Among the most popular cars in the domestic engineering industry, it is worth highlighting the VAZ 2110, or as it is also called “Ten”. This vehicle was produced in 1995 - 2007. The 8 valves of the VAZ 2110 were a kind of replacement for the usual carburetor. The main difference between the models is the method of supplying fuel to the fuel cylinders. In the injection machine, everything happened under pressure.

The VAZ 2110 has 8 valves and a more powerful engine. At the same time, fuel consumption is less. Car repair requires the use of additional equipment and painstaking work. Engine capacity 1.5 – 1.6 liters. How to correctly set the ignition on a VAZ 2110 injector with 8 valves? To do this, you need to know the technology of work and then all the actions will seem simple. This will be discussed further.

Setting timing marks on a 16-valve VAZ-2112 with your own hands

Car : VAZ-2112. Asks : Kostikov Vladimir Igorevich. The essence of the question : I can’t fix the timing marks, how can I set the marks on the timing belt?

I have a problem. When replacing the timing belt, the upper pulleys were not fixed, and now it is not clear how to align them. The marks on the pulleys do not “look” in exactly the same direction. Maybe it would be easier to tighten all the pulleys to the TDC position in cylinder 1? If we are talking about 16 valves, I am familiar with setting the marks on the VAZ-2112: I performed this operation on the timing belt 21124. Well, I have a 1.5 engine. Are there any differences?

Timing belt price

Separately, a timing belt on a VAZ 2112 costs about 1,000 rubles. However, all drive elements should be replaced at the same time. This will make it more clear what the shared resource is. The cost of a set, including a belt and 2 rollers (tensioner and support) is about 2500-3000 rubles.

At service stations they can charge you from 800 to 1200 rubles for replacing a kit.

To save money, you can replace the timing drive kit on a VAZ 2112 yourself, but first you need to choose the right spare parts. The table below shows several types of kits from trusted manufacturers, indicating catalog numbers.

About timing marks and their displacement — Lada 2111, 1.6 l., 2005 on DRIVE2

I have been looking for information on timing phases on a 124 internal combustion engine for a long time and came across this material quite by accident. In general terms, I understand what is being said here. But it would not be bad if someone thoroughly chewed on what exactly a change in one direction or another means in pulsations, the angle of inclination of the first tip, the transition through zero, and the value of the maximum vacuum rarefaction.

From my own experience, I can say that shifting the intake 1 tooth to the right adds elasticity. As well as the displacement of the intake together with the exhaust to the right. And shifting the exhaust to the left gives a noticeable jerk-kick (acceleration) somewhere around 3500 rpm.

Timing PHASES on VAZ 2112. The belt was specially rearranged by tooth, back and forth. Engine 21124 (1.6 16kl.) gears:

• ХХ = 840 rpm (engine is warm, measurement after turning off the fan, t = 97 degrees) • difference between DR and DPKV is 0.32 degrees • SOP for DR 14 degrees (real 14 degrees) Note: 1) the difference between DR and DPKV is calculated as follows: First, auto-adjustment is done according to DPKV, then a marker (1 or 2) is placed at the beginning of the ruler (i.e., the value of the marker displayed on the ruler will be 0). Next, auto-adjustment is done according to the DR and the value of the marker (on the ruler) set earlier at the beginning of the ruler is looked at. The displayed value will be considered the difference. 2) the difference between DPKV and DR is calculated as in point 1 only in reverse. First, auto-adjustment is done according to the DR, then according to the DPKV 3) Real UOZ - UOZ according to the scanner 4) As a result of all the experiments, the ECU did not produce a DF (phase sensor) error

Issue 0 tooth is normal; Intake 1 tooth back

Issue 0 tooth is normal; Intake 1 tooth back

Issue 0 tooth is normal; Intake 1 tooth forward

Issue 0 tooth is normal; Intake 1 tooth forward

Release 1 tooth forward; Intake 0 tooth normal

Release 1 tooth forward; Intake 0 tooth normal

Will a spark ignite a flame? Not always! — “Electrics” on DRIVE2

This modification will be useful in almost the entire line of VAZ injection engines, regardless of the type and composition of the ECM equipment and the ignition system in particular.

