The VAZ 2112 temperature sensor not only allows you to monitor the condition of the engine and coolant. The data obtained from it allows you to regulate the amount of fuel supplied to the combustion chamber.

It is necessary to check the condition of the sensor, and if it breaks down, replace it immediately.

What functions does the sensor perform?

This device performs a lot of tasks. Based on its readings, the fuel mixture is prepared and the ignition timing is changed. The element also gives commands to turn on the fan in case of overheating.

Enrichment of the mixture is always associated with increased temperatures in the power plant. The lower the engine temperature, the richer the mixture needs to be fed into it. Any electronic control unit works on this principle. And the domestic top ten is no exception.

Sensor device

At the dawn of the automotive industry, simple thermal relays were used as coolant temperature sensors (hereinafter referred to as coolant temperature sensors) - they were installed on most internal combustion engines. These sensors can now be found on K-Jetronic single-injection systems and the like. These were used on old Mercedes from the 80s and 90s. How it works? When the relay contact is in the open position, the engine warms up. When the contact is closed, the electronic control unit understands that the engine has heated up to operating temperatures. The concentration and composition of the mixture changes.

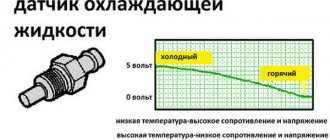

Nowadays, thermistors are used as DTOZ. These are resistors that change resistance depending on the temperature of the environment. In the VAZ-2110 car, the coolant temperature sensor is of this type. Heating is monitored continuously, without interruption. Thermistors for these sensors are made from nickel oxide or cobalt oxide. These alloys have a peculiarity: as the temperature rises, the number of free electrons in them increases, due to which the resistance decreases.

The thermistor located inside the DTOZH has a negative temperature coefficient. The maximum resistance level is achieved when the engine is cold. A voltage of +5 V comes to the temperature sensor and as the engine heats up, it decreases. The ECU records the slightest changes in voltage, and thus the coolant temperature is determined.

Sensors with positive temperature coefficients can be installed on engines from Renault and some other power units. They are arranged similarly. However, as the antifreeze temperature increases, the resistance on the sensor does not fall, but increases.

Diagnosis of VAZ 2112 16 valves with your own hands. Why pay extra?

In addition, despite modern equipment, the level of diagnostics in services is practically not growing. Not everywhere there are specialists who can correctly assess the condition of the car. Therefore, in most cases, self-diagnosis will be the best option.

True, special devices may be needed to carry it out, but their purchase will more than pay off in savings on trips to a car service center. It should be noted that the tenth VAZ family has the same microcontroller installed. Therefore, instrument diagnostics are performed here in the same way.

Visually. Do-it-yourself diagnostics of a VAZ 2112 16 valves begins with an inspection of the car. Carefully inspect all components

Pay special attention to the suspension and steering. Parts must not have cracks or other damage

The brakes and body are also inspected. All these design elements are important for the normal operation of the car. However, many of their faults can be seen with the naked eye.

The twelfth model uses the January-4

" This device constantly diagnoses the condition of the vehicle. All detected faults are stored in the controller’s memory and remain there until they are erased. The source of the problem can be determined by the two-digit code. Codes from 12 to 61 inclusive are used here.

For timely detection of errors and diagnostics, there is a “CHECK ENGINE” light on the dashboard; in common parlance it is referred to as a “check”. This lamp is connected to a microcontroller. And when a malfunction occurs, it lights up. Signaling the need for an urgent check of all engine systems.

When the ignition is turned on, the light comes on and all engine systems are checked. If there are no breakdowns, the “check” goes out when the engine is started. If the malfunction is intermittent, then “CHECK ENGINE” will light up and go out. Please note that intermittent problem codes are also stored in memory and may interfere with diagnostics or, conversely, provide clues about the true cause of the failure.

