Many motorists, especially beginners who have just purchased a VAZ-2114, have wondered how the 8-valve injection engine that is installed on this car works. This article will discuss the design of the motor, its main characteristics, as well as dismantling and repair features. This information will be very useful for beginners and those who do not know how the main power unit works.

Video about the VAZ-2114 engine

Video review of the VAZ-2114 engine operation, features and characteristics.

Engine VAZ 2114 injector 8 valves device

- home

- Price overview

- VAZ engines

- Sellers

- Write to us

- Helpful information

Characteristics of the VAZ engine

- 11183i-(1.6l., 82hp)

- 11194i-(1.4l., 89hp)

- 2103- (1.5l., 71hp)

- 2104i- (1.5l., 68hp)

- 2106- (1.6l., 74.5hp)

- 21083- (1.5 l., 69 h.p.)

- 2111i- (1.5l., 77hp)

- 21114i-(1.6l., 81.6hp)

- 21116i-(1.6L,90HP)NEW

- 21124i-(1.6l., 89hp)

- 21126i-(1.6l., 98hp)

- 21128i-(1.8l., 105hp)

- 21213- (1.7l., 79hp)

- 21214i-(1.7l., 82hp)

- 2123i- (1.7l., 82hp)

- 2130- (1.8l., 82hp)

Main engine elements

- Cylinder block

- Piston.Piston.

VAZ engines.

Select VAZ engine model

Engine VAZ 21114-100026080. Characteristics of the VAZ 21114 engine.

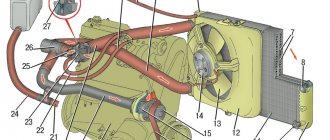

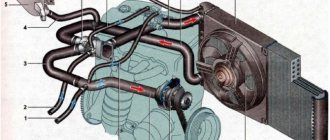

The engine is four-stroke, with distributed fuel injection, in-line, with an overhead camshaft. The engine cooling system is liquid, closed type, with forced circulation of liquid. The engine has a combined lubrication system: pressure and splash.

ICE VAZ 21114–00 (60 or 90) – Euro 2;

ICE VAZ 21114–20 (50 or 62) – Euro 3;

ICE VAZ 21114-70 (72) – Euro 4.

Engine Features.

The VAZ 21114 engine can be used for installation on VAZ Lada Kalina, VAZ 2108, 21083, 2109, 21093, 21099, 2113, 2114, 2115, 2110, 2111, 2112 and their modifications.

The VAZ 21114 engine is a modified version of the 2111 engine. The purpose of the modification was to increase the volume of the internal combustion engine to 1600 cm3 (2111 - 1500 cm3) and increase environmental performance to the requirements of European standards. There are several configuration options. Engine 21114, depending on the configuration, can meet the environmental requirements of Euro 2, Euro 3, or Euro 4. Motors equipped with VAZ 21114–00 (60 or 90) – Euro 2; VAZ 21114–20(50 or 62) – Euro 3; VAZ 21114-70(72) – Euro 4.

It should be noted that the 21114 engine does not differ from the 11183 model in terms of the design of the main components: block, cylinder head, camshaft, valve mechanisms and crank mechanism.

A new cylinder block 21114-1002011-10 was developed. Structurally, it differs from the 2110 cylinder block only in height (see “Cylinder block”). To increase the volume, it was necessary to increase the height of the block by 2.3 mm. (height from the axis of the crankshaft to the upper surface of the block - 197.1 mm). The mounting holes for attaching the block head are made with M12 x 1.25 mm thread. The nominal diameter of the cylinders is 82 mm.

Crankshaft 11183 -1005016 installed. In terms of seats, it corresponds to the crankshaft 2112. This shaft has a crank radius increased by 2.3 mm, compared to the 2112 shaft, this provides a piston stroke of 75.6 mm. The shaft is marked: the model “11183” is indicated on the counterweight.

The flywheel and crankshaft pulley are used from the VAZ 2110.

Attention!

The engine uses a connecting rod and piston group 2110.

The cylinder head received the index “11180”. The head has an enlarged combustion chamber (81mm x 50mm).

The VAZ-21114 engine uses phased injection. This distinguishes it from the VAZ-2111 internal combustion engine with pairwise parallel fuel injection. Therefore, on such engines a camshaft with index 2111 is installed. In this modification, at the end of the shaft, there is a pin for monitoring the position of the shaft with a phase sensor. The camshaft is driven by a toothed belt 2108-1006040-10.

The camshaft pulley 11183-1006020 differs from the VAZ-2111 pulley. On the installed pulley, the mark for setting the valve timing is shifted by two degrees relative to the mark of pulley 2111.

The choice of a poly-V belt for driving a generator and other attachments is determined according to the presence of the same design features as on the VAZ 2111 engine.

The VAZ 21114 engine receiver is made of plastic and differs in shape from the model used on the VAZ 2111 engine.

Changes have been made to the engine fuel system. There is no return fuel line. An injector ramp model 1118-1144010 was installed.

Install injectors “SIEMENS” VAZ20734 (yellow) or “BOSCH” 0280 158 022.

