As you know, for the VAZ-2114 engine to function normally, there must be normal compression in the cylinders. But not all motorists understand how to measure it and what should be the norm. This article will talk about the compression rate in the engine cylinders, as well as the reasons for the increase in the indicator and the measurement process.

Video about measuring compression on a VAZ-2114 with your own hands:

The video will tell you how to measure compression in a car.

Correct compression (norms) for VAZ-2114

The process of measuring compression in engines

According to the regulatory and technical documentation, a limit value of compression in the cylinders of the VAZ-2114 engine has been established. Thus, an increase or decrease in the indicator is not considered normal, since excessive compression of the air-fuel mixture in the engine can lead to not very good consequences.

Also, it is worth noting that the compression in all cylinders should be relatively equal. Different indicators are not the norm and these are the first signs of a major engine overhaul.

Normal compression in the engine cylinder

As practice and many years of experience of motorists show, the compression in the cylinders should be 14 bar, but the lower limit should not fall below 11 bar .

When measuring, the difference in compression between the cylinders should not exceed 1 bar .

Example of a bad and normal compress

Let's give a clear example: 12-13-12-13 is normal compression for the engine, but 12-11-12-8 is not normal and it is believed that the engine needs diagnostics and major repairs.

Reasons for increasing compression

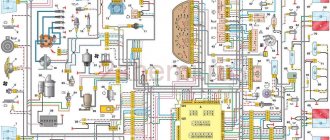

Compression gauge for replacing compression

It becomes clear that a decrease in compression in the engine is associated with wear of key elements, such as pistons and compression rings, main and connecting rod bearings, as well as valves. But what are the reasons for the increased compression?

So, let's look at the main ones:

- When performing repair operations related to the gas distribution mechanism, an error was made in the adjustment work , which changed the order of operation of the unit, and, accordingly, the compression in the cylinders.

- Heat on the valves , as well as the accumulation of carbon deposits on the cylinder walls and throttle assembly, leads to an increase in the compression ratio due to a decrease in space in the nodes.

- Also, the reasons for increased compression in the cylinders include engine overheating.

- The last reason for increased compression is the “occlusion” of the valve stem seals. The malfunction is diagnosed quite simply - the spark plugs are unscrewed and the oil wells are examined. An oil film indicates that there is an excess of oil and the need to replace the valve seals.

Do-it-yourself compression test

Compression in the cylinders must be measured using a special device - a compression meter. There are many types of them, but threaded ones are considered the best and most accurate.

- So, to measure the compression in the cylinder, you need to unscrew the spark plug and screw in the compression gauge fitting.

- Then, turn the ignition key until the engine begins to turn the crankshaft.

- The engine should start and the car enthusiast adds gas so that the engine runs a little.

- So, the compression meter measures the most accurate value.

The compression should not be lower than 11 bar, otherwise it is necessary to understand the causes of the malfunction.

We carry out checks for an 8 valve car

So, the procedure for checking the motor yourself is not particularly difficult. Having the necessary skills and a device with which you can measure pressure, the procedure can be carried out independently. Naturally, for this you will have to follow certain requirements, which are listed below. If you know what the compression should be in the internal combustion engine, then you can start working.

Step by step instructions

The first thing you will need to measure the pressure level in the engine is a device with which you will do this. How can we measure this coefficient? The device for this is called a “compressometer”. Such a device can be of several types:

- universal device;

- threaded;

- flexible;

- clamping

This is what the pressure measuring device looks like disassembled

You will need to find such a device. Also, in this matter you will need the help of a friend, since you will have to simultaneously perform some actions both inside the cabin and in the engine compartment. In addition to the compression gauge, prepare a wrench for removing the spark plugs. Please note that it is better not to perform any work if the battery is not working. Therefore, fully charge your battery. So, let's start checking:

- First, get behind the wheel and start the engine. Let it idle and warm up to 90 degrees, that is, to operating temperature.

- After this, open the hood and take the key to remove the spark plugs. You need to remove the high-voltage wires, and then dismantle all the spark plugs. The wires fit to the spark plugs, you just need to pull them out.

- Now remove the ECU fuse to avoid possible damage to the device.

- When the spark plug is dismantled, you need to install your device in its hole to check the pressure level. Do this carefully so as not to damage the threads.

