Unlike its predecessors, the Vesta platform is completely original, and not an improved modification of the VAZ G8. The manufacturer announced this at the model development stages.

At the moment, when the first “Vesta” has already rolled off the assembly line and has been taken for all sorts of test drives by automotive experts, we can take a closer look at the features of its chassis.

The last adjustments and tests that the Lada Vesta suspension underwent took place this winter at the Spanish IDIADA test site, after which the car acquired the optimal combination of comfort, handling and safety. As a result, we have the opportunity to evaluate the results of the work of automotive professionals.

Front suspension of Lada Vesta

The desire for perfection and competitiveness served as a pretext for significant improvements to the suspension of the Lada Vesta, especially in the front part of the car; tuning can often be found in this part. As a result, a subframe appeared in front, which was an innovation for models from a domestic manufacturer. The developers also used L-shaped levers. The subframe in the chassis appears as a strength element, which gives the body rigidity and serves as protection for the engine, the design of which has improved the car many times over.

This approach made it possible to increase the safety level of the Lada Vesta and provide the car with good handling. Structurally, the front suspension is quite simple and provides convenience during repair and maintenance work. The steering rack has moved from its usual location to the lower area of the engine compartment. This transformation made it possible to ensure a kinematic connection between the steering rod and the steering knuckle.

Previous AvtoVAZ models could not boast of this design solution. The modernization also affected the front levers, which are the plant’s own design.

The steering mechanism of the Lada Vesta uses an electric amplifier. Here, the design solution for its installation also has no similarities with previous AvtoVAZ models, because the device ended up on the steering column.

The transverse stabilizer has been slightly redesigned. As a result of some design modifications to the torsion bar, handling has become noticeably better. In older models, you can fix the problems yourself by tuning.

Summing up: was the change in chassis beneficial?

After the developers finally made a good tuning of the old suspension options, the steering reached a completely new level. Drivers unanimously claim that the centered position of the steering wheel is felt throughout the entire trip, and the car does not shake when cornering. Vesta also has many advantages on uneven surfaces. When turning, the steering wheel does not vibrate and remains easily in your hands. But when driving on our roads, Vesta eventually begins to knock or even creak, which is definitely a minus of the new suspension.

Using the example of modernizing the platform for Vesta, AvtoVAZ managed to make a breakthrough in the development of domestic cars. The new suspension of the Lada Vesta has made it possible to create a higher level of steering for this model; driving will become safe and dynamic. Although there are some minor flaws. But, in any case, it is encouraging that VAZ is moving away from old traditions and striving for development. In the future, we expect more and more advanced Russian-made cars from Tolyatti representatives. And judging by the progress trends, evidence of which is the updated Vesta suspension, AvtoVAZ has potential for growth.

The described suspension problems will be useful for those who love tuning. It is clear which parts of the Lada Vesta need tuning.

Replacement of the rear beam on any LADA (VAZ) Vesta car will be performed:

- using quality spare parts;

- as soon as possible;

- at the best price;

- with preservation of the factory warranty.

Our Lada car services (VAZ) in Moscow have everything necessary to provide high quality services. Choose experienced professionals if you need to replace your rear beam.

Rear suspension of the domestic model Vesta

When developing their own models, any manufacturer strives for maximum unification of components. AvtoVAZ also follows this trend, which is noticeable in the design aspects of the Lada Vesta. The basis of the stern suspension was borrowed from Renault-Nissan. This is a transverse beam, a device with spaced springs.

The manufacturer decided to leave the stern brakes as drum brakes. This is caused by the market price of the model, which does not allow budget versions to acquire disc brakes. With non-aggressive driving, the “drums” cope with their “task” with sufficient efficiency. If we touch on the station wagon body modification, here the manufacturer replaces the springs with stiffer options and adjusts the entire suspension differently, which slightly changes the handling compared to the sedan.

Suspension life and reliability

It is too early to talk about the reliability of the new suspension. How to analyze the situation with sedans. The manufacturer promises trouble-free operation for five years, which equates to 100,000 km. The most adequate results are shown by tests carried out on the initiative of leading car clubs. The bottom line is the intensive (sometimes even merciless) use of the car at testing sites.

The picture turned out to be not so optimistic. Already at 25,000 km the shock absorbers began to leak. It is noteworthy that Reno’s sores were passed on to Vesta, as if by inheritance. The silent blocks of the rear beam can be considered a consumable material that will have to be replaced after a quarter of the declared resource. We can only hope that over time it will be possible to purchase components from HUTCHINSON or Lemförder.

About Vesta suspension malfunctions

Despite the significant modernization of the chassis in the Lada Vesta, such an element as the front suspension or rear suspension can upset owners with various breakdowns. The appearance of a malfunction traditionally begins to be accompanied by knocking and squeaking noises when the car overcomes uneven road surfaces. Here, the owner requires maximum attention necessary to promptly identify a breakdown and then eliminate it.

