What will LADA Vesta tell us? We are studying the 1.8 engine with 122 hp. (VAZ-21179)

Pavel [therock9618]

13.12.2020,

Hello! In the last issue, we touched on the new VAZ engine, which is truly reliable in every sense, with a volume of 1.6 and a power of 106 hp, which simply amazed us with its condition even after 300 thousand kilometers. And today let's talk about its dark side, the 1.8 liter engine with 122 hp. and marking VAZ-21179. A common scourge of this unit is its excessive appetite for oil, which begins on average at 40 thousand kilometers. These problems also occurred with 30 and even 20 thousand km. It all starts, of course, with low consumption, about 400-500 grams per 1000 km, and this is far from the limit. The plant allows consumption of up to 600 grams per 1000 km and often refuses to fix the problem under warranty, since the consumption rate has not yet exceeded the permissible limit.

Having made a slight digression from the main topic, let's remember a little the history of the birth of the 1.8 engine from the auto-VAZ - and it was always born somewhere in the hands of a Kulibin in the garages, with Indian crankshafts, pistons for some unknown reason, bored, and as a result it turned out to be a “miscarriage” "with a volume of 1.8, which was not particularly reliable. And now, please, meet the serial 1.8 engine, which the plant has finally begun to produce! Let's find out what came of it.

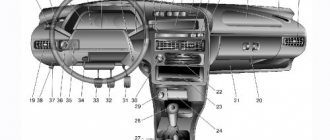

Here it is, a miracle of VAZ technology, with a consumption of one liter per thousand with 70 thousand kilometers! Let's start with the most important thing. Among the innovations we see an increased volume intake receiver with variable geometry. As a result, in the place where the camshaft position sensor used to be (in the area of the first cylinder), there is now a receiver blade actuator, and the camshaft sensor has moved to the casting on the head, where the 4th cylinder is located. The receiver is removed without any problems and the next innovation is revealed - the exhaust manifold.

Huge, isn't it? And in this giant there is a catalyst that really does not like oil and is immediately destroyed because of this. I don’t even see the point in replacing the catalytic converter, since the new one will also quickly become unusable. It is cheaper to install a flame arrester and a snag on the lambda probe. In the photo above you see the manifold with the catalyst removed and a flame arrester installed.

The engine itself has a cast iron block, which Korean engines fervently dream of, and this is not sarcasm. What's next? And then the confused timing system. We see that there is an oil phase shifter on the intake camshaft. We also see that there are no more marks and to replace the timing belt you will need a special tool. And one more thing - the pump. Let the factory finally listen to us in these engines and install a pump with a metal impeller, since the plastic one always crumbled. But this decision at the State Russian Museum is simply insane.

Not only do you need a special tool to lock the camshafts and crankshaft, there is also a cunning system - in order to install the tool on the camshafts, you need to remove the intake manifold, remove the camshaft position sensor, remove the valve cover and unscrew the plugs into which you will insert a special key and remove it from intake camshaft adjuster. In fact, the bar for locking the camshafts is inserted from the rear of the engine.

Just imagine, you stopped in the God-forsaken village of Kukushkino and discovered that the pump was leaking. Even if you are lucky enough to buy a pump for your car at the nearest auto shop (strangely enough, there is a big shortage of spare parts in Togliatti now), it will not be so easy to change it with your own hands. As I already said, you need to disassemble the motor to this state:

And local Kulibins are unlikely to have a similar strip for camshafts on hand. I can imagine what kind of setup awaits you. Then, in addition to a can of oil and a suitcase with keys, you also need to carry locking bars, which on average will cost you 5-6 thousand rubles.

We remove the head and observe the “high-quality” milling of the plane. Just notice the amazing finishing and graininess. It seems that the factory does this with the same cutter from the 80s. This occurs even on the plane under the crankshaft rear oil seal cover.

As for the plane of the valve cover, it’s even more or less even. The lid sits on Loctite, and from its traces, you can see where there are still depressions in the plane.

By the way, in order to prevent oil from getting into the spark plug wells, instead of just putting regular round rubber bands there, the plant decided to increase the plane of contact between the valve cover and the head.

Now the pistons. The 1.8 engine is “plug-in”, that is, if the timing belt breaks, the owner will face the sad fate of the valves after they meet the piston. The pistons themselves are T-shaped with a very short and narrow skirt. The oil scraper rings are box-shaped, and in their seating grooves there are very small holes for oil drainage. This is where the oil leak comes from, since the holes that are too narrow become clogged, the rings become coked and cease to perform their function properly. But two holes for oil drains do not help the situation. The quality of the oil that can presumably be poured into the engine, the replacement time and small holes under the rings are not the last reason for coking. The plant also does not take into account that during a cold start, especially in winter, a mixture that is too rich leads to a thinning of the oil film in the cylinders.

By the way, the design of the connecting rod and piston group, including the crankshaft, is identical to that of the 1.6. You can also find oil injectors inside, exactly the same as on the 1.6. That is, we can safely conclude that this engine was made from 1.6, by thinning the main and connecting rod journals, lightening the connecting rods and pistons. In the photo above, you see a repair piston on the left, and a factory one on the right. If you compare them, then the repair pistons contain a whole sheet of A4 technical solutions, after reading which you can fall off your chair =). I would not say that this is sarcasm, since with the installation of repair pistons, the oil consumption actually goes away and reliability increases. But how long the engine will run after repair is a purely debatable question.

So, the repair pistons, even by appearance, make it clear that they are reinforced, have a wider skirt, larger holes for oil drainage and 4 holes for oil drains instead of two. The manufacturer also assures that there are stiffening ribs, which for some reason I could not see, and in fact we see that the landing groove with the first compression ring has moved lower by 0.8 mm, which made it possible to increase the heat zone of the piston and this is worthy. Also, the presence of millings for the valves on the surface of the piston indicates that now if the belt breaks, the valves will remain intact, but do not forget that all these millings weaken the rigidity of the part itself.

There are no complaints about the crankshaft, with the exception of thin necks, but the liners could have been made wider - there is enough space. And there would be more resources.

I would also like to note the quality of the crankshaft half rings. The reinforced one was installed only on one side, on which the crankshaft presses during load. And as the factory says, the ring is made with a coating of baked powder. In fact, this half-ring is simply disgusting and during a major overhaul, if of course you had to deal with this, install reinforced half-rings with a brass layer on both sides - it’s not worth saving!

What do we have as a result? And as a result, if earlier 1.8 was made from 1.6 by garage craftsmen, now the factory is doing the same thing, but the factory does not take into account many factors and therefore we got a “miscarriage”, which, before reaching 100 thousand kilometers, begins to consume oil excessively , the connecting surfaces are made by rough milling (this is no longer an innovation for VAZ engines), and there is a “stand” with a timing mechanism. Keep this in mind before you become the owner of a VAZ-21179 1.8 engine with 122 hp.

Model features

The external parts of the Vesta Cross body resemble the features of a predatory animal that is ready to rush at all nearby road users. A characteristic feature of the car’s exterior are the x-shaped elements in the body stamping. This version of the body is not a repetition of the past Lada cars. The headlights in Vesta SW Cross fascinate the observer thanks to the chic chrome elements inside and outside the device. It is also worth noting a new product that has become available for the only time in the history of the Russian automobile industry - a rear view camera located just below the Lada nameplate.

Question about competitors

All journalists, as one, insist that the main competitors for the Lada Vesta St. Cross station wagon are Kia Rio, Hyundai Solaris, Volkswagen Polo sedan and Skoda Rapid. Personally, we do not share this opinion, because... these are completely different cars and we see the Renault Duster as competitors (yes, it’s a crossover, but for the same money you will get a car with almost identical characteristics, front-wheel drive and mechanics), the Chinese also have a Chery Tiggo 2 crossover, and by paying a little extra money you can consider buying Korean crossover Hyundai Creta.

Safety

Seat belts with squib.

Driver airbag + passenger airbag with deactivation function (depending on equipment).

Body rigidity - 18500N.m/degree. It is worth noting that this is a very decent indicator; the car has the right to be called safe!, as recent crash tests have shown.

Emergency warning system ERA-GLONASS (on all trim levels)