers several methods for correcting the suspension.

At first it was recommended to put a special grease into the stabilizer bushings. Then polyurethane bushings appeared, they were also installed on foreign cars. But even if all this had a positive effect, it was for a short time. As a result, this problem was completely overcome by installing a new stabilizer with vulcanized bushings that were non-removable.

After this the problem completely disappeared. The second problem associated with the suspension of these cars in the early years of production is the stabilizer struts, or rather their hinges. They began to play already at short runs. The play produced creaking and knocking noises when driving over uneven surfaces. This problem was solved quickly, and in recent years the stabilizer links have been running for a long time without causing any problems.

There were also some problems with the front struts for some time. When driving on uneven roads, they made a characteristic knock and were loud. This problem was especially pronounced on Vesta SV Cross cars. Some installed racks from another manufacturer, or simply put up with the malfunction.

But AvtoVAZ has carried out corrective measures, and on cars of recent years of production there are no problems with struts. They serve more than 100 thousand km.

Rear suspension

The Lada Vesta, like the Grant, has a semi-independent rear suspension. The arms are also connected by a cross beam, but there are some design differences. For example, the springs are installed separately from the shock absorbers. This provides more comfort, as shocks from the road are evenly distributed throughout the body. In addition, this design is easier to maintain.

Double-acting shock absorbers provide good ride comfort. Structurally, the rear suspension of Vesta is also simple, there are no problem areas. All units last for more than 100 thousand km.

Front

Let's look at the front of the car. We removed the protection, it is fake. Although it is made of metal, it is no better than a plastic mud one. The subframe catches your eye. The steering rack and one of the engine mounts are attached to it. Now the car's rigidity should be fine, and the steering will be more interesting. One of the reasons why they installed a subframe was not just to add rigidity.

The subframe allows you to more accurately assemble suspension elements and align the steering rack. If on previous VAZ models there were installation tolerances of 2-3 mm, now it is no more than 1 mm, that is, everything in the suspension is set much better.

The suspension is now mounted on a subframe, and its design has changed. If the Grant or Kalina had a reaction rod and a lever, now it has been replaced by an L-shaped lever. The steering rack is now connected not to the shock absorber strut, but directly to the steering knuckle.

Comparison of the suspension of the Lada Vesta sedan and station wagon

It so happened that for many years the weak link of VAZ cars was the chassis. In his new product, the manufacturer offered a revised and improved version of its predecessors. The bulk of the changes were made to the front suspension. Many new parts have appeared, such as a subframe to increase body strength, L-shaped levers made of high-quality steel.

The rear suspension designs are almost identical. Vesta SW has modified springs and shock absorbers, which increases strength properties and allows them to withstand increased loads. The rear springs in the CW model are 9 mm larger.

Owner reviews

Vesta's handling is truly excellent. This is not just a step forward, but a real challenge to Europeans.

The combination of components with the level of noise insulation returns the user to harsh reality. Drivers complain about knocking noises in the suspension. Stabilizer struts and ball joints wear out quickly. Dirt accumulates where the lever attaches to the subframe. It will not only cause the formation of rust, but also complicate the dismantling of the unit.

And now about the pleasant things. Despite the listed shortcomings, the suspension of the Lada Vesta is assessed positively and at the moment there are no particular complaints about the operation. It’s too early to judge maintainability.

Vesta SW, who lived in the Za Rulem editorial office for several months, was replaced by the same “car”, but with the Cross prefix. The mileage has already exceeded 15 thousand kilometers, and this is quite enough to reveal all the pros and cons of the Cross compared to a regular station wagon.

LADA > Vesta SW

Advantages and disadvantages

The release of Vesta SW was a serious breakthrough in the domestic automobile industry. The cars in the series are distinguished by good handling and safety, which were achieved by the manufacturer through a large number of innovations.

There were some shortcomings too. Car enthusiasts who have already tested the car note the weakness of the stabilizer struts, leading to tapping and squeaking of the rubber bands, which is especially noticeable when driving on difficult terrain. During long-term vehicle service, excessive corrosion of the subframe in the place where the silent blocks are attached is likely due to the exaggerated size of the pockets.