On the engine, the exhaust pipe of the muffler is combined with the catalytic converter (catalyst collector).

The cooling system has a new thermostat mod. 1118-1306010.

Generator 9402.3701 (80 A) is used.

The VAZ-21114 engine uses a four-terminal ignition coil, instead of the ignition module used on the VAZ-2111 model.

The electronic engine control system is carried out by the M7.9.7 controller. or "January" 7.2.

What does it mean that the 21114 engine specifies clutch 18?

The 11183 engine has a 2108 clutch, and the 21114 engine has a 2112 clutch.

Wiring diagram for VAZ 2110 carburetor

In the instrument panel wiring harness, the second ends of the wires of white, black, orange, white with a red stripe and yellow with a blue stripe are connected to each other at the same points. The bends of the wires at the points of entry into the harness indicate the direction of their laying in the bundle.

See the complete diagram in one file below (click to enlarge):

1 – headlight 37 – instrument cluster 2 – front brake pad wear sensor 38 – rear fog light switch 3 – fan motor switch 39 – fog light indicator lamp 4 – engine cooling system fan electric motor 40 – rear window heating indicator lamp 5 – sound signal 41 – clock 6 – generator 42 – rear window heating switch 7 – oil level sensor 43 – steering column switch 8 – carburetor solenoid valve control unit 44 – block for switching wires when installing headlights of another type 9 – heater controller 45 – switch instrument lighting 10 – recirculation valve switch 46 – ignition switch 11 – illumination lamp for heater control levers 47 – connectors for connecting the headlight cleaner wiring harness 12 – switch 48 – socket for a portable lamp 13 – carburetor limit switch 49 – directional light 14 – control sensor oil pressure lamps 50 – brake light switch 15 – spark plugs 51 – interior lamp 16 – carburetor solenoid valve 52 – on-board control system unit 17 – coolant temperature indicator sensor 53 – fuel level indicator sensor 18 – ignition distributor 54 – hazard warning switch 19 – ignition coil 55 – driver’s seat belt sensor 20 – starter 56 – cigarette lighter 21 – heater fan motor 57 – ashtray backlight lamp 22 – additional resistor for heater motor 58 – glove compartment light switch 23 – speed sensor 59 – connector for on-board computer 24 – reverse light switch 60 – glove box lighting lamp 25 – micromotor gearbox for heater flap drive 61 – side turn signal 26 – recirculation valve 62 – switch in the front door pillar 27 – brake fluid level sensor 63 – switch in the rear door pillar 28 – pads for connecting the rear window washer motor 64 – parking brake warning lamp switch 29 – battery 65 – trunk light 30 – windshield washer motor 66 – interior air temperature sensor 31 – washer fluid level sensor 67 – external rear light 32 – level sensor coolant 68 – internal rear light 33 – windshield wiper motor 69 – license plate light 34 – mounting block 70 – block for connecting the rear window heating element 35 – blocks for connecting the warning light harness 71 – block for connecting an additional brake signal 36 – outdoor light switch

Engine design features

Initially, the engine of the VAZ-2114 was 8 valve, had a volume of 1.5 liters, complied with Euro-2 standards, and was marked 2111. In 2005, these engines were boosted:

- to increase the volume to 1.6 liters, the block is increased in height by 2.3 mm;

- Several configurations have been created - for Euro-2 version 21114-00, for Euro-3 model 21114-20 and for Euro-4 modification 21114-70;

- The crankshaft, valve system, camshaft correspond to 11183;

- The cylinder head received an enlarged combustion chamber of 5 x 8.1 cm, which increased power.

Combustion chamber of internal combustion engine 21114

An important feature of the 21114 internal combustion engine is phased rather than pairwise-parallel injection, which was used in the original 2111. The attachments have become more compact:

- catalytic collector instead of the neutralizer and exhaust pipe;

- injector ramp instead of the fuel return line.

Catcollector

At the same time, VAZ-2114 began to be equipped with engines from Kalina 11183, which have some differences from the previous version:

- the shape of the combustion chamber has been improved;

- The generator is secured with a bracket, the tensioner is modernized.

In 2008, the 2114 engine received a new M73 ECU, and in 20011, the M74 “brains” to achieve Euro-4 standards. The control became completely electronic, but for another whole year the designers corrected firmware defects until they created its final version I414DE07.

ECU M74

The next engine, 2114, was installed on the car by a subsidiary of the manufacturer AvtoVAZ, called Super-Auto, in 2009. It was the 16 valve engine 21124 of the “tenth” VAZ family with improved characteristics:

- “high” blue block (197.1 mm);

- injectors pressed into 2–5 main bearing supports, cooling the pistons with oil;

- The groove depth of the holes in the valves is 5.53 mm, which ensures the safety of the valves in the event of a timing belt break; major repairs are not required.

Blue block

The following year, the fourteenth models began to be equipped with 21126 engines from export Priors. After tuning the 21124 engine, the internal combustion engine device differs in the following nuances:

- honed cylinders, gray block;

- crankshaft pulley and timing belt with semicircular tooth;

- the weight of the connecting rod and piston group is reduced;

- there is no friction in the lower head of the connecting rod;

- candle glasses are built into the head.

