Wheel bearings facilitate the rotation of the wheels, they account for part of the car's support, while they fix its axles and bear a high load. This part is an important element of the chassis, and if it breaks, the front wheel bearing of the VAZ classic models will need to be replaced. If this is not done in time, an unpleasant hum will appear, the vehicle's rolling will worsen, and fuel consumption will increase. If the bearing fails, the machine will be unusable.

↑ How to remove the front suspension wheel bearings

Unscrew the hub nut and remove the washer and inner race of the outer bearing.

If necessary, if the outer bearing cage is damaged along the way, we do not press out the outer ring of the bearing, but replace only its inner part. However, at the first opportunity we install a completely new bearing.

Carefully, trying not to damage the cuff, remove the hub together with the brake disc from the steering knuckle axis.

Using a 12mm wrench, unscrew the two guide pins and remove the brake disc and spacer ring from the hub.

We clean the inner cavity of the hub from old lubricant, wash all parts with kerosene and add fresh lubricant.

To remove the outer race of the outer bearing, secure the hub in a vice.

Using a beard, trying not to damage the hub, we hit the perimeter of the outer ring of the bearing and knock it out of the hub.

We take out the hub cuff by prying it off with a screwdriver.

A spacer bushing is installed under the cuff.

We remove the inner bearing from the hub in the same way as the outer one.

Causes and symptoms of malfunction

Original wheel bearings on a classic VAZ can last up to 100 thousand kilometers before they require replacement. But there are several factors that negatively affect it, reducing its service life:

- Overheating associated with wheel rotation, especially in winter. A well-lubricated bearing is less likely to overheat; in addition, it is advisable not to get carried away by driving too fast.

- Condition of the roads. This is the main cause of breakdowns, after which the front wheel wheel bearing needs to be replaced. It is he who takes on the load of a dynamic impact when the wheel falls into a hole or hits a ledge on the surface.

- Aggressive environment. If the bearing protection is damaged, dust and dirt, as well as reagents used to treat roads during the cold season, begin to get into it. This quickly damages the bearing.

The main sign that the bearing has failed is a characteristic noise when driving, coming from the front hub. There are other signs by which a malfunction can be identified:

- Having raised the front wheel on a jack, take it on the sides and carefully move it left and right, as if turning the wheel, and then up and down. If you feel play in the wheel bearing with a characteristic tapping sound, it is worn out and requires replacement;

- In neutral gear, spin the wheel, listening to the operation of the bearing; it should not creak, buzz or make other extraneous sounds. Please note that sometimes when turning the wheel you can hear the pads rubbing, this has nothing to do with our problem.

Video: Replacing the front wheel bearing of a VAZ 2106

Once you identify a problem, you need to quickly solve it. Replacing the front wheel bearing is quite a painstaking job, but with minimal skills you can do it yourself, especially since it does not require special equipment. To do all the work, you will need a set of keys, a hammer, a screwdriver with a strong handle or a chisel, attachments for knocking out clips - small-diameter steel rods.

↑ Installation of bearings

- We press the outer rings of the bearings in a vice, using the corresponding rings from old bearings.

- The old rings should be oriented with a smaller cone diameter inside the hub to facilitate their removal after pressing in the new rings.

- Using caution, you can press the inner races of the bearings with light blows of a hammer through the gasket.

- We put about 40 g of Litol-24 lubricant in the separator of the internal bearing and the internal cavity of the hub. We cover the new cuff with the same lubricant.

- Install the inner bearing into the hub.

- We install the spacer bushing.

Design of the unit being repaired

The VAZ 2107 hub consists of the following elements:

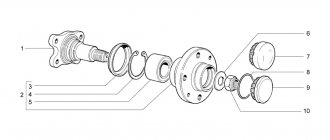

The diagram shows:

1 — steering fist; 2 — hub seal; 3 — remote ring of the front wheel hub oil seal; 4.5 — hub bearing; 6 — washer 2101; 7 — nut M18x1.5 left; 8 — hub cap.

All parts are located inside the hub housing.

12.14. Changing the gearbox oil

The frequency of oil changes is every 75,000 km or every 5 years.

Transmission housing capacity:

five-speed - 3.3 l; four-speed - 3.0 l.

The manufacturer recommends using oils of the following brands:

"REXOL-T" (80W-85; GL-4); "OMSKOIL TRANS P" (80W-85; GL-4/5); "VOLNEZ TM4" (80W-90; GL-4).

It is recommended to drain the oil immediately after a trip, while the gearbox is still warm.