To read error codes, you will have to use the connector located at the bottom left of the dashboard. Diagnostics can be carried out in two ways:

- Diagnostic scanner (let’s just say EML 327 is not suitable);

- Counting the "check" flashes.

To check for errors using a lamp, connect output “B” of the diagnostic block to the “minus” of the machine. The easiest way to do this is to connect this output to output “A”, which is “ground”. After this, the key is turned to the “ignition” position. You need to carefully monitor the behavior of “CHECK ENGINE”. To begin with, the light will display the diagnostic system operating code. It will look like a flash, pause, flash, flash. This means - 12. This code is repeated three times. After it, the system issues fault codes.

It's easy to decipher them

. The first part of the flashes means dozens, then there is a pause and another one to nine flashes occur. This is what makes up the fault code. If there is no code “12” the problem is in the controller itself. All codes will be displayed 3 times.

You cannot disconnect contacts immediately after completing the diagnostics. This may damage the diagnostic device. First the ignition is turned off. Only after 10 seconds should the contacts be opened.

It is much easier to diagnose using a scanner. If it is not available, you can use a laptop. Just download the test program and get a USB adapter (K-Line adapter). The majority of programs evaluate a large number of parameters in addition to errors. You can view and evaluate all the main indicators of the motor. This option will be the most optimal.

Reset errors

. The controller remembers errors and will show them even after the fault has been eliminated. Therefore they need to be reset. This is the only way to ensure that the problem is corrected correctly. To reset, turn off the power to the device for 15 seconds. To do this, simply remove the negative terminal from the battery. Do not perform this action with the ignition on. This may damage the controller.

Conclusion

. Any car owner wants to control its condition. Constantly going to the service center to check is quite expensive. Therefore, diagnosing the VAZ 2112 16 valves yourself is the most optimal solution. The great thing is that you can do it at any convenient time.

- Diagnosis of HBO 4th generation with your own hands. When it makes no sense to pay a service station

- Do-it-yourself diagnostics of the Gazelle 405 engine. Not interesting for long

- DIY diagnostics of VAZ 2114 and 2115. Find out everything that's broken

- DIY Ford Focus 2 diagnostics. Learning to avoid service stations

Operating principle of DTOZH

The VAZ-2110 temperature sensor works as follows. The thermistor located inside the sensor is an electronic device with a negative indicator of heating modes. The mode of temperature values up to 130 degrees reduces the resistance within 70 Ohms, and the lower limits at -40° increase the resistance to 107 kOhms.

The detector supplies +5 V to the temperature sensor through a constant resistor located inside it. The element determines the heating level of the antifreeze thanks to the potential difference across a thermistor with variable resistance.

Where is it located?

Owners of cars of this model are well aware of various problems associated with this device. Often the device requires replacement. Beginners do not always know where the temperature sensor is located on the VAZ-2110. In cars, this element can be installed in a variety of places.

So, in classic models the thermistor is located directly in the cylinder block. And in AvtoVAZ models of the tenth family you can find DTOZH in the thermostat. By the way, on the VAZ-2110 there is not one temperature sensor - there are two, but the second one does not perform any important tasks. It is connected only to the instrument panel bottom temperature indicator.

Replacement

Before purchasing a new device to replace the old one, it is worth checking the markings on the old sensor. It is better to purchase exactly the same device.

Other, although similar elements, may give the wrong readings, the ECU will misunderstand them, and the driver will see false readings on the instrument panel. A copper washer must be included with the new element. If it is missing, it is purchased separately.

Sensor malfunctions

As you know, the ratio of fuel and air in the combustible mixture depends on the readings of the device. All owners have already encountered or will continue to encounter various problems that the temperature sensor creates. It also determines whether the fan will start when overheated or not.

You can suspect a malfunction of the coolant sensor on a VAZ-2110 based on the following symptoms. So, the first signs are problems starting the engine on a cold frosty morning. You may also experience poor exhaust and fuel consumption will be significantly increased.