Piston group 21126

The internal combustion engine uses the principle of hydraulic compensation of valve clearances; the 0.45 mm thick cylinder head gasket is made of multilayer metal. The motor is equipped for Euro-3 with a collector 11194-1203008-10 or Euro-4 with a collector 11194-1203008-00. The service life of the pump has been increased due to a new design of the oil seal and bearing, and changes to the toothed pulley.

Hydraulic compensators

VAZ-2114 engine diagram, 8-valve injector

To independently repair a VAZ-2114 with an 8-valve injector, you need to know the structure and operating principle of the engine. With this knowledge, you can determine the cause of the malfunction without resorting to outside help. VAZ series engines are equipped with a distributed fuel injection system, which improves driving performance and typically reduces the percentage of toxins in exhaust gases. There are two types of fuel injection systems: with and without feedback, they may differ in details. Everything depends on the export or import of products. Feedback injection is usually used in car models supplied abroad and is equipped with a neutralizer. The open-loop system (sold domestically) contains a CO potentiometer that regulates the exhaust gases.

Which is better: carburetor or injector?

And now a little about which VAZ-2110 engine will be more reliable: an injector or a carburetor? But you need to look at this issue from different angles. For example, beginners will like the injector. Constant speed, there is no need to shut off the air supply in cold weather, and starting off is much easier. But there is another advantage - the car is more responsive at high speeds. Even at a speed of 120 km/h, when you press the gas pedal, the car quickly picks up speed. With carburetor engines this happens much more slowly. Therefore, overtaking in a car with an injector is safer. But when starting from a traffic light, the carburetor will easily “break” the injector. And the reason is higher torque at the bottom. And the cost of maintenance, of course, is higher for injection “tens”, since sometimes it is not easy to make an accurate diagnosis in the event of a breakdown.

Motor maintenance

When the design and main technical characteristics inherent in the VAZ 2114 engine have been reviewed, it is necessary to consider maintenance and provide answers to questions that motorists are increasingly asking.

Maintenance

If you believe the plant, the manufacturer, the VAZ 2114 engine must be serviced every 12-15 thousand kilometers. It depends on what marking the motor is installed on the vehicle. Maintenance scheme for all engines installed on the “fourteenth” model:

- At the first maintenance, the oil, oil filter and air filter element are replaced, as well as the functionality of all systems is checked.

- The second maintenance is done after 12,000 km. In this case, it is necessary to change the oil and oil filter element.

- Third maintenance – 25,000 km, replacing not only the oil, but also the air filter, and ongoing repair of faults.

- After 45,000 km, it is necessary to replace the timing belt and roller so that the VAZ 2114 engine does not have to be overhauled.

Subsequent maintenance is carried out in accordance with 2 and 3 maintenance.

Frequently asked questions and their answers

The process of repairing a VAZ 2114 engine.

Many car enthusiasts on forums ask the same questions. Let's try to classify all of them, and also give answers according to factory standards and recommendations.

What kind of oil should be poured into the VAZ 2114 engine?

If you rely on the manufacturer’s data, then different oil is poured into the VAZ 2114 engine, depending on the type. So, what kind of oil should you put in the VAZ 2114? If you take it for an 8 valve engine, then ideally it would be suitable with the 10W-40 marking. If it is a 16 valve engine - 5W-30. In any case, the oil for the VAZ 2114 should be semi-synthetic.

What is the operating temperature of the engine?

Based on the manufacturer's data, the operating temperature of the motor for engines installed on models 2113-2115 is 87-103 degrees Celsius. After 105 degrees the electric fan turns on.

Where is the engine number on the VAZ 2114?

The engine number is quite easy to find. It is located on the gearbox side, near the thermostat. The engine number always has a pad on the cylinder block, which is located in a visible place.

What is the resource of ICE 2114?

The service life of the VAZ 2114 engine is 150 thousand km for an eight-valve power unit and 180,000 km for a 16-valve power unit. To extend the service life, you need to know what oil to pour into the engine, as well as service it on time. Although driving style and careful operation of the car play an important role.

Do valves bend on VAZ 2114 engines?

Of course, like in any other engine, the VAZ 2114 has a valve mechanism that bends. This often happens due to overheating, when the head bends. The valves can also bend if the timing belt breaks.

What to do if the engine does not develop power and the speed drops?

In this case, it is worth carrying out a comprehensive diagnosis of the power unit. The issue may lie either in the inoperability of one of the sensors or in the mechanics. You can find the fault on your own or with the help of professionals at a car service center.

Engine malfunctions and repairs

Disassembled VAZ 2114 engine.

The fault diagram of the 2114 motor and its modifications is quite typical. Typically, the most common ones are floating speed, tripping, pump failure, as well as others that car owners are familiar with in detail. Where certain faults are located can be determined by carrying out diagnostic work.

After 150,000 km, the engine will need a bulkhead (overhaul). Every car enthusiast can repair his engine on his own, but many do not take risks and turn to a car service center.

For the VAZ 2114, repairs are carried out by analogy with the 2108 engine, since they are quite similar. In order to replace the timing belt, you will have to fix the camshafts. The set of replacement operations includes changing the timing belt, a roller or two, as well as adjusting the valves.

