The term “forward flow”, known among tuning enthusiasts, refers to a special design of the vehicle’s exhaust system, designed to minimize the resistance of exhaust gases. For this purpose, there are no partitions in the exhaust pipe of the direct-flow muffler, which change the trajectory of the exhaust gases and disperse them inside the pipe in order to reduce the noise of the engine. Only the outer sound-absorbing layer of the pipe, made of basalt wool or other material with similar properties, is responsible for sound absorption. Owners of the “Seven” will be interested in knowing why they install forward flow on the VAZ 2107 and how you can make it yourself.

What is a direct-flow exhaust system

To understand why to install a direct-flow muffler, it is important to know how the car’s exhaust system works.

Main goals:

- Filling the cylinders with a prepared fuel-air mixture, and in diesel cars - forming the fuel mixture in the combustion chamber;

- Ensuring the removal of spent fuel gases from the engine and passenger compartment outside the vehicle;

- Reducing the emission of toxic gases and harmful substances into the atmosphere thanks to the built-in catalytic converter;

- Reducing noise levels in the cabin and surrounding area.

The operating principle of the exhaust system is partly based on the law of inertia.

Thanks to the action of this law, a vacuum zone is formed behind the exhaust valve into which gases rush, and their place is immediately taken by a fresh portion of the fuel mixture.

This happens due to the fact that the phases of fuel intake and exhaust gases overlap each other, as is provided for in the design of modern engines.

After the exhaust valves are closed, next to the high-pressure zone formed as a result of exhaust gases escaping under pressure, another low-pressure zone is formed in the manifold, which moves along the exhaust pipe at the speed of sound.

Entering the muffler, the vacuum zone encounters resistance in the form of partitions, is reflected and goes in the opposite direction to the valves.

The ideal case is when this zone approaches the motor at the moment the valves open, but this depends on the frequency of the engine and the distance to the obstacle.

And since in modern cars such a distance is large, the vacuum zone from one cylinder, as a result, at the moment the valve opens, ends up in another, and not in the one from which it left.

Thanks to the design of the “spider” (exhaust manifold), where pipes of the same length are provided, the effect of vibration damping occurs, since the vacuum zones go from 4 pipes into one, where resistance is created at the junction of the latter, and they also partially dampen each other.

But the muffler plays a leading role in noise reduction, because the exhaust manifold and other elements are unable to greatly reduce noise.

But on many sports cars such a device may not be found; the role of a muffler there is played by a special turbine, which smoothes out vibrations and reduces the force of the exhaust by grinding the outgoing gas flow.

About direct flow or PG

A direct-flow muffler (PG) is an improved alternative to a stock exhaust, which is not capable of ensuring a quick and timely release of gases from the engine system (ICE). The standard exhaust system especially suffers (chokes) after installing a sports camshaft or after boring the cylinder head cylinders (in other words, on a forced engine).

A straight-through muffler is designed to improve the exhaust system

The GHG is designed to modernize the exhaust system, which increases gas emissions. In addition, a correctly installed PG will provide an increase in internal combustion engine power by 10–15 hp. However, you need to be prepared for drastic changes: everything will need to be replaced, from the catalyst to the tip.

Increasing the power of a power unit using a PG, unfortunately, also has a “other side of the coin”, associated primarily with a loud sound attack of about 120 dB. This is the norm for sports cars, but hardly for civilian ones. And this explains the mass of cases of fines issued by law enforcement inspectors to the owners of such cars.

To minimize this modernization flaw, craftsmen use various methods to reduce sound. Installing a flute muffler, oval or round resonator are all types of methods to improve the performance of a forward flow muffler. “Form and content” can make it quiet.

For example, craftsmen say that a square resonator installed in the middle of the path (the path for gases to escape into the aircraft) reduces noise much better than an oval or round one. And in general, it’s better not to use a round one, but to use an oval one as a last resort, since it has a larger volume of cans and, accordingly, a quieter sound.

Oval resonators from Volvo S60R and Saab have proven themselves to be quite good.

Before thoroughly understanding what GHG is, you should remember the functioning of the vehicle exhaust system. Many motorists do not even suspect how many tasks it performs, although it does not seem so at first glance.

The forward flow kit is a ready-made option for tuning

Of course, the main task of the exhaust is to remove gases. But an equally important function is to ensure timely and high-quality ventilation of the internal combustion engine cylinders.