Just a word of caution - based on the results of comments and questions. ! ! ! Intervening and making changes to the electrical circuit of a car requires at least basic skills in electrical engineering and awareness of the actions being performed! ! ! If you feel that electrical circuits and car electrics are a little out of your profile, contact a more qualified person or an experienced auto electrician. This is in your own interests. And it will save you from unpredictable consequences.

Updates and additions are at the end of the article.

A detailed detailed analysis of changes in the ignition system after modification is described here: Part two.

Expanded results In order. Engine VAZ 21124. 1.6 liters, 16 valves. Individual ignition coils (or dual module with high-voltage wires). Everything is beautiful. And at first glance, it seems that everything is thought out, so it should work clearly and reliably. It turns out that this is far from true. This is a VAZ!

Customized ignition coils

Quite a lot has been written about ignition problems on this engine - about the choice of spark plugs, replacement and selection of individual ignition coils (hereinafter - IKZ).

So I came face to face with this problem.

The main manifestations are that the engine rotates unevenly at idle (speeds dance in the range of approximately 720-840 rpm), sluggish acceleration with twitching, increased consumption. In principle, most people understand that misfires are rare, but they do happen. The ECU doesn't see them directly. Last year, one coil clearly started to fail - the ECU saw it. I replaced it and it started to loosen up a bit. But still the engine was missing something. What a good spark! Here's more about this. From the versions: - replacing the spark plugs (the current NGK ones lasted only 7 tons km) with something more expensive from the “platinum, iridium” series, etc. - an expensive option. — changing the IKZ, and they are a little over 7 years old (the original ones are BOSHevsky, the mileage is 75 tkm) - it’s a little expensive (the cost of one IKZ is around 540 UAH ($22), and there are four of them) and there is no confidence that the problem will go away. — Mass air flow sensor, which is also not fun... — look into the ECU to check the serviceability of the keys, current-limiting resistors, etc. Acting at random or based on assumptions is not my method or my approach.

Reading the ECU showed: 1. Speed jumps 2. Injection time jumps, slightly 3. Reduction ratio jumps at idle (9-15 degrees) - a bit too much 4. Power supply, mass air flow sensor, TPS - everything is stable and beautiful.

5. ECU masses - everything is ideal (previous modifications and correct wiring were made) Verdict - unstable sparking.

The ICP parameters were measured - resistance of the primary winding, inductance, resistance of the secondary winding (taking into account the diode in the high-voltage circuit), checking for the absence of short circuits.

www.drive2.ru

Set the timing marks correctly - otherwise you will bend the valves!

The VAZ-21124 engine has a special feature: no matter how its pulleys are turned, it does not bend its valves. With the 21120 engine (16 v 1.5 l) such jokes will not work! If the pulley positions are not too far off, try putting on the belt and turning the mechanism to the “TDC 1 and 4” position. From now on, always use the following instructions:

- The crankshaft is set to the required position by checking the mark on the generator drive pulley (photo 1) or on the crankshaft pulley (photo 2);

Alternator drive pulley and crankshaft pulley

Exhaust and intake shaft pulley

In theory, on the VAZ-2112, marking is carried out the same way, no matter what engine we are talking about. Here are photos for engine 21120.

What it looks like in reality and in the instructions

Take the time to find the inspection window on the gearbox housing. There is another mark under the plug.

The last step is optional. And they do it so as not to redo all the work “from scratch.”

Updates for VAZ-21124

On a 1.6 engine, all actions are performed in the same way as described above. There is one exception - the generator drive pulley is aligned according to the mark on the casing (see photo).

Generator drive pulley, motor 21124

However, if this mark is not there, use the proven method: 20 teeth are counted from the DPKV body. Instead of the 21st there should be a “pass”.

The timing pulleys can be rotated as you like - the pistons will not touch the valves in any case. Compare what the pistons of two different engines look like and it will become clear what we are talking about.

Two different 16 valves

For those who don't understand anything

In theory, you can use an alternative configuration method. Let the camshaft pulley marks point straight down. Then the mark on the crankshaft pulley should face up (TDC 1 and 4).

If there is no fixing device, you can make it yourself. Even a puller for suspension springs will do (see photo).

Checking and adjusting the marks on the eight-valve injection valve

To adjust the ignition you will need the following tools:

- jack;

- wheel wrench;

- key (head) 10;

- key to 13;

- key to 17;

- key to 19;

- large slotted screwdriver;

- flashlight.

