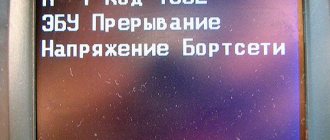

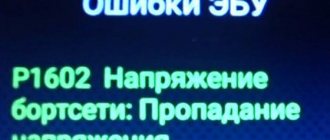

Error p1602 stands for “Control system controller, board voltage interruption.” In practice, this means that somewhere in the car’s electrical network a contact has disappeared, most likely a “minus” one. Most often, error p1602 occurs on domestic VAZ cars, starting from the tenth model (VAZ-2110) and higher - on Kalina, Priora. The difficulty of diagnosis lies in the fact that the electronic scanner is not able to show in which particular area or specific device the on-board voltage has disappeared. Therefore, localizing the location of a breakdown sometimes takes a lot of time and effort.

What does the error code mean?

Error P1602 is diagnosed on cars when one of the on-board voltages is not supplied to the engine control unit (ECU). Various options are possible: both permanent absence and short-term outages (one-time or periodic).

As a rule, the control unit receives voltage via several buses:

- 30 bus – on-board network voltage, which operates constantly, parallel to the positive terminal of the battery;

- 15 bus – on-board network voltage through the ignition switch (relay);

- 50 bus – on-board network voltage supplied when the “engine START” key is turned on.

In this case, the engine control unit can receive direct power from various contacts of the ECU connector. Thus, monitoring the voltages supplied to the engine control unit is difficult in the absence of a circuit diagram. Depending on which power supply is missing, the vehicle may behave differently with the same P1602 error.

The most characteristic symptoms:

- the ignition does not turn on;

- the ignition turns on, the starter does not start;

- the ignition turns on, the starter operates when the engine starts, the engine does not start;

- the ignition turns on, the engine starts, does not respond to the accelerator pedal or other controls;

- the ignition is turned on, the engine starts, there is color music on the dashboard (indicator lights blink, dial gauges deviate chaotically);

- The car is operating normally, the error is diagnosed.

Error P1602 does not necessarily indicate a complete lack of voltage at one of the power inputs. The battery may have been discharged to a critical level or was temporarily disconnected from the terminals. After connecting the battery, error P1602 remains in the memory of the control unit, and it is enough to delete it (erase from memory) for the engine ECU to exit the emergency mode.

Decoding P1602

- Low voltage supply to the engine control unit (AUDI, ISUZU, SAAB, VOLKSWAGEN).

- Knock Sensor Module Performance (BUICK, CADILLAC, CHEVROLET, GMC).

- Speed Control Solenoid (DODGE) Circuit.

- Problem with the wiring of the engine control unit (HYUNDAI, KIA).

- Engine control unit immobilizer error (MAZDA).

Where is the P1602 sensor located?

The image above shows the ECU connector of an Audi Q7, terminal 30 is circled.

It should be noted that this code does not refer to the voltage at terminal #30 as shown here, but to the various and multiple terminals in the connector that should have a certain voltage across them when the ignition is turned off. Therefore, the presence or absence of power at terminal No. 30 (as shown here) when the ignition is turned OFF should NOT be taken as evidence of failure or malfunction unless the manual for the vehicle in question explicitly states that the specified voltage should or should not (depending on depending on the circumstances) be present at this terminal when the ignition is turned off.

Operating principles of the on-board computer

The electronic control unit of the VAZ 2114, as on other cars, is primarily designed to monitor the condition of various components and assemblies, as well as for subsequent indication of breakdowns if they occur. The introduction of the concept of self-diagnosis is a sound decision designed to facilitate both the operation of the car for the driver and possible repairs for the car service center.

The system works simply: if a unit breaks down or there is no signal from it, the ECU displays a coded message on a small display, which can be deciphered using the appropriate car manual.

Alas, as often happens with the domestic auto industry, the electronic brains of the ECU may begin to fail for one reason or another, giving the VAZ 2114 error 1602 in situations where there is no real breakdown. At the same time, the problem cannot be ignored under any circumstances, because once out of ten the control unit can signal that there are actually problems in the system.

Instead of immediately going to a service center and paying money for diagnostics, experts recommend trying to find out the cause of error 1602 on your own - it is quite possible that even an inexperienced car owner will be able to solve the problem.