- Now you will need a friend's help. Ask him to sit in the driver's seat. The assistant must press the gas pedal all the way so that the throttle valve can open completely.

- Then turn on the starter and turn the crank pulley with it. This is done until the readings on the compression gauge stop increasing. As a rule, this takes no more than 10 seconds. In this case, the crank pulley must rotate, and its rotation speed should not exceed 100 rpm.

- Now you can read the received readings. Better write them down. Remember what the compression should be and compare these readings with the received ones. Once the readings are recorded, the device's needle can be set to zero.

- This procedure should be repeated for each cylinder of the VAZ 2114 8 valve engine.

As you understand, there is nothing particularly difficult in this procedure. You just need to carry out all the measuring steps correctly and you will get the most accurate results.

conclusions

It was found that normal compression for a VAZ-2114 engine is 11-14 bar . An increase or decrease in this indicator, as well as a gap of more than 1 bar between the cylinders, is not considered normal and is subject to diagnosis. Engine compression is measured using a compression gauge.

There are several inaccuracies. Firstly, compression is traditionally measured with the engine not running at the starting speed generated by the starter! This is important: the pressure at the end of the compression stroke depends on the crankshaft speed, so if the engine is running, the compression will be much higher than the specified range - up to several times! Secondly, compression is measured on a warm engine (although there are some “former” ones who measure it on a cold engine, but the result is no more than a “funny letter”!). Third, the throttle must be fully open. Otherwise, the required amount of air will not be supplied, so the readings will be underestimated (there is nothing to compress!). On an injection engine, when the throttle valve is fully opened, the fuel supply and sparking stop (so-called cylinder purging). So there is no need to additionally turn off the ignition system (unlike carburetor engines). Fourthly, not only the absolute value of the pressure itself is important, but also how quickly it builds up. This indicator characterizes the condition no less accurately than the pressure itself. Ideally, a fixed value should be achieved in 2-3 “pumps”. And fifthly, the compression level is also affected by the condition of the starter and the flywheel ring gear: if the teeth are worn out and jammed, the compression value will also be underestimated. In general, for a more accurate assessment of the condition, the leak method is now much more often used.

Signs of low compression and how to measure it on a VAZ engine

Compression on a VAZ 2114 should be measured every 30 thousand kilometers. This is usually done in conjunction with adjusting the valves. However, signs of low compression may not only appear with a routine check. As you use your car, signs of poor compression are easy to spot; you just need to keep a close eye on your engine. These are phenomena such as:

- ICE strength drops sharply;

- the engine fires, this can happen when low compression occurs in one cylinder;

- significantly increases oil and gasoline consumption.

Why is verification needed?

The compression of the VAZ 2114 8 valve engine indicates the working condition of the engine. This indicator determines the engine power and its service life. The process of measuring the compression of a VAZ 2114 8-valve engine should be carried out at least every 20-30 thousand kilometers. In addition, this should be done before purchasing a car.

VAZ 2114 car with 8 valve engine

WHAT THE COMPRESSION SHOULD NOT BE IN AN ENGINE

At first glance, it may seem that the higher the compression parameters of the air-combustible mixture, the better. But actually it is not. Compression has an upper threshold that cannot be crossed, as this will lead to overheating of the engine, and, as a result, deposits of carbon deposits, excessive load on the pistons and rings, as a result of which engine parts may fail.

Low pressure in the engine leads to excessive consumption of fuel and oil. It is not permissible that in individual cylinders it differs sharply from neighboring ones. Different compression in the cylinders indicates serious problems in the engine - wear and defects that have appeared that require replacement or repair of parts.

Thus, bad compression is:

All of these signs of poor compression are a sign that the heart of the car needs repair.

CORRECT COMPRESSION

How much compression should be in the engine for its long-term and trouble-free operation? Long-term practice of operating cars shows that ideally it should be 14 barrels in each cylinder. But a reduction to 11 barrels is allowed, provided that the difference in compression in the cylinders should be no more than 1 barrel. For example, a compression pattern of 11-12-11-12 is considered acceptable, but if the pressure in different cylinders is 11-12-11-9, or another combination of indicators that differs from normal, then the engine already needs repair.

