The car suspension is designed to level the movement on any type of road surface and provide comfort for the driver and passengers. The presence of vibration for a long time negatively affects all components and assemblies of the car - bolted and screw connections are weakened. Serious consequences include bent door hinges, sagging doors, and loose closure of the hood and trunk.

The chassis of the Lada Granta has become more modern and modernized. Especially in comparison with previous AvtoVAZ models - two generations of Samara and first generation Kalina. The car has rear and front suspensions, which differ significantly from each other.

The rear suspension of the Grant is the same for the sedan and liftback. In fact, this is the same beam with springs and shock absorbers that is installed on Kalina, Samara and Samara 2. Instead of a stabilizer, a beam is used, which means the structure is dependent.

Front suspension "Lada Grants"

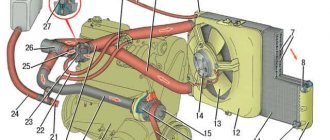

It has an independent suspension with wishbones and a stabilizer bar. Damping of vibrations is carried out by hydraulic shock absorbers. The main structural element is the stand. It includes a swivel bearing, shock absorber and spring. The latter uses coils of variable diameter. The spring itself is made of a metal rod with a circular cross-section. It can have variable and constant hardness.

The front suspension of the Lada Granta is designed so that the lower part of the strut rests on the steering knuckle. When the wheels turn, the spring and shock absorber rotate with it. The stand itself remains motionless. Thus, the engineers achieved an increase in the service life of the elastic element while maintaining the inlet hole in the shock absorber body.

The pillar support has also been improved. Suspension creaking on the Lada Granta appears much less frequently than on Kalinas and Priors. To reduce roll, the design includes a stabilizer bar. It is made of spring steel. The stabilizer is installed with its ends to the lower suspension arms. Its middle part is fixed to the body.

Model options

The new Kalina is equipped as standard with electric power steering, a shortened steering rack, an airbag, sun-reflective glass, electric windows on the front doors and 14-inch wheels. All these improvements are missing on the Granta.

It is not advisable to compare the most expensive car configurations, since they have a large difference in price. It makes sense to compare the top version of the Granta and the mid-range version of the Kalina, since they fall into the same price segment.

In addition to the above improvements, both models have the following equipment:

- heated, electrically adjustable exterior mirrors;

- fog lighting;

- power windows on the rear doors;

- exterior mirrors;

- door handles are painted in body color;

- built-in on-board computer;

- alarm on the control panel;

- heated front seats;

- cabin air filter and air conditioning;

- ABS+BAS;

- touchscreen multimedia system with LCD display.

In addition, Kalina 2 is equipped with a windshield heating system, which Granta does not have.

Rear suspension

Unlike the front, it has undergone virtually no changes. Here, just like on the first Soviet G8s, a semi-independent beam is used. It is attached to the body on hinges (fortunately, there are no “crabs” in the design). A helical spring with constant stiffness is used as an elastic element. To dampen vibrations and prevent swinging, two shock absorbers are used.

The elements come from the factory are oil type. The spring is fixed together with the shock absorber. This greatly simplifies maintenance work, but has a negative impact on handling. Often the rear axle skids when cornering. But despite the archaic design, the owners speak positively about this suspension and highlight a number of advantages:

- High reliability. The design does not have additional levers, which, in addition, can bend when falling into a large hole.

- Energy intensity. The Lada Granta absorbs all bumps perfectly, especially if oil shock absorbers are installed at the rear.

- Cheap maintenance. Due to its simple design, this pendant can be rebuilt even with your own hands. And the cost of new rubber-metal elements is unlikely to empty the pockets of even the most stingy car owner.

The main difference between the “Grant” suspension is the wheel alignment angles.

They have a positive camber of about 0.1°). On Priora, for example, this figure is -1 degree. Next, we will consider the main malfunctions of the chassis on the Lada Grant.

Chassis

Brake system

The Granta has brakes: discs at the front and drums at the rear. We could have ended there, since the service life of disc rotors, pads and calipers is not very long, but sufficient, and their price is low. ABS is common, fortunately all trim levels above the “Standard” relied on it, although the “Norma” sedan version may not have it.