Specifications

VAZ 2114 car

The technical characteristics of the VAZ 2114 engine are quite typical for the 2113-2115 series of cars. In addition, this power unit is developed on the basis of the “eight” engine, which has declared itself to be reliable and easy to repair. The car was produced from 2001 to 2013. During this period, the vehicle received five valuable power units.

VAZ 2114 engine structure

As was said earlier, the 2114 was equipped with five different power units, which differed in power and valve mechanism. Three of them had 8 valves, and the other two had 16. The gas distribution mechanism had a belt drive. Until 2007, the engine was equipped with a simple on-board computer, which did not regulate the operation of the engine based on sensor readings. Therefore, the motorist had to regulate the processes the old fashioned way, manually. Since 2007, an ECU was installed, which, receiving data from sensors, independently adjusted many processes.

Design features of the engine.

Since the second generation had a so-called two-way electronic engine control unit, it is worth considering what electrical circuit was installed.

Electrical diagram of a VAZ 2114 car.

Main characteristics of the motor

All engines that were installed on the vehicle had approximately the same characteristics and design features. So, the motor is easy to service and repair with your own hands. Let's look at the main technical characteristics of the VAZ 2114 engine:

VAZ 2111

| Name | Index |

| Volume | 1.5 liter (1499 cm3) |

| Number of cylinders | 4 |

| Number of valves | 8 |

| Fuel | Petrol |

| Injection system | Injector |

| Power | 77 hp |

| Fuel consumption | 8.2 l/100 km |

| Cylinder diameter | 82 mm |

VAZ 21114

| Name | Index |

| Volume | 1.6 liter (1596 cc) |

| Number of cylinders | 4 |

| Number of valves | 8 |

| Fuel | Petrol |

| Injection system | Injector |

| Power | 81.6 hp |

| Fuel consumption | 7.6 l/100 km |

| Cylinder diameter | 82 mm |

VAZ 11183

| Name | Index |

| Brand | 11183 |

| Marking | 1.6 8V |

| Type | Injector |

| Fuel | Petrol |

| Valve mechanism | 8 valve |

| Number of cylinders | 4 |

| Fuel consumption | 9.6 liters |

| Piston diameter | 82 mm |

| Resource | 200 – 250 thousand km |

VAZ 21124

| Name | Index |

| Volume | 1.6 liter (1599 cc) |

| Number of cylinders | 4 |

| Number of valves | 16 |

| Fuel | Petrol |

| Injection system | Injector |

| Power | 89.1 hp |

| Fuel consumption | 7.0 l/100 km |

| Cylinder diameter | 82 mm |

VAZ 21126

| Name | Index |

| Volume | 1.6 liter (1597 cc) |

| Number of cylinders | 4 |

| Number of valves | 16 |

| Fuel | Petrol |

| Injection system | Injector |

| Power | 97.9 hp |

| Fuel consumption | 7.2 l/100 km |

| Cylinder diameter | 82 mm |

Engine VAZ 2114.

All engines were equipped with 5-speed manual transmissions. Engine volume ranges from 1.5 to 1.6 liters. This car was not equipped with a large power unit. The average engine power of the VAZ 2114 is 85 horsepower.

Typical breakdowns

The very first 1.5 liter engine 2114 has disadvantages:

- periodic valve adjustment;

- unreliable injection system;

- loosening the exhaust manifold nuts;

- Leaking gaskets of the fuel pump, distribution sensor of the ignition system.

The next 1.6 liter engine does not cause any particular problems for the owner, with the exception of high vibration and noise loads. The weak point traditionally remains the valves, which have to be constantly adjusted.

Adjustment of valves

The internal combustion engine from Lada Kalina 11183 was installed on the fourteenth model solely to meet Euro-3 standards. It has typical disadvantages for a linear series and is no different.

The first sixteen-valve engine 21124 does not bend the valves, the gaps in which are adjusted by hydraulic pushers. However, the belt needs to be tightened after 15,000 km due to the large number of attachments. The second and last in the line of fourteenth ICE models, ICE 21126, has increased power. In addition to typical malfunctions, if the timing belt breaks, the piston will bend the valve due to insufficient recess depth.

Maintenance schedule

To avoid having to carry out expensive overhauls of the Lada Samara 2114 yourself, you should follow the manufacturer’s recommendations for servicing the internal combustion engine:

| Maintenance object | Time or mileage (whichever comes first) |

| Timing belt | replacement after 100,000 km |

| Battery | 1 year/20000 |

| Valve clearance | 2 years/20000 |

| Crankcase ventilation | 2 years/20000 |

| Belts that drive attachments | 2 years/20000 |

| Fuel line and tank cap | 2 years/40000 |

| Motor oil | 1 year/10000 |

| Oil filter | 1 year/10000 |

| Air filter | 1 – 2 years/40000 |

| Fuel filter | 4 years/40000 |

| Heating/Cooling Fittings and Hoses | 2 years/40000 |

| Coolant | 2 years/40000 |

| Oxygen sensor | 100000 |

| Spark plug | 1 – 2 years/20000 |

| Exhaust manifold | 1 year |

What is the difference between the VAZ 2114 and the “nine”

The VAZ-2114 was created on the basis of the ninth model, but at the same time it has its own features that the ninth model does not have. This applies to both the appearance and technical characteristics of the machine.