Ventilation of the cylinders is carried out as follows. When the valves of one cylinder of the internal combustion engine are closed, a vacuum is created in the exhaust manifold. It moves through the system at high speed, and, having been reflected from obstacles, returns to the collector. At the moment the gases leave the cylinder, a reduced pressure is created here, which promotes better ventilation and purge.

Among other things, the exhaust system (ES) is designed to combat noise. This is what the muffler is designed for.

Compared to a conventional standard muffler, the PG does not have many separate sections inside. Accordingly, it has a more simplified design. It is this fact that allows craftsmen to make it at home or in the garage.

But is it even worth it for an ordinary motorist to change the standard muffler to a PG one? Certainly not. If he does not prefer active driving, does not intend to use the car for sporting purposes, does not have complexes about a “gray” car that does not stand out from the general traffic flow, then he should not carry out modernization.

On the contrary, if the bassy and thoroughbred roar of the engine resonates in the soul of the car enthusiast, then the installation of direct flow must be carried out. Moreover, this gives many advantages of the following nature:

- the power of the internal combustion engine increases due to increased throughput;

- The service life of the entire aircraft is extended due to the use of high-quality materials.

As for the disadvantages of modernization, these are:

- problems with the law due to loud noise (can be excluded if the installation of GHGs is carried out using a new system);

- possible difficulties with service maintenance;

- greater sensitivity of the power unit to low temperatures;

- decreased clearance.

Do not confuse forward flow with a muffler. The fact is that the entire exhaust system is called direct flow, and in most cases only part of it is subject to modernization - the muffler.

Types of devices

The standard exhaust system of a modern car includes a resonator (the first one comes from the engine) and the muffler itself.

The resonator cuts off low-frequency vibrations, and the muffler cuts both low-frequency and high-frequency vibrations, which together leads to a good result.

But the above scheme, both jointly and separately, may include the following types of mufflers:

- Made of aluminized steel;

- Stainless steel;

- Silencers, limiters, absorbers and reflectors;

- Resonator type;

- Direct-flow (sports) analogues.

Aluminized steel

Devices made of aluminized steel are characterized not only by a long service life, from 5 to 10 years, but also by a high price.

It will be difficult to choose such a muffler for your car, since only a few companies produce such devices, and making it yourself will be problematic.

Stainless steel

The devices are in the inexpensive segment, but their service life is only from 2 to 5 years. A big plus is that you can match the element to almost any car.

Limiters

They are usually used as an additional device installed in front of the main one.

The operating principle is based on creating low acoustic resistance.

Structurally, this is done like this: in the pipe, a large diameter turns into a small one, then there is a sharp increase in volume according to the principle of a large bottle with a narrow neck. The sound, entering a large space, decreases.

Reflectors

Used as a secondary muffler installed after the main one.

Exhaust gases entering the device encounter a group of acoustic mirrors on their way. Reflecting from them, the gases dissipate their energy one by one, and the output is a weak sound.

Absorbers

Can be used as a main muffler. The principle of operation is based on the absorption of vibrations by a porous material, usually glass wool, the fibers of which are heated by oscillating, thereby converting sound into thermal energy. Structurally close to direct-flow analogues.

They are considered ineffective because they absorb only high-frequency vibrations and transmit low-frequency ones.

Resonator type

As a rule, they are used first in exhaust systems as additional ones.

The principle of noise absorption is based on the presence of chambers of different sizes, through which the sound is effectively muffled.

Everything is arranged like this: a pipe with slots runs through the center of the resonator, which is surrounded by chambers of different volumes. Through the slots, exhaust gases penetrate into the chambers, where their energy is lost.

After this, the sounds enter the main device, where they are further reduced.

Direct flow

They are also called sports mufflers. As a rule, they are made of stainless steel. Installed on sports and tuned cars.

After installing a direct-flow muffler, the suction of the air-fuel mixture into the cylinders is improved, and the resistance in the exhaust system created by conventional analogues is reduced.

A direct-flow muffler is structurally somewhat similar to a resonator; there is the same pipe with holes and empty cavities separated by partitions. Only the cavities themselves are filled with basalt wool (or other material), which can withstand high temperatures.

Consisting of long mineral fibers, basalt wool absorbs sounds well, but only until it is blown out of the direct flow and even special protective metal mesh does not save the situation.

