Injectors for VAZ 2110–2112 cars

Cars of the “tenth” family are equipped with various injection engines, each of which is designed to work with a specific model of injectors. Despite the fact that they have their own “names,” motorists usually use a “folk” classification based on color and thickness. For example: black thin ones.

This simplification usually works, but does not fully guarantee the compatibility of the injector with the engine. To avoid having to contact the chip tuner once again to correct the firmware of the electronic injection control unit, check the part number before purchasing.

Table: compatibility of injectors and engines of VAZ 2110–2112 cars

| Engine | Volume (l) | Number of valves | Controller (ECU) | Firmware | Injectors | |

| Siemens | Bosch | |||||

| VAZ-2111 | 1,5 | 8 | M1.5.4 | January-5.1 | VAZ6238 (thick gray) | 0 280 150 996 (turquoise thick) |

| VAZ-2111 | 1,5 | 8 | M7.9.7 | January-7.2 | VAZ6393 (beige thick) | 0 280 158 502 (black thin) |

| VAZ-21114 | 1,6 | 8 | M7.9.7 | January-7.2 | VAZ20734 (orange thin) VAZ20734 (yellow thick) | 0 280 158 017 (black thin) |

| VAZ-2112 | 1,5 | 16 | M1.5.4 | January-5.1 | VAZ6238 (thick gray) | 0 280 150 996 (turquoise thick) |

| VAZ-21124 | 1,6 | 16 | M7.9.7 | January-7.2 | VAZ20735 (blue thin) VAZ20735 (pink thick) | 0 280 158 022 (black thin) |

conclusions

As practice shows, cleaning the injectors (nozzles) of the 16-valve VAZ-2112 engine should be done in a car workshop on a special stand. If after cleaning they do not function normally, they must be replaced. Also, at the first sign of injector malfunction, it is worth cleaning them to avoid carbon deposits and other engine malfunctions.

The injector is an important element of the fuel injection system. The nature of the vehicle's movement, engine power and response, and environmental parameters depend on the operation of the part. How to repair them and, if necessary, replace them on VAZ 2110-2112 cars?

Differences between injectors for eight and sixteen valve engines

Among some motorists there is an opinion that the injectors for the “ten” differ depending on the number of engine valves. Others believe that the determining factor is the volume of the cylinders.

Clogged injectors can cause the car to jerk when driving.

In reality, neither one nor the other is wrong. The parts must match the engine design, model and firmware of the electronic control unit.

When replacing, it is best to install the same ones that were installed previously. Otherwise, there may be difficulties with startup and operation in transient conditions. To eliminate the shortcomings, you will have to adjust the firmware, which is almost impossible in a garage environment.

In-cylinder fuel injection has been known since the very dawn of the automobile industry. In the early 1890s, the German Rudolf Diesel and the Englishman Herbert Ackroyd-Stewart secured the rights to their own designs for an internal combustion engine running on fuel oil.

Most common reasons

There are three main factors that can lead to unstable operation of the fuel injection system:

- Low quality fuel is a common problem in all post-Soviet countries.

- A long service life can equally be attributed to both advantages and disadvantages.

- Unprofessional repair work.

It should be noted that unqualified repairs are the most dangerous factor that can affect the normal operation of the injector.

In the absence of certain theoretical and practical knowledge, it is not recommended to try to repair or clean the injector yourself. It is best to entrust such work to professionals who are well aware of all the nuances and features of carrying out work of this kind. Unskilled cleaning of the injector can be harmful

. There can be a great many reasons for the malfunction of the injector, so in this article we will analyze only the most typical signs of injector malfunction, inherent in engines of various types, and give recommendations for eliminating them.

Replacing injectors for VAZ 2110–2112 cars

Failure of injectors causes interruptions in the supply of fuel to the cylinders and a violation of the proportions of the combustible mixture. These consequences are reflected in the vehicle's movement pattern, ignition operation, fuel consumption, idle speed stability and CO content in the exhaust.

Table: malfunctions of injectors of injection engines

| Malfunction | Manifestation of malfunction | Method of identification and accompanying symptoms of malfunction |

| clogging (coking) of the spray nozzle |

| inspection and testing of the removed injector |

| valve depressurization (nozzle leaks) |

| exceeding the CO standard by 1–1.5% for each faulty part |

| valve stuck (valve closed) | engine "troits" | lack of response from a running motor when the power supply to the injector is turned off |

| unstable valve sticking |

|

|

To replace injectors you will need the following tool:

- open-end wrenches for 17 and 13,

- hex key 5,

- socket wrenches 10 and 13,

- Phillips screwdriver.