The main task of the designers was to create a more modern and convenient car, which would at the same time retain all the positive aspects of the 2109 model, which became the “people's car”.

The first thing that catches your eye when comparing two VAZ models is the smoother and “softer” contours of the VAZ-2114. Like the ninth model, the fourteenth is a five-door hatchback. But modification 2114 changed the outline of the hood, headlights, and added moldings. The front and rear bumpers have also changed.

Other differences between the VAZ-2114 and the “nine” include:

- New, more comfortable interior design with greater sound insulation.

- Front power windows, ashtrays for passengers were added, and the seats became more comfortable.

- The characteristic knocking sound that was in the cabin of the “nine” disappeared.

- The heating system was replaced with a more modern one, in comparison with the outdated system of the ninth model.

- The instrument panel has been replaced with a “European panel”, equipped with an on-board computer with sensors for temperature, network voltage, state of car systems, etc.

- There was a gradual modernization of the engine from 8-valve to 16-valve, with increased volume.

- Since 2011, a new electronic control unit has appeared on the car.

Differences between VAZ 2114 and VAZ 2109

The dimensions of the car have remained virtually unchanged - the VAZ 2114 is only 40 kg heavier and 10 cm longer than its predecessor. The suspension also remained the same, with minor modifications to the struts and shock absorbing system. According to reviews from car owners, the quality of the metal has improved - it is less susceptible to rust.

DESIGN FEATURES

The engine we are considering has a cast cylinder block, the oil supply holes in which are machined, and the holes for antifreeze are made during the casting process. The engine cylinders are also machined inside the monolithic structure.

At the bottom of the structure there are supports for the main bearings, the covers on which are an irreplaceable part of the engine - they are adjusted to size at the stage of manufacturing the supports, and it is impossible to find two covers of the same size.

Inside the supports there are inserts made of a steel-aluminum alloy, and inside the third support there are half rings that prevent axial displacement of the crankshaft.

The pistons of the VAZ 2114 engine are aluminum, with cast steel rings, the connecting rod is steel. The cylinder block of the fourteenth is placed on a metal tray, on top of which a vibration-damping lining is laid.

The crankshaft, located under the cylinder block, is equipped with a mount for the flywheel. The lightweight flywheel on the VAZ 2114 has a special mark, through which its correct location on the crankshaft flange is selected - it must be placed strictly perpendicular to the connecting rod journal of cylinder No. 4.

Electronic control unit

This is, so to speak, the very heart of the system. On the VAZ-2110, the injector circuit comes down to precisely this device. A small case with many pins, and inside is the most interesting thing - a microcontroller. It is he who regulates the entire operation of the engine. The internal memory contains a so-called fuel map. Using it, the controller determines how much air and gasoline must be supplied to the ramp so that the engine operates in normal mode and detonation does not occur. But the most important thing is how long it is necessary to apply an impulse to the fuel injectors so that they open and inject the mixture into the combustion chamber.

VAZ 2114 engine repair

AvtoVAZ claims the engine's service life is 150 thousand kilometers, after which it will require major repairs. But with proper maintenance and regular oil changes, every 8-12 thousand km, the VAZ 2114 engine can travel up to 250 thousand km without major problems.

Different models of VAZ 2114 engines have their own design flaws.

1.5i engine VAZ 2114 injector 8 valves:

- early fuel injection systems were unreliable;

- It is better to replace the exhaust manifold mounting nuts with brass ones, since the factory version is unreliable;

- oil leaks from under the fuel pump, ignition distributor sensor and valve cover;

- valve clearances require frequent adjustment;

- Some components of the cooling system wear out quickly.

1.6i engine VAZ 2114 8 valve injector:

- less often, but also requires adjustment of valve clearances;

- high vibration and noise during operation.

16V 1.6l (124) engine VAZ 2114 injector 16 valves:

The timing belt must be manually tightened every 15 thousand km.

16V 1.6i l (126) engine VAZ 2114 injector 16 valves:

- A timing belt break leads to expensive repairs because the valves are deformed. The condition of the belt should be monitored much more carefully. The problem can be solved by installing a “plug-in” piston group;

- The main requirement for reliable operation of an internal combustion engine is high-quality components and spare parts, so you should not skimp on them.

Main components and how they work

The entire scheme of the VAZ 2114 fuel system is built on the injection principle, implying complete electronic control over the system’s operation process - starting with fuel supply and ending with the formation of a working mixture and combustion. Because of this, its constituent components are very different from devices characteristic of the carburetor principle.

So, it includes:

- fuel tank;

- pump (gasoline pump);

- pipelines for supplying gasoline;

- fuel filters;

- fuel rail;

- tank filler cap;

- nozzles;

- recycling block.

VAZ 2114 fuel system diagram

They perform the following functions.

Tank - provides storage of fuel reserves.