If the direct-flow muffler, when you tap on it, begins to sound like an empty metal container, then it needs to be filled again with cotton wool or replaced. And the sound produced by the exhaust system will be different.

Videos about the muffler

There are many videos on the Internet in which the authors inventively and simply demonstrate how to make a direct flow with their own hands.

Video: how to make a straight-through muffler with your own hands

Another clear example of making a muffler from scratch. The straight-through version is made of stainless steel with two exhaust pipes.

Video: how to make a straight-through muffler from stainless steel

https://www.youtube.com/watch?v=zhxpX0O7E8s

Sounds made and their features

After installing a direct-flow exhaust system, the sound emanating from the car immediately changes; as a rule, it is low-frequency “growling”, “bass” and “mumbling”.

This happens because mineral wool placed in the co-current cavities removes only the high frequencies, while leaving the low bass unchanged.

The resistance to exhaust gases is also greatly reduced, and this affects the increase in engine power (but only in combination with other measures).

But the nature of the sounds largely depends on the number of holes and their diameter in the central pipe, as well as the characteristics of the material embedded in the cavity.

As was noted, mineral wool does not support low frequencies, and in most cases the engine produces sounds in the low range.

Therefore, it is not surprising when a car with direct flow makes sounds of engine operation through the muffler, and the higher the frequency the latter operates, the more it clogs the ears.

This is felt especially well inside the car, when such sounds, coinciding in frequency with body vibrations (and they are close to the frequency of the engine), lead to resonant vibrations inside the car and the strength of the sound increases significantly.

Therefore, it is almost impossible to make a quiet direct-flow muffler.

Noise standards and liability for exceeding them

Responsibility for loud exhaust from a muffler is provided for under Article 8.23 of the Code of Administrative Offenses. The driver is charged for operating a vehicle with excess noise levels in accordance with the Technical Regulations of the Customs Union 018/2011 “On the safety of wheeled vehicles”, paragraph 9.9.

Table: dependence of the maximum permissible sound level on the vehicle category

| Vehicle category | Sound level (in decibels) |

| M1, N1, L | 96 |

| M2, N2 | 98 |

| M3, N3 | 100 |

Category M1, N1 and L are passenger cars with no more than 8 seats, trucks with a permissible maximum weight of no more than 3.5 tons, motorcycles/mopeds/ATVs. Category M2 and N2 are cars with more than 8 seats (except for the driver), but whose maximum weight does not exceed 5 tons, and trucks with a permissible maximum weight from 3.5 to 12 tons, respectively. Category M3 and N3 are full-fledged buses and trucks with a permissible maximum weight of more than 12 tons (trucks, most dump trucks).

According to 12.5.1 of the Code of Administrative Offenses, the driver (or owner) is charged for making changes to the design of the car without the permission of the supervisory authority - the traffic police.

So, the fine for a straight-through muffler can be either a warning plus a fine of 500 rubles, or two fines of 500 rubles each (in practice, two warnings cannot be issued).

The manufacture of a direct-flow muffler and its further improvement is within the power of most car enthusiasts. Despite the restrictions on the operation of such devices in our society, there are more and more people who want to make their own and install a direct-flow muffler on a car. Thanks to detailed instructions with photographs and videos, it will be much easier to make a forward flow.

Didn't find the information you are looking for? on our forum.

Power and forward flow, three different opinions

Many owners of VAZ cars or, for example, Mitsubishi Lancer 10, Mazda 3, installing direct-flow exhaust systems on their vehicles pursue several goals, as a rule, there are two of them:

- Tuning your car;

- Increase the engine power, they say installing a sports analogue will leave many behind when starting at a traffic light.

The first opinion is that this is true. There is no debate about tuning; we are missing this point. But there is another opinion about increasing power, and it is the opposite.

The second opinion is that a sports muffler without deep tuning of the engine will not give an increase in power and partly it coincides with the opinion of experts.

The third opinion from professionals is that a noticeable increase in engine power is possible only after significant processing, and a direct-flow muffler is a secondary part of the issue.

The tuned power unit produces more exhaust gases, and, therefore, the standard exhaust system will not cope with its tasks, especially at high speeds.

Therefore, it will be necessary to increase the diameter of all pipes, install a tuned manifold, and only then a direct-flow muffler.

It is on sports cars that they install not simple engines, but ones that require special attention. And the direct-flow exhaust system fits into the overall picture of the tuning engine.