These disadvantages are not significant and are unlikely to reduce the success of the Lada Vesta.

Self-diagnosis of problems

If you don't like the way your vehicle drives over obstacles after a while, or turns into turns less smoothly. First, carry out diagnostics to eliminate other “suspects” and come to the technical center with a clear task for specialists:

- Release the brake pedal. Take the wheel with both hands by the opposite parts and rock it. If a pronounced play is noticeable, this may mean that the problem is in the hub bearing - it must guide the wheel correctly, strictly in one plane; if it is neglected, it can “go figure eight”.

- If the wheel play does not occur due to the hub, then the fault is in the chassis. In this case, play appears even when the brake pedal is pressed.

- If the car “wobbles” in a vertical plane, the stabilizer link is poorly secured or the ball joint is worn out.

- If the car wobbles “horizontally” (push it into the front fender, after tightening the handbrake), it may be that the rod ends have worn out and become unusable.

Knocks, crunching in the rear suspension

In the rear suspension, knocking is eliminated according to AvtoVAZ's instructions. It is necessary to remove the rear shock absorber strut and place a washer under the upper support (No. 5).

It is worth noting that after such modification, a gap appears between the support and the body, into which dirt can get in. To eliminate this, it is recommended to install a gasket according to the following dimensions:

Other sources of extraneous noise from the rear:

- handbrake cable (fasten to ties);

- trunk lid dampers (lubricate with silicone grease, loosen);

- trunk lock (lubricate the lock, eliminate play);

- in the area of the rear support, pull the bump stop down along the strut rod (pull it out of the support sleeve), spray silicone spray into the support sleeve and put the bump stop in place.

- rear seat back locks (lubricate, apply electrical tape).

- things or tools in the trunk.

How to diagnose the Vesta suspension yourself. If the rear knock only appears when braking, then this is a different case.

Let us remind you that another drawback of this sedan is associated with the creaking of the glass seals. Other instructions for tuning and modifying the new Lada can be found in this category.

Advantages and disadvantages from users

Most Vesta owners highlight the following advantages of the updated suspension.

Lada Vesta Cross (lada vesta cross)

- The rear suspension has separate springs and shock absorbers.

- A subframe appeared ahead.

- The quality of steering has improved.

You may be interested in: Lada Vesta instrument panel - review of the new panel The separate location of the shock absorber and spring simplifies replacement in case of breakdown (no need to separate the shock absorber)

The presence of such an important part as a subframe is a huge plus for Lada Vesta drivers. This has a positive effect on the stability of the vehicle's suspension.

The steering was improved by modernizing the connections. The steering rack is attached directly to the steering knuckle.

It is worth noting the disadvantages presented by the Vesta suspension.

- ABS sensors are not covered.

- Already after the five-thousandth mileage, Vesta can hear knocking and creaking while driving over bumps and potholes.

Suspension device

| Aspect | Problem |

| The rear part has the same problem that the Renault Logan developers made./td> | <ABS (anti-lock braking system) sensors located near the wheel are not covered by anything from dirt, wind, or snow. This is a potential threat of premature failure of the ABS. |

| The chassis is significantly different from its counterparts on previous models. | At the time of the release of the first Vesta cars, the developers stated that the update would only lead to the better. But some Lada owners complain that, despite the tuning of the Lada Vesta, after some period of driving this car, the suspension makes various sounds when driving over bumps and potholes on the road surface. |

| As for mileage, many argue that knocking and squeaking appears after five thousand kilometers traveled. | A muffled sound is produced, as if the posts are touching a plastic covering. The squeaking sounds like a tire is rubbing. The services claim that the reason is that the rubber stabilizer bushings are of poor quality or the muffler mounts are not sufficiently lubricated. They are lubricated with grease. They deal with the creaking by replacing the bushings with the same ones, but made of polyurethane. |

They should be replaced with new ones. But in most cases, with low mileage, the cause of the problem is not the struts. Their replacement may be required after prolonged use. In the rear suspension, knocking is eliminated as follows: it is necessary to disassemble the structure of the rear strut and use a washer as a lining for the upper support. But after this, a space may form between the support and the frame, and dirt may enter there, so it is recommended to install a gasket.

