All modern cars with automatic fuel injection, including the Lada Kalina, are equipped with a gasoline vapor recovery system (VAP). This is a mandatory requirement for cars whose environmental class starts from Euro 3. The system is designed primarily to prevent fuel vapors from entering the atmosphere, but in addition it allows you to maintain stable engine operation and also save fuel.

One of the main components of the SUPS is the canister purge valve. What this element is, how it works and what it is intended for, we will discuss in this article. In addition, we will look at the signs of valve malfunction, the reasons for failure, and also describe the process of replacing it using the example of a Lada Kalina car.

Why do you need a fuel vapor recovery system?

Gasoline belongs to the category of highly volatile hydrocarbons, and its vapors are highly volatile. While the engine is running, the gasoline in the tank heats up, at least a little. In addition, it sways while moving. These processes accelerate the evaporation of fuel, creating increased pressure in the container. Previously, car tanks had only a primitive ventilation system, which simply released vapor through special openings into the atmosphere. Naturally, this caused some harm to the environment, and there was no talk of fuel economy at all.

The introduction of a gasoline vapor recovery system made it possible to solve both of these problems simultaneously. With it, fumes are not wasted into the environment, but are used for their intended purpose, i.e. to ensure engine operation.

Catalytic converter

To comply with Euro II standards for the content of harmful substances in exhaust gases, it is necessary to use a catalytic converter in the exhaust system.

The use of a catalytic converter provides a significant reduction in emissions of hydrocarbons, carbon monoxide and nitrogen oxides from the exhaust gases, provided that the combustion process in the engine is precisely controlled.

To speed up the process of converting hydrocarbons, carbon monoxide and nitrogen oxides into non-toxic compounds, the neutralizer has oxidation and reduction catalysts.

The oxidation catalyst is platinum. It promotes the oxidation of hydrocarbons and carbon monoxide contained in exhaust gases into water vapor and carbon dioxide.

The reduction catalyst is rhodium. It accelerates the chemical reaction of reducing nitrogen oxides into harmless nitrogen, which is one of the components of air.

Oxygen is required to neutralize hydrocarbons and carbon monoxide. At the same time, nitrogen oxides are reduced. Therefore, for the neutralizer to operate effectively, it is necessary to accurately maintain the balance of the air-fuel mixture supplied to the engine.

An increased residual oxygen content in the exhaust gases (during the combustion of lean mixtures) makes it difficult to restore nitrogen oxides. The reduced oxygen content in the exhaust gases (during the combustion of rich mixtures) makes it difficult to oxidize carbon monoxide and hydrocarbons. Only an accurate balance of the air-fuel mixture ensures effective neutralization of all three toxic components.

The most complete combustion of the air-fuel mixture and the most effective neutralization of the above-mentioned toxic components of exhaust gases are ensured with an air-to-fuel ratio of 14.5. 14.6:1, i.e. 14.5. 14.6 kg of air per 1 kg of fuel.

When operating a faulty engine, the converter may fail due to thermal stress (above 970 °C) to which it is exposed during the oxidation of excess amounts of hydrocarbons. Under thermal stresses, the ceramic blocks of the neutralizer can collapse (clog), causing an increase in back pressure.

What does a vapor recovery system consist of?

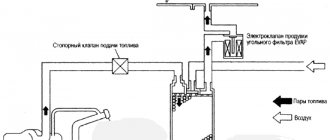

The management system in Kalina consists of the following elements:

- fuel outlet and return lines;

- separator;

- adsorber;

- canister purge valve.

As you can see, the system is quite simple. Let's consider the purpose of each of its elements separately.

As for fuel lines, these are simply tubes through which gasoline vapors leave the tank, and also through which fuel returns back to it. The separator is used to collect fuel vapors and condense them. The adsorber is designed to capture those vapors that did not have time to turn into a liquid state. The adsorber purge valve (“Kalina”) is necessary to direct gasoline vapors to the intake manifold receiver.

Principle of operation

The adsorber itself allows fuel vapors to accumulate in a special place - the separator. As a result, gasoline turns into condensate and goes back to the tank. Vapors that have not undergone treatment go through double valves of the system, one of which prevents fuel from spilling out during an emergency (for example, a coup), and the second “is engaged” in regulating the pressure in the tank. The adsorber purge valve is located under the hood, and the adsorber itself is located on the tank. The control unit ensures the normal operation of the entire system: it ventilates and removes condensation.

How the system works

Fuel vapor rises and concentrates at the top of the tank. When the pressure in the tank rises, vapors enter the fuel line and from there into the separator. There the process of cooling and condensation occurs. Some of the vapor settles on the walls of the separator, turns back into a liquid state and returns through the return fuel line to the tank. The other part, which did not have time to condense, enters the adsorber. The device is a regular plastic jar filled with crushed activated carbon. Vapors accumulate in the adsorber until the engine starts.

When we try to start the engine, the solenoid valve for purge the adsorber (“Kalina”) comes into operation. The signal to open it is supplied from the electronic engine control unit. At the moment of startup, the valve opens and gasoline vapors are supplied through the pipeline into the intake manifold receiver. Thus, fumes, which no one had even taken into account before, help save fuel and also do not pollute the environment.