Lada 2109 Vazentador › Logbook › Making the exhaust “quieter”

So my little lovers of cans and their modifications)) In this post there will be a story about how I made the exhaust quieter... Initially, when I bought the exhaust system, I didn’t even bother about the sound and selected the can according to the design that matched the body kits and that’s all for me liked.

As a result, after starting the Vazentador plant, I realized that the jar was mega loud. Of course, it’s fun sometimes even when you’re racing straight away... but in everyday life it’s already starting to get boring. As a result, I began to think what and how... Fortunately, there is our favorite site and there was a lot of advice on what and how (a topic was created in the group). And by a general consensus between myself and myself, I decided to try to refill the jar with glass wool. Well, we go to the garage, remove the can and saw it...

We also see glass wool there, already burnt and with a half-empty middle, we shake out all this crap from there

Rinse, etc. ...Next I made small cuts on the pipe, which is closer to the resonator, in order to increase the blown space of the can, otherwise, given its size, there is not enough space there anyway

Then we grab the glass wool... although wait, first we put on rubber gloves

otherwise you are guaranteed a fun sleepless night

And we begin to hammer our jar tightly (any auxiliary objects will do: a hammer, a crowbar, hands, etc.)

I got one and a half sheets of cotton wool in there, pretty good for this micro-jar... Well, having finished my work, I went to a friend who was a metal “surgeon” and he, as a “doctor” who took the oath of a welder-saw-sawker, surgically sewed up my creation for me)) )

Satisfied, I fly to the garage, quickly put everything back together and voila...

Good luck to everyone on the roads and have fun driving))

Source

Making a direct-flow muffler with your own hands

If you want to manufacture and install direct flow on your car, then it is better to conduct such experiments with domestic cars, for example, VAZ.

It is better to tune the exhaust system of Mitsubishi Lancer 10, Mazda 3 and other foreign cars by contacting special companies that do this professionally.

We discussed the design of the direct flow above. The difference between a sports muffler and a regular muffler is shown below.

We will be tuning the exhaust system of a VAZ-2110 (8 valve 1.6 liter volume).

To do this you will need the following materials and tools:

- Metal pipe with a diameter of 52 millimeters (a little more than 2 inches);

- Grinder with a disc for cutting metal 1 (1.6) mm;

- Welding machine, preferably inverter;

- Metal sponges (brushes) for cleaning dishes - at least 50 pcs.

Work progress

Dismantle the old device or prepare a similar one taken, for example, from disassembly.

Cut out the gutter and all the insides as shown below.

Leave a 4 cm protrusion on both sides so that a new pipe can be welded into this area.

Prepare a new pipe by cutting it to size and drilling holes with a diameter of 6-8 mm in it at a distance of 1-2 cm from each other.

This is labor-intensive work, so you can use an alternative method - using a grinder with a 1.6 - 3.2 mm disc, cut holes in the pipe in the shape of a herringbone at a distance of 1-2 cm from each other.

Weld a pipe with holes to the sections in the muffler and fill the entire space with metal pipe cleaners.

On the reverse side, the electrode may be missing, no problem, the hole left will be additional to the rest drilled or sawn. But if you go by principle, you will have to cut out the other side of the muffler.

Weld the outer part back and, if necessary, update the pipe running from the forward flow towards the exhaust.

Completely clean the device, prime it with primer and paint, this will extend its service life.

It’s worth taking a closer look at the filler. In the example described above, a metal mesh was used, but still the best option would be expanded clay (in the middle), and put fire-resistant mineral wool on top.

How to make the quietest muffler for a car yourself?

When the issue with noise during car operation has gone too far, and you have decided to make the quietest muffler for the car, then you need to start by preparing the tool. We will need:

- welding machine, an inverter or semi-automatic will do;

- angle grinder and discs for it;

- workbench with a vice.

The surest and most inexpensive way to make a muffler quieter is to weld in an additional resonator. This can be done in a garage yourself.

An additional resonator can be placed between the standard resonator and the muffler. You can install a ready-made resonator; you just need to weld it into the desired place in the pipe. Or you can assemble the resonator yourself. For those who doubt whether the exhaust will become quieter if an additional resonator is welded in, the answer is clear - the exhaust will become quieter. If everything is done correctly.

We make direct flow from scratch

To do this you will need to use the services of a turner. We order two pipes:

- One made of steel 2 mm thick with a diameter of 130 mm and a length of 42 mm.