To get to these parts, you must remove the fuel rail. The dismantling sequence for eight and sixteen-valve engines is different.

Types and symptoms of regulator malfunction

The types of RTD malfunctions are as follows. The valve does not hold - fuel begins to circulate freely throughout the fuel system, the pressure in which decreases because of this. As a result, the engine does not have enough fuel when the speed increases, and its power decreases; The pressure in the system should not change after stopping the engine, but since the valve is not able to hold it, when starting the engine, you have to work with the starter for a long time to create the required pressure.

A completely inoperative valve means fuel is not discharged into the tank, and because of this, the pressure in the system increases. As a result, the amount of fuel supplied to the combustion chambers through the injectors increases - there is overconsumption and incomplete combustion of gasoline.

Signs of a faulty RTD are the following engine operation:

- unstable;

- stalls at idle;

- insufficient pickup;

- cannot develop full power;

- the crankshaft rotates at idle speed with a reduced or increased frequency;

- dips and jerks while the machine is moving;

- difficult starting - not always;

- the content of CO and CH in the exhaust gases significantly exceeds the permissible standards;

- excessive consumption of gasoline.

Removing the fuel rail of an eight-valve VAZ-2111 engine

- Disconnect the battery from the car body.

- Disconnect the vacuum line from the fuel pressure regulator.

- Loosen the gasoline supply and drain fittings and release the pressure. Unscrew the fuel lines and note their position.

Loosen the gasoline supply and drain fittings and release the pressure. Unscrew the fuel lines

- Disconnect the rack electrical connector.

Disconnect the rack electrical connector

- Unscrew and remove the bracket securing the supply and drain pipes.

- Unscrew the rack fasteners.

- Pull the rail and remove the injectors from their seating areas. Remove the rack.

Engineer Jonas Hesselman managed to combine ideas... In 1925, he released the first direct gasoline injection engine in the history of transport. It was a kind of hybrid engine that ran on anything that burned: gasoline, kerosene, diesel fuel, oil could serve as fuel for it...

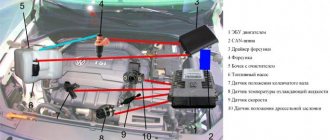

General diagram of the injector operation

- there is a so-called group of information sensors, which is carried out exclusively by data collection;

- all information goes to the controller, which is the analytical center of the injection system;

- depending on a number of factors, the controller sends an electrical pulse of a certain length directly to the nozzles themselves, which open for a strictly specified time period;

- The efficiency of the cylinders and, consequently, the engine itself depends on how much fuel and air are supplied from the injectors.

Note. A certain amount of air corresponds to a certain amount of fuel (if this ratio is violated, then the engine power will correspondingly decrease significantly).

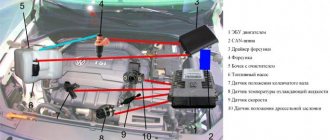

VAZ 2110 injector relay diagram

The price of an injector (see VAZ 2110: flushing the injector on your own) is a flexible concept and depends on a number of components. However, the cost of fixing an injector problem at a car service center is very significant. The DIY repair instructions allow you to fix the problem, but you need to have a good understanding of the injector circuit. Photos and videos - materials in this matter will become the most valuable practical assistant.

Dismantling the fuel rail of the VAZ-2112 engine

- Disconnect the battery.

- Remove the engine protective shield.

- Disconnect the high-voltage wires from the spark plugs.

- Loosen the air and crankcase hose clamps. Remove the air hose assembly

- Disconnect the crankcase primary circuit ventilation hose from the throttle body

- Loosen the fastening, remove the damper cable from the bracket

- Unscrew the throttle assembly fasteners. Remove the assembly from the studs along with the hoses, move it to the side and secure with improvised means. Disconnect the electro-pneumatic valve hose from the receiver.

- Disconnect the vacuum booster hose.

- Unscrew the receiver mounts.

- Loosen the intake manifold clamps.

- Remove the receiver, close the manifold holes with rag plugs.

Disconnect the crankcase ventilation hose from the cylinder head cover.

- Unscrew the fastener and remove the oil level indicator guide tube.

- Disconnect the fuel rail electrical connector.

- Unscrew the fittings, disconnect the fuel supply and drain hoses. Remember their position.

- Unscrew the fastening, remove the bracket for the fuel supply and drain pipes.

- Unscrew the fastening screws with a hexagon.

- Remove the fuel rail assembly.

Removing parts

The injectors can be removed and replaced after the fuel rail has been removed.

Compress the retaining spring and disconnect the electrical connector for each injector.

- Slide and remove the parts lock on the fuel rail.

- While rocking, pull out the nozzle. Remove any parts that require replacement.

Install new injectors, fuel rail and other dismantled parts in the reverse order.

Do not use used injector rubbers; install new ones, first lubricating them with engine oil.

If necessary, replace the fuel pipe O-rings.

Troubleshooting

After you remove the injectors, proceed to carefully inspect them. When the removal of the VAZ 2110 injectors is completed, you can see that one of them remains in the inner pipe of the engine. It will be necessary to replace its retainer and the rings responsible for the seal. In addition, injectors are also replaced when the rings lose the elasticity of their coating or when there are cracks.

Check how the injectors spray. Connect the harnesses and attach everything to the battery. Then place the nozzle in a glass container and turn on the starter to see if the gasoline is spraying correctly. Each nozzle must have at least 4 jets, in addition, the gasoline that is carried through them in containers must be at the same level. If the sprayer begins to leak, the nozzle needs to be replaced.

If it does not spray at all, you need to check whether the nozzle is receiving power. If it does not pass gasoline, disconnect the wires leading from the block and connect the battery directly with the ignition on. If it starts spraying gasoline, it means there is a problem in the electrical circuit. After the injectors have been replaced or cleaned, they will need to be reassembled, but before that, lubricate each ring with gasoline.

If the car has low-quality fasteners, they will also have to be replaced. To do this you will need to move them to the edge of the ramp. If you need to replace the fuel rail, unfasten all the wires and harnesses and install a new one, connecting all the parts in the reverse order. Good luck!

I didn’t really like being a pedestrian, walking from and to stops, waiting for buses... and all because there was no time to work on the car (defending a report on practice, consultation on state laws and the state authorities themselves)

. Today I finally started working on the car right after I arrived from the military registration and enlistment office. Yesterday evening after the state government, I stopped by the store and bought a carburetor cleaner and an injector repair kit.

Repair

Before removing the injectors from the dismantled rack, it is advisable to check their functionality. To check you will need:

- four identical containers,

- tester,

- wires.

Functionality check

- Connect the gasoline supply and drain hoses and the power connector to the rail with injectors.

- Place the rack over the measuring cups.

- Crank the engine with the starter.

- Evaluate the performance of the sprayers. The shape of the cloud should be approximately the same for all nozzles. The amount of fuel in the measuring containers should not differ much. Significant differences indicate contamination and changes in performance. Coked with resinous deposits and clogged, they require cleaning. A complete lack of fuel at the nozzle outlet indicates a valve malfunction and the need for replacement.

The shape of the cloud should be approximately the same for all nozzles

- Turn off the ignition. Disconnect the power connectors from the injectors.

- Measure the electrical resistance of the winding of each part. Its nominal value is 11–15 ohms. Deviations from the norm indicate the presence of hidden problems in the solenoid valve, which indirectly affect the shape of the torch and performance. It is advisable to replace such an injector.

- Turn on the ignition. Make sure the injector valves are tight. If a part is leaking, it should be replaced or at least try to wash it and check its functionality again.

- It is difficult to check the injector for unstable valve hanging, since this malfunction can occur quite rarely. To identify, connect the electrical connector of the injector with separate wires to the battery. Periodically turning the voltage on and off, watch the spray pattern. The shape and intensity of the torch of a working injector is the same every time; periodic changes occur when the valve does not open completely. If the background sometimes “accidentally” does not work, it must be replaced.

After the war, Germany received a ban on the development of injectors for aircraft engines. And engineers began adapting direct injection systems for passenger cars, discovering another important advantage compared to carburetors - efficiency.

Main symptoms

Lack of fuel mixture in the injector. Often, the presence of this symptom does not indicate a malfunction of the injector itself, but a failure of the fuel pump, or its incorrect installation after repair work.

In some cases, the reason may be a clogged fuel mixture inlet into the fuel pump. The fuel pump has failed.

Significant increase in fuel consumption. A fairly common phenomenon that indicates a clogged injector. Due to the small diameter of the injector nozzle, even slight contamination can significantly disrupt the mixture formation process, reducing the percentage of engine efficiency. This is explained by the fact that a clogged nozzle no longer forms a cone-shaped cloud of gasoline, which means that a significant amount of fuel begins to burn out in the exhaust manifold. The consequence of these processes is a deterioration in the dynamic characteristics of the vehicle and an increasing load on various electronic equipment of the car: coil, spark plugs, wiring, etc.

Idle speed sensor needs to be replaced

Unstable idle speed of the fuel injection system. This symptom can be the result of many malfunctions. The most likely cause is a malfunction of the idle air control valve or a clogged internal surface of the throttle pipe.

Problems starting the engine. If the vehicle engine does not start while the sounds of the fuel pump are heard, it becomes necessary to check whether the injector has a spark. For these purposes, experts advise using a spark gap.

It is not recommended to resort to checking the spark for a break, because Such actions can damage the ignition module and controller.

Trouble due to cylinder failure

Troit injector. In most cases, the culprit of this symptom is the presence of one or more inoperative cylinders. The breakdown can be eliminated by identifying non-working cylinders and then repairing them or replacing them with new parts.

Overflow of fuel mixture in the injector. This symptom also requires detailed diagnostics, which is best started by checking the sensor responsible for the throttle position.

Professional washing of the injector

The above signs of injector malfunction indicate the need for repair and maintenance work. You should not diagnose and clean the injector yourself if you are not 100% confident in your knowledge and experience. Specialized service stations are equipped with high-tech equipment, which, in addition to cleaning the injector nozzle, carries out its comprehensive diagnostics, showing the mechanical wear of the needle, the actual performance of the injector, etc.

If professional washing of the injector does not solve the problem of injection of the fuel mixture, then a reasonable solution would be to replace the injectors with new ones.

Replacing injectors

Replacement or flushing?

Some problems can be eliminated by cleaning and flushing. Others are “treated” only by replacement.

Table: problems with injectors

| Malfunction | Remedy |

| reduced performance | flushing, replacement if flushing fails |

| leakage | flushing, replacement if flushing fails |

| increased productivity | replacement |

| valve sticking | replacement |

| unstable valve sticking | flushing, replacement if flushing fails |

| overestimated or underestimated winding resistance | replacement |

In these cases, flushing is not a panacea. This method should be used taking into account the mileage and quality of service during operation.

During operation, the injector nozzles inevitably become coked and clogged with resinous deposits. The picture is aggravated by low-quality fuel, which can introduce additional pollutants.

For some time, fuel atomizers continue to operate without any visible changes, but sooner or later contaminants accumulate, changing the shape of the spray and reducing performance.

Injector life expectancy is limited even when using the cleanest fuel. Manufacturers recommend changing them every 100–120 thousand kilometers. Due to the fact that motorists use imperfect gasoline, and the one that can be bought at gas stations, the part has to be changed after 80-100 thousand km.

There is an opinion among motorists that “there is no need to interfere if everything works fine.” This opinion is justified, but only if the owner is ready to replace the nozzles with new ones approximately every 50 thousand kilometers.

The fact is that by getting rid of minor deposits as they accumulate, the owner extends the life of the consumable, since pollutants do not have time to cause irreparable damage.

Clogged injectors begin to interfere with normal operation after 30–50 thousand km.

Initially, negative processes manifest themselves only in increased fuel consumption. Owners do not always associate the increased “appetite” of the engine with injectors, since there are many reasons for this phenomenon.

In the range of 50–80 thousand km, pollution, having accumulated, can cause interruptions in engine operation, which is no longer undetectable. It becomes clear that “you have to get into the injectors,” but cleaning them at this stage may be useless. When a clogged part is used for a long time, the diameter of the nozzle often increases. Flushing will remove contaminants, but the original parameters will not be restored.

To extend the life of trouble-free operation and postpone replacement, you should regularly check the

pour injector cleaning fluid into the tank or use it in another way recommended by the manufacturer.

Motorists' opinions about the effectiveness and safety of injection chemicals are contradictory. Many people fear that flushing without removing it from the engine will clog the cylinders.

Indeed, if the car owner has not touched the injectors for a long time, it is impossible to do without removing the rack. The chemicals in the tank can cause harm instead of benefit. If you use cleaners regularly, without waiting for characteristic malfunctions to appear, there will be no harm to the engine from the chemicals.

Although injection chemistry has a beneficial effect on slightly dirty injectors, its use does not guarantee that the atomizers will comfortably “live” the entire period “allotted” to them by the manufacturer. You can unsuccessfully fill the tank with “left” gasoline at almost any gas station.

To minimize the accumulation of deposits, manufacturers recommend additional preventive flushing with special products every 30 thousand kilometers.

Table: advisability of flushing and replacement depending on mileage

| Mileage (thousand km) | Flushing | Replacement |

| up to 30 | preventive flushing with fuel additives every 3–5 thousand km | individual replacement of faulty parts |

| 30–80 | preventive flushing with a special agent every 30 thousand km | individual replacement |

| 80–120 | preventive flushing with a special agent every 30 thousand km | complete replacement of all injectors if at least one faulty one is detected |

Cleaning

There are two ways to clean fuel nozzles, each of which has its own nuances. Choose for yourself which one you like best or is more affordable, taking into account the available funds.

Spray to the rescue

| Cleaning method | Necessary materials | Features of the event |

| First way | You will need:

|

|

| Method two | You will need:

|

|

Easy way to clean

Both operations take approximately 2-3 hours, but cost several hundred rubles. This is ten times cheaper than replacement and about the same amount more affordable than service stations.

After cleaning the injectors, check their operation. If this does not work, you will have to change it.

Loading …

Flushing without removing from the engine

At the first sign of clogged injectors, repairs should not be put off for a long time, as delay only aggravates the situation. You can turn to professionals for help, but you can also wash it yourself.

To assemble a homemade device and wash them, you will need:

- flushing liquid - 1 l;

- plastic bottle with cap;

- fine fuel filter;

- rubber hose with a diameter of 12 mm - 1 m;

- clamp 12–14 mm - 2 pcs.;

- nipple assembly (fungus) - 2 pcs.;

- foot or electric pump with pressure gauge.

Washing sequence:

- Drill holes in the bottom and cap of the bottle and install nipples in them.

- Connect the bottle cap nipple and the fuel filter with a hose. Secure the connections with clamps.

- Start the engine, warm it up to 90–95 ° C.

- Turn off the engine. Relieve fuel pressure.

- Disconnect the gasoline supply hose from the injector rack. Instead, connect the filter outlet of a homemade flushing device to the fitting.

- Pour the rinsing liquid into the bottle. Screw on the lid.

- Connect the pump to the free nipple, bring the pressure inside the container to 3 kgf/cm².

- Start the engine with flushing fluid. Let it idle for 15 minutes. Maintain pressure in the container using a pump.

- Stop the engine, wait 15 minutes. Repeat the work and rest cycles until the flushing fluid runs out.

- After stopping the engine yourself, release excess pressure in the bottle using the nipple. Disconnect the flushing device. Connect the gasoline supply hose.

In a similar way, you can wash the fuel rail assembly removed from the engine without dismantling the injectors.

Cleaning the fuel pump mesh

We take the fuel pump out of the tank, remove the screen and wash it. Before installing the fuel pump, it would be a good idea to check it for leaks and the reliability of the connection of its tube (arrow in photo 5) to the fuel line.

%rtb-4%

You will certainly ask what to do if the supply line is clean, the pump is humming, and the pressure is still below normal. In this case, you need to change the pump itself - it has exhausted its service life! Or it may happen that the pump seems to be functioning normally, but there is no pressure in the rail! This can happen in winter if there is a lot of water at the bottom of the fuel tank. When the grid freezes, it interrupts the flow of fuel to it. What should I do? Lighting a fire under a gas tank, heating it with a blowtorch or some other source of fire - this should not be done under any circumstances. It is preferable to remove the fuel pump and clear it of ice. The second option is for those in no hurry: roll the car into a warm room and wait... Then it would be a good idea to drain the water from the fuel tank. It's a troublesome task, but a rewarding one.

Washing removed from the engine

To wash an injector removed from the engine, it is necessary to create increased pressure of the cleaning liquid at its inlet, and then periodically turn the solenoid valve on and off, simulating the operation of the car’s electronic control unit.

Increased pressure can be easily created by using carburetor cleaner in an aerosol can. In addition to this, you will need:

- DC voltage source 12 V,

- wires,

- non-latching button,

- terminals for connecting to the injector,

- disposable syringe 5 ml,

- cambric (plastic tube) for connecting the syringe and the spray can,

- container for collecting flushing liquid.

Washing procedure:

- Remove the plunger from the syringe. Connect the nozzle of the syringe and the nozzle of the aerosol can with a cambric. Secure the connection with wire or tape.

- Connect the nozzle to the power source via the button.

- Place the wide end of the syringe onto the inlet of the nozzle.

- Direct the outlet into a container to collect liquid.

- Press the aerosol can nozzle and fill the syringe with flushing fluid.

- Press the power button and open the nozzle.

- Repeat washing until you get an intense torch of an acceptable shape at the output.

- If necessary, flush the nozzle in the opposite direction in the same way, applying the flushing liquid not to the inlet, but to the outlet.

Replacing O-rings

To prevent fuel leakage, do not reuse the O-rings of the injector and injector body. They are replaced with new ones every time they are removed for any reason.

To remove the old ring, just pry it up with a screwdriver. When installing new ones, do not use hard tools; install the seals by hand. Before installing the injector, lubricate the rubber bands with engine oil.

An injection engine is not at all complicated, as owners of carburetor cars sometimes believe. Injectors are reliable parts that require only a little attention. Show it, and the engine will thank you.