The bulk of the complaints concern the rear drum brakes and frankly unsuccessful drum cylinders. The design itself is not bad, although the high efficiency is achieved due to the large diameter of the composite drums with an aluminum body. But they “sag” a little over time, and therefore they are often replaced with all-cast iron ones, which are very heavy, which affects the driving characteristics. True, it is not the housing that fails, but the historical hydraulic cylinder, without limiters, with poor sealing and a short service life. It can leak over runs of up to hundreds of thousands of km, but whatever! – and at 40-50 mileage there are enough cases of leaks. Well, replacement, as you understand, involves a complete overhaul of the mechanism. It's not that expensive to rebuild, but often the rear brakes on cars without ABS are simply disabled. And some owners are trying to improve braking by turning off the rear axle brake force regulator. Numerous videos of Grants skidding when braking are precisely the result of such intervention.

Against the backdrop of problems with the rear brakes, increased noise from the front calipers, weak pins and boots that require constant monitoring are trifles. Fortunately, the consumables cost just a penny: for a hundred rubles you can buy a pack of spare parts in the nearest store. Buying a new caliper of quite decent quality, and even more so - fresh rotors and pads is also not a problem, prices are extremely low with generally good quality. True, fakes and frankly “crooked” copies are very common. At VAZ, alas, they still rivet the consumables “on the knee”.

Rotting tubes and swelling hoses are found mainly on cars in “advanced” years - all these elements serve their five years honestly, but after that it’s up to you to see how it goes.

For those who lack the standard brake system, and there are many of them among Grant owners, literally everything can be redone. Fortunately, there are certified HA kits, and enlarged rotors for the front wheels, and options with notches, perforations, and simply from good brands. Every whim for your money.

The main thing to remember is that all alterations often actually lead to a decrease in the efficiency of the brakes, because the standard ones were not so bad and were still made by engineers, and not by garage “practitioners”.

Suspension

The Granta also has a suspension, and what a charm it is. It is precisely for these suspensions that people in the outback still love VAZ. Here the ground clearance is good, the moves, and the energy consumption are quite decent. Cars in the “Standard” configuration are usually equipped with a basic suspension with classic twin-tube shock absorbers, while the “Norma” and “Lux” have gas-filled ones. Both the springs and the stabilizer are different. In any case, the brand is SAAZ, the markings of the first suspension elements, shock absorbers and springs start at 2190, and the second - from 21980.

In theory, the second option should handle better, but in fact both are designed more for confident driving on very bad roads and comfort. If you need controllability, then there are modification kits. Moreover, the scale is impressive; you can even buy a front subframe with wishbones. Thanks to the “factory tuning” in the person of Granta Sport with its sports tubular arms on the subframe and Demfi struts, which set a good standard for the quality of suspension tuning.

As in the case of brakes, in practice it is not so easy to obtain excellent handling by installing any tuning elements; many modifications lead to its deterioration. But installing upper and lower braces and stiffer crabs usually gives the maximum result for a car without special preparation of the body and rear suspension.

The peculiarity of the Granta suspension is that its front MacPherson strut is very archaic in design. There is no subframe, the rack is located high on the engine shield, and a scheme is used with the main support arm and a stretcher arm attached to a forward bracket (the so-called “crab”).

The main advantage of such a suspension is comfort and low quality requirements for rubber products in its composition. The disadvantages are the high compliance of literally all attachment points of the levers relative to the engine shield and rack and, as a consequence, the difficulty in adjusting the handling and its dependence on the design solutions of the body.

At Grant, the designers already understood the basic principles that gave the 2108 sharp steering, and the 2110, on the contrary, jelly steering, so that even the basic cars had taxiing and comfort characteristics that were quite acceptable at the beginning of the 2000s. But with an emphasis on comfort, of course.

In addition to constructive ones, there are other disadvantages. Thus, high bending moments acting on the strut support cup are not supported by the strength of the body, and as a result, the standard support amplifier and the cup itself bend. And the strut support suffers, although modern Grant ones are made with a large bearing, similar to foreign ones.