It is important to remember that first of all, you should exclude the possibility of an error in the operation of the ECU itself and sensors if any error is detected on the screen. It will be useful to buy only original electronics parts in advance when operating a car, and not install cheap analogues (the same is true for unlicensed firmware).

This is interesting: What to do if the smell of gasoline appears in the car interior

As for the general list of reasons that can alert the ECU with a problem message, the most common factors are:

- Changing the type of fuel system without flashing the controller.

- Low quality fuel, which has a complex effect on the entire energy system.

- Clogged air or fuel filter.

- Inept attempts to reconfigure the “brains” of the controller.

- System failure of the ECU or failure of one of the sensors.

Do not forget that any intervention in the factory settings of the computer or replacement of sensors (as well as cables and connectors) with unofficial ones, not produced by AvtoVAZ, is fraught with frequent errors in the operation of the ECU - as a result, this means lost nerves and money in the future.

Messages 4

- max-xx

- Moderator

- Inactive

- From: Moscow

- Posts: 2,877

- Thank you: 373

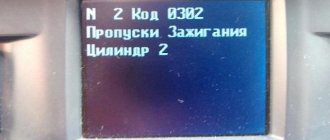

Topic: Errors P0363 and P130_(1-4) or how the ignition module dies

So a problem occurred - the car began to shake while idling in a traffic jam. Then the meat grinder flashed and the on-board alarm beeped with an error. The car began to shake more noticeably. The engine was troublesome. Then he started doubling. 3 errors popped up. P0363, P1301, P1304. P0363 – misfires detected, fuel supply to idle cylinders is turned off. P130_(1 to 4) – Cylinder (1-4), misfires detected, critical for the converter. After turning it off and on, cylinder 4 started up, only 1 remained. So I spent 1.5 hours in traffic jams. Sometimes even 4 would turn off. The restart gave it life again. If one error from 130_ popped up, then you could rack your brains and you wouldn’t immediately think about the module (spark plug, explosive wire, injector). And so if a pair of 1 and 4 or 2 and 3 is 99% dead, the ignition module is a characteristic sign, so to speak. Why is this topic raised? My mileage is 42 thousand. A friend of mine on Kalina 2 also had a 40 thousand coil. I know that many have gone through more without problems. Because there is no time to run around under warranty and ride on 3 cylinders first to work, and then under warranty, or use free evacuation - I bought a BOSCH F000ZS0211 for 1800 rubles at a good stall I know. They still had them at the old prices. Now under 3000r. they ask. You could have ours for 900 rubles. but there is no confidence that it will work adequately. Therefore, it is 2 times more expensive, BOSCH. Our module is marked 21110-3705010-03 or 2111-3705010-03.

Possible reasons

When diagnosing error P1602, the engine control unit is insufficiently powered from the on-board network. What could be the reasons:

- temporary disconnection of the battery terminals (terminals) from the on-board network for the period of repair or maintenance;

- critically low battery charge;

- voltage dips in the on-board network during engine startup with low residual battery capacity (for example, during engine startup at extremely low ambient temperatures);

- fuse blown in the power supply circuit;

- fraying of contacts or malfunction of relays servicing the engine control unit;

- contact failure of the control unit connector;

- abnormal operation of car alarms;

- error on the CAN bus (communication bus between control systems);

- problems with the generator;

- violation of the common wire (ground) of the car;

- control unit malfunction;

- previous polarity reversal when installing the battery.

Lada Vesta ECU and suitable scanners

Vesta electronic control received a CAN interface. Brains communicate with various systems through digitally encoded signals. Moreover, the Itelm M86 ECU is easily coordinated with third-party security devices (alarms), GPS trackers, and multimedia systems. The only requirement is the presence of an appropriate data bus.