It is also advisable to involve an assistant.

- We install the car on a horizontally flat surface. We block the rear wheels.

- Using a wheel wrench, unscrew the bolts securing the right wheel and jack it up. Unscrew the bolts completely and remove the wheel.

- Open the hood, use a 10 mm socket to unscrew the three bolts securing the front protective cover of the timing drive. Let's take it off.

- Using a 13mm wrench, loosen the generator belt tensioner nut and remove the belt.

- Using a 19mm wrench, unscrew the nut securing the generator pulley. To do this, you will need an assistant, whose task is to hold the brake pedal in the cabin when fifth gear is engaged. When all this is done, you will have the opportunity to see all the ignition marks of the VAZ-2110.

- We rotate the front wheel so that the lug on the camshaft gear clearly coincides with the protrusion on the rear timing drive cover. When they are aligned, take a flashlight and look at the position of the mark on the crankshaft pulley. It should point to the test point located on the oil pump cover. If they coincide, without letting go of the flashlight, we move to the engine compartment and compare the position of the marks on the flywheel crown. When the ignition is set correctly, it should also be aligned with the mark on the gearbox housing. In this case, everything is in order with the valve timing. The ignition marks are in their places. If, although the marks on the camshaft and the rear cover coincide, the tide on the crankshaft gear does not coincide with the point on the oil pump cover, it is necessary to make an adjustment.

- Using a 17 key, unscrew the timing belt tensioner pulley. We remove the belt.

- Without touching the timing shaft gears, rotate the wheel until the mark on the crankshaft pulley coincides with the marked point.

- We insert a slotted screwdriver into the inspection window so as to immobilize the flywheel.

- Carefully, so as not to change the settings, put the belt on the camshaft gear and crankshaft pulley. We tighten the tensioner pulley and fix it. Check to see if the marks have gone astray. If necessary, repeat the procedure.

Injector types

The injector controls fuel injection and can also control the ignition. On all new injection machines, the ignition is set by a computer and regulated by filling in different firmware. But this was not always the case, and on older cars, the same Japanese from the 90s, the computer regulates only fuel injection, and the ignition timing is set using a distributor and is set in the same way as on old Lada models, and depending on the speed The ignition timing is adjusted using a more complex vacuum system than on carburetor Zhigulis. Sometimes, one tube breaks, and during operating mode the traction may disappear; you will have to look for and correct this defect.

ECU (brains) VAZ

The electronic engine control system detects failures associated with wire breaks, short circuits to each other or to ground. With poor contact quality in the connectors. And also with a malfunction of the sensors themselves. However, there are malfunctions in the power and ignition systems that have external signs that are noticed by the driver, but no fault codes are recorded in the memory of the electronic unit. Main symptoms of malfunctions:.

The electronic engine control system detects failures associated with wire breaks, short circuits to each other or to ground.

Ignition system sensors and marks

For the ignition system to operate correctly, the computer needs to read the correct information from the sensors. Subsequently, this information will be processed in accordance with the fuel maps hardwired into the injector.

The main signal comes from the crankshaft sensor. This sensor shows what position the crankshaft is in at a given time and, based on it, calculates at what moment it is necessary to inject fuel, and at what moment this same fuel should be ignited, depending on the engine speed, which is also determined by this sensor.

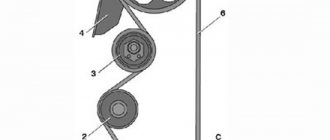

1 – crankshaft drive disc; 2 – crankshaft position sensor; 3 – angle of rotation of the crankshaft; 4 – output signal of the crankshaft position sensor

And this is what a typical signal received by a computer from the crankshaft sensor looks like. Pay attention to 270° - this is like the zero point, showing the computer that the engine has completed a revolution and a new cycle begins. This is achieved due to the absence of a tooth on the crankshaft drive sprocket.

Video

Perhaps adjusting the gap on the spark plugs will help solve the problem:

Or setting ignition marks:

Ignition timing is the most important parameter that determines the operation of the ignition system. This concept refers to the time during which the ignition system ignites the compressed working mixture with a spark discharge. It is defined as the position of the crankshaft of a car engine at the moment an impulse is applied to the spark plug in advance of the top dead center in degrees.

