The transmission is designed to transmit torque from the engine to the driving wheels of the car.

The car uses a mechanical transmission, which includes: clutch, gearbox, transfer case, cardan drives, final drives, differentials (inter-wheel and center-axle) and drive wheel drives.

A schematic diagram of the transmission of the Niva VAZ-2121 car is shown in Fig. 33. Torque from engine 1 is transmitted through clutch 2 to gearbox 3, where it changes in accordance with the gear engaged. From the gearbox, torque is transmitted through cardan gear 4 to transfer case 5, in which it is distributed equally between the front 14 and rear 8 drive axles of the vehicle by the center differential 6. From the transfer box, torque through cardan gears 7 and 13 is supplied to the main gears of 9 drive axles , in which it increases, and further through differentials 10 and drives 11, 16 to the rear 12 and front 15 drive wheels. In cross-axle differentials 10, the torque is distributed equally between the right and left wheels of each axle. The drive of the rear axle drive wheels includes

only axle shafts. The front axle wheel drive consists of two cardan drives, each of which has two universal joints. This makes it possible to supply torque to the front drive and steered wheels.

Rice. 33. Schematic diagram of a car transmission

The transmission is designed to transmit torque from the engine to the driving wheels of the car.

The car uses a mechanical transmission, which includes: clutch, gearbox, transfer case, cardan drives, final drives, differentials (inter-wheel and center-axle) and drive wheel drives.

In Fig. Figure 25 shows a schematic diagram of the transmission of the Niva VAZ-2121 car.

Composition of transfer case 2121

The device is present only on models with two drive axles. The Niva transfer case is installed behind the gearbox. A cardan (part of the transmission) is placed on the RK itself, connecting it to the rear axle.

The Soviet-made transfer case includes:

- body part;

- drive and intermediate shaft;

- gears;

- bearings;

- satellites;

- front and rear axle drive shaft;

- couplings;

- oil seals;

- flanges;

- differential;

- control levers.

The rigid connection of the gearbox with the transfer case passes through the shaft and coupling.

For better operating efficiency of the vehicle, a subframe is installed, which reduces the torsion of the rear of the machine when moving in dangerous places on the road or in the absence of it.

Transmission

Transmission device

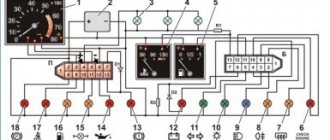

| 1, 3 – Front wheel drive; 2 – front axle; 4 – clutch; 5 – gearbox; 6 – front driveshaft; 7 – intermediate shaft; 8 – transfer case; 9 – transfer case gear shift lever; 10 – differential lock lever; | 11 – rear propeller shaft; 12 – rear axle; I – differential unlocked; II – differential locked; III – low gear engaged; IV – neutral position; V – high gear engaged |

Transmission Specifications

The Niva car is all-wheel drive, i.e. All wheels are driven. All-wheel drive is permanent: torque from the engine is always transmitted to both axles at once (the axles are not disabled). This scheme increases the vehicle’s cross-country ability, while simultaneously reducing the load on the transmission units, but slightly increases fuel consumption.

The front and rear axles are connected through a center differential, allowing the front and rear wheels to rotate at different angular speeds depending on the trajectory and driving conditions. The center differential is located in the transfer case and is similar to the cross-axle differentials located in the front and rear axles. However, unlike them, the center differential can be forcibly locked (the locking lever is located on the floor tunnel). In this case, the front and rear driveshafts become rigidly connected to each other and rotate at the same frequency. This significantly increases the vehicle's maneuverability (on slippery slopes, in mud, snow, etc.), but worsens handling and increases wear on transmission parts and tires on surfaces with good grip. Therefore, the differential lock can only be used to overcome difficult areas and at low speeds. A warning lamp on the instrument panel serves to warn the driver that the locking mode is on.

You can engage the differential lock while the car is moving, if the wheels do not slip. Locking the center differential does not relieve the car from the danger of “diagonal hanging”, when one of the wheels on each axle loses traction with the ground - in this case, pour soil under the suspended wheels or dig it under the others.