The high variable load on the front end of the spar does not have the best effect on the durability of its seams, and the strength of the tension brackets is always insufficient; making them stronger means worsening the already poor passive safety of the body. And for confident movement in the style of “more speed - fewer holes”, the strength of the standard one is not enough.

The rear beam is structurally almost ideal, but it has no margin of safety at all. Soviet weight discipline is still noticeable. As a result, its properties as a torsion bar for anti-roll bar are not very pronounced. And she really needs a separate stabilizer to help.

Okay, enough theory. In a large city like Moscow or St. Petersburg, the resource of the Grant suspension is limited mainly by the aging of rubber elements due to chemistry and has little to do with loads, unless we are talking about minor accidents and impacts on curbs. It confidently withstands its four to five years and a hundred to one and a half thousand kilometers, gradually losing the characteristics of the shock absorbers, especially quickly - the rear ones, which do not like loads. At the same time, the front support amplifier is bent. At high peak loads, the corresponding elements, bracing brackets, supports, and, less often, the transverse arms of the front suspension are usually given out.

To make a tragedy out of suspension repairs on a Grant means to be either a formalist or a very greedy person. Prices for decent spare parts are at the level of a mid-range budget foreign car and even lower.

Of course, you won’t achieve the legendary “Mercedes” suspension mileage, nor comfort, but in general you can get good performance for an inexpensive price. And you don’t need to order anything; completely normal spare parts can be found in any corner of the country. But, as with other spare parts for VAZ, you need to be careful: silent blocks made of raw rubber and brackets made of recycled materials, re-painted used shock absorbers are found on sale alarmingly often.

Steering

The rack here is simple mechanical and well known to at least two generations of mechanics. It lasts 150-200 thousand if you keep the anthers intact and do not abuse off-road driving and flying over uneven terrain.

On cars with an electric power steering there is a shorter one, on cars without an amplifier there is a longer one, but they are structurally similar. The attachment to the engine shield is not very good, but the design is clearly forged in the fire of the old school of engineering. In the sense, it is optimized for minimum production cost, weight and acceptable resource.

The EUR on the Grant is an add-on for the steering column, and it exists in two versions. The domestic gearless one from Avtoelektronika from Kaluga pleases with its steering quality, and the Mando from Korea is simply more reliable due to a better torque sensor, but it can jam at the most inopportune moment. Unfortunately, it is difficult to combine the advantages, and even the latest versions of the Kaluga electric power steering suffer from not very good soldering, including the torque sensor cable, but Mando seemed to be completely abandoned in 2014 after a loud scandal with a jammed steering wheel on cars for journalists. And it’s true: it’s better without power assistance than with a steering wheel that’s tightly jammed.

But in fact, you can find Korean amplifiers on later cars: for example, almost all Granta Sport are equipped with them. By the way, many owners of cars with electric power steering advise lubricating the amplifier gearbox by adding new grease using a grease nipple through the hole of one of the bolts. According to reviews, this significantly improves responsiveness in the near-zero zone.

As for the rest, it is worth noting the regular problems with cardan joints, the short service life of rods and ends (but how elegantly the nuts are locked on the factory versions). And also the low cost of all consumables.

Shock absorber

This element is a damping device. The shock absorber serves to reduce the range of vibrations of the car body. In other words, the element prevents spontaneous rocking. The work of the shock absorber is based on hydraulic resistance. Inside it there is a liquid of a certain viscosity. It moves through a special valve. Thus, the device absorbs sharp impacts while preserving vulnerable suspension parts. Therefore, the shock absorber is one of the most important components in the chassis. On our roads, this element lasts about 60-80 thousand kilometers. But this period may be shorter, even with careful driving. It is enough just to damage the protective boot, and all the dirt will accumulate in the rod seal.

The rear shock absorbers suffer the most wear because they have much longer stroke. When driving quickly through potholes, the hydraulic fluid may simply boil. This is one of the reasons why a shock absorber fails. But most often it leaks - the valve loses its tightness due to a strong breakdown or impact. As a result, the outer side of the cylinder becomes coated with an oily liquid. How to determine that this element has failed? It’s very simple - you will hear a characteristic knock in the suspension of the Lada Granta. Moreover, it is clearly visible in the cabin. From the outside, you can hardly hear a broken shock absorber. This knock is so strong that even good music cannot interrupt it. You will hear a broken shock absorber immediately.