This is due to the fact that in order for the combustion of the working mixture in the cylinder to occur, it takes some time, because the speed of propagation of the flame front is approximately 20-30 m/s. If the mixture is ignited with the piston in the TDC position (i.e., top dead center), then its combustion will occur during the expansion stroke, as well as partially during the exhaust. As a result, effective pressure on the piston will not be provided. Therefore, the ignition timing, which is optimal, is selected so that the maximum pressure of the burnt gases occurs at top dead center.

The optimal ignition timing depends on

piston speed (i.e. engine speed), degree of lean/rich/mixture and, to some extent, the fractional composition of the fuel, which affects the combustion rate of the mixture. To automatically bring it to the optimal value, vacuum or centrifugal regulators are used, as well as an electronic control unit.

It should be noted that in gasoline engines under load conditions at optimal ignition angles, detonation often occurs, i.e. explosive combustion of the mixture. Accordingly, in order to prevent such a situation, the actual ignition timing must be slightly larger, i.e. to the threshold of detonation.

Relative to the optimal, both “late ignition” and “early ignition” lead to a drop in the power of a car engine and a decrease in efficiency due to a decrease in efficiency. In addition, this leads to excessive heating of the engine and excessive stress on its parts. It should be noted that “early ignition” also leads to strong detonation, this is especially true if the gas pedal is pressed too sharply.

Typically, the process of adjusting the ignition timing on vehicles consists of setting the earliest timing that does not yet lead to detonation during acceleration.

Replacement process

When does a belt need to be replaced? If you naively trust the manufacturer and hope that it will last the entire 100 thousand km, problems cannot be avoided. An experienced and competent driver always conducts a visual inspection, noticing replacement signals such as:

Note. It would also be a good idea to check the tensioner roller, which, if faulty, can cause enormous damage not only to the belt, but also to the main parts of the internal combustion engine.

Replacement is carried out using the following tools:

Belt removal

We begin the replacement, presented here in the form of step-by-step instructions:

Note. To easily unscrew the bolt securing the generator drive, you need to rest a pry bar against the crankshaft so that it does not turn. It is better to use the services of an assistant who will hold the crankshaft from turning while the bolt is unscrewed.

Installation

Before you begin installing a new timing belt, you should carefully prepare everything. First of all, this concerns cleaning the pulley from oil and dirt, as well as cleaning the tension roller.

Note. If the parts are heavily soiled, it is recommended to use a rag soaked in gasoline or white alcohol.

Note. When installing a new belt, pay attention to the tension of the drive branch.

Note. If after installing the belt you hear a characteristic noise in the camshaft, it is likely that there are problems with the tension roller bearing, which is also of great importance for internal combustion engine mechanisms.

To verify this, you should remove the rollers and begin to slowly rotate the bearing, making sure there is no play or jamming. In addition, you need to pay attention to traces of oil leaks. If the malfunctions described above are detected, then the roller itself needs to be replaced.

Belt faults

You can determine that the timing belt has become unusable by visually inspecting it. Its further use is not recommended if:

- there are cracks or cuts on the surface of the belt;

- delamination of its structure takes place;

- its teeth are damaged on the inside.

The listed malfunctions are a consequence of:

- operation beyond the recommended period;

- contact with the surface of active substances (oil, coolant, fuel, etc.);

- mechanical impact due to malfunction of the water pump, tension or support rollers;

- incorrect belt tension adjustment.

Failure to timely diagnose the condition of the belt can cause the rollers, pump, and generator to go out of working order if fragments of a broken timing belt get on its pulley or shaft.

But the main danger is that if it breaks, the pistons and valves begin to move randomly, which leads to their collision.

If this happens, the valves bend, damaging the top surface of the pistons, as well as the cylinder head and timing components.

In this case, it will not be possible to do without a major overhaul of the engine.

The timing belt on a VAZ 2112 should be changed at least every 50 thousand kilometers. In addition, its condition must be checked once a month. If the slightest damage is detected, the belt must be replaced.

Ignition control

Electronic ignition control

How to set the ignition angle? On systems with electronic ignition control systems, this can be done using computer diagnostics that connect to the Electronic Control Unit (ECU) or the “brains” of the car. And there you can see how the engine operates in real time - what signals are received from the sensors, what engine speed, fuel consumption, injection timing, ignition timing and other input and output data.