- The second is made of steel with a thickness of 2.5 mm, a diameter of 52 mm and a length of 42 mm with holes with a diameter of 8-10 mm, every 2 cm;

Two flanges with a diameter of 130 mm with an internal hole of 52 mm, metal thickness 2-2.5 mm can be ordered separately.

Prepared:

- Asbestos rope;

- Glass wool or mineral wool.

Asbestos rope is wrapped around the inner pipe. This is done in order to protect the mineral wool, which will be the top layer, from overheating.

We fill the top layer, assemble and scald the structure. We weld the fasteners and attach the forward flow to its regular place. For beauty, you can put a muffler attachment on it.

Another design of the device is shown below.

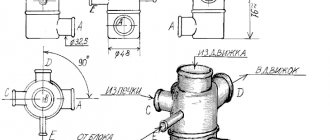

Blueprints

There are a lot of ways to make a direct-flow muffler; the main thing here is to understand the principle of operation of the device and use your imagination. And for car owners who find it difficult to do this, use the methods and drawings described above, they are simple and accessible to many.

Also tell us in the comments what type of forward flow is installed on your car and how you can do it yourself, this will help many people understand this topic.

How to make forward flow quieter

To reduce exhaust volume, devices are used that reduce the flow area of the exhaust pipe of the muffler. Let's look at the damper and flute commonly used on cars.

Damper installation

The damper is installed either before or after the muffler. The volume of the forward exhaust will be clearly reduced only when the damper is completely closed. Technological clearances of 3-5% remain for the passage of exhaust gases - so the engine does not stall. In this regard, engine power is significantly reduced due to blockage of the exhaust system.

the damper is made by hand

A damper is also used to switch from a direct-flow to a return-flow muffler and vice versa, if necessary. In this case, a new muffler is installed parallel to the old one, and the damper is mounted in front of them. This scheme is already used on some brands of cars from the factory.

mechanical adjustment of the damper is carried out on the move by the driver from the cab

You can drive a short distance with the throttle closed, but driving constantly is unacceptable for the engine.

the damper is installed in front of the muffler

Making and installing a flute

The flute (silencer) has more preferable characteristics. It dampens the exhaust pipe clearance much less than a damper. You can buy a flute, knowing the internal diameter of the outlet pipe, or make it yourself. Various silencer designs are shown in the photo.

Flute mounting options

Possible versions of the flute.

- External - for outlet pipe diameters up to 50–60 mm.

method of attaching a flute to a small diameter exhaust pipe

a properly designed flute “helps” you ride more quietly

the sound becomes “more pleasant” to the ears of the traffic inspector

Tools and materials for making a flute

- Bulgarian;

- electric drill;

- welding machine;

- spanners.

It is better to choose blanks from stainless steel with a thickness of 0.8–1.2 mm, which guarantees long service life. Blanks made of “ferrous” metals are acceptable with a thickness of 2.0–2.5 mm or less if we plan to use the flute for short periods. As blanks we use two pieces of pipe and sheet metal for the flange.

Making a flute with your own hands

The order of work performed:

- We adjust all parts to the required dimensions. We measure the dimensions of the flange and larger pipe “on site”.

- We drill holes.

the notch divides the gas exhaust into two streams, which reduces the exhaust volume

To further relieve the exhaust system from excess exhaust gas pressure, holes are drilled in the flange.

additional holes allow for a freer exhaust

the flow of exhaust gases is suppressed due to unloading holes and counterflow

There is no need to paint stainless steel

Videos about the flute

Video: sound of exhaust through forward flow without flute

Video: sound of a flute on the same car

How to install a stinger exhaust on a vaz 2114

My next story is about the purchase and installation of a “Stinger” exhaust system, a 4-2-1 spider and a “Stinger” barrel resonator.

- Exhaust manifold/Spider 4-2-1 “Stinger” for VAZ 2114.

- Material:

steel 08 PS, used for the manufacture of high-quality exhaust systems. This model can be made of stainless steel. - Dimensions:

primary pipe diameter 38 mm, wall thickness 1.5 mm, secondary pipe diameter 43 mm, outlet 51 mm. - Advantages:

Installing this exhaust manifold on a car gives an increase in power. Can be used as a replacement for a failed standard cat-manifold.

