An impressive portion of modern cars have bolts on their rims. Most often, this method of fastening wheels is found on German cars. Typically, car owners do not pay attention to how the wheels are attached. But when you have to face the need to dismantle and mount a wheel, you want this process to be as simple as possible and not take much time. This is possible if you install wheel studs instead of bolts.

Advantages and disadvantages of using bolts or studs on car wheels

Most production street cars leave the factory with rims equipped with either bolts or strong metal pins protruding from the hub - wheel studs, onto which the rim is already placed. Readers, of course, will remember the third type of wheel installation, although it is used very rarely on cars. We are talking about installing wheels with central locking. But they are typically used in racing disciplines for high-performance racing and road sports cars.

So what exactly is the difference? Team O'Neil Rally School expert Knox White quickly explained the what's what and why, showing the advantages and disadvantages of using bolts or studs if you use your car for sporting purposes or just for daily driving.

Studs instead of bolts VAZ 2110

Installing studs on a VAZ

What do we gain from this? •Firstly, switching to studs makes it possible to install wheels with a 4x100 drill without any problems!! There are more opportunities to experiment with different spacers to increase the wheel offset, you can also put beautiful nuts in different colors.

•Secondly, removal and installation will become much more convenient (those who once changed a cast wheel in pouring rain will understand me well).

•Thirdly, with frequent replacement, the thread in the hub wears out quite quickly, but since it is deep, it is difficult to notice its wear. And here the thread is visible, and replacing a stud is much easier, faster and cheaper than replacing a hub.

But the most interesting thing is that when switching from bolts to studs, we do not violate the deeply respected GOST 51704 “Motor vehicles. Safety requirements, as well as technical condition and verification methods." There is simply no clause about securing the wheels. That is, this modification is completely legal.

So how is it done? First, let’s talk about where to get these studs and nuts for them. The easiest option is to buy studs from Chevy Niva and nuts from Niva or Oka.

Further. We need a thread locking compound. It can be domestic, it can be imported - the difference is small.

Now to the garage! We hang the wheel, unscrew the standard bolts and remove the wheel. Apply a little sealant to the stud (two or three drops are enough). Lightly distributing it along the thread, screw in the pin by hand. Finally tighten the stud using two nuts. The tightening force is approximately the same as when tightening wheel bolts. Put the wheel on and tighten the nuts. We finally tighten the nuts by lowering the car from the jack. The result is in the photo!

Good day.

I came up with the idea of installing wheel studs instead of bolts on a VAZ 2110. I see the advantages in the ease of removing and installing wheels and the possibility of installing 4x100 wheels, etc. when selecting longer studs, install wheel spacers from 5 to 25mm.

Before starting work, we read a lot of material on our favorite website DRIVE2.RU. Of the various options, I settled on studs from the Kamaz axle shaft.

Here are the studs themselves from the Kamaz axle shaft M12x1.25 (total length 54mm):

Wheel nuts from Niva:

And thread locker:

The installation process did not take any special problems, except for eliminating the wheel guides, which were terribly stuck and did not want to get out!

I removed the brake drums, coated the threads with sealant, tightened them, tightened them, and so on many times.

I am very pleased with the result. Wheels are now 10 times easier to put on, especially those that do not have holes for guides. By the way, there are quite a few of them, starting from the Chinese and ending with VSMPO Aurora R15 (why this particular model - because I have such and it’s the same there) 4x100 disks, by the way, fit without problems. The studs bent slightly under them and the nuts were pressed completely. After this, when installing the original size 4x98, the studs returned to their original position. If this situation may bother anyone, you can replace the studs with new ones; their price at the time of installation on the 2110 was 12x16 = 192 rubles.