What compression should be on a VAZ 2114 8 valve also depends on how long and under what conditions the car is operated. Ideal pressure, as a rule, occurs with a new engine, or one that has just come out of a major overhaul. During vehicle operation, compression may drop by 1-2 barrels. And this will also be within the normal range.

Handle the compressor correctly

Before you begin, you need to study the theory of how to use the device correctly and pay attention to the following:

- Before operation, the engine must be warmed up to a temperature no higher than 40-60 degrees Celsius. After this, you need to turn off the fuel supply.

- The battery must be well charged, the charge should be from 12 to 14 Volts.

- Air humidity should be low, so work can be carried out either outside in dry weather or in a heated, dry room with normal humidity.

- Before measuring, the spark plugs must be removed from all cylinders. The ignition must be turned off.

- Please note that compressors are produced differently and may not fit your engine model; this must be clarified before purchasing the device. The fact is that conventional measuring instruments have a short tip, and they are not suitable for 16-valve units.

- Measure compression with a pressure gauge twice. In one case the throttle valve must be fully open, in the other it must be closed. The difference needs to be compared. Ideally, the same compression will be detected in the engine cylinders; the norm is not observed if in one case the indicator is sharply higher, since this means that the engine needs repair.

- It is worth noting that a small error between different cylinders is acceptable, this is due to their uneven wear, but the difference should not be too large.

If you notice that your engine is running worse, then it may be time to check the engine compression level. What should be the compression of VAZ 2114 8 valves? How can I check it? We will tell our readers about this in this article.

REASONS FOR INCREASED COMPRESSION IN THE ENGINE

Let's look at the main reasons:

- Incorrect adjustment of the timing belt leads not only to increased compression, but also to decreased compression, depending on the direction of regulation.

- The appearance of scale on the valves, which appears due to the use of low-quality gasoline, oil or other automotive chemicals. Carbon deposits on the throttle assemblies and in the combustion chamber also appear due to engine overheating. Thus, overheating of the internal combustion engine is not only a consequence, but also a cause of high pressure of the air-combustible mixture. The operating temperature of the VAZ 2114 8 valve engine should not exceed 85-90 o C.

- High compression can be caused by stuck oil seals. This reason is not difficult to detect. You just need to unscrew the spark plugs and inspect the cylinders. The appearance of an oil film on their walls will indicate an excess of oil in them, and the need to change the caps.

Compression is also affected by the level of oil pressure in the engine. If it is too high, then this leads to increased pressure of the air-combustible mixture.

Low pressure occurs if the rings are worn out or the valves are burnt out. The operating temperature of the engine also affects. If it is below normal, this will also affect the pressure of the air-combustible mixture.

The reasons for the lack of compression in the engine lie in improper operation and untimely preventive repairs. Sometimes air breaks through from several sides at once - for example, through valves, and at the same time through pistons with rings. Then the pressure disappears completely. It's simply not acceptable to let the car get into this state.

Abnormal indicators

As you probably could have guessed, this is when in one of the four cylinders the pressure is significantly different from the others, for example in one it is 5.0, and in the others it is 9.5 atm. YES and the engine will not work stably. There are abnormal indicators in two and even three or four “pots”. But this already means that your engine is almost dead and needs to be overhauled!

So why does this happen - when in one the pressure is much less than in the others? There may be several reasons for this, all from my experience, but you almost always need to remove the cylinder head:

1) The gasket is broken . This happens very often when the gasket between the block and the block head breaks - we just replace it.

2) The head is not tightened . This is a continuation of the first reason - if the head is not tightened correctly, the gasket can also leak pressure.

These are the simplest reasons, but they are the most common - for example, this often happened on my new purchased VAZs, in particular on a VAZ 2114 and a friend on a VAZ 2110. So, first of all, we go there, on new "our brands" - the problem This will be 80%. Then there are more complicated problems.

1) O-rings leak . This happens due to wear and tear, or because they are broken. However, if the pressure has dropped in one of the cylinders, then it is most likely broken. The repair is complicated, you need to disassemble the block itself to remove the pistons.

2) The rings are coked . I decided to put it in a separate section - low-quality motor oil can cause the rings to become coked.