Next, we will consider the most common faults that have become typical for the front and rear suspensions of the LADA Vesta.

Shock absorber struts quite often “respond” with knocks. You can check the shock absorbers yourself. This should be done with the car just stopped, when the fluid inside the strut housings is at operating temperature. To do this, you will need to rock one of the sides of the car and observe the behavior of the body. The operation is performed first on the front and then on the rear axle. If the body oscillates in the vertical plane no more than two times, then the strut is in good condition. When this is not observed, it is recommended to replace the shock absorber.

Advice! When diagnosing the suspension, you should adhere to generally known safety rules.

For a more detailed check of the chassis, you will need to hang the wheel from one side of the car. The following shortcomings may be identified here.

- If the brake pedal is not pressed and there is noticeable play when manually pressing the wheel, this indicates a faulty wheel bearing.

- When play is heard when acting on the levers or steering tips, then most likely the ball joints of these suspension elements have become unusable, which also requires their replacement.

- We subject the shock-absorbing struts to a detailed inspection of the working surface to ensure there are no fluid leaks. When it appears, it is recommended to replace the racks (two).

- We also inspect the fastening elements of the stabilizer (struts and bushings) for tears in the rubber components and anthers.

- Noises and squeaks from the front can be caused by a lack of sufficient lubrication in the support bearings of the struts.

- In the stern suspension, noise effects can sometimes be eliminated by installing washers under the racks. After such manipulation, a gap appears between the pillar and the body support, which must be isolated in order to prevent moisture and dirt from penetrating there.

- In some cases, the muffler may make knocking noises. Here the “culprits” are the fastening components, which also need to be lubricated or replaced.

- The LADA Vesta wheel bearing may also begin to make noise and show play. This is caused by the absence or insufficient amount of lubricant. Since the bearing cage is structurally closed, it will not be possible to replenish the lubricant. Although the manufacturer guarantees the effectiveness of the lubricant for the entire scheduled service life of the product, in reality the situation may be completely different. If the presence of these defects is detected, the bearing must be replaced. You can do it yourself if the owner has a special tool (press, pullers, etc.) and has experience.

Important! If the car is supported by a jack, then during repair procedures it is necessary to place suitable supports under the body for safety reasons.

- The lower shock absorber bushings in the rear suspension (pictured) are also capable of making knocking noises when they become critically worn.

- Driving along country roads is fraught with the risk of debris (stones) getting inside the brake drum, which provokes an unpleasant sound effect. Over time, these “artifacts” fall out on their own, but there are often cases when dismantling the drum is required to remove them.

Important! If the front suspension's levers and steering ends (also rods) were replaced, then after the repair work it is necessary to immediately adjust the wheel angles. If this procedure is neglected, the front tire treads will be subject to uneven wear and handling will deteriorate significantly.

Attention! An element such as a handbrake cable can cause knocking noises in the LADA Vesta suspension. Here you will need to inspect its placement under the bottom and, if sagging areas are observed, take measures to tie them up.

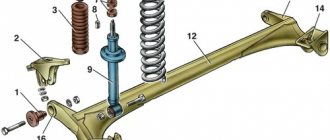

Front Features

The front part of the Lada suspension has taken on the maximum of innovations. Let's look at these features in more detail.

The drawing below shows the front suspension of the Lada Vesta. As you can see, its supporting base is a subframe. By changing the design, it unloads the metal of the body, and at the same time participates in the distribution of force after passing through irregularities. The steering rack, anti-roll bar attachment points, and lower arms were moved to the subframe.

Diagram and design of the front suspension:

- Additional subframe spar;

- Front suspension subframe;

- Lower front suspension arm;

- Steering knuckle with hub assembly;

- Telescopic front suspension strut assembly;

- Anti-roll bar with struts assembly

Vesta front suspension features:

- The concept of architecture has changed; the structure is assembled on a subframe. Thanks to this, rigidity indicators were increased, geometry accuracy increased, and vibration-acoustic properties were improved.

- The steering rack is now located at the bottom, thanks to which the wheel rods are directly connected to the hubs. This made it possible to improve the handling of the Lada and achieve real competitiveness in relation to foreign models;

- The castor angle is 5 degrees, the suspension is independent. MacPherson struts are used. There is a new stabilizer. The system is more sensitive than on previous models and provides smoother control.

The anti-roll bar has also been upgraded. The torsion bar has acquired a more advanced shape and is now equipped with long struts. This significantly improved the handling of the Lada.

Photo of the front:

The front suspension is maximally adapted to Russian roads and allows the Lada Vesta to confidently perform in any situation.