Or log in using one of the services

Published by metrolog, March 16, 2007

The standard is: Wheels with bolts

Wheel bolts are standard on many German-built vehicles. As you know, such bolts are not made according to a very conventional pattern. Yes, they have cut threads of a standard pitch, but the bolt head has a completely non-standard shape, which allows these elements to fit more tightly to the wheel rim when installing the fasteners in place and to protrude minimally above the surface of the wheel. The bolt is threaded through the wheel rim, brake rotor, going straight into the hub, fixing all the elements together.

Difficulties with using bolts usually arise for beginners when changing wheels. Small bolts make it more difficult to get into the threaded socket while holding the wheel suspended, while it is necessary to hold a heavy wheel so that the sockets on the wheel rim coincide with the sockets in the hub.

The second problem, as noted in the video, is also related to the misalignment of the holes. For example, the brake disc spun on the hub while the wheel disc was removed, there is nothing to center the elements, so in theory this can happen. An example is shown at 40 seconds into the video. This means that you need to align the brake rotor in relation to the hub (along with the rim) when you put everything together. Inconvenient.

Also, bolts from each make and in some cases model of car may be suitable exclusively for that make or model. You simply won’t install them on other cars due to the special shape of the rear of the bolt head.

When overtightening, if the thread in the hub breaks, this can result in a large repair costing money and time.

However, there are undeniable advantages of the bolted wheel mounting system. Firstly, the bolts cannot be broken or bent. Secondly, you can easily buy new ones at a car store in case of loss or damage to the fastener. Thirdly, you can install security bolts.

Studs, nuts, spacers

Wheel mounting plays a truly key role in driving safety.

The wheels of VAZ cars are attached to the hub using bolts. To make it easier to mount the wheel, short guide pins are screwed into the hub, which also secure the brake disc. Many owners of VAZ cars have encountered the problem of installing wheels with alloy disks when they have to remove the guides. The mounting holes often shift when the wheel is put on and it becomes difficult to hit the bolt. Sometimes, if the bolt hits the wrong way, the threads in the hub are broken, which leads to its replacement. When tuning VAZ cars, bolts are replaced with wheel studs .

Wheel studs have the following advantages:

1. It’s easier to put on a wheel when replacing it; it won’t fall off or fly away;

2. Less likely to break threads in the hub when changing wheels frequently;

3. Versatility of the length of the studs , there is no need to select the required bolt length;

4. The sporty look of your car;

5. Possibility of using nuts with increased long edges;

6. Possibility of installing wheel spacers to increase the vehicle track;

Another very popular thing for tuning are wheel spacers for VAZ , which are made of light alloy materials.

1. Widen the vehicle track, which in turn has a positive effect on handling;

2. Allows you to install wider rims and tires without fear that they will touch fixed suspension elements or the car body;

3. Some types of wheel spacers allow you to change the bolt pattern;

4. The offset of the wheels gives the car a more sporty and aggressive look.

We offer you a wide selection of wheel studs, nuts and attachments of various sizes.

Wheel studs instead of bolts

Wheel studs, as you know, differ in the method of installation. Essentially, this is a long piece of bolt that is mounted on the hub, protruding above the central part of the brake rotor, which is simply pushed onto the protruding elements.

The main advantage of such a fastening system is the installation of brake and wheel discs. The wheels are easy to center and easy to put on the studs. Just a matter of seconds! Also, to adjust the fit of the wheel, you can install spacers on the studs, and to prevent this wheel from being stolen, it is easy to select locking nuts.

However, there are also disadvantages:

The studs bend. If the thread on a stud breaks, it can be replaced, this is a plus, but in some cases this will be very difficult to do.

As you can see, both options have their advantages and disadvantages. Therefore, we will not say for sure which system is better, and there is no need to do so - both options for installing wheels have earned trust and have the right to life.

How to install

Replacing bolts with studs on car wheels is completely legal and uncomplicated. A set of wheel studs can be purchased at an auto store, but the price is quite high. Therefore, it is easier to make them yourself. This will require 16 bolts to secure the alloy wheels. Then, using a screw-cutting lathe, they are turned into studs with an M12x1.25 thread, 12 mm long. There is no need to make the threaded part longer.