Also note that the damping element changes in pairs. That is, in the event of a breakdown of the rear left shock absorber, the rear right shock absorber also changes. As for the front struts, they are more durable. Often they are replaced already assembled with a spring, since they fail no earlier than after 150-200 thousand kilometers.

Car appearance

By creating the design of both models, the plant's designers took a big step forward. For their category, the cars look quite modern; their external outlines show the influence of such European brands as Renault Logan and Renault Sandero. At the same time, they did not lose the characteristic features of Russian cars, standing out from their predecessors.

Kalina 2 is very similar to the previous generation model, but there are some nice changes. For example, the car body has been redesigned in such a way that the car now looks more like a sports car, and aggression has become felt in the design. Grant's appearance has several original solutions. The first thing that catches your eye is the shape of the front and rear headlights, as well as the overall fit of the body.

Silent blocks

By 100 thousand, the silent blocks of the cross member and lower arms fail. Signs of a malfunction are a dull knock from the front suspension of the Lada Granta. Motorists recommend replacing these elements with polyurethane ones.

They are characterized by higher strength and good service life. At the factory, rubber silent blocks are installed that do not withstand the impacts of our roads. To replace, we need to press out the old element. First, the bead is cut off from it, and then knocked out using a mandrel or chisel. Pressing is done using a vice. It is important to maintain alignment and not mix up the installation side. For easier pressing, it is recommended to use lubricant.

The silent blocks of the anti-roll bar also fail. These bushings are also replaced with polyurethane ones.

Design of Granta and Kalina 2 cars

A whole group of engineers worked on the design of both cars, and this time they did a much better job. The cars turned out to be quite modern, similar to some foreign cars, but have their own recognizable features.

The Granta's design was created from scratch and is not similar to previous AvtoVAZ cars, and the second Kalina is not very different from the first, but looks much more modern and aggressive.

Cause of malfunction

The main cause of element malfunction is a violation of the boot seal. Once it starts to crack, dirt and dust will get inside. They act on the ball like an abrasive. As a result, play appears and the support begins to break on its own. Is it possible to repair it? The Lada Granta suspension is designed in such a way that the ball joints cannot be restored and must be replaced entirely with new ones.

These elements are replaced as a set. The price of two balls is about 700 rubles. The service station will charge about 600 for installation. Although you can replace them yourself. All you need: a jack, a pit, a set of sockets and a special sprocket wrench. But please note that the bolts in this place may become sour. When replacing, there is a high risk of licking off the edges of the sprocket. Unscrew all bolts very carefully - do not press too hard. The service life of original ball joints is about 40 thousand kilometers.

Cabin interior and noise insulation

The instrument panel on both models has similar characteristics and contours. The only difference is in the design of the ventilation devices, which have a different shape on each car. The new Kalina model is equipped with seats that adapt to the anatomical features of passengers, as was the case on the previous model. Grant's seats are made of cheap material, they look plain and are not very comfortable.

A test drive on different road surfaces showed that noise insulation in Granta is performed at an extremely low level. Kalina 2 has average performance in this regard. In general, the sound insulation of both cars leaves much to be desired.

The interiors of both cars have impressive volumes both in the rear and in the front. The legs of the driver and passengers are positioned quite freely. It is no secret that in order to reduce the cost of the car, AvtoVAZ installed low-quality cladding in the Grant, which quickly wears out and looks unattractive. Both generations of Kalina are equipped with good quality plastic casing, which does not cause any complaints.

Wheel bearing

This element serves for uniform rotation of the car wheels. There are 4 such bearings on the Grant. On average, their resource is 100 thousand kilometers. What are the signs of a problem? The main symptom is a characteristic hum when moving. It may get worse as the car turns. The hum can occur on either side of the car, depending on which bearing has fallen apart. The entire assembly is replaced with a new one, and it doesn’t matter whether the Lada Granta’s rear suspension or the front one. It is pressed out using a puller with special paws. Pressing takes place in a vice. It is important to maintain alignment when pressing. If a bearing is installed crookedly, it will be subjected to high loads and may fall apart after just a thousand kilometers.