For diagnostics, reading indicators and errors, ELM327 automotive scanners are used. They also use other multi-brand devices that operate using the OBD2 protocol and CAN bus:

Diagnostic capabilities of LADA VESTA systems:

| Diagnosable LADA VESTA system | Main functions | |||||

| Fault codes | Options | Actuators | Special Features | Auto detection | Identification | |

| Engine, ECU M86 | + | + | + | ECU reset, adaptation reset, settings reset, learning reset, cruise control and speed limiter reset, throttle adaptation, etc. | + | + |

| Automatic transmission ZF AMT (robot) | + | + | + | ECU reset, clutch learning (in MI control mode) | + | + |

| ABS BOSCH 9.0 | + | + | + | ECU reset, steering angle sensor learning, acceleration sensor learning | — | + |

| Takata airbags | + | + | — | — | — | + |

| Dashboard | + | — | — | ECU reset, settings reset, adaptations | — | + |

| Electrical package T4V20 | + | + | + | ECU reset, ECU internal protection reset, VIN recording | — | + |

| Electrical package T4VS | + | + | + | Record VIN | — | + |

| Power steering | + | + | — | Recording VIN, ECU reset, ECU reset with initialization, adaptations (wheel speed index, outside angle sensor, rack end stop, etc.) | — | + |

ECU location:

On this vehicle, the ECU is located in the engine compartment, on the right side (view from the front). Fixed with several screws to the shock absorber shell. The wire connection blocks are located at the bottom of the block, but the ECU itself is rotated 90 degrees. The tires are secured with latches. To remove the chip, unlatch the lock and remove the block.

By the way, removing the ECU is only necessary when flashing the controller firmware.

Chip tuning and firmware of Vesta ECU:

The original firmware is tailored to harmonize engine emissions with EURO standards. Chip units have modified software that disables some sensors (lambda) for high dynamic performance. You can find out the firmware type through OpenDiag. How to flash the ECU will be discussed below.

Error 1602 on VAZ cars: what is the reason

If you look through the VAZ manuals that came with the car, you will find information in them that this malfunction can only occur under the following conditions:

- With the ignition off;

- If the controller notices that some data has been lost.

This problem occurs on almost all relatively new VAZ models, for example:

- Priora;

- Grant;

- VAZ 2110;

- VAZ 2112;

- VAZ 2114;

- Kalina;

- Niva Chevrolet;

It’s difficult for me to immediately see all the reasons for error P1602. I will try to talk about the main ones. I will describe the problem using the example of individual units in which an error can most often occur:

- Battery. It may be discharged or you have poor terminal contact. I once had a problem due to a large number of electrical appliances (I connected an electric winch and plugged in a few more lamps). The system couldn't cope. Also, P1602 may appear if you change the battery or when starting the engine on a discharged battery.

- Generator. The reason may be its power or the fact that the contact disappears. The problem often occurs on Priors, Kalinas and VAZ 2114

- Signaling. There are modern car protection systems that turn off the battery when the alarm is turned on. It is assumed that if thieves get into the cabin, they will not start the engine. However, the system may generate this exact error.

- Minor power loss. For example, you start your car in cold weather. A large flow of energy went from the battery to the starter. The controller was left without power for a short time. As a result, the system issued P1602.

- “Mass” of the controller. The reason is quite common. Your car contact is simply oxidized, and the system thinks that it has been left without power and generates an error.

- "Mass" between the body and the engine. This happens if your engine is damaged (for example, after an accident), contacts are oxidized, or wire insulation is damaged.

- Safety block. The wires in them can also periodically oxidize. As a result, the voltage may also drop. Although the block itself is also worth checking, the reason may be in itself.

- Control electrical unit. The error may also appear due to hardware problems. Then I recommend that you contact the service; if you don’t understand it, then it’s better not to get into the firmware yourself.

This is interesting: How to choose a mass air flow sensor

P1602 loss of controller power supply voltage – All about Lada Granta

Errors in the engine control system on VAZ cars equipped with injection engines of the tenth family (and this is almost the entire model range, starting with the VAZ 2110, Kalina, Priora...) are not as rare as we would like. Among them there are error codes that require immediate elimination and identification of causes, and there are those that appear from time to time. Among them, one of the leaders was error P1602. What the error code means, what it means and how to fix it, we’ll figure it out together.

Elimination methods

Methods for eliminating error p1602 directly depend on the reason why it was formed in the memory of the electronic control unit. However, before performing the steps listed below, it makes sense to programmatically reset the error. If there are no visible breakdowns, then it is quite possible that the error “Court Controller, loss of supply voltage” was generated accidentally.