You will also need:

- degreaser;

- screwdrivers;

- nuts;

- key;

- jack;

- sealant-fixer;

- pin driver

Once all the tools and materials are ready, you can proceed directly to the installation procedure:

- Place the jack, unscrew the bolts and remove the wheel.

- Degrease holes and studs.

- Apply sealant-fixer to the rod, evenly distributing it along the threads.

- Screw in the stud by hand and tighten it completely using a stud driver or 2 nuts.

- Reinstall the wheel and finally tighten the lug nuts by lowering the vehicle from the jack.

The entire replacement process is simple and quick and does not require special tools or skills. But if you are not confident in your abilities, it is better to entrust this matter to experienced specialists.

Studs for VAZ

#1 Serega Zhdanov

- Users'

- 87 messages

- Users'

- 1,060 messages

- Gender: Man

- City: Tsimlyansk

I read a lot on the Internet about installing studs instead of bolts on the wheel hub in our car industry, so I wonder if anyone has done this trick on their car? where can I buy them in our city? I don’t consider advice like cutting the cylinder head bolt with a grinder and screwing it in, or leaving the bolts, because... I’m not interested in this issue for nothing)

#2 Sergey Shchedrin

I've never seen it in the city. Buy Bimec online or something like that.

Why did they surrender to you?

The message was edited by Sergey Shchedrin: 05 December 2014 – 23:07

#3 kentyku

It’s convenient to change wheels if there are no guides)))

#4 Serega Zhdanov

I have to change wheels often, at least this year I changed them 4 times) the result is one broken thread and 2 more damaged due to the fact that they slipped a couple of bolts with a different pitch, now this thread ruins the threads of the bolts when changing wheels, I tried to fix it with a sword, the result zero, now I’ve decided to screw in these studs once and forget the problem)

Installing studs instead of bolts on a vase

Subscribe to topic

Notification by e-mail about replies to a topic during your absence from the forum.

Subscribe to this forum

Notification by e-mail about new topics on the forum during your absence from the forum.

Download/Print theme

Download the theme in various formats or view a printable version of the theme.

“Bolts are a manager’s decision, and studs are an engineer’s” ©

Part 1. Choice

While riding on standard castings, I didn’t seriously think about abandoning wheel bolts in favor of studs and nuts, I just didn’t see the point in it. But after purchasing wheels with a larger size and weight, as well as the need to remove guides from the hubs, a reason to study this topic with subsequent implementation appeared.

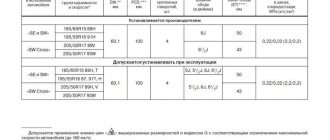

Hairpins

chose from a small improvised list compiled after studying the personal experiences of people who had encountered this. • M12x40 studs for the VAZ2121-13532821 front axle gearbox - People ride around and don’t seem to complain, but in this case I was confused by the need to shorten them. • M12x41 wheel studs VAZ21210-3104039-00 - This is an interesting option due to its original purpose for fastening wheels. The repulsive factors were the difficulty of installation, and even the impossibility in front, and the need to damage the threads in the hub. • Studs from cylinder head bolts VAZ2108-1003271 - Firstly, here again you can’t do without an angle grinder. Secondly, there is no jumper on the thread, which would provide additional reliability for fixing the stud in the hub. Well, thirdly, these bolts are hardened - someone will say that they are stronger and to some extent this person would be right, but at the same time the bolts are still more fragile, that is, they burst under increased loads, while ordinary ones stretch. Agree, it’s better for the pin to stretch out than to burst - if it’s stretched out, you can still get to the repair site, but with a broken piece, such an issue will no longer work. • Kamaz 4310 axle shaft stud M12x1.25x35 art. 1/35302/31 - According to those who chose the same option for the same purposes, no modifications are needed, the studs fit perfectly. Application in such heavy equipment as Kamaz also inspires some confidence.