Exhaust Manifold/Spider 4-2-1 Stinger

Direct-flow resonator with a “Stinger” barrel on a VAZ 2110.

steel 08 PS, used for the manufacture of high-quality exhaust systems, powder coating.

pipe diameter 51 mm, barrel diameter 100 mm, wall thickness 1.5 mm.

Installing this direct-flow resonator on a car gives an increase in power. Can be used as a replacement for a failed standard resonator.

Additional information: filling - basalt wool and basalt fabric (heat resistance 1200 degrees C) to prevent the wool from blowing out. During installation, standard clamps are used.

Direct flow resonator with barrel

- Exhaust manifold gasket - 140 rubles

- Neutralizer repair kit (O-ring and 2 bolts with conical springs) - 130 rubles

- Receiver gasket - 40 rubles.

- The installation process is quite difficult and took about 6 hours.

- I will not describe the entire process of removal and installation; anyone interested in what and how to remove can watch here.

I’ll briefly tell you what problems we encountered during installation:

- After removing the factory exhaust manifold, we installed the 4-2-1 “Stinger” spider and it fit like original.

- The first nuance when installing the 4-2-1 spider was that due to its more massive dimensions, the exhaust manifold came into contact with the hose going to the stove.

- A day later, the hose frayed and had to be replaced with another one; I took another hose, which is sold by the meter, to stretch it past the exhaust manifold; installing it at the factory would have also frayed.

- Having removed the factory resonator, I discovered that it was rotten, so it was doubly pleasant that money was not thrown away, the part was replaced with a more advanced one)

- The purchased “Stinger” Resonator for 2114 did not fit into place.

- I had to replace it with another one for model 2110 16V, which had to be shortened a little.

Factory exhaust manifold.

Factory exhaust manifold

Difference between 4-2-1 spider and stock exhaust manifold.

Due to the fact that the 4-2-1 spider is longer than a standard exhaust manifold, a direct-flow resonator under the spider is required for installation.

When installing the 4-2-1 spider, pay attention to the heater hose! Contact of the heater hose with the exhaust manifold is not allowed! The heater hose will leak when exposed to high temperatures.

To install a straight-through exhaust manifold/spider 4-2-1 with a crankcase guard, it is necessary to remove the crankcase guard before installation.

Bottom view of Spider 4-2-1 Stinger

Welding and fitting work when installing a direct-flow resonator. The direct-flow resonator was shortened by several tens of centimeters.

The direct-flow resonator with the “Stinger” barrel on the VAZ 2110 is in place.

Direct-flow resonator with a “Stinger” barrel on a VAZ 2110.

After installing the exhaust system, the first thing I liked was the sound of the exhaust, it became more serious, I didn’t really feel anything in the speakers, since I hadn’t flashed it yet. After the firmware I’ll tell you about the results and post a video with the exhaust sound. I left the muffler stock for now, until I decide, I will select it for a good sound.

↑ External tuning of VAZ-2107

The positive side of this type of tuning is that it does not require serious intervention in the exhaust system of the car, and it does not require large capital investments. In other words, a car enthusiast can do simple external tuning on his VAZ-2107, for example, installing stainless muffler tips on his own, without involving specialists from a repair shop.

↑ Exhaust "Dragon's Tongue"

A few words about the “Language of the Dragon”. If you want to do something more complicated, for example, the so-called “dragon tongue,” then you cannot do without specialists, since this requires some change in the exhaust system.

"Dragon Tongue" is a feature where flames are emitted from the exhaust pipe. It looks impressive, although it is only noticeable when the vehicle is stationary. Therefore, before “bothering” with this tuning, I recommend thinking carefully.

Assembling a direct flow in the body of an old muffler

If for one reason or another you are not satisfied with the option of purchasing a ready-made direct-flow muffler, there are two options for creating it yourself:

- assembly in the body of an old muffler;

- construction of a new part.

The first option is simpler and cheaper. To carry it out, relatively straight arms and a welding inverter are enough. The advantage of this method is the minimal impact on the computer settings for the oxygen sensor and a slight (if assembled correctly) change in engine noise. The sound will become more bassy at revs, no more.

Ready homemade forward flow

- Remove the old muffler and cut out a full-length window in the body.

- Remove contents and outlet pipe.

- Make and weld into the muffler a “flute” from a perforated pipe or an ordinary pipe, in which cuts are made with a grinder or holes are drilled with a drill. This design disperses the flow of gases, reduces noise and exhaust temperature.