Valve operating phases

When the engine is turned off, the adsorber purge valve (“Kalina”) is de-energized and is in the closed position. In other words, the vapor recovery system is blocked on the power unit side. At this time, gasoline vapors are concentrated in the adsorber under pressure. When the engine starts, the electronic control unit supplies power to the valve, activating the electromagnet. It opens the shut-off device and gasoline vapors are naturally sucked into the intake manifold. When the engine stops running, the valve is de-energized and shuts off the pipeline. Gasoline vapors stop entering the receiver. This is how the adsorber purge valve (“Kalina”) works.

Some modern foreign-made cars are equipped with more complex devices. Their design is supplemented with sensors that allow the electronic unit to additionally receive information about the saturation of the adsorber with fuel vapor, estimate the percentage of air and, based on the data obtained, control the fuel supply to the injector.

Signs of a malfunctioning canister purge valve

The adsorber purge valve (Lada Kalina), like any other electromechanical part, can fail. Signs of its malfunction are:

- the appearance of the message CHECK on the dashboard (during testing, an error code P0441 is detected, corresponding to a malfunction of the gasoline vapor recovery system);

- floating engine speed at idle;

- unstable engine operation while driving;

- increased fuel consumption;

- increase in CO2 level in exhaust gases.

In addition, in Lada Kalina cars, a malfunction of the canister purge valve can manifest itself in the appearance of a characteristic smell of gasoline in the cabin. This phenomenon occurs when the pressure in the vapor recovery system exceeds design values.

Diagnosing the valve is not difficult, but you need to know where to look for it.

Error P0441

Owners of Lada Kalina often note that during the operation of the car, error P0441 appears, indicating that the gasoline vapor purge system is not operating correctly (the air flow differs from the norm). The cause of this malfunction may be:

- inoperative adsorber valve;

- clogging of the air line from the control unit to the air filter;

- air leakage through connecting pipes.

What should not be immediately considered is the line from the gas tank to the adsorber; here, a breakdown does not in any way affect the readings of the computer or diagnostic scanner. Still, most often Evap-Solenoid fails; this is a characteristic “disease” on Kalina.

If the EVAP valve stops functioning normally, it is not at all necessary that the engine will lose power, the fuel pump will fail, and so on. Mainly due to problems with the control gear, exhaust toxicity increases, and the Check Engine on the dashboard periodically lights up. There are car owners who do not pay attention to the diagnostic warning light, continuing to operate the car, but do not experience any great inconvenience. And most often in such a case, gasoline consumption does not exceed the norm, the engine starts normally, and no serious problems occur in the fuel system.

Valve check

If you suspect that the device is out of order, rush to diagnose it and, if necessary, replace it. No, its failure does not have critical consequences. The car has driven and will continue to drive, it’s just that the engine will work in emergency mode, and it will consume more fuel. But how to check the canister purge valve on Kalina on your own?

This process will not take much time. And all you need in terms of tools is a multimeter, a screwdriver and a pair of wires. We lift the hood and find the valve. Next, disconnect the wiring harness from it. To do this, release the block fastening clamp. First of all, let's check whether voltage is supplied to the valve. Turn on the multimeter in voltmeter mode. We connect its black probe to the ground of the car, and the red one to connector “A” on the wiring harness block. Turn on the ignition and look at the instrument readings. The voltage at the terminals must match the battery voltage. If it is not there at all, or it is much smaller, the problem is not in the valve, but much deeper.

If the voltage is okay, we move on. Remove the purge valve. To do this, use a screwdriver to loosen the fastenings of the hose clamps and remove them from the fittings. Slide the valve up the bracket and remove it.

Testing the device involves connecting it directly to the battery terminals. We take one wire and connect it to the positive terminal of the purge valve. We connect the second wire to the negative wire and connect both wires to the corresponding battery terminals. At this moment, a click should be heard, indicating that the electromagnet has worked. In this case, the adsorber purge valve can be considered working. If nothing happened when connecting, the device will have to be changed.

Reviews

| № | Positive |

| 1. | Vladilen: I have no problems with the gas exhaust system, the mechanism works properly. I regularly carry out technical inspections and fill up with high-octane fuel. |

| 2. | Vitaly: at 30,000 km the purge valve began to knock. I took the car to the service center, they replaced it with a new one, since then there have been no comments on the work, the mechanisms are working properly. |

| 3. | Kirill: I’ve been actively driving Grant for the second year, it works like a watch, there are no complaints. I believe that compliance with maintenance schedules, high-quality oil, high-octane fuel is the key to long-term operation |

| 4. | Ivan: I’ve been actively using the car for a year and a half, there are no complaints about the quality of workmanship or assembly. Breakdowns happen, but they are minor. I fix it myself, I don’t go to a workshop. |

| 5. | Vladlen: two years have passed since I bought the car, I haven’t made any investments. My recommendations to motorists: buy domestic. |

| 6. | Dmitry: in a year and a half of using the car, I went to the service station twice unscheduled, no breakdown was found, but there was a whistle in the exhaust system. |

| 7. | Georgy: I’m happy with the purchase of the car, the car works like a watch, there are no complaints. I strictly comply with the manufacturer’s requirements, visit official services, and fill up with high-quality fuel. |

| Negative | |

| 1. | Ignat: the first valve flew 30,000 km, the second after 20,000 km. The workmanship is low, the model is crude, there are many shortcomings and shortcomings. I expected better from the Lada Grant. |

| 2. | Dmitry: I drove it for a year and a half without problems, after which the car began to fall apart, I visit service stations more often, carry out repairs and preventive maintenance. |

| 3. | Victor: I do not recommend the domestic brand due to the poor quality of the machine and many defects. |