Basically, you don’t need to change anything during operation unless you change the firmware. That is, if the machine somehow began to work incorrectly, then most likely there could be several reasons:

Therefore, as such, the ignition is not set on injection machines, it is already built into the system, but it is worth checking whether the marks are set correctly.

Adjusting the ignition marks on the VAZ-2110 injector

When the engine is running, there are some phases that must work synchronously, the camshaft must coincide with the crankshaft, and the timing of fuel injection and ignition must correlate with them. Let's look at all this using the example of the VAZ-2110.

How to set the ignition on a VAZ 2110 injector

If the car doesn't start, it shoots, sneezes and everything goes wrong - the marks are not set somewhere and you need to sort it out.

On any car, the timing marks must be set perfectly, only then it will work normally. On the VAZ-2110, the crankshaft mark is located on the flywheel. You need to look through the inspection window on the gearbox housing; you can see the flywheel through it. It’s better to illuminate it with a flashlight, because it’s so easy to see.

Starter problems

Many VAZ 2110 owners had a situation where the starter did not turn after inserting and turning the key. They heard characteristic clicks. This indicates that the solenoid relay is not working.

What to do in this situation? Some will say that you need to determine where the ignition relay is located on the VAZ 2110

and solve the problem.

But the fact is that the “ten” does not have a starter relay, that is, an ignition relay as such. Instead, a solenoid relay works. It is supplied with a positive contact from the ignition switch. Mount this relay to the starter. It has a round shape and is approximately half the size of the starter itself.

How to set the ignition on a VAZ 2110

Among the most popular cars in the domestic engineering industry, it is worth highlighting the VAZ 2110, or as it is also called “Ten”. This vehicle was produced in 1995 - 2007. The 8 valves of the VAZ 2110 were a kind of replacement for the usual carburetor. The main difference between the models is the method of supplying fuel to the fuel cylinders. In the injection machine, everything happened under pressure.

The VAZ 2110 has 8 valves and a more powerful engine. At the same time, fuel consumption is less. Car repair requires the use of additional equipment and painstaking work. Engine capacity 1.5 – 1.6 liters. How to correctly set the ignition on a VAZ 2110 injector with 8 valves? To do this, you need to know the technology of work and then all the actions will seem simple. This will be discussed further.

How does a malfunction of the electronic control unit affect the operation of the injector?

The electronic control unit of the VAZ-2110 car consists of 3 high-precision components:

- ROM – devices for storing data (memory);

- PROM – a device for transmitting dynamic data;

- RAM is the regulating memory of the block.

Advice: the entire complex of presented elements will function only if there is voltage in the circuit. If there is no voltage in the wiring, then it is necessary to eliminate the faults in the fuse box on the VAZ-2110.

Thus, the electronic control unit acts as a kind of microprocessor that is responsible for the operation of the entire fuel supply system. If it breaks down, even an experienced motorist cannot fix it with his own hands. For repairs, contact your nearest car service center and wait for the result. If the unit does not have any malfunctions, the breakdown must be looked for among the elements of the injector and controller.

Tip: in the center of the dashboard on a VAZ-2110 car, a warning light called “CHECK ENGINE” may light up. In this case, the problem definitely does not lie in the control unit, the problem is related to malfunctions in the controller.

So, if you notice that your engine begins to constantly stall while driving and spends more fuel at the same distance as before, refer to the injector diagram for the VAZ-2110. Having a little understanding of each of the elements, you can quickly find the faulty element and replace it.

When to tension the timing belt

The timing belt of the VAZ-2112 and other VAZ models is tensioned in the following cases:

If the cause of the intervention is a broken or “slipping” belt, you must first ensure the integrity of the valves. A broken gas distribution mechanism (drive) leads to engine damage on 16-valve 1.5-liter power units. However, in cases of drive failure at high speeds, valves and CPGs are also destroyed on other engines.

They check the operation of the timing belt on the VAZ-2114 and other models equipped with 8-valve units by turning the camshaft manually. A working mechanism should turn with some effort. A faulty one, as a rule, cannot be affected.