You may be interested in: Real fuel consumption of Lada Vesta

conclusions

If the service life of some units has come to an end, then they need to be replaced urgently, since one breakdown can lead to others, and the entire mechanism will go into disarray.

If we return a little to squeaks, then with significant fatigue of the ball joints, steering tip and rack, failure of the shock absorber, or its broken supports, unnatural irritating sounds may appear. Then it is best to go for a diagnosis and then treat the problem.

In previous AvtoVAZ developments, the chassis is the most vulnerable point of the car. In the new Lada Vesta, the developers undertake to eliminate this problem. As the test results showed, indeed, the chassis of the Lada Vesta has undergone significant changes and improvements.

The new car has two completely new components added:

- Stretcher;

- L-shaped arms.

A subframe is a power unit that serves as protection and increases the strength level of the body. Installing such a component helps:

- Significantly improved safety levels;

- Increased driving comfort;

- Increased body rigidity.

Some main parts of the Lada Vesta chassis are mounted on the subframe: the steering rack, the main suspension components and the engine. The location of these units differs significantly from previous models.

The L-shaped levers on the Lada Vesta are analogues of the saber-shaped levers that are present on the Priora and Kalina models. Such levers have a triangular shape, which has the highest degree of rigidity among other geometric shapes. The components of the levers are made of high quality steel, and the steering knuckles are made of cast iron. The development has significant similarities with Renault, despite this, employees of the domestic plant claim that they are the authors of the L-shaped levers on the Lada Vesta.

Restaling rear suspension of Lada Vesta

The rear suspension of the Lada Vesta was borrowed from Renault Nissan in order to reduce the overall financial costs of production. The rear suspension on the car is a transverse beam with spaced springs and drum brakes. The experts chose the drum type due to the low cost and long service life of the components. In civilian modes of movement, drum brakes are not inferior in technical properties to disc brakes. In addition, in Lada Vesta the drum brakes are additionally protected from possible ingress of dirt and dust. The original rear suspension can last for about 120-150 thousand kilometers without any deformation.

The main differences in the structure of the front suspension of the Lada Vesta in comparison with previous VAZ models

The front suspension is installed on the Lada Vesta subframe. This placement increases rigidity, improves handling and minimizes noise and vibration. To improve handling, the steering rack was installed at the bottom. This action made it possible to influence the rotation of the wheels by the hubs. AvtoVAZ developers chose the path of unification: the electric version of the power steering was placed on the steering column, that is, it is not built into the steering mechanism, like in previous Lada models. The anti-roll bar has also undergone re-staling. At the moment it has a completely different look and additionally long racks have been added to it.

Wheelbase of Lada Vesta for any type of road surface

The wheelbase of the Lada Vesta sedan is 2570 mm. The track of the front and rear wheels is slightly different: front – 1495 mm, rear – 1502 mm. As for the ground clearance of the Lada Vesta, it varies significantly depending on the body type:

- Sedan – 178 mm;

- Hatchback – 180 mm;

- Station wagon – 190 mm.

Subject to the permissible load, the sedan's ground clearance will be 170 mm. The wheels of the Lada Vesta are practically no different from the previous development - Priora. Such technical characteristics allow you to move unhindered on country roads, which is especially important for residents of rural settlements.

Controllability

What should have a positive effect on control accuracy? Those who have driven VAZs know about the problem of the car pulling to the side due to different lengths of the CV joints. The story is the same here. But we found some kind of rubber damper on the long CV joint. What else does this pendant have in common with Loganovskaya? The suspension of the Lada Vesta assumes a different arrangement of ABS sensors, open to all winds, dirt, etc.

The problems will potentially be the same. Otherwise there is nothing new. The attachments have been slightly changed. There are two holes in the protection. They are needed to drain the oil from the engine and gearbox without removing the protection. The bumper mount is of high quality. It is attached to the spar. There is not as much space under the hood as we would like for tuning enthusiasts.