These symptoms do not necessarily indicate that the sensor needs to be replaced. Sometimes it is enough to clean the contacts and clean the sensor itself from corrosion. If a visual inspection fails to identify problems, then you need to check the element.

Sensor diagnostics

All car owners should know how to check the temperature sensor on a VAZ-2110. By checking, you can save on the cost of a new device, although its price is not entirely high.

You can test the element by heating it. You need a suitable container. It could be a glass or a teapot. Hot water is poured into it. The water should be heated to approximately 100 degrees - the heating should be monitored with a thermometer. Next, the working part of the device is lowered into water. However, it is precisely the part of the temperature sensor that is located in the motor that needs to be lowered. Contacts must not be in water. Then a multimeter is connected to the contacts and the resistance is measured.

A working sensor at a liquid temperature of 100 degrees has a resistance of 177 ohms. At +50 degrees the resistance is 973 Ohms. If the values do not correspond to the norm, then the faulty element should be replaced. If the indicators are within these norms, then everything is in perfect order.

Mass air flow sensor

The power unit of the "tens" is controlled using the ECM - an electronic system. This system must always know how much air needs to be supplied for a certain volume of gasoline. These two parameters are closely related to each other, since with their help a combustible mixture with the required density is formed in the engine power unit.

After the system determines the required volume of air, it begins to select the appropriate amount of gasoline. As for the regulator, it is responsible for the suction volumes.

Air controller for the “ten”This controller has certain disadvantages, in particular:

- its performance may be impaired if the controller is exposed to moisture;

- if the car is moving at lower speeds, the controller can produce higher readings;

- as practice shows, at idle the air regulator does not work entirely correctly;

- when starting the power unit, certain difficulties may arise;

- the power unit may stop abruptly for no reason after an increased power mode;

- Gasoline consumption during vehicle operation may increase.

We've dealt with the shortcomings, now let's talk about how the device functions:

- The controller design consists of several sensitive elements installed directly in the line itself through which the air flow passes. One of these components is designed to fix the temperature of the air flow, and the other two are always heated to the required parameters.

- To correctly determine the air flow rate, the principle of measuring electrical power is used to maintain the desired temperature level.

- The air regulator controller has a special mesh installed in the line, designed to filter the air flow.

- Thanks to this, the sensor can transmit the necessary data to other regulators designed to activate certain modes. Subsequently, these regulators either change or support the loads.

How to remove

First of all, they look at what is preventing you from getting to the thermostat and sensor. The air filter housing is in the way - it needs to be removed. Next, it is recommended to drain the antifreeze from the engine, but this is not always necessary. When replacing, only a little fluid will spill, and you can always top it up to the level.

Then, after draining the liquid, remove the terminal from the battery, select the desired sensor and remove everything connected to it. After disconnecting, the element is simply unscrewed, holding its edges with your hands or a key. After this, the device can be removed.

Installing a new coolant sensor

The new coolant temperature sensor on the VAZ-2110 is installed in the reverse order. Experienced motorists recommend lubricating the threads of the element with sealant.

Sometimes coolant leaks are observed from under the new sensor. The replacement process is extremely simple and even beginners who just got behind the wheel and didn’t know anything about cars can handle it without difficulty.

Why does the engine overheat?

Sometimes you can see vehicles on the side of the road with clouds of steam rising from under the hood. This is engine overheating. Boiling of liquid in the cooling system of a VAZ-2112 car can occur for the following reasons.

Loosening the timing belt tension

The timing belt begins to slip along the pump drive pulley. As a result, the antifreeze does not have time to quickly pass through the radiator and cool. The belt is subject to immediate tension adjustment.

Pump bearing failure

The pump starts to jam. Antifreeze stops flowing through the large circuit through the radiator, the liquid temperature quickly reaches a critical threshold (100 C0) and boils.

Thermostat failure

When the liquid heats up, the thermostat stops opening the valve of the large cooling circuit and the antifreeze. Remaining in the engine jacket, it boils.