During the procedure, it is necessary to check the compression in each of the cylinders. The easiest way to do this is to tightly cover the spark plug hole with paper. If there is pressure in the cylinder, the plug is knocked out of its seat at a certain stage of camshaft rotation. It is not recommended to carry out a similar test on 16-valve engines. The risk of damage to an initially good valve mechanism is too great. There are no grooves in the pistons of one and a half liter engines of this type. Therefore, valves that move down bend when they contact the piston surface.

How to remove the coolant temperature gauge sensor?

Before removing the coolant sensor, remove the air filter, it will interfere with its unscrewing. And first of all, drain the antifreeze (antifreeze). We will merge as follows:

- The engine must be cool.

- You will need spanners for 8, 13, 17.

- Prepare a container for the coolant to drain!

- We remove the engine protection, use a wrench to unscrew the radiator mounts

- We set the heater to maximum, then open the heater tap and the cap of the expansion tank.

- We place the container under the radiator and SLOWLY (if you do it quickly, you will flood the generator) unscrew the drain plug.

- Let him run away for about 10 minutes.

- Let's move on to the engine itself: similarly, we place the container under it and unscrew the plug (under the ignition module) on the cylinder block.

- Let it flow again for 10 minutes.

Before closing all the plugs, wipe the neck of each of the holes!

We remember where the coolant temperature sensor is located on the VAZ 2114, and begin to remove it:

- found it, removed the protective rubber layer;

- we look at the body, look for the markings (on one of its 6-sided parts), remember it, so that later we can put everything in accordance with the system;

- unscrew the meter with the twenty-first key;

- install a new one.

How to change the temperature sensor on a VAZ 2114:

- bought a new one;

- Using the same key number 21, we turn the new one into its rightful place;

- remember the markings;

- add a little heat sealant to the threads just to be sure;

- pour coolant (antifreeze or antifreeze) back into the heating system (radiator) and the engine cylinder block.

If the VAZ 2114 coolant temperature sensor still does not work, then carefully check the following:

- Its quality may be defective (take it to the store and ask for a replacement), therefore, always keep the receipt for any spare parts purchase. parts!

- There may be a coolant leak, or perhaps you have splashed the generator after all.

- You just might not have refilled the antifreeze.

- The sensor is not screwed in tightly enough

We checked everything, but the meter still does not show the temperature of the VAZ 2114 engine. Then you should contact a service center. As with any vehicle, everything in the fourteenth is interconnected. The system may fail for a related reason: for example, when you removed the DTOZH, you decided to remove the ignition module so as not to interfere. The decision is correct, however, removing the module and putting it in its place is also an art.

The second point related to the temperature sensor: coolant level. It may be unstable, it may be that the meter for this level (also a sensor) has failed, and so on. Keep an eye on the antifreeze and save your nerves and your coolant temperature meter.

The service will replace the sensor for you and guarantee a high-quality replacement with proper high-quality assembly of all parts in their places. Naturally, you can buy a coolant temperature sensor on the spot, and the cost of replacement work will be twice the cost of the device.

How much a VAZ 2114 coolant temperature sensor costs should be judged based on geographic location: from 80 to 400 rubles in any store that sells auto parts. The pleasure, in principle, is not expensive, but, given the fact of fairly frequent breakdowns (the car stopped being produced in 2013, breakdowns are a natural process), it is still expensive. Therefore, you should not bother with the service, you need to try to figure out the situation yourself. Moreover, now the Internet is saturated with all sorts of useful links, forums, photographs, diagrams and even videos on replacing one or another auto part.

Despite its importance, DTOZH is a relatively simple sensor; its task is to monitor the condition of the coolant (coolant) in the cylinder block jacket. The temperature sensor promptly reports changes in coolant temperature, after which it transmits this information to the electronic control unit (ECU).

DTOZH is often confused with DTUOZH (coolant temperature gauge sensor)

The difference is that the second displays information on the instrument panel in order to keep the motorist informed about what is happening in the engine, essentially about the coolant temperature. While the DTOZH works with the ECU, which, after receiving information about the high coolant temperature, turns on the fan.

DTOZH is often confused with DTUOZH (coolant temperature gauge sensor). The difference is that the second displays information on the instrument panel in order to keep the motorist informed about what is happening in the engine, essentially about the coolant temperature. While the DTOZH works with the ECU, which, after receiving information about the high coolant temperature, turns on the fan.

Setting the piston of the first cylinder to the TDC position of the compression stroke

Setting the piston of the first cylinder to the TDC position

When carrying out work related to removing the camshaft drive belt (timing), the valve timing may be disrupted; to prevent this from happening, the piston of the 1st cylinder is set to the TDC (top dead center) position of the compression stroke. If the valve timing is incorrect, the engine will not be stable or operate properly. Set TDC according to the mark on the camshaft pulley (when installing according to the marks on the flywheel or crankshaft pulley, the piston of either the 1st or 4th cylinder may be in this position). After this, be sure to make sure that the marks on the flywheel or on the crankshaft toothed pulley are aligned (if the generator drive pulley is removed). If the marks on the flywheel or crankshaft pulley do not match, then the valve timing is incorrect (the piston of the 1st cylinder is not installed at TDC). In this case, it is necessary to remove the camshaft drive belt and rotate the crankshaft until the marks align. Important! Rotate the crankshaft exclusively by the pulley mounting bolt (do not rotate the crankshaft by the camshaft pulley itself).

TIP Since it is inconvenient to turn the crankshaft using the bolt that attaches the pulley to it, you can do this in one of two ways

Features of ignition settings in a carburetor engine

Setting the ignition according to the marks on a carburetor engine is carried out in exactly the same way as on an eight-valve injection engine. The only difference is the need to manually adjust the ignition angle. In a service station environment, this is done using a strobe light and tachometer.

But you can also make adjustments “by eye”. All that is required for such an adjustment is a 10mm spanner. The algorithm is as follows:

- Raise the hood and use a wrench to loosen the three nuts holding the ignition distributor cap to the body.

- We scroll the lid so that the mark on it coincides with the “zero” mark on the housing scale.

- We start the engine and warm it up to operating temperature.

- Scroll the cap clockwise until the engine begins to produce the maximum number of revolutions. After that, turn it half a division to the left.

- We get behind the wheel and accelerate the car to 60-70 km/h in 4th gear. We press the gas pedal sharply down and listen to the engine. If there is persistent detonation (fingers knocking), we have too early ignition. We stop and turn the lid a little more counterclockwise. With the ignition angle set correctly, when we press on the gas, detonation should last no more than 2 seconds, after which the engine, having picked up speed, continues to operate normally.

- Having achieved the desired result, tighten the cover nuts.

How to evaluate the work already done

Accurate diagnosis is carried out using a computer. However, it is also possible to independently assess how correctly the circuits are functioning.

For the carburetor model VAZ 2110, marks are also set in order to regulate the ignition system.

If the ignition of the VAZ 2110 8-valve injector occurs early or, conversely, late, then the ergonomics of the entire engine deteriorates. Power also decreases. The engine is exposed to high temperatures and excessive loads. Among other things, detonation may occur. All this can lead to the VAZ 2110 losing ignition.

How the device works

Instead, an ignition module is used, consisting of high-energy control electronics and two coils. The advantage of the new system is that it does not require regular maintenance and maintenance, since there are no moving elements. Also, no special adjustment of the system is required. The reason lies in the presence of a controller.

is the one

responsible for setting up and adjusting.

Setting the ignition timing

Required only for carburetor models. For the work you will need one tool - a strobe light. It is sold in almost any auto store and has a reasonable price. It is also advisable to have a wrench so that you can unscrew the nut that secures the distributor.

When the ignition timing is correctly set, mark 1 on the flywheel should be between the middle division (notch) 2 and the previous division 3 of the scale. Otherwise, adjust the ignition timing.

To adjust the ignition timing on a VAZ 2110 you need to:

To understand the ignition adjustment process in more detail and clearly, it is recommended to watch the corresponding videos. To resolve the issue of how to set the ignition on a VAZ 2110 injector 8, you can additionally consult with experienced car owners.

A little about prices

We have already noted which switch and transistor are used when repairing the ignition module of a dozen. The first costs about 3 dollars, and for the second you will have to pay about 6 dollars.

Some craftsmen use a domestic analogue of the transistor - model KT848A. Of course, it costs less. But its problem is its lower quality and larger size, which somewhat complicates the repair process.

We recommend watching:

- Replacing high-voltage wires Kalina 8 valves

- After warming up the engine runs intermittently

- Zil 130 shoots into the carburetor reasons

- Expiration date of spark plugs

- Why doesn't the starter start?

- Why does the car jerk at high speeds?