Sources

- https://sabla.pp.ua/remont-kpp-21083/

- https://mobiauto.pp.ua/vaz-2108i-remont-korobki-peredach-kpp-mkpp-v-moskve/

- https://automn.ru/vaz-2108/vaz-35552-10.m_id-4604.html

Important Notes

A few points:

- When seating the clips using the impact method, it is necessary to carefully orient the plane of the spacer, avoiding accidental slipping;

- excessive application of the lubricant promises squeezing out the oil seal;

- Old bearing housings are suitable as a mandrel.

After adjusting the gap, you need to drive the car and listen to the bearing. If noise is noticeable or the wheel gets hot, you need to unscrew the nut, correct the play and tighten a new one.

Caliper

When considering the chassis of the VAZ “six”, you cannot ignore the brake caliper. This unit is mounted on the steering knuckle and holds the brake pads and brake wheel cylinders through appropriate holes, slots and grooves. There is a special hole in the caliper for the brake disc. Structurally, the product is made in the form of a monolithic steel part. When the piston of the working brake cylinder acts on the brake pad, the force is transmitted to the brake disc, which leads to the deceleration and stopping of the car. If the caliper is deformed, which is possible with a strong impact, the brake pads wear unevenly, which significantly reduces their service life.

The “six” caliper is a part without which full braking is impossible

The caliper may receive the following damage:

- appearance of cracks. Since the part is constantly exposed to loads, over time cracks appear on it due to metal fatigue. This indicates the need to replace the caliper, since it is unsuitable for restoration;

- formation of oxides on moving elements. The working cylinders gradually become covered with dirt and an oxide film, and the pistons begin to jam over time, which reduces braking efficiency. In this case, repair or replacement of the cylinders is required.

Rounded fist

An equally important element of the six's chassis is the steering knuckle. Force is transmitted to it from the steering linkage through the lever, resulting in the rotation of the wheels of the front axle. In addition, ball joints (upper and lower) are attached to the assembly through the corresponding eyes. On the reverse side of the steering knuckle there is an axis on which the hub with bearings is placed. The hub element is fixed to the axle with a nut. The left trunnion uses a nut with a right-hand thread, and the right one uses a left-hand thread. This was done in order to prevent the bearings from being tightened while moving and to avoid overheating and jamming.

Malfunctions

The resource of the steering knuckle is practically unlimited, if you do not take into account the quality of roads and neglect of adjusting the wheel bearings. Sometimes a product can travel 200 thousand km. The part is made of cast iron and can withstand heavy loads. However, if it fails, then the owners of Zhiguli cars often change it along with the bearings and hub

It is necessary to pay attention to the steering knuckle when the following symptoms appear:

- the car began to pull to the sides, and the problem is not eliminated by adjusting the wheel alignment;

- It was noticed that the wheels turned out at a smaller angle. The cause may be problems with both the steering knuckle and the ball joint;

- wheel break. This happens due to the breaking of the threaded part of the steering knuckle or the ball joint pin, which happens relatively often on Zhiguli cars;

- unadjustable play. If the wheel bearings were adjusted untimely or incorrectly, then in the places where they are installed, the steering knuckle axis will gradually wear out, which will lead to the appearance of play, which cannot be eliminated by adjustment.

Sometimes it happens that during car repairs a small crack is discovered on the steering knuckle. Some car enthusiasts advise fixing the problem by welding. However, it must be taken into account that safety directly depends on the condition of the steering knuckle. Therefore, such elements should not be repaired, but replaced with known good ones or new ones.

How to increase wheel turnout

Many owners of the VAZ 2106 and other “classics” are interested in the issue of increasing wheel turnout, since the model in question has a rather large turning radius, which is not always convenient. Those who are seriously involved in tuning their car simply install a set of suspension elements (levers, bipod) with changed parameters. However, such sets for the average owner of a VAZ “Six” may not be affordable, because for such pleasure you will have to pay about 6-8 thousand rubles. Therefore, other more affordable options are being considered, and they exist. You can increase the wheel inversion as follows:

- We place the car on the pit and dismantle the bipod installed on the inside of the hub.

- Since the bipods have different lengths, we cut the longer part in half, remove the part, and then weld it back together.

Spare parts sizes

List of suitable spare parts with nominal size:

| Manufacturer | Cat. number | Dimensions | price, rub. | |

| 1 | OberKraft | 103504 | 80*90*70 | 660 rub. |

| 2 | AVTOVAZ OJSC | 21010-3101800-86 | 700 rub. | |

| 3 | TD EPK LLC | 2101-185 | 720 rub. | |

| 4 | RUMELIA APS GROUP | ES737630 | 660 rub. | |

| 5 | PKF Niagara LLC | RG2101-3101800 | 330 rub. |

Installation of parts of other configurations is unacceptable by design.