Owners of 8–16-valve fuel-injected cars produced in Togliatti often encounter engine malfunctions. At the same time, the Check Engine light often lights up. Among the mass of possible malfunctions, diagnostics often reveal a malfunction of the camshaft position sensor (CPS). Error code P0340 is a common problem on VAZ models. Next, we will tell you why the problem occurs, what signs indicate a DPRV failure, and how to change it.

Where is the unit located?

The sensor is located on the engine in two versions: on an 8-valve engine it is installed on the cylinder head, and on a 16-valve engine it is installed on the side of the drive camshaft in the area of the generator. It can be easily found and dismantled without visiting a car dealership, although the second option will require more effort and skills.

Phase sensor connector VAZ 2114 (8 valves)

On which engines does p0340 pop up more often?

According to the observations of service workshop specialists, failure of the air flow control valve occurs more often on 16-valve engines. But engines with 8 valves also suffer from error P0340, especially after installing gas equipment (LPG). Moreover, the malfunction is repeated regularly, so the technicians have to adjust the gas equipment to the optimal fuel supply mode again and again. As a result, such cars have chronic problems with engine starting and loss of power.

What are the errors that determine the malfunction of this mechanism?

Error code - 0340

A fairly common phenomenon occurs when the “meat grinder” on the dashboard (check engine) lights up. This process appears like this: when starting the engine, the starter works for several seconds, and then phase sensor error 0340 is displayed. The thing is that when starting the car, the electronic unit The engine control waits for a certain signal from the phase sensor. If it is absent, the control unit does not send an impulse to the ignition system and fuel supply system. Consequently, the engine does not start, and the engine control lamp comes on, indicating “error 0340” on the VAZ 2114. You can diagnose the breakdown using the car’s on-board computer, or contact a specialized service center.

Check engine error on VAZ 2114

Symptoms of this problem:

- Increased fuel consumption.

- Difficulty starting the engine.

- Perceptible noise when turning on the ignition key.

Error code - 0343

Indicates a high level of the regulator pulse; this error in the VAZ 2114 phase sensor is less common than the first, and it is directly related to a malfunction of the device itself. The problem is solved by completely replacing the unit; it does not require diagnostics or visits to specialized salons. Error 0343 may be associated with simple oxidation of the wires on the mechanism, which need to be cleaned and their integrity checked.

Attention: there should be 12V at the mechanism terminal and at pin A, and 0V at the rest.

An error in the phase sensor can be caused by a malfunction of the crankshaft position sensor, it is also possible that the timing belt has slipped onto a tooth, the key of the generator belt pulley has been turned out, the crankshaft gear has become loose, wear has occurred on the upper and lower gears. As you can see, there can be many clues; the main thing is to correctly diagnose and effectively fix the problem.

Signs of a malfunction of the phase sensor on the VAZ 2114 associated with this error may be:

- deterioration in speed gain when accelerating a car;

- problems in engine operation, when starting the unit;

- The starter spins for 4 seconds when starting and the check light comes on;

- diagnostic mode failure;

- exhaust gases become transparent, the level of carbon dioxide emissions increases.

Attention: the “Check Engine” control signal (a light on the instrument panel that indicates a malfunction in the engine control system), with a working engine, should go out 0.6 seconds after starting. This is quite enough for the diagnostic system to state that everything is in order.

If the light continues to light, then there is a malfunction, and the error on the VAZ 2114 is an exact confirmation of this. It can be identified using a professional scanner at a service station or “with your own efforts.” We are talking about a superficial diagnosis of the cause, which can give an idea of the approximate identification of a product malfunction. What to do next is up to the car owner to decide; you can replace the sensor with a new one and get rid of all “instrument errors”, and you can also do a general cleaning of the mechanism wires, completely rinse the entire sensor in a special liquid.

Attention: there is such a situation - I changed the sensor, and after a few hours the light comes on again. This problem can arise when refueling with low-quality fuel, or the mechanism is incorrectly installed and requires professional intervention from specialists! You can also get caught in a marriage, and this happens. It is necessary to do initialization after changing the sensor in order to avoid such a problem.