According to the owners' reviews, the car's chassis is made to last, Vesta walks on the road very smoothly and even outperforms foreign competitors such as Hyundai Solaris and KIA Rio.

Fundamental differences and characteristics of the new suspension

The Vesta suspension borrowed its backbone from Renault. The prototype was the Zoo model, which, by the way, is an electric car. The chassis was modified and adapted for the VAZ.

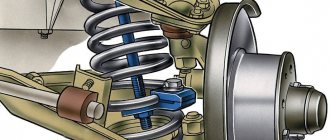

Vesta's rear suspension has a power beam mounted on special dampers, whose deformation limit is calculated. In the event of a jump on a pit, they level out the impact energy so that there is no excessive pressure on the supporting elements of the car. The bottom of the car is treated with a special coating. All technical holes and connections are treated with a special anti-rust mastic.

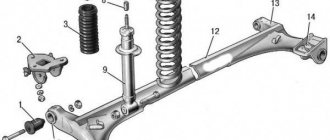

The rear suspension includes a semi-independent (with levers that are connected to each other) modern beam. The springs are barrel-shaped screw springs, the double-acting shock absorbers operate hydraulically. At the connections between the nodes there are massive silent blocks (rubber-metal hinges that dampen vibrations between the nodes and prevent knocking).

The cross beam has also changed its shape. On previous VAZ models it was made in the form of a C-shape, now the beam has a U-shape and is turned down. Inside the beam there is a connecting lever, which acts as a stabilizer bar. This detail was lengthened by 5 centimeters especially for Vesta, which also emphasizes its uniqueness. Now these beams are manufactured at AvtoVAZ. The shock absorbers were manufactured specifically at the Skochinsky Automotive Aggregate Plant (SAAZ).

The front suspension, unlike the rear, where the French chassis was tuned, was developed exclusively in Tolyatti and is completely original. It is independent and is mounted on a subframe (metal support), which adds stability. There is a brace on the subframe (two support points for the engine). Two more points on which the motor rests are located on the base of the machine frame - the spar.

Unlike the rear of the car, the front uses MacPherson struts. These are struts in which the shock absorber is located inside the spring. The design of the front suspension has changed compared to the old one. It does not have a single rod with a lever. Now these 2 parts are replaced by one L-shaped lever. The steering rack is no longer connected to the shock absorber strut, but is attached directly to the steering knuckle, which has a positive effect on steering accuracy.

Previously, many VAZ cars had the problem of the car pulling to the side due to different lengths of CV joints (constant velocity joints). With an optimal length, they should ensure uniform transmission of torque at large angles of rotation relative to the axis.

Rear suspension

In order to give an objective assessment of the chassis of the Lada Vesta, we study the suspension of the rear of the car. Everything is simpler here, everything is done according to the classical scheme. But there are a few innovations that have been built into the rear. What you see is a new arrangement: barrel-shaped coil springs are mounted on a transverse beam with spaced shock absorbers and brake drums.

Rear suspension diagram:

- Rear suspension arms;

- Lower spring gasket;

- Rear suspension spring;

- Upper spring gasket;

- Upper support assembly;

- Compression stroke buffer with protective casing assembly;

- Rear suspension shock absorber;

- Rear wheel hub axle;

- Brake drum with rear wheel hub bearing assembly

Let's look at the changes in more detail:

- Springs and struts are now arranged in a new, spaced-out way, and this is a serious step forward for Lada and for the entire Russian automobile industry;

- The suspension was tuned at the Renault plant using European technologies;

- It is worth noting that the rear track on Vesta was expanded to 1510 millimeters, due to which the rear wheel arches were enlarged.

We can conclude that Vesta’s body is equipped with a modern rear suspension, which means that now passenger comfort and a smooth ride will become integral qualities of the new Russian car.

According to real reviews from Lada Vesta owners, some experience creaking and extraneous noise in the rear suspension. The squeak may be due to a lack of lubrication of the bushings - the problem is easily solved, go to the dealer or service station, they will lubricate the bushings and the squeak will disappear. You need to look at the noise, a possible solution to the problem would be to install washers on the shock absorbers. More details below, in the section Reviews and faults

What's new: about built-in technologies and stabilization system

In addition to the Vesta features listed above, it is worth considering a number of other innovations in the chassis, which are no less important. First of all, it is necessary to note the use of systems such as ABS, ESP, and EBD. In addition, the Lada Vesta has power steering from Nissan, and its braking system is equipped with components from Renault Logan and Renault Megane. Acting together, these factors give the car high status and reliability.

The new Lada Vesta has a built-in stabilization and traction control system. The system allows you to easily overcome various skids and drifts of the car while driving.