We list possible solutions to the problem in the same sequence as the reasons that caused them:

- Battery. Use a normally charged battery that holds a charge well and also has the appropriate capacity suitable for a particular vehicle (this is especially true for winter, when difficult engine starts are expected). Periodically check the charge level, electrolyte density, the quality of the terminal contacts on the battery, and if necessary, clean and lubricate them. Clean the contacts on the wires in the same way. If possible, you can check the battery leakage current. Sometimes an action that helps get rid of the error is to remove the negative wire from the battery for about 5 minutes (a few seconds are not enough!!!), and then quickly put it on and set it in such a way as to ensure tight contact between the wire and the terminal battery It is also advisable to first clean and lubricate the contact.

- Generator. It makes sense to double-check the operation of the diode bridge, check the voltage at the terminals (on most modern passenger cars the corresponding value should be about 13.7...14.0 V). Check the ground of the generator and, if necessary, inspect the wire and corresponding contacts. Similarly, clean all accessible contacts on the generator, as well as tighten them. You can also re-stripe the wires and make new contacts to improve their quality. Clean the base of the generator mount and the engine block at the point of contact. In some cases, tightening the alternator belt helps (especially if it slips and whistles); if the belt is significantly worn, it is better to replace it with a new one. In rare cases, the generator is completely replaced.

- Signaling. Regarding the alarm system, it is advisable to consult with the employees who installed the alarm system on the car, or find documentation for it on the Internet and find out whether it disconnects the battery from the system as protection or not. If yes, then you will have to come to terms with this error, or, as a last resort, change the alarm system to another one without a similar function.

- Short-term voltage drop. Usually in this case, this error is simply reset programmatically from the ECU memory. It should not be restored in the future.

- "Mass" of the ECU. Check the quality of the ground; if it is damaged, restore the integrity of the contact and/or wire. The chip may be damaged.

- Ground connection between the body and the engine. Inspect the wires and contact connections; the tips (if any) may be damaged. If necessary, test the wire with a multimeter to check for continuity or damage to the insulation. If the wire is broken or damaged, it must be replaced with a new one. In this case, it is advisable to use tips.

- Fuse box. Check the contacts in the block. Moreover, both coming from the battery and internal ones, directly on the fuses themselves. If necessary, tighten the contacts, remove oxides, and lubricate. It is especially necessary to check the fuse that goes to the electronic control unit, as well as its seat, the quality and cleanliness of the contact, and if necessary, inspect and clean it. It is also advisable to check the condition of the contacts in a special block under the hood. To do this, it is better to use a special contact cleaner.

- Electronic control unit. If there is such a possibility, it is advisable to install an ECU of the same model with the same firmware version on the car. At the same time, check whether voltage is coming to the supply terminal of the control unit and what its value is. However, it is best to seek help from official dealers or a car service that repairs electronic “brains,” since reflashing or changing settings yourself can be fraught with big problems.

This is interesting: What is a cabin filter in a car and how to replace it yourself

As practice shows, error 1602 itself is in most cases harmless, and the car owner finds out about it only when he uses a scanner to remove information from the ECU along with other errors or there is an on-board computer with a screen on which the relevant information is displayed. Therefore, if it does not affect the behavior of the machine (and in most cases this is the case), then the machine can be used and “bothered” about it. As for elimination, the cause is usually poor ground or battery contact.

Lada Vesta ECU and suitable scanners

Vesta electronic control received a CAN interface. Brains communicate with various systems through digitally encoded signals. Moreover, the Itelm M86 ECU is easily coordinated with third-party security devices (alarms), GPS trackers, and multimedia systems. The only requirement is the presence of an appropriate data bus.

For diagnostics, reading indicators and errors, ELM327 automotive scanners are used. They also use other multi-brand devices that operate using the OBD2 protocol and CAN bus:

Diagnostic capabilities of LADA VESTA systems:

| Diagnosable LADA VESTA system | Main functions | |||||

| Fault codes | Options | Actuators | Special Features | Auto detection | Identification | |

| Engine, ECU M86 | + | + | + | ECU reset, adaptation reset, settings reset, learning reset, cruise control and speed limiter reset, throttle adaptation, etc. | + | + |

| Automatic transmission ZF AMT (robot) | + | + | + | ECU reset, clutch learning (in MI control mode) | + | + |

| ABS BOSCH 9.0 | + | + | + | ECU reset, steering angle sensor learning, acceleration sensor learning | — | + |

| Takata airbags | + | + | — | — | — | + |

| Dashboard | + | — | — | ECU reset, settings reset, adaptations | — | + |

| Electrical package T4V20 | + | + | + | ECU reset, ECU internal protection reset, VIN recording | — | + |

| Electrical package T4VS | + | + | + | Record VIN | — | + |

| Power steering | + | + | — | Record VIN, ECU reset, ECU reset with initialization, adaptations (wheel speed index, outside angle sensor, rack end stopper, etc.) | — | + |

