As often happens, after the release of a new model, a lot of defects and “diseases” are found in it, which are, in fact, shortcomings and miscalculations of the engineers who worked on this car. Lada Vesta was no exception, and despite the fact that its appearance is largely due to the foreign automobile industry, it has characteristic sores that, according to tradition, we, car owners, have to correct.

In this article I want to talk about how to overcome the constantly tearing exhaust corrugation, and at the same time get rid of excessive engine vibration with just one small modification.

As it turned out, after the serial production of Vesta, the muffler corrugation fails very quickly, while the power unit itself simply “sausages” after several thousand kilometers. The reason for this anomaly was the engine mount, which was borrowed from a Frenchman named Logan. The support turned out to be either defective or simply weak; as a result, due to constant loads, it failed. This led to increased vibrations, which in turn loosened and destroyed the flexible element of the exhaust tract.

Most owners eliminated the consequence, that is, they replaced the corrugation, not realizing that the cause should be eliminated. And the solution to this issue actually lay on the surface, all that was needed was to replace the engine mount with a Lada Vesta, and not with the same “Loganov” one, but with a reinforced one, which runs longer and can easily withstand all the necessary loads. You can buy a ready-made reinforced Vesta engine mount (code: 112381035R or 8450031975 from Vesta Sport), or you can make one yourself quite quickly and easily. You will now find out how to do this.

Review of reinforced right engine mounts for Lada Vesta

One of the reasons for the appearance of extraneous knocks from the front right on the Lada Vesta family is a “tired” right engine mount.

To solve the problem, the engine mount is lubricated, modified, or replaced under warranty. There are cases where the engine mount was replaced four times in a short period of time. In such a situation, there is reason to think about installing an alternative, reinforced right engine mount. Are there any analogues? Vesta's standard right engine mount has article number 8450030109 and is offered at a price of 2,000 rubles. It is worth noting that it is used on VAZ engines. Lada Vesta with a CVT and a Renault-Nissan engine has a different original engine mount.

Currently, there are several analogues of this part.

- Reinforced cushions are installed without modifications in the standard mounting points.

- According to the manufacturer, reinforced supports are more reliable and durable, which eliminates the appearance of extraneous sounds over a long period of operation.

Examination

It is not difficult to assess the need to replace the engine mounts of the Lada Vesta and X-Ray. This requires looking under the hood and visually inspecting the cushions for damage - breaks in rubber components, cracks in metal, etc.

In general, if you experience the following symptoms, you should consider replacing:

- During a sharp start or when braking with the power unit, knocking noises are heard from under the hood;

- Vibrations are felt while the engine is running;

- The cabin fills with noise when driving.

The steps described below are relevant for two engines - VAZ 21129, as well as HR16, which were installed under the hood of the XRAY and Vesta models.

The sound of the engine mounts can be clearly heard in the video.

Hydromount from BMW

1. First version Stage 1

Engine mount 2495601 from BMW 3 (E46) was taken as a basis. The price is about 2800 rubles.

The peculiarity of the support is that it is hydraulic (the design uses not only metal and rubber, but also oil).

a) at idle, soft support: b) in motion, hard support: 1 – lower (expansion) chamber; 2 – throttling channel; 3 – upper (working) chamber; 4 – movable membrane; 5 – hydraulic support housing; 6 – damping fluid channel.

The difference between a hydraulic and standard support is demonstrated in the video:

The weight of the pillow is 1.76 kg.

5300 rub. (the LEMFORDER 2495601 support itself costs about 2800 rubles).

2. Modified version of Stage 2.

The hydraulic mount itself is essentially the same thing with the addition of a guitar of the same manufacturer. Due to this, we managed to save some money, so the price increased only for the silent block itself.

Silent block from jikiu be21058, there are no analogues.

DIY reinforced lower engine mount for Lada Vesta

- So we buy a new pillow, a regular one without an amplifier.

- We dismantle the old pillow; to do this, you need to unscrew the two fastening bolts with an “18” key.

- Next, we cut out the plate of the required configuration (stainless steel pipe, diameter 51 mm, thickness 2.5 mm, see photo), for further installation in the stock support. Some people make two plates on the sides; in this case, one solid one was used.

- Now, using a press and lubricant, we press the plate into place.

- Some simply bend the edges of the seat, flaring it along with the plate, but, in my opinion, grabbing the fragment by welding will be much more practical and effective.

- We carefully grab the plate with several welding points on both sides for greater reliability.

Hydromount from BMW

1. First version Stage 1

Engine mount 2495601 from BMW 3 (E46) was taken as a basis. The price is about 2800 rubles.