The oil simply burns at the points of contact and seals the rings in one place - although this is not correct, the rings do not move along their grooves, and only one side is machined, which leads to rapid wear - although in this way the pressure will drop in all 4 cylinders. Because oil lubricates all 4 pieces.

3) Wear of the block wall . This is rare - but it does happen, that is, the ring has nothing to do with it, but it is the walls that they rub against that suffer. Most likely, this is low-quality material.

4) Engine overheating . When overheated, the tightness of the rings and walls of the block is lost, they begin to leak both pressure and engine oil. An indirect sign is blue smoke from the exhaust pipe during operation.

5) Burnt out - the piston itself broke . In such cases, compression may simply drop to “zero”.

Sometimes the piston itself burns out, it can be a small “burnout” on the side, or a very large one – for example, in the middle. It also happens that the piston breaks, for example from meeting a valve when the timing belt breaks - again we lose atmosphere.

6) Valves . There are many reasons for this. This is also an incorrect adjustment. And it happens that a valve burns out - only one burns, so the compression will vary in exactly one cylinder. It can also break if the timing belt breaks.

These are the main reasons why the values will differ in exactly one pot out of all four.

PREPARATION FOR MEASUREMENTS

Engine compression is measured with a fully charged battery. After charging and installing the power source in place, check the starter. It shouldn't create any problems either. Then warm up the engine. Its temperature during measurements should be 70-90 O C.

It is necessary to unscrew all spark plugs from all holes. Also unscrew the fuel hose to stop the fuel supply. Prepare the compression gauge for use.

Compressometer

Repair

As I wrote above, it’s really difficult to make repairs yourself. Unless, of course, you have a blown gasket, it’s possible to repair it, but again, it’s not so easy. How to replace a short video.

Diagnostics are carried out with the cylinder head removed - here the malfunction can be determined 100%. You are unlikely to do it yourself; contact specialists at a service station, or people who understand.

I think my article was useful to you - read our AUTOBLOG.

(

27 votes, average: 4.11 out of 5)

Source

COMPRESSION MEASUREMENTS IN THE ENGINE. COMPRESSOMETER

A device consisting of a pressure gauge and a rubberized tube that measures compression in the engine is called a compression gauge. The following devices are used:

Experts believe that of all types of compression gauges, it is better to use threaded ones. They provide more accurate information. It is necessary to measure the compression in the engine in each cylinder separately. The measuring instrument hose is inserted into the spark plug socket.

Now that everything is ready for measurements, start the engine and squeeze the gas all the way, let the engine run for a while. Check the pressure gauge readings and record them. Move the compression tester hose to the next spark plug hole, and take measurements in the second and subsequent cylinders in the same way. Write down all the results and compare them.

INJECTION ENGINE PRESSURE

Below you will learn how to correctly measure compression in a VAZ 2114 engine with injection type power.

If in at least one cylinder the pressure gauge shows a pressure below 10 barrels, then we need to look for the reason for such a low indicator. Otherwise, very soon it will fall in other cylinders.

Fill a medical syringe with about 10 milligrams of oil and spray it into the cylinder. Take the measurement again. If the pressure gauge readings increase, it means the piston rings are worn out and require replacement. If it remains at the same low level, then it is necessary to adjust the clamped valves or replace the burnt valves.

WHAT TO DO IF YOU DO NOT HAVE A COMPRESSOMETER AT HAND?

Is it possible to measure compression without a device? Practice shows that yes, it is possible. But this method will give relative and approximate readings. To measure the compression indicator without instruments, remove the spark plugs from all cylinders except the one being tested. Manually rotate the crankshaft until the compression stroke ends (watch the marks - they should match). Perform this operation on all cylinders one by one. Where the pressure is low, it will take less effort to turn the crankshaft. In this way, of course, you will not get accurate compression readings in the engine. But it is possible to understand the presence of problems.

It is recommended to measure compression every 20-30 thousand kilometers, so every car enthusiast is recommended to have his own compression gauge. Its price is not so high that it is worth saving on it.

The approximate price of a device for measuring engine compression in online stores in the capital is from 600 rubles to 2 thousand. Branded models from Western manufacturers are more expensive – up to 8 thousand. In the regions, a device for measuring compression costs no more than in the capital. Its price varies depending on the manufacturer.