ECU location:

On this vehicle, the ECU is located in the engine compartment, on the right side (view from the front). Fixed with several screws to the shock absorber shell. The wire connection blocks are located at the bottom of the block, but the ECU itself is rotated 90 degrees. The tires are secured with latches. To remove the chip, unlatch the lock and remove the block.

By the way, removing the ECU is only necessary when flashing the controller firmware.

Chip tuning and firmware of Vesta ECU:

The original firmware is tailored to harmonize engine emissions with EURO standards. Chip units have modified software that disables some sensors (lambda) for high dynamic performance. You can find out the firmware type through OpenDiag. How to flash the ECU will be discussed below.

Other automaker definitions for P1602

- Engine Control Module (ECM) Anti-lock Braking System (ABS) / Traction Control System (TCS), CAN Data Bus - Communication Failure (GM).

- Battery Voltage Monitor - Malfunction (Toyota).

- Engine Control Module (ECM) - Low Battery Voltage (Volkswagen).

- Engine control module (ECM) - low battery voltage (Audi).

- CAN Data Bus - Anti-lock Braking System (ABS) / Traction Control System (TCS) (Buick).

- CAN Data Bus - Anti-lock Braking System (ABS) / Traction Control System (TCS) (Cadillac).

- CAN Data Bus - Anti-lock Brake System (ASS) / Traction Control System (TCS) (Chevrolet).

- Engine Control Module (ECM) Unprogrammed (Chrysler).

- Engine Control Module (ECM) Unprogrammed (Dodge).

- Transmission Control Module (TCM) - Serial Communication Problem (Hyundai).

- ECM communication with ABS - circuit malfunction (Isuzu).

- Engine Control Module (ECM) Unprogrammed (Jeep).

- Transmission Control Module (TCM) - Communication Lost (Kia).

- Battery voltage monitoring - malfunction (Lexus).

- Immobilizer control module/engine control module (ECM) - communication error (Mazda).

- ECM for LSI system - communication failure (Mitsubishi).

- CAN Data Bus - Anti-lock Brake System (ABS)/Traction Control System (TCS) (Oldsmobile).

- Engine Control Module (ECM) Unprogrammed (Plymouth).

- CAN data bus. Engine Control Module (ECM) Anti-Lock Braking System (ABS)/Traction Control System (TCS) - Signal Malfunction (Pontiac).

- Engine control module (ECM) - faulty (Saab).

- CAN Data Bus, Anti-Lock Brake System (ASS), Traction Control System (TCS) to Engine Control Module (ECM) - Lost Communication (Saturn).

- Engine Control Module (ECM) - Programming Error (Subaru).

- Electronic Throttle System (ETS), Throttle Return Spring - Malfunction (Volvo).

Sources

- https://voditeliauto.ru/poleznaya-informaciya/to-i-remont/kod-oshibki-p1602.html

- https://elm3.ru/diagnostika/oshibka-p1602

- https://remontvazov.com/oshibka-1602-na-vaz-2114

- https://kody-oshibok.ru/avtomobili/vaz/oshibka-1602-na-avtomobilyakh-vaz.html

- https://etlib.ru/blog/1166-oshibka-r1602

[collapse]