The main enemy of a bearing is moisture. Therefore, during installation it is so important to ensure the element is sealed. Some manufacturers cover it with a special cap (it is put on the fastening nut), which will prevent salt, water and other reagents from getting inside. But as soon as dust penetrates the bearing, the latter begins to operate outside of its temperature range. As a result, the lubricant is washed away, and the dirt acts as an abrasive. Untimely replacement of this element can provoke a sudden wheel wedge, which is fraught with consequences.

What's under the hood of cars?

Both cars have fairly similar 4-cylinder engines with the same volume - 1598 cm 3 . Three trim levels have maximum engine power, which is 87, 98 and 106 hp. With. At the same time, Granta has a basic configuration with an 82 hp engine. With. Car engines run on gasoline, their torque reaches 4200 rpm. at 148 N.m in the most expensive configuration. Fuel consumption is 8.5 liters in urban conditions, 7.3 liters in the combined cycle and 5.7 liters per 100 km outside the city.

The engine allows you to reach a maximum speed of 175 km/h for Granta and 171 km/h for Kalina. The higher speed of the first model is due to the optimized aerodynamic characteristics of the body. In general, both cars are equipped with engines that differ little from each other. According to the head of the Grant and Kalina projects, Oleg Grunenkov, the cars are equipped with an updated type of suspension, the development of which was focused on the suspension of budget cars produced in Russia. This means that both cars have an upgraded suspension with increased service life.

Speaking of transmission, it is worth mentioning that there is no clear leader in this issue either. The latest configurations of both models are equipped with a modern 5-speed manual transmission. Gears shift quite smoothly, and there is no unnecessary noise or rumble while driving. Each of the cars has special configurations with automatic 4-speed gearboxes from the Japanese manufacturer Jatco, which specializes in manufacturing automatics for foreign cars such as Nissan Tiida and Nissan March.

Under the hood of Kalina

It is necessary to dwell separately on the Granta generator, since it fails on almost all cars produced in the first half of 2012. Owners complain that the breakdown is detected after 3-5 thousand kilometers, and dealer service stations refuse to fix it, citing a lack of spare parts.

How to change a support bearing without a wheel alignment on a Lada Kalina

Replacing the support bearing on Kalina without removing the strut is impossible, or will not be correct, but replacing the part without further camber is still possible. In this case, the technology for removing the rack will change:

- After removing the wheel, unscrew the hub lock nut.

- Disconnect the steering knuckle from the ball joint and steering rods.

- Then we remove the steering knuckle from the CV joint with the strut and shock absorber spring, this way you will not break the camber bolts.

Transmission

Again, it is not clear who is better here... The latest releases of Grant's car receive a new manual gearbox with a cable mechanism, the same ones are planned to be installed on Kalina 2. The new gearbox is distinguished by good selectivity, absence of vibrations and ease of switching. Don't forget the fact that Kalina 2 and Granta will have the same Japanese automatic transmission. The automatic transmission from Jatco (a subsidiary of Nissan), although not the latest development, receives only positive reviews. Nissan Tiida cars are still supplied with this automatic transmission. Again it's a draw - our cars have the same gearbox.

Body and paint

After the release of Granta, many began to measure the thickness of the body and were surprised: the new AvtoVAZ product had a very thin layer of metal body! The manufacturer explained this by saying that for the Granta a completely different metal is used, with better qualities and, in general, equal in characteristics to the first Kalina. We beg to differ with this and assure you that bending the body of a Granta is not that difficult; the body is really made of thin metal. They even saved on the plastic bumper - the thickness is no more than 2-3mm. At the time of writing, it is not yet known about the thickness of the body of the updated Kalina 2, but if compared with the first Kalina, the Grant is inferior here.

Here we also note the quality of door locking. If everything is still fine on the new Grant, then over time, closing/opening the doors (especially) the rear ones becomes difficult, you need to make an effort. There is no such defect observed on Kalina.