The peculiarity of the support is that it is hydraulic (the design uses not only metal and rubber, but also oil).

a) at idle, soft support: b) in motion, hard support: 1 – lower (expansion) chamber; 2 – throttling channel; 3 – upper (working) chamber; 4 – movable membrane; 5 – hydraulic support housing; 6 – damping fluid channel.

The difference between a hydraulic and standard support is demonstrated in the video:

The weight of the pillow is 1.76 kg.

5300 rub. (the LEMFORDER 2495601 support itself costs about 2800 rubles).

2. Modified version of Stage 2.

The hydraulic mount itself is essentially the same thing with the addition of a guitar of the same manufacturer. Due to this, we managed to save some money, so the price increased only for the silent block itself.

Silent block from jikiu be21058, there are no analogues.

: withdrawn from sale.

Replacing the engine mount of the Lada Vesta and X-Ray begins with dismantling the mudguard of the power unit, after which the engine must be jacked up on the right side. The support itself is fixed to the spar using 3 bolts.

For dismantling you will need:

- Using a 16mm wrench, unscrew the 2 bolts that secure the cushion to the body.

- Remove the 2 bolts that secure the cushion to the power unit bracket. A TORX E12 bit is used for this.

When everything is done, you can remove the support.

Installation proceeds in the reverse order, and the bolts should be tightened in the range from 53 Nm to 71 Nm.

As for the right motor mount of the HR16 series, it has a slightly different layout.

How to change airbags on a Vesta car

In order to correctly adjust the engine mount, it is not at all necessary to go to an official dealer - contacting him will still result in the installation of exactly the same part.

Replacing the left engine mount

Before work, prepare and “clear” your way to the part: remove the battery, battery shelf, air filter mount and crankcase protection from under the hood; all components will have to be put aside and then reinstalled. The Lada Vesta cushion itself is attached to the side member on the body with four bolts, and to the gearbox bracket with two bolts. In order not to worry about the reliability of the structure, make sure for yourself that this bracket is attached to the gearbox housing with three bolts.

The replacement procedure is as follows:

- Jack up the gearbox - this will reduce the load on the cushion, because the jack will “take” it.

- Using keys 16 and 18, unscrew all the bolts that are responsible for fastening the pillow. When retightening the mounting bolts to the side member, stop at a torque of 53-71 Nm.

- As for the mounting bolts to the bracket, their tightening torque is 90-120 Nm.

- Remove the right engine mount.

- Place the new part in place of the old one and tighten the bolts until you are sure that the structure is stable.

Replacing the right engine mount

Depending on the engine model: HR16 or 21129, the design of the right airbag of the Lada Vesta is different. In the VAZ 21129 engine, the right support is located next to the spar, to which it is attached with two bolts, and the engine itself, to which it is attached with three bolts.

The HR16 engine has a slightly different design, and the part can be found next to the fuel pipe and the gasoline vapor recovery system pipe. Three bolts secure its body to the motor, two more hold the bracket. This power unit support in the Lada Vesta is located on the right.

To replace, unscrew all the fastening bolts (depending on what kind of “engine” is in your car) with a 16mm wrench and a TORX E12 wrench and remove the pillow itself.

When you assemble the structure, tighten the bolts to a force of 53-71 Nm.

Replacing the rear additional engine mount

This part is installed below, on the rear side of the motor. The mounts are different on the two types of motors. On the 21129 engine of the Lada Vesta, it is “tied” into a large network of fasteners. So, on one side it is held in place by a bracket that is firmly supported by two bolts. On the other hand, it is attached to the subframe with a bolt and nut. On the HR16 engine, the fastening is simpler: on one side, one bolt secures the part to the subframe, on the other, two bolts secure it to the gearbox.

Manufacturers and prices of analogues

The cushions for Lada Vesta engines are considered by owners to be not particularly reliable and are even being modified to increase the effect of vibration absorption.

The TuningProsto studio is developing improved spare parts from AvtoVAZ, including a recent development - an engine mount. Their price will be on average 3,000 rubles, orders are still being accepted. The tests were successful, and on a car dealer's car intended for a test drive - the car is used very often.

Otherwise, there are no special attempts to create analogues, because the “craftsmen” have already drawn the attention of Vest owners to two modification options:

- Came from Renault owners. It is necessary to create for each problematic pillow a metal plate 80 mm long, 38 mm wide and two grooves on the sides measuring 23 mm wide and 38 mm deep. The funny thing is that the X-Ray, which is in many ways similar to the Vesta, has the same engine (21129), but there are no problems with the upper right support - it’s just different.

- If the part itself is still intact, it can be lubricated with silicone grease where the rubber hits the metal body.

Problem

As sad as it is to realize, West owners are not spared this problem either. Many owners notice knocking noises under the hood of the Lada Vesta, and they come from the right side.