RђРІС‚омобили Р'РђР—: ремонт, обслужРевание, тюнинг

RћS€РёР±РєРё РІ скстеме SѓРїСЂР°РІР»РµРЅРёСЏ RґРІРІРіР°С‚елем РЅР° Р°РІС‚РѕРјРѕР±РёР»С ЏС… Р'РђР—, оборудованных Ренжект орными двигателями десятого SЃРµРјРµР№СЃС‚РІР° (Р° это РїСЂР°РєС ‚ически весь модельный СЂСЏРґ, начиная СЃ Р 'РђР — 2110, Калина, РџСЂРеора…), встречаются РЅРµ так редко, как С …отелось Р±С‹. Среди РЅРёС… есть РєРѕРґС‹ ошибок, которые S‚ребуют немедленного устранения Рё выявления причин, Р° есть S‚ акие, которые RїСЂРѕСЏРІР»СЏСЋС‚СЃСЏ RІСЂРµРјСЏ РѕС‚ времени. Среди РЅРёС… РѕРґРЅРёРј РёР· R»РёРґРµСЂРѕРІ оказалась ошибка Р 1602. Что РѕР±РѕР·РЅ ачает РєРѕРґ ошиР±РєРё, расшифровка Рё как ее SѓСЃС‚ранить, будем разбираться RІРјРµСЃС‚Рµ.

How to properly clean contacts

Often the voltage in the on-board network of the VAZ-2114 disappears due to oxidation of the contacts. In this case, you need to clean them, and then try to start the engine again and check the on-board computer readings. Contact cleaning is carried out according to the following rules:

- First check the condition of the negative terminal of the battery. If oxide is visible on it, it must be removed using a stiff wire brush or file. Similar work needs to be done with other contacts.

- Repeat this work with the positive terminal of the battery.

- Another node that must be checked when error 1602 appears is the side of the generator. There is also a wire leading to it, which often oxidizes. It is attached to the generator casing using a nut. If you see oxide on it, that should also be cleaned off.

The remaining conductors can simply be inspected for breaks and winding damage. Heavily worn wires need to be replaced.

Instructions for diagnosing VESTA via OBD2 connector with your own hands via a laptop or smartphone

Determine where the OBD2 connector is located

Determine which scanner is suitable for your car

The selection of a scanner (adapter) for LADA VESTA depends on the ECU model, as well as the needs of the diagnostician / car owner.

To select diagnostic equipment, use the calculator: “Selecting a scanner for Lada Vesta”

Download the diagnostic program for the scanner

The diagnostic adapter requires software that can be installed on a laptop or smartphone/tablet. Auto scanners with their own software shell and display do not require software.

To select a program for the adapter, go to the section: “Programs”

Use the instructions and carry out diagnostics

When you purchase an adapter, instructions are included with the adapter. More detailed instructions on diagnostic car scanners and descriptions of their operation are posted in the section: “OBD2 car scanner reviews”

Identify errors and decipher them

Error codes and their interpretation are displayed in the scanner program interface. You can also study the complete database of errors for your car in the section: “OBD2 error codes for Lada Vesta”

Make repairs according to the error code

The unit is repaired according to the decoding of the error (problem) or contact a car service to eliminate a particular malfunction.

Check errors again

Scan Tool Pro - budget multiscanner for Lada Vesta

A good choice for a novice diagnostician

Nowadays there are scanner models with different versions of firmware and chips on sale. Scan Tool Pro with firmware 2022 is the most stable version so far, and also has maximum compatibility with cars manufactured since 2001, including Lada Vesta.

Symptoms

Error P1602 on the VAZ 2114 is notable for the fact that sometimes it can appear asymptomatically. The owner learns about it only from the readings of the on-board computer or when conducting diagnostics with a scanner. Therefore, it can be difficult to determine. Additionally, the occurrence of this code may be intermittent.

In some cases, when the ECU reports this code, problems with starting the engine may occur. It may start poorly, not the first time, or not start at all. But this is also not a characteristic feature of this problem. In a similar way, a machine can report many faults.

Check Engine

When the ignition is turned on, the indicator should light up, so the ECM checks the serviceability of the lamp and control circuit. After starting the engine, the indicator should go out if the controller memory does not contain the conditions for turning it on.

- The Check Engine light is constantly on - in this case, the driver is obliged to make the vehicle available to service technicians as soon as possible.

A flashing Check Engine Light indicates a problem that can cause serious damage to the ECM (for example, a misfire can damage the catalytic converter).

To protect against random, short-term errors that may be caused by loss of contact in electrical connectors or unstable engine operation, the warning light turns on after a certain period of time after detecting a malfunction in the ECM. During this period, the on-board diagnostic system checks for a malfunction.

After eliminating the causes of the malfunction, the alarm will turn off after a certain delay time, during which the malfunction does not appear, and provided that there are no other fault codes in the controller’s memory that require turning on the alarm.