Pump - located inside the gas tank and serves to pump fuel to the ramp. Thanks to the sensor connected to it, it detects and transmits data on the level of remaining gasoline to the electronic unit.

Pipeline system - serves to move fuel to the engine and drain the remaining excess into the tank. It includes a system of metal tubes and flexible hoses, among which are the VAZ 2114 fuel hose, return hose, hose for connecting the adsorber and others.

Filters - serve to purify gasoline from possible impurities and sediments. The service life of the injectors, as well as the quality of the resulting fuel mixture, directly depends on their operation. That is why they should be replaced at least every 10,000 km.

Fuel rail - consists of two chambers separated by a diaphragm. One of them plays the role of a fuel container in which the optimal gasoline pressure is maintained, which changes when the diaphragm bends as a result of air being pumped into the second chamber of the ramp.

The tank lid is designed according to the valve principle and serves to relieve excess pressure.

Injectors are a system of valves with electromagnetic control. They spray gasoline directly into the combustion chamber, forming a working mixture in it.

Recycling unit - serves to absorb fumes generated in the throttle assembly (in accordance with the requirements of the Euro-3 standard). It is a container with activated carbon that adsorbs unnecessary fumes.

Diagram of the injection system

So, now in more detail about the power supply systems of the VAZ-2110 injection engine. First on the list is the fuel pump. It is mounted directly in the tank, together with the filter, and the engine rotor is driven only when the ignition is turned on (provided that the pressure in the ramp is below the minimum level). Next, the fuel flows through the tubes into the ramp. This is where the mixture is formed. The air first passes through a filter for purification. The filter housing is connected to the throttle assembly by a flexible pipe.

VAZ 2114 engine: power, design and characteristics

With the start of production of VAZ 2113, 2114 and 2115 cars, they used a carburetor-type engine with a volume of 1600 cubic centimeters. After long-term operation of this sample, several problems characteristic of the carburetor power system were identified. Namely: contamination of the jets, incorrect adjustment of the quality and quantity of fuel, unstable idle speed, etc. Therefore, it was decided to replace the type of power system with a more reliable one.

After the engineers chose which options to weed out and which to leave, the VAZ 2114 and 2115 with an injector engine were released. With the modification carried out, the engine design changed radically: power and speed increased, acceleration time to 100 km/h decreased. The engine size and number of valves remain the same. Let's look at what exactly the updated device contained, point by point.

What gasoline to use

This question is one of the most pressing for domestic car enthusiasts, because, on the one hand, gasoline prices are constantly rising, and you want to save money. But, on the other hand, the quality of fuel at most gas stations leaves much to be desired, and you don’t want to fill your car with anything.

That is why you should adhere to the basic principle - the 14th gasoline in the passport indicates exactly 95th gasoline, which means that this is what you need to fill it with.

Gasoline for VAZ 2114

As for bad fuel, if possible, you should choose from the nearest gas stations those that have the highest quality gasoline (based on the behavior of the car after refueling), and then refuel only at these stations.

True, you can also notice that many owners of the 2114 fill it exclusively with 92-grade gasoline and, according to them, do not see much of a difference in the operation of the car and in the rate of wear of the components of the gasoline system. Whether to follow these tips or use exclusively suitable fuel is up to everyone to decide for themselves.

Should high-voltage wires be replaced and when?

No matter how well the armored wires are made, they also have a limited service life. According to current regulations, they must be replaced after every 30,000 km traveled. In practice, many motorists ignore this rule, continuing to travel with wires that have already outlived their useful life.

Such inattention can cause a whole host of problems, including:

- poor ignition;

- overclocking problems;

- engine tripping;

- inability to start the car.

All these troubles are caused by one single factor - an increase in the electrical resistance of the core of high-voltage wires, as a result of which it becomes “more difficult” for the impulse from the coil to reach its destination.

You can check whether you can still drive with the old wires or not - at home.

To do this you need:

- Turn off the ignition.

- Remove one of the armored wires.

- Measure its resistance using a megohmmeter or multimeter in the appropriate mode.

- If the resistance turns out to be equal to or close to the figure indicated on the wire insulation, then it is in good condition, but if it turns out to be greater, then the wire should be replaced.

- Repeat this operation on the remaining three wires.

It should be remembered that if only one of the wires is faulty, then all four should still be replaced.

Also, do not forget about the cleanliness of the contacts of high-voltage wires - they can also cause ignition problems. If oxides are noticeable on the metal tip, they should be cleaned with fine sandpaper or a cloth moistened with kerosene. By following these simple rules for caring for armored wires and replacing them, you can almost completely avoid troubles associated with the ignition system.

Engine design features

Initially, the engine of the VAZ-2114 was 8 valve, had a volume of 1.5 liters, complied with Euro-2 standards, and was marked 2111. In 2005, these engines were boosted:

- to increase the volume to 1.6 liters, the block is increased in height by 2.3 mm;

- Several configurations have been created - for Euro-2 version 21114-00, for Euro-3 model 21114-20 and for Euro-4 modification 21114-70;

- The crankshaft, valve system, camshaft correspond to 11183;

- The cylinder head received an enlarged combustion chamber of 5 x 8.1 cm, which increased power.