If the car is on the road and error 0343 or 0340 appears, then the following option can be used as a temporary solution to “treat the problem”: rotate the sensor a few degrees around its axis, and then securely fasten it again.

Reasons for failure

Quite often, the cause of error P0340 on VAZ models is the sensor itself (DPRV). Over time, its internal contacts are destroyed. But sometimes a failure occurs due to other reasons, such as:

- Wear of camshaft pulleys (appearance of backlash).

- The timing belt jumped 1-2 teeth.

- The wires on the power supply have oxidized.

- Broken wire or short circuit.

- The plug came loose randomly.

Very often error P0340 appears on VAZ Kalina models. The car simply refuses to drive without changing the throttle. Here, the fault is often the controller itself, located under the heating radiator, where it is simply filled with coolant (antifreeze, antifreeze) when depressurized. The experts already know: if the “brains” are washed and dried, the fault disappears and Kalina will drive again.

Re: 2114 high signal level of the phase sensor

A high level is, as you were correctly told, a cliff. When the sensor is disabled, the level will be “High”. The sensor is checked very easily: remove the connector from the sensor, find 1 contact of the connector (wire white/black) - this is ground (GND), on the next contact (pink/black) - +12V (sensor power supply, this is constant power from the output of the main relay ), on pin 3 (pink wire, I think) when the sensor is disconnected there should be 11.8-12.2 V, this is the signal power supply from the ECU. If all these voltages are present, then we proceed to checking the phase sensor itself: pull out the sensor, connect it to the connector, use a tester to test the negative probe on 1 contact, the positive probe on 3 contact. The voltage should be 11.8-12.2V, now bring a knife, screwdriver or flat metal plate to the end of the sensor (where type 13K is written) - the voltage should drop to 0V, removing the plate the voltage will rise to 11.8-12.2 volts. If all these conditions are met, the sensor is operational.

Sensor errors

If symptoms of a faulty phase sensor appear and the engine error icon lights up, it is advisable to diagnose the control system. If you have an on-board computer, then on it you will be able to see errors with numbers 0343 or 0340. But do not rush to change the device immediately, it is quite possible that there is damage to the wires with which it is connected to the computer. Very often the sensor simply becomes dirty, which makes it impossible to read information. But if, after checking the sensor, a malfunction is discovered, you need to purchase a new one and install it. The cost of the device is no more than 600 rubles.

Re: 2114 high signal level of the phase sensor

I couldn't find a topic for my question, so I'll ask it here. The essence of the question: VAZ 2115 error: low signal level from the phase sensor. The client has already changed 3 sensors. This car came to me with a request to turn off the 2nd DC (leave the 1st DC partially). I did my job, but the client came with a complaint “the check light is on”, I connect the scanner and take a look. I say that there is an error in the phase sensor, but he tells me that he has already changed 4 sensors, but the result is the same. The sensor that was on his car was really “dead”, the voltage at the output “C” of the connector was really 0V. He replaced the sensor with another (which he was told was faulty) - the voltage rose to the required 11.8 V, installed it on the machine, the oscilloscope showed the pulses, even, with the marks in place. Released the client. Yesterday he arrived - the check light is on again, the error is again low signal level from the phase sensor. I connect, look, it’s really 0v. I disconnect the sensor (on the connector) 11.8 V, connect it to 11.8. I start the car - it works, the pulses go. (!) BUT the pulses go until you turn off the ignition and the main relay turns off, after which 0.43 V hangs at terminal “C” for some time, and then the voltage rises to 1, 35c. After this, turning on the ignition, the sensor displays 0.38V, which does not rise when starting. If you disconnect and connect the sensor connector, the voltage is restored to 11.8 and the sensor starts working. Again until the ignition is turned off. That's the problem. Today the client will bring another phase sensor, I'll try it. But for some reason I’m sinning on the ECU (it has a Bosch M7.3). If all else fails, I'll reflash it without a phase sensor. Has anyone encountered this problem?

Replacing the DPRV

If there is no wire break, and the power supply is not in place, then most likely the problem is in the DPRV itself. It needs to be changed. To work, you will need a 10 mm socket wrench (head). The sensor is located in a visible place, on the right side of the head. Attached with only 2 bolts. But despite the close and convenient location, getting to the distant bolt is very inconvenient. There have been cases in practice when owners removed the intake manifold and the ramp with injectors. Other owners simply broke the sensor housing and then removed the bolt. In general, the process of replacing the DPRV looks like this:

- Disconnect the negative terminal from the battery.

- Disconnect the DPRV plug.

- Unscrew the 2 sensor mounting bolts.

- Install a new DPRV.

- Connect the power plug.

- Place the negative terminal on the battery.

There is no need to start the car right away. First, turn the ignition on and off 2-3 times. Let the ECU see the working sensor. Then you can start the car and check the quality of the engine. If the Check Engine icon is still on, you need to connect the controller and erase error P0340.

Meter design and location

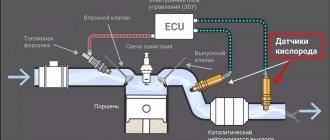

The operating principle of the DPRV is based on the Hall effect - the sensor reacts to the approach of a metal mass by changing the voltage on the signal wire. The design of the device is similar to another element - the crankshaft position detector. Inside the plastic case there is a coil where the 12 V on-board voltage is constantly supplied.

The meter is installed on the engine cylinder head in close proximity to the camshaft. The latter is equipped with a special plate or gear, whose rotation affects the DPRV. The work algorithm looks like this:

- After turning on the ignition and starting the engine, a supply voltage of 12 V is supplied to the sensor. Through the third signal wire, the element supplies the controller with a voltage of 90–95% of the original one.

- When the protrusion on the rotating part of the camshaft passes next to the DPRV housing, the voltage at the signal contact drops to 0.2–0.4 volts, depending on the design of the device and the vehicle model.

- When the voltage drops, the electronic unit clearly “sees” the valve timing, promptly supplies the fuel mixture to the engine cylinders and directs the spark discharge to the desired spark plug.

Note. On cars with 16-valve engines, 2 sensors are installed - one for each camshaft.

When the meter is faulty, the electronics are unable to control the operation of the gas distribution mechanism. In such cases, the control unit goes into error and is guided by the signals of other meters. Spark generation and fuel supply are adjusted according to the programmed program, which affects the operation of the power unit.

Recommended Tools to Troubleshoot P0340

- Reading error codes and engine parameters - LAUNCH X431.

- Car charger - this or similar.

- To measure wiring use a digital multimeter.

- Electrical contact cleaner.

- Advanced diagnostics - oscilloscope.

Previous post Error P0562 - what it means, symptoms, causes, diagnosis, solution

Next entry Error P0137 - what it means, symptoms, causes, diagnosis, solution

Characteristic symptoms of the problem

Practice shows that a malfunction of the camshaft position sensor does not lead to engine failure and immobilization of the vehicle. The engine continues to operate with some deviations that interfere with the normal operation of the car. Symptoms of DPRV failure are quite vague and similar to problems with other measuring elements:

- Unstable engine operation at idle and while driving.

- Instead of dynamic acceleration, after pressing the gas pedal, there is a series of small jerks and a sluggish increase in speed.

- The power of the power unit decreases. The effect becomes noticeable when the load increases - on a hill, sharp acceleration, while towing a trailer.

- The Check Engine light on the dashboard does not always come on. But many drivers note that if the meter is faulty, the display flashes after the crankshaft speed increases to 3000 rpm or more.

- Fuel consumption is naturally increasing.

Conditions for generating error p0340

It is immediately worth noting that these conditions may differ for different electronic control units on different machines. However, most often, to generate an error signal p0340, the following factors must be met:

- no signals are received from the camshaft sensor for more than 5 seconds of starter rotation;

- No signals are received from the camshaft sensor to the electronic control unit at engine speeds of 600 rpm or more.

For some cars, this error is formed not in one trip, but in three. However, in this case, diagnosis will be difficult.