When the electronics in a car are correctly and professionally configured and are capable of simulating a differential lock, then the vehicle’s cross-country ability significantly improves. The Lada Vesta has just such a system and it is configured really effectively. Now you don’t have to worry about getting into mud, snow, uneven surfaces, or driving off to the side of the road. When the stabilization system is turned on, the Lada goes into all-terrain mode and is able to get out of a difficult situation.

Differences between the Lada Vesta sedan suspension and SW and SW Cross

In fact, the suspension of the Vesta sedan and station wagon is similar; they have the same wheelbase. But given that the Lada Vesta SV has increased body dimensions, the settings for this part are slightly different.

Also, with a similar design base, the SW Cross has some differences - it has original springs and is equipped with 17″ wheels. Due to this, the ground clearance is increased to 203 mm. In addition, Vesta Cross is equipped with disc brakes and the track width has been increased by 25 mm. That's basically all the differences.

Owner reviews

This topic is pure philosophy.

For one positive review you can find a dozen negative ones and vice versa. Therefore, let's focus on constructive points. Vesta's handling is truly excellent. This is not just a step forward, but a real challenge to Europeans.

The combination of components with the level of noise insulation returns the user to harsh reality. Drivers complain about knocking noises in the suspension. Stabilizer struts and ball joints wear out quickly. Dirt accumulates where the lever attaches to the subframe. It will not only cause the formation of rust, but also complicate the dismantling of the unit.

And now about the pleasant things. Despite the listed shortcomings, the suspension of the Lada Vesta is assessed positively and at the moment there are no particular complaints about the operation. It’s too early to judge maintainability.

tweet

back Lada Vesta with independent suspension: myth or reality?

Next Lada Vesta SV suspension: what owners need to know about the shortcomings

Reviews and detected malfunctions in the suspension

Enough time has passed since the release of the production Lada Vesta for drivers to evaluate the handling and operation of the car’s mechanisms. Based on reviews from Vesta owners, we can conclude that innovations in the design have improved the quality of vehicle handling and passenger comfort.

However, there are also negative reviews, mainly related to the appearance of extraneous noise in the rear suspension during operation. To solve this problem and eliminate noise, experts suggest installing gaskets on the rear shock absorbers. Knocking and squeaking noises can be caused by a lack of lubrication in the bushings or if the rear shock absorber is missing a washer.

How to identify a problem in your car

To identify problems, you need to hang the car so that the front wheels do not touch the surface. By moving the wheel in both planes, we determine the play and the corresponding malfunction:

- If the brake pedal is released and you feel play, there is wear on the front wheel bearing.

- If play is felt when the brake pedal is pressed and released, there is a suspension malfunction,

- If you feel play in the vertical plane, then either the strut is poorly secured or the ball joint is worn out,

- If there is play in the horizontal plane, there is a problem with the front suspension module, namely the tie rod end.

And here’s an additional bonus for you - wheel alignment angles for the Lada Vesta:

Suspension test in real conditions

Innovations have significantly improved the car's handling. The main difference between the suspension is its excellent combination of comfort, maneuverability and safety. The car responds perfectly to all the driver’s movements and allows for maximum mutual understanding.

Moving along a straight road, the driver clearly feels the zero position of the steering wheel, and during turns, he can fully control the entry trajectory. At the same time, during braking, increasing speed and other maneuvers, no shocks are felt in the steering wheel, as was the case in previous VAZ models.

When the road is rough, vibrations from the body are absolutely not transmitted to the steering wheel. It fits well in your hands and does not break out of your hands even with strong shaking. This ensures safety and confidence when driving, which is proven by numerous test drives of the new car.

During the design period of the Lada Vesta, AvtoVAZ stated that the designers were planning to introduce a new suspension platform, and that the rear suspension of the Lada Vesta would be fundamentally different from the long-used prototype based on the Lada Samara. After the launch of the car for sale, a certain period of time had already passed, the chassis was tested through various test drives and mileage in operation among ordinary Russians. Now, based on the reviews of Vesta owners, we can consider in more detail the pros and cons of the new platform and form an objective impression of it.

Conclusion

After studying the numerous innovations that were used in the manufacture of the suspension, we can conclude that AvtoVAZ took the creation of the Lada Vesta very seriously. It's clear that close attention has been paid to more than just the engine and design. Creating a high-quality design and giving the car excellent driving characteristics indicates that the company cares about its reputation and thinks about its customers. The new stabilization system allows Vesta’s suspension to be considered revolutionary in the Russian automobile industry.

Analogs

The choice between the original and the analogue is as simple as it is difficult. The original part is made in a unique design, has a company logo, and is matched to the style of its brand, taking into account the car. Reinforced fastening, higher quality material, selected size. Analogues have a large variety, low price and an endless range of colors. Disadvantages include low quality, lack of a logo, weak fastenings, mismatched sizes, you need to know the radius of the wheel 100%, and it’s better to try it on before purchasing.