Combustion chamber of the internal combustion engine 21114

An important feature of the internal combustion engine 21114 is phased, rather than pairwise-parallel injection, used in the original 2111. Attachments have become more compact:

- catalytic collector instead of the neutralizer and exhaust pipe;

- injector ramp instead of the fuel return line.

Catcollector

At the same time, VAZ-2114 began to be equipped with engines from Kalina 11183, which have some differences from the previous version:

- the shape of the combustion chamber has been improved;

- The generator is secured with a bracket, the tensioner is modernized.

In 2008, the 2114 engine received a new M73 ECU, and in 20011, the M74 “brains” to achieve Euro-4 standards. The control became completely electronic, but for another whole year the designers corrected firmware defects until they created its final version I414DE07.

ECU M74

The next engine, 2114, was installed on the car by a subsidiary of the manufacturer AvtoVAZ, called Super-Auto, in 2009. It was the 16 valve engine 21124 of the “tenth” VAZ family with improved characteristics:

- “high” blue block (197.1 mm);

- injectors pressed into 2–5 main bearing supports, cooling the pistons with oil;

- The groove depth of the holes in the valves is 5.53 mm, which ensures the safety of the valves in the event of a timing belt break; major repairs are not required.

Blue block

The following year, the fourteenth models began to be equipped with 21126 engines from export Priors. After tuning the 21124 engine, the internal combustion engine device differs in the following nuances:

- honed cylinders, gray block;

- crankshaft pulley and timing belt with semicircular tooth;

- the weight of the connecting rod and piston group is reduced;

- there is no friction in the lower head of the connecting rod;

- candle glasses are built into the head.

Piston group 21126

The internal combustion engine uses the principle of hydraulic compensation of valve clearances; the 0.45 mm thick cylinder head gasket is made of multilayer metal. The motor is equipped for Euro-3 with a collector 11194-1203008-10 or Euro-4 with a collector 11194-1203008-00. The service life of the pump has been increased due to a new design of the oil seal and bearing, and changes to the toothed pulley.

Hydraulic compensatorsPossible causes of failure

During the operation of the internal combustion engine, various malfunctions are possible. To detect them, you should perform the following sequence of actions:

- First you need to start the car. The engine should idle. At this time, you should listen to what sounds are coming from the exhaust pipe. If you hear regular popping noises, then one of the cylinders is faulty. The cause may be faulty spark plugs and lack of spark. The malfunction can also be caused by a large amount of incoming air or insufficient compression in the cylinder.

- It is necessary to inspect the candles. If there is carbon deposits, moisture or oxidation, you need to clean it. Check the gap between the electrodes, which should be 0.8 - 0.9 mm.

- Replace all spark plugs, regardless of their appearance and vehicle mileage.

- If there are irregular emissions, you need to inspect the high-voltage wires. There should be no traces of oxidation on their tips, and the insulation should not be damaged. If defects are found, the wire should be replaced.

Wires connecting to the coil

- The gas distributor cap should be inspected. There should be no soot or cracks on it. The carbon contact should be checked for damage and wear.

- The rotor needs to be inspected. It must be solid and have no signs of burnout. All parts with defects must be replaced.

- The pressure in the cylinders is allowed to be no lower than 1.1 MPa, and the compression difference should not exceed 0.1 MPa. If the indicators do not correspond, engine repair is necessary.

If after the above steps the problems remain, then you need to contact a service station to undergo a more accurate diagnosis of the VAZ 2109 engine and adjust the ignition system on the stand.

Supply system

The air filter is located in the front part of the engine and is equipped with rubber retaining elements. If it becomes necessary to replace them, the corrugation is located on the same parallel with the center line of the car. The main function of the throttle pipe is determined by dosing the air flow entering the intake pipe. The air entering the engine is adjusted thanks to the throttle valve, which is connected to the accelerator pedal. The throttle pipe consists of two components: the throttle position sensor and the idle speed control.

Engine tuning

For naturally aspirated engines, the following type of tuning is usually used:

- receiver complete with 54 mm throttle body at the inlet;

- straight-through spider 4/2/1 at the outlet;

- camshaft Nuzhdin 10.93 or Dynamics 118 instead of the factory equipment.

Camshaft Dynamics 118

For 16 valve engines, tuning has the same principles, since chipping it does not make sense. To achieve 120 l. With. You can increase the damper to 56 mm, use a direct-flow type exhaust, Nuzhdin 8.85 or Stolnikov 8.9 280 camshaft.

Thus, only one engine, modification 21126, bends the valves on the VAZ 2114. All other engines are considered safe and provide a real service life of about 270,000 km.

Improving dynamic characteristics (tuning)

For many owners, the standard dynamics of the VAZ 2114 are not enough. Engine tuning allows you to improve the dynamics and customize the character of the car.

As practice has shown, chip tuning of VAZ 2114 engines does not lead to tangible improvements.

Let's look at more serious improvements:

- For owners of eight-valve engines, the easiest way to improve dynamics is to install a cylinder head from a 16-valve engine. Modification of the 1.5l block is also possible.

- The easiest way to tune a VAZ 2114 engine is to install camshafts different from stock. For example, OKB Dynamics 108 will give an increase in the highs without a noticeable loss in the lows.

- By supplementing the shaft with a sliding timing gear and a suitable phase setting, you can get + 7 hp. With.

- Installing an enlarged throttle valve (54 mm), a receiver and a 4.2.1 spider will improve cylinder purging and give noticeable changes during acceleration (the level is close to Priora).

- A modified cylinder head, lightweight valves and a modified intake manifold paired with an increase in engine volume to 1.6 liters will allow you to achieve a power of 110 hp. With. Tuning up to 120 horsepower will take place without loss of resource.

The principle of improving the power characteristics of sixteen-valve engines is similar to the process of refining V8 1.5i l and V8 1.6i l. More evil camshafts, direct-flow exhaust, a receiver, an enlarged damper, a lightweight Priorov piston group, in the case of the Kalina engine (124) and proper tuning will give a significant increase in dynamics.

Regardless of the number of valves per cylinder, the power of the VAZ 2114 engine can be significantly increased by installing a compressor or turbocharging. Engines modified in this way easily reach 170–190 hp. With.

There are many different configurations and options for improving the vehicle's dynamic performance. You can decide for yourself how to increase the power of the VAZ 2114 engine. Remember that the selection of mechanical modifications and software must match each other.

Engine life and operation

A cross-section of the VAZ-2114 engine with a description of the internal elements. In order not to beat around the bush, let’s immediately move on to the issue of engine life.

So, according to the technical documentation, the engine installed on the VAZ-2114 has a travel potential of 150,000 km.

8 valve engine in a car. A little tuning, a zero-resistance filter installed

A week has passed since the engine was washed (editorial car)

An editorial employee's car, or rather its engine compartment

When can we expect a major overhaul?

What's next? - novice motorists may ask themselves a question. Next comes a major overhaul, since the service life of most internal parts has been exhausted. The basics of this operation will be discussed below.

Before considering what will be included in the repair and restoration work on the engine, let’s consider the factors that influence increased wear of the main power unit:

- Driving style. This factor has a primary impact, since frequent engine overloads will lead to increased wear on the internal parts of the power unit. Thus, measured driving can significantly extend the life of this structural element. As practice shows, drivers who drive carefully and carefully are less likely to carry out repairs on car components. Especially those that concern the engine than those that like to drive.

- Timely repair operations. On-line repair is a fairly important factor in the life of the power unit. Thus, valves that are not adjusted in time, or untimely replacement of the cylinder head gasket can significantly reduce the service life.

- Maintenance. Timely maintenance, namely oil changes, can extend engine life. This is due to the fact that the lubricating fluid takes care of all the physical and chemical processes in the engine. The production of one of the parts, namely the metal shavings, will all go into motor oil.

- Quality of spare parts used. Not only the dynamics and power, but also the life of the main power unit depends on what part you install. Thus, a high-quality part has not only greater potential, but also less production, which can end up in the oil in the form of residues.

16-valve VAZ-2114 engine

Now that we have considered the main reasons that affect the engine’s performance potential, we can also consider the basic concepts that will be included in the overhaul of the power unit after the end of its service life:

- Grinding the crankshaft to repair dimensions for main and connecting rod bearings.

- Boring and honing of the cylinder block.

- Installing a new piston according to the block bore size.

- Replacing a set of motor gaskets.

- Repair or replacement of the oil pump.

- Replacement of valves and guide bushings.

- Replacing the camshaft.

- Replacement of the water pump and other elements of the cooling system.

- Grinding the surface of the block and cylinder head.

- Replacing the oil filter and engine oil.

- Restoration work. For example, argon welding of the block head in places where cracks form.

- Other work aimed at restoring engine life.

As practice shows, after a major overhaul of the engine, the service life of the power unit is reduced. Typically this figure is 120-130 thousand kilometers.

Increase in resource

Increasing the service life of the main power unit is an issue that many experienced motorists are struggling with. This is due to the fact that foreign analogues of the VAZ-2114 have a real engine potential of 250,000 km and above. Therefore, every owner of this car wonders how to increase the life of the engine.

Physically, this is practically impossible to do, except for the option of replacing most of the parts with sports ones, which are superior in quality to standard spare parts.

There is a second option, which does not require investment, and will also extend the life of not only the engine, but also other parts of the car. So, let's consider the conditions under which the engine life can be increased to 250,000 km:

- Careful operation.

- Timely on-line repairs.

- Routine maintenance in accordance with all rules.

- Do not overload the engine. Jerks and other loads negatively affect internal parts.

- Avoid catastrophic consequences of malfunctions, such as overheating.

- Installation of only high-quality spare parts.

Pros and cons

The above description of the parameters exceeds the characteristics of the entire line of internal combustion engines existing at that time, produced by AvtoVAZ. However, “inherited” from the 21083 and 2110 engines, the 2111 engine received disadvantages:

- breakage of studs in the muffler-exhaust manifold mounting;

- breakdown of the fuel submersible pump;

- leaking valve cover gasket;

- low resource of cooling system elements;

- periodic adjustment of valves.