Changing the purge valve

Trying to repair a valve is a thankless task. And it's inexpensive. Depending on the modification, the price can range from 350 to 600 rubles.

Replacing the adsorber purge valve on Kalina after checking and dismantling it is carried out using one tool - a screwdriver with a Phillips bit.

The procedure for installing the device is as follows. First of all, we connect the gasoline vapor supply hoses to the valve fittings. Using a screwdriver, tighten the screws securing the clamps. We install the valve on the bracket and slide it along the guides down until it stops. Connect the wiring harness. Turn on the ignition and start the engine. If its performance has noticeably improved, the speed has become stable, and the error message has disappeared from the dashboard, then we have done everything correctly.

Video: Where is the Adsorber on Kalina

A faulty canister purge valve is responsible for idling. The Kalina engine has low thrust. When the engine is running, the characteristic beep will not be heard if the valve is faulty.

Carefully unscrew the tank cap and listen carefully. If a hissing sound is characteristic, this means that there is a vacuum in the tank, that is, the ventilation system is faulty. If there is any sign of damage, replace the canister valve with a new one. A faulty Kalina valve will affect the filtration and purge system. It will be bad to collect and accumulate steam, they will leak. This situation will be indicated by the unpleasant smell of gasoline in the showroom and near the car.

Of course, it's worth checking other components of the fuel system. For example, steam leakage may occur through a leaking tank lid or hole. But if the cause of the entire system is not checked, the purge valve is faulty.

Removing and installing a new valve on a viburnum

The only tool you need for this procedure is a Phillips screwdriver. The work will not take much time and effort and can be done independently in the garage. First, disconnect the terminal from the negative battery and remove the reciprocating compressor (KPA) plug.

In Lada Kalina, access to the valve is a little difficult, so you will need to slightly loosen the clamp on the intake pipe and remove it from the mass flow sensor. Move everything to the side so that it does not interfere with work, and secure it during repair work.

Replacing a valve on a car

If the DMRV is in the way, it can be removed, but it is best to move the valve mount slightly to the side and remove it without any problems. The nozzle must be bent by a maximum of 1 cm and, after some effort, tighten the valve upwards in the direction of the grooves. If everything is done correctly, the part can be removed quickly and easily.

Finally, disconnect the fittings from the system. One of them can be easily and simply removed, but the other will have to tinker, because it is fixed with a special latch. To release the second nozzle from the grooves, you need to carefully press the latch and tear off the antennas using a suitable sharp object, slightly moving the fitting to the side.

The valve is installed in the reverse order of disassembly. It is important to note that when replacing a valve on a Lada Kalina, you must follow the markings: they must correspond to the old and new parts.

How to check the adsorber valve? Attach a regular medical syringe to the outlet with a piston extended a short distance (2-3 cm). You can use a drain hose to make the connection easier. Press the plunger of the syringe. If there is pressure in the valve, the syringe plunger will be pushed down hard and will usually return to its original position.

Then a 12V DC source must be applied to the valve and repeated using a syringe. In this case, the internal pressure should disappear, the valve will open, and the syringe plunger will easily move down. If this does not happen, the valve must be replaced.

Valve repair

Checking and purging the valve

The first signs that the Kalina adsorber needs repair are the appearance of a constant smell of gasoline in the cabin and difficulties that arise during draining the fuel. For repairs, it is necessary to remove the adsorber and disassemble it. Since the device is usually one piece, it is necessary to disassemble the cover for disassembly. This is easy to do with a regular file. After repairs and replacement of major parts, the cover is usually simply sealed. For complete sealing, the seams are treated with resin. The resin dries within 12 hours. It can then be lightly sanded to bring the filter into proper shape.

Spent and unusable coal is poured out of the adsorber. Foam rubber is suitable as an intermediate filter. Remove old filters and replace them with new ones prepared in advance. Some craftsmen believe that foam rubber is not particularly effective and will allow all the dirt to pass along with the coal, so filters can be made from felt. You can place a piece of cotton between the appliance and the felt to prevent small threads from getting into the system. The resulting seals are glued to the base and sealed with sealant.

New coal can be mined from gas masks. It is important that it is completely dry, so it should be thoroughly dried before entering the system.

Once the dry carbon is filled, the filter filters are reinstalled. All plates and springs are installed in place, and then the filter itself. As you can see, diagnosing and repairing the viburnum absorber valve is not difficult, you can do it yourself. Good luck