When clearing (deleting) fault codes from the controller’s memory using diagnostic equipment, the indicator goes off.

How to check the generator and replace the brushes on it

If you have tried all possible troubleshooting options on your VAZ-2114, but nothing worked, check the generator. To do this you will have to dismantle it:

- Remove the negative terminal from the battery and disconnect the wire leading to the generator casing.

- Remove the nuts from the upper and lower alternator mountings, then loosen the tension bolt and remove the alternator belt.

- Remove the clamping bar.

- Remove the generator along with the casing.

There are several ways to check the generator. One of them is to use a stand, but it is only available in car services. Ordinary car enthusiasts will have to disassemble the generator, check its coil with a multimeter and inspect the components. Particular attention should be paid to the brushes, which need to be replaced if necessary. Often a coil or bearing wears out its life, in which case you will need to purchase these components and install them in place of the failed ones.

Source

Diagnostic methods for Lada Vesta

There are two types of reading errors from the memory of the car’s on-board computer.

- Self-diagnosis - the on-board computer can show the motorist any existing errors. A simple procedure allows you to perform repairs without additional equipment. The disadvantage is the impossibility of determining the exact location of the breakdown or its system - the BC will only indicate the direction in which the defect should be looked for.

- Using a diagnostic scanner is a complex procedure that cannot be done at home. For normal diagnostics, you will need to connect a laptop or tablet with a special program to the machine. Usually this is done exclusively in specialized workshops.

Alternator belt problems

Everything is simple here. When the belt is loose, the generator can rotate without problems without load, but when it appears, it simply stops. As a rule, quite often with such a breakdown a characteristic belt whistle is heard. Accordingly, correct tension adjustment or replacement of a stretched alternator belt eliminates the problem.

Similar miracles can also happen even if the belt is new and well tensioned. For example, in wet rainy weather, due to design flaws in the engine compartment, water gets between the generator pulley and the belt. It works like a lubricant. As a result, the belt simply slips along the pulley, and the driver sees wild voltage drops in the on-board network on the voltmeter.

If engine oil is leaking from all the cracks, so to speak, it won’t be long before it ends up on the generator pulley or belt. The result should already be expected and understandable. By the way, about rainy weather and water. When it rains, what do we do? That’s right, we turn on the stove so that the windows don’t sweat, as well as the headlights, fog lights, etc. so that we can be seen on the road. And this is all the load on the generator, due to which even just a little water on its pulley will lead to belt slipping

Please take this into account and pay attention if necessary.

Lada Priora error P1602. Phase sensor error. Increased fuel consumption. How to fix.

Let's take a closer look at such an error as P1602, it means that the power to the ECU Electronic Control Unit is lost. I purchased this device for a couple of thousand rubles:

This is an on-board computer, it fits many cars. The cable for connecting it is included. It connects to an outlet located in the glove compartment. This on-board computer is capable of displaying numerous information about the car, fuel consumption, outside temperature, and, most importantly, errors. He immediately pointed out a faulty phase sensor. It is located under the hood and can be easily changed, although in a slightly vandal way. Here you can see one mounting bolt:

The second one is behind the phase sensor itself, there is no way to get to it. We unscrew the visible bolt, then prop it up with a screwdriver, breaking off the ear on the second bolt. After successfully replacing the phase sensor, this error disappeared, fuel consumption decreased significantly, until that moment it was 16-19 liters per 100 km. mileage, but a new error P1602 appeared. It signals to us that the power supply to the unit (Bosch 797) has failed. All masses were checked, everything under the hood is normal, the second mass is located under the foot air duct near the front passenger:

Next, we trace the wires, ground contacts are 80 and 61 on the block, plus 12:

After the diagnostics were carried out, a problem was identified in the 12 positive wire (red). The contacts are marked on the ECU itself. The problem with the positive wire was that the terminal at its end was slightly deformed and it was loose on the contact in the ECU itself, which resulted in error P1602. The repair was simple, this terminal was bent a little (this must be done carefully so as not to break it), after which the wire stopped hanging out, the computer signals that there are no errors.

Video error P1602, phase sensor error in Lada Priora:

Reserve video error P1602, phase sensor error, increased fuel consumption in Lada Priora: