In a car, the adsorber absorbs fuel vapor from the gas tank ventilation system and supplies it to the intake, because according to environmental standards, the gas tank must be isolated from the atmosphere.

From Wikipedia ;

Adsorber (from Latin ad - on, with and sorbeo - absorb) is a device for absorbing (thickening) a surface layer of a solid, called an adsorbent (absorber), of dissolved or gaseous substances, not accompanied by a chemical reaction. The adsorber is used in chemical, oil refining and other industries. The process occurring inside this apparatus is called adsorption.

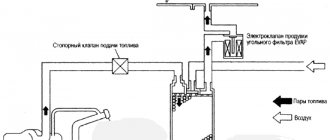

Gasoline vapor filtration system. The diagram is quite conventional, but it reflects the essence. Gasoline vapor from the tank passes through a carbon filter, is cleaned and supplied to the inlet through a solenoid valve controlled by the ECU.

Now the first question is - why filter gasoline vapors if they still go into the intake? The answer is simple - adjusting the internal combustion engine control program by adding the nth number of clean air at the inlet is much easier than making adjustments based on the fuel-air mixture (gasoline vapor from the tank) of an unknown proportion.

And now the answer to the main question - why delete it? So, although some manufacturers claim that this device will have enough resources for the entire life of the car, we know that they are lying)

In general, over time, the adsorber becomes clogged and stops passing air. As a result, we get excess pressure in the tank, which interferes with the normal operation of the fuel pump. In the cabin (sometimes under the hood) we get a periodic smell of gasoline, the vapors of which are squeezed out of the ventilation tube. And the engine starts running on a rich mixture due to lack of air.

Now guess how our country solves this problem? That's right, most people simply throw out the adsorber and turn off the system as shown in the diagram:

A fuel filter from a carburetor classic is usually placed on the tube from the gas tank, and the solenoid valve, through which clean air should flow into the engine, is simply shut off with a bolt.

In the picture I already wrote that this is wrong and here’s why. This method of removing the adsorber only partially solves the problem. Yes, the smell of gasoline disappears, the tank is ventilated, but no air is supplied to the intake and the engine continues to run on a rich mixture.

And now the following diagram:

And now it already shows how it SHOULD be done. The same filter from the classics is put on the hose from the valve to the adsorber, which now serves as an air filter and prevents dirt from getting into the receiver. This is how the fuel-air mixture is brought to normal parameters.

Principle of operation

The adsorber itself allows fuel vapors to accumulate in a special place - the separator. As a result, gasoline turns into condensate and goes back to the tank. Vapors that have not undergone treatment go through double valves of the system, one of which prevents fuel from spilling out during an emergency (for example, a coup), and the second “is engaged” in regulating the pressure in the tank. The adsorber purge valve is located under the hood, and the adsorber itself is located on the tank. The control unit ensures the normal operation of the entire system: it ventilates and removes condensation.

Why do you need a gasoline vapor recovery system?

Injection vehicles (including Kalina), whose environmental class belongs to Euro-3, must be equipped with an EPS. This prevents fuel vapors from entering the atmosphere, polluting it. In addition, the system guarantees more stable operation of the power plant and saves gasoline. How to check the adsorber valve included in the SUBS and how it functions will be discussed further.

Design and operation of the adsorber purge valve

The KPA is an electromagnetic locking device that operates from the vehicle’s on-board network. The valve consists of:

- plastic case;

- valve with spring;

- windings;

- metal core;

- connector

When the vehicle's engine is turned off, no voltage is supplied to the valve and it remains in the closed position. That is, on the motor side, the system that captures vapors is blocked. At the same time, the adsorber begins to “collect” vapors. When the power unit starts, voltage is applied to the valve, causing it to open and fuel vapors to enter the intake manifold. As soon as the ignition is turned off, the control unit is de-energized and the pipeline is closed: no vapors enter the receiver.

Device

Engines with distributed fuel injection first appeared on front-wheel drive Ladas, starting with the 2111 model. They differ greatly from their carburetor predecessors in a more complex power system design. It consists of 2 subsystems: fuel supply to the fuel rail and gasoline vapor recovery. One of the components of the latter is the adsorber in the VAZ-2114.

A solenoid valve is placed on top of the plastic cylinder and is controlled by the engine control unit. This part is removable and secured with plastic latches. The valve body is rectangular, and there are 2 fittings (inlet and outlet) and a connector for connecting the ECU.

The hoses are secured to the fittings using clamps. The incoming one is connected to the gravity valve and then to the separator and the gasoline tank. The outlet is connected to the throttle valve assembly.

Signs of a malfunction of the control unit

First, start the engine: at idle or in cold weather, you will hear a characteristic, barely audible chirping sound. It indicates that the valve is working properly. In order not to confuse this sound with the noise from a working timing belt, sharply press the gas. The character of the chatter should not change. The following signs indicate a malfunction of the control unit:

- lighting of the CHECK signal on the instrument panel;

- determination of error PO441 during testing;

- increased gasoline consumption;

- unstable operation of the power unit when driving;

- unstable idle;

- increase in CO2 content;

- a hissing sound when unscrewing the tank lid (a vacuum has appeared);

- the appearance of a fuel smell in the cabin.

Dismantling the adsorber Lada Granta VAZ 2190

How to change:

- Move the latch stopper upward.

- Disconnect the block with wires from the valve by pressing the latch.

- Disconnect the connection tube with the intake manifold by pressing the spring clips.

- Similarly, we disconnect the connection tube with the adsorber from the valve branch pipe.

- Remove the adsorber valve from the bracket.

Installation of the canister purge valve is carried out in the reverse order.

On a Lada Kalina car, changing the canister purge valve will be somewhat more difficult than on other models of AvtoVAZ vehicles, but in general it is a fairly simple operation that even a beginner can do. To change this part you only need a Phillips screwdriver.

Replacing the adsorber valve on Kalina is carried out in the following sequence:

- Disconnect the negative terminal from the battery.

- Disconnect the power plug from the canister valve.

- To get to the part itself, you need to move the inlet pipe slightly to the side. To do this, use a screwdriver to slightly loosen the clamp of this pipe, and then disconnect the pipe and the mass air flow sensor. After this, the inlet pipe can be easily moved to the side.

- To avoid removing the air flow sensor, bend the valve mount to the side and simply pull it up along the grooves. It will come off without any special effort.

- Disconnect the two fittings that are located on the sides of the part. One of the fittings is fixed with a latch; to remove it, you will need to slightly press the lock and, prying up the plastic antennae, pull the fitting to the side.

Installation of the part is carried out in the reverse order. If you are not confident in your abilities, you should entrust the work to car service professionals.

Almost continuous operation of the fuel vapor absorption system canister can cause damage to the purge valve. A malfunction of the canister valve often leads to damage to the fuel pump. Due to poor ventilation of the adsorber, gasoline accumulates in the intake manifold, the engine loses power, and fuel consumption gradually increases. This may cause the engine to stop completely. The operation of the entire vehicle depends on how the adsorber valve works.

Checking the absorber valve

In order to notice and correct problems in time, regular checks of the adsorber valve are necessary. In this case, a breakdown can be identified by certain indirect signs. When the engine is idling or in cold weather, the vapor absorption system makes characteristic sounds, like the canister valve clicking.

Some people confuse this sound with a faulty timing belt, rollers or other parts. You can check this by sharply pressing the gas pedal. If the sound has not changed, it means the canister valve is clicking. Experts can explain what to do if the canister valve knocks too loudly. To do this, you need to tighten the adjusting screw, and first it is cleared of epoxy resin.

The screw turns approximately half a turn. If you tighten it too much, the controller will generate an error. This adjustment of the adsorber valve will make its operation softer and the knocking noise quieter. However, how to check the adsorber valve for damage? Valve failure can be determined using an error diagnostic system or mechanical testing.

Electronic error codes are stored in the controller's memory and indicate electrical damage. To check the valve, it is recommended to pay attention to errors generated by the controller, such as “open circuit of the canister purge valve control circuit.” Signs by which a malfunction of the adsorber valve can be mechanically determined:

- The appearance of dips at idle speed of the engine.

- Very low engine thrust.

- There is no sound of valve operation when the engine is running.

- A hissing sound when the gas tank cap is opened indicates a vacuum in the system. This is a sure sign of a malfunction in the adsorber ventilation.

- The appearance of a fuel smell in the car interior. However, its appearance can also be caused by other reasons.

- Open the hood and find a cylindrical device - an adsorber.

- Remove the negative terminal from the battery.

- Disconnect the wire block by pressing the latch and pulling it towards you.

- Loosen the valve.

- Remove the fittings under the latch and disconnect the hoses.

- Remove the valve together with the bracket from the adsorber.

- The new valve is installed in the reverse order.

Thus, even such a small element as the adsorber valve performs important functions and its malfunction can seriously disrupt the operation of the entire engine. Therefore, it is important to monitor the condition of your car and carry out diagnostics on time.

The gas tank of any car always contains vapors formed due to a decrease in atmospheric pressure or heating of the fuel. In order to prevent the leakage of fuel vapors into the vehicle, a special gasoline vapor recovery system (VPSU) is installed. Thanks to it, the vapors retained by the adsorber (essentially activated carbon) enter the intake manifold and burn in the engine cylinders. To regulate the amount of gasoline vapor coming from the adsorber to the manifold, a special solenoid valve is used.

Injection vehicles (including Kalina), whose environmental class belongs to Euro-3, must be equipped with an EPS. This prevents fuel vapors from entering the atmosphere, polluting it. In addition, the system guarantees more stable operation of the power plant and saves gasoline. How to check the adsorber valve included in the SUBS and how it functions will be discussed further.

First, start the engine: at idle or in cold weather, you will hear a characteristic, barely audible chirping sound. It indicates that the valve is working properly. In order not to confuse this sound with the noise from a working timing belt, sharply press the gas. The character of the chatter should not change. The following signs indicate a malfunction of the control unit:

- lighting of the CHECK signal on the instrument panel;

- determination of error PO441 during testing;

- increased gasoline consumption;

- unstable operation of the power unit when driving;

- unstable idle;

- increase in CO2 content;

- a hissing sound when unscrewing the tank lid (a vacuum has appeared);

- the appearance of a fuel smell in the cabin.

Regardless of the modification of the power unit (8 and 16 valve), the sensor is installed in the upper left part of the engine compartment. Closer to the drive belt.

In the 16-valve engine version, the top of the engine is covered with a decorative plastic cover. Before starting work, carefully remove the decorative element and begin the repair.

- We place the car within the perimeter of the repair area, install wheel chocks, and activate the parking brake.

- We open the hood, the engine cools down to a safe temperature so as not to damage the skin.

- An adsorber valve is installed in the upper left part of the engine compartment. Carefully pry up the block with wires with a screwdriver and remove the contacts.

Removing contacts

- Unscrew the screw and remove the sensor from its original place

- We troubleshoot the unit, check the integrity of the circuit, the absence of deformation or damage.

- We install a new valve and assemble the structure in the reverse order.

Replacement of the Lada Granta adsorber sensor is completed.

Replacing the adsorber sensor

| Signs | Diagnosis/fix |

| Systematic smell of fuel in the car interior | The circulation of gases is disrupted, there is a leak. Due to the proximity to the air filter, gases enter the car interior. |

| Valve knock | To check the serviceability of the valve, it is enough to sharply accelerate; if the knocking does not disappear, the purge valve is faulty. Replace with a new one. |

| Increased fuel consumption | A faulty gas ventilation valve cannot fully control the flow. Install a new valve. |

| The flow of exhaust gases in the exhaust system has increased | The solenoid valve for purge the adsorber does not work properly. |

| Engine operation is accompanied by hissing | The first sign of excessive gas accumulation. Maintenance of the unit, replacement of worn elements. |

| Uncharacteristic sounds coming from the gas tank | At the same time, the valve can operate normally without giving any “signs”. Maintenance of the unit, dismantling the vapor trap. |

| Error - P0441 | Diagnostics of the on-board computer, deletion, elimination of data in the firmware. |

Failure to respond to a malfunction in a timely manner contributes to premature wear of the fuel pump. Gasoline vapors accumulate in the intake manifold, the engine loses power, and fuel consumption rapidly increases. This ultimately leads to a complete engine stop.

The instruction manual does not contain an exact replacement interval. A prerequisite is preventative maintenance at every scheduled maintenance. The technicians install a new valve as soon as the standard one fails.

In practice, the average service life is 75 – 85 thousand km.

At the beginning of the article, we looked at the process of replacing the adsorber purge valve. However, this is only an integral part of the entire system, which includes:

- adsorber;

- vapor separator;

- gravity valve.

Each of the above elements is dismantled from its regular place for the purpose of prevention and replacement.

- According to the above scheme, we dismantle the separator.

- We remove the gravity valve, having previously pressed out the seal in the form of a rubber bushing.

Removing the gravity valve

- We unscrew two nuts, two bolts, remove the plastic holder, and remove the gravity valve assembly.

- We install a new gravity valve.

Due to the design features of the Lada Grant, access to the adsorber is difficult. First we perform the following steps:

- We remove the fuel tank from the bottom of the car, unscrew the six bolts around the perimeter, and disconnect the block with wires from the fuel pump.

- Disconnect the canister vent pipe and press the lock.

| № | Name | Address |

| 1. | "Diesel Master" | Russia, St. Petersburg, Moskovskoe highway, 13A, Zvezdnaya metro station |

| 2. | "Author " | Russia, St. Petersburg, Mineralnaya str., 13O, Vyborgskaya metro station |

| 3. | "Service Team" | Car service, automatic transmission repair, tire side cut repair, car air conditioner repair, Strogino metro station, Marshala Proshlyakova street, 12k1s1 |

| 4. | Car services, repair of electronic vehicle control systems, repair of electrical equipment, repair of fuel equipment for diesel engines, metro station Gagarina Square, Vavilova, 13a, 1st floor | |

| 5. | "Kulibins" | Kyiv, st. Borova 2/38 |

| 6. | "Renault-Life" | Kyiv, st. Novokonstantinovskaya, 1 G |

Valve check on site

You will need a tester (voltmeter, multimeter) and a screwdriver. The KPA itself is installed on the radiator frame. The device can be recognized by seeing two tubes approaching it, through which the evaporation moves. Further:

- disconnect the electrical connector from the control unit by releasing the block lock;

- using a multimeter, check for the presence of voltage by touching the negative (black) probe of the device to ground, and the red probe to “A” (the letter on the block connector);

- turn on the ignition: the multimeter should show the vehicle's on-board voltage. If not, check the wiring.

Complete removal of the adsorber from the power system

Some VAZ 2114 owners decide to completely remove this part from their car for reasons of savings and to prevent future malfunctions. There are two ways to do this.

Method 1. After completely removing the adsorber from the VAZ-2114, the hose leading to the throttle valve assembly is closed using a plug. A fuel filter from any VAZ carburetor engine is inserted into the hose running from the gas tank to the adsorber.

Method 2. The adsorber is removed along with the support. The hoses previously connected to it are closed using plugs. A small hole (1-2 mm) is drilled in the standard gas tank plug to connect the cavity to the atmosphere. You can also use the cap from a carburetor “eight” or “nine” to depressurize the fuel tank.

After upgrading the power system, it may be necessary to update the firmware of the engine control unit, since it will perceive the absence of an adsorber as a malfunction in the engine and switch to emergency operation. This threatens to significantly reduce the traction qualities of the car.

The adsorber in the VAZ-2114 is an important element in the engine power system, which allows you to slightly reduce fuel consumption and eliminate the smell of gasoline in the cabin.

Instructions for checking and independently replacing the canister purge valve on LADA Samara 2114, 2113, 2115 cars.

To perform work on replacing and checking the adsorber purge valve you will need:

Disconnect the wiring block from the canister purge valve.- We connect the negative probe of the multimeter to the “ground” of the car

- Turn on the ignition and check the supply voltage at terminal A of the wire block. The voltage should be 12V. If the voltage is less or absent, you need to check the battery charge, the health of the power circuit and the serviceability of the computer.

- Loosen the clamp securing the hose to the valve and remove the hose. In this case, you need to make sure that the hose does not break off.

- Using a screwdriver, remove the valve from the adsorber.

- To check the functionality of the valve, you need to apply 12V voltage to the valve terminals. The plus goes to pin A, and the minus goes to pin B. After power is applied, the valve should open with a characteristic click. If this does not happen, the valve must be replaced.

- Before installing a new valve, check the O-ring. A damaged ring must be replaced.

- We install the new valve in place in the reverse order.