- Weld the exhaust pipe. For aesthetics, you can use a single or double chrome pipe. Perforate the part that is inside the muffler with a drill.

- It is advisable to fill the muffler with mineral wool. You can also use asbestos sheet, glass wool or other heat-resistant material.

- Weld the window in the housing.

To minimize the carryover of filler through the holes in the perforated pipe, it can be pre-wrapped with a metal mesh.

The design of the exhaust system of a VAZ-2109 car

It’s worth noting right away that there is nothing particularly complicated here.

In fact, the exhaust system of the “nine” is very simple, without any electronic gadgets, and it can be called classic. Accordingly, if you decide to do repairs or tuning, then no unexpected problems are expected here. The exhaust system of the “nine” consists of: Speaking about the components listed above, it is worth explaining their purpose. In particular, a lambda probe is located inside the exhaust pipe of cars with an injection engine. It analyzes the composition of the exhaust gases and at the same time the mixture going into the cylinder block. The pipe itself is connected with four studs to an exhaust manifold made of cast iron.

conclusions

Whatever the purpose of replacing the muffler and the reason for the desire to make it yourself, there is nothing difficult in both technologies if you have basic welding skills.

The term “forward flow”, known among tuning enthusiasts, refers to a special design of the vehicle’s exhaust system, designed to minimize the resistance of exhaust gases. For this purpose, there are no partitions in the exhaust pipe of the direct-flow muffler, which change the trajectory of the exhaust gases and disperse them inside the pipe in order to reduce the noise of the engine. Only the outer sound-absorbing layer of the pipe, made of basalt wool or other material with similar properties, is responsible for sound absorption. Owners of the “Seven” will be interested in knowing why they install forward flow on the VAZ 2107 and how you can make it yourself.

Powder fire extinguisher muffler

Modification of a standard muffler is possible on the basis of a powder fire extinguisher whose service life has expired.

Necessary materials

Additionally, you should prepare:

- welding electrodes 1.5 - 2.5 mm;

- electric welding machine;

- compact grinder with cutting wheels for metal;

- parts of the old muffler;

- two pieces of steel pipe with an internal diameter of two inches.

Stage-by-stage execution of work

The manufacturing process is as follows.

- Prepare a pipe of a suitable size with a diameter of 30 - 52 mm. It is unlikely that you will be able to find thin-walled factory-type pipe, so just use tap pipe.

- Unscrew the cap from the fire extinguisher and get rid of the remaining powder.

- Enlarge the hole until the pipe you prepared fits snugly into it.

- A similar hole must be made on the other side of the cylinder, but it should be slightly shifted towards the wall of the fire extinguisher.

- Use a grinder to create perforations on the end sections located inside the pipes (12 - 15 cm).

- Insert the pipes into the cylinder, calculating the opposite arrangement of the perforated sections opposite each other. The ends should be inserted 60% into the balloon.

- Weld the joints on both sides of the cylinder in a circular direction. Be careful not to burn the metal of the fire extinguisher.

- Remove the fasteners from the old fire extinguisher and weld them onto the resulting homemade structure. Please note that the water pipe is heavier than the factory car pipe, so provide reinforcement for the fastening. On the other hand, the heavier the pipe, the quieter the muffler.

- To reduce noise levels and increase the service life of the structure by two years, insert a flexible corrugation into place after the exhaust manifold. The housing can be filled with glass wool to further reduce noise.

- If you are making a muffler from stainless steel, provide for the possibility of disassembling the structure. It can be partially dismountable, and you will have the opportunity to periodically clean the cavities and make repairs if necessary.

- Be sure to check the tightness and reliability of the welds by plugging one of the pipes and filling it with water upside down. There should not be even a slight leak.

- Drain the water and use a compressor to blow out the product and remove any remaining moisture.

- The design is ready for installation on a car.

We also advise you to carefully read our expert’s article, which describes in detail how the muffler resonator is designed.

You may also be interested in an article by our specialist, in which he talks about how to choose a thermal tape for a muffler.

The design involves moving exhaust gases and coolants in a parallel direction in a closed circle. The exhaust is carried out through a large-diameter pipe, it has few joints and smooth walls. There is no sound absorber in this case. Thanks to the design features, exhaust gases are removed from the engine faster, due to which the efficiency of the unit increases by 15%, and the power also increases.