As a rule, you don’t have to search for long, since the situation is well known. It appears on sedans that were equipped with engine mounts from the VAZ 21129. As a result, a whole cacophony of sounds began to be heard from the engine compartment, including knocks, clicks, squeaks, etc. Moreover, these sounds are so loud that they can be heard even in the cabin.

The knock from the support is quite loud

And the best confirmation of this is numerous videos in which owners of the domestic model demonstrate trouble.

And in this video you can hear knocks directly inside the car.

In addition, some owners began to “dig deeper” and found out that a similar situation occurs not only on Vesta, but also on other models of the Renault-Nissan Alliance. In particular, on the Nissan Qashqai. This is also confirmed in the video.

As for the Lada X-Ray, the hatchback has not noticed such a problem, even though its engines are the same as those on the sedan. The whole point is that X-Ray is equipped with different supports for the power unit.

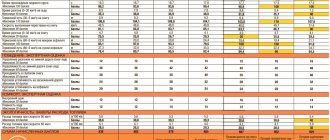

Standard support left, right, rear – article number and price

The entire engine support system, called the suspension of the Lada Vesta car, consists of 14 parts, for each of which it is worth giving brief information:

- Right engine mount assembly. Article: 8450030109. Price: from 1800 rubles.

- Engine mounting rod with cushion and silent block assembly. Catalog number: 112381035R. Cost: from 700 rubles.

- Rear engine mount bracket. Article: 8450006293. Price: from 3,900 rubles.

- Reinforcement bracket for rear engine mount. Article: 8450030214. Price: from 70 rubles.

- Left engine mount cushion assembly. Article number: 8450006299. Cost: from 1000 rubles.

- Left rear eye for lifting the engine. Serial number: 8450008699. Price: from 600 rubles.

- Bolt M10-1.5-35 10-9 SA3GS. Article: 7703602240. Cost: from 300 rubles.

- Nut M10x1.25. Article: 8450001014. Cost: from 30 rubles.

- Lower right engine mount bolt. Catalog number: 8450007980. Cost: from 60 rubles.

- Upper right engine mount bolt. Catalog number: 8450008999. Cost: from 70 rubles.

- Bolt M12-1.75-90 10-9 SA3GS (for bracket amplifier). Article: 7703602269. Price: from 600 rubles.

- Hex nut with flange M12x175. Article: 7703033210. Price: from 350 rubles.

- Rear engine mount bracket mounting bolt. Catalog number: 8450007985 (the lower bolt is numbered 8450007986). Cost: from 300 rubles.

- Bolt M10X1, 25X53 TORX E Article: 8450008989. Price: from 30 rubles.

- An additional engine mount for the Lada Vesta is sold under number 8450031975 and costs from 1,400 rubles.

Left pillow

The left engine mount of Lada Vesta and X-Ray is fixed to the body with 4 bolts. Also, the cushion is attached to the gearbox bracket with 2 bolts. In turn, the bracket is fixed to the gearbox housing using 3 bolts.

Replacing the part is complicated by the fact that access to it is blocked by several components at once - the crankcase protection, the filter (air) mount, and the battery shelf. Therefore, to get to the support, all this will have to be dismantled.

First you need to unload the cushion, for which you slightly raise the gearbox using a jack.

Next, using a 16mm wrench, unscrew the 4 bolts that secure the left engine mount to the body.

Then, using an 18mm wrench, you need to unscrew 2 more bolts that secure the cushion to the transmission bracket. Once this is done, the part can be removed.

Assembly is carried out in reverse order.

Replacing engine mounts for VAZ 21129 and HR16 (Lada Vesta and XRAY)

_x000D_

The power unit (motor with gearbox) is suspended on supports, which are also called engine mounts. Strong vibrations transmitted from the engine to the body indicate wear on these rubber parts. To prevent this negative effect from occurring, it is recommended to replace the engine mounts as they wear out.

This manual covers the replacement of VAZ 21129 and HR16 engine mounts installed on the Lada Vesta and XRAY models.

Rear cushion

This support is located at the bottom of the rear side of the motor. It is designed to reduce engine vibrations, as well as suppress knocking and dampen vibrations.

To dismantle it, you will first have to remove the protection of the power unit. When this is done, you need to unscrew the nut with an 18mm wrench while holding the bolt so that it does not turn.

Next, using the same 17mm wrench, unscrew the bolt marked in Figure No. 1, and then loosen the bolt marked No. 2. All that remains is to remove the bolt and remove the support.

When tightening, the prescribed torque is from 90 Nm to 120 Nm.

As you can see, replacing the Lada Vesta and X-Ray engine mounts yourself is quite possible and does not require a large number of tools.