To increase the torque supplied to the wheels, a low gear in the transfer case is used, its gear ratio is 2.135. The highest gear, intended for normal driving conditions, has a gear ratio of 1.20. Thus, the driver can use one of two rows of gear ratios - with a high or low gear in the transfer case. The total gear ratios of the “top” row (from 1st to 5th gear) are 4.40; 2.52; 1.63; 1.20; 0.98, “lower” – 7.82; 4.47; 2.90; 2.13; 1.75. The low gear in the transfer case is switched on before overcoming snowy, sandy areas, steep climbs, when towing loads, etc., when there is a lack of engine traction or for driving at very low speeds. It is necessary to engage a low gear in the transfer case in advance, with the car stationary, since the gear shift clutch does not have synchronizers. With some skill, it is possible to engage the highest gear even when driving at a speed no higher than 30–35 km/h, however, if possible, it is better to reduce the speed or stop.

A vehicle with permanent all-wheel drive places special demands on tires. They should be the same not only in size, but also in the degree of wear. Different tire rolling radii will cause increased wear on the differentials under normal driving conditions, and when the lock is engaged, increased wear on other transmission parts and wheel slip.

Video

VAZ 21213 and 21214

VAZ 21213 is an SUV with all-wheel drive and the ability to lock the differential. Niva transfer case 21213 has 3 transmission positions:

During normal driving, the PK device is in first gear. How does neutral work? Shifting to neutral completely disables the transmission, in such conditions the car is unable to move. Note that the gearbox also has a neutral position.

Transfer cases on Niva 21214 differ only in the presence of a speed sensor drive.

How to use a transfer case with a range multiplier on a Niva 2121

The normal position for the RK handles, ensuring adequate behavior on the road of good quality:

- front - away from you;

- back - towards you.

Photo No. 3

The special operating mode of the transmission is switched on not long before the car begins to overcome an obstacle (rut, mud, ford or rise). The transition to the lowest row must be done while stopping. Returning to top gear is allowed on the go, although it causes problems for beginners due to the lack of the usual synchronizer.

It is somewhat more difficult to properly handle the forced manual locking of the center differential. On the contrary, it turns on when the car moves slightly (up to 20 km/h) due to misalignment of the grooves on the locking clutch, satellites and ring gear.

To simplify turning the lever into the desired position, taking into account the Niva 2121 transfer case, pick up a small speed, then, shaking the steering wheel, pull the handle towards you.

Photo No. 4

Problems can also arise when disengaging the lockout, as the clutch teeth literally catch on the ring gear. Engage reverse and, rocking the steering wheel, push the lever away from you. This action is performed immediately after overcoming a difficult section in order to avoid overloading the gearbox.

It is most effective to disable the differential together with the transition to lower stages. In this case, only diagonal suspension of the wheels can stop a Niva 4x4, since standard inter-wheel locking is not provided.

When performing the above operations, you must not give free rein to physical strength. An attempt to “push” the transmission will most likely result in expensive repairs.

Differentials Niva 2121

The purpose of the differential is to distribute engine power to two wheels, allowing them to move at different speeds. The average wheel speed is displayed on the panel. Thus, the differential is the device that makes an SUV an SUV.

If manufacturers decided not to include a differential in the transfer case structure, the result would be frequent tire wear. This would have been a blessing for tire manufacturers, but the developers turned out to be smarter. In addition, the differential reduces the load on the axle.

Modified versions

The Niva's standard transmission, for all its advantages, often causes uncomfortable noise in the cabin. This is generally related to the design, but using engineering developments, you can modernize it and make the car much quieter.

This approach has already been applied in VAZ-21213 cars; as a result, even at a speed of 100 km/h you don’t feel any unpleasant noise, you can talk calmly and hear your interlocutor without effort. For these purposes, a number of modernization methods have been used: from unloading the floor near the transfer case and manual transmission mounts, reducing the load on shaft bearings to smoothing out peak torques under conditions of increasing loads on the transmission. The effect is achieved by changing the mounting location of the front axle gearbox, which in the modernized version is suspended at a distance from the engine on rubber supports. This approach makes it possible to reduce to a minimum the reactive torque in the longitudinal-vertical direction and the noise level at speed.

The noise in the modernized Niva transmission is comparable to that of a Zhiguli. It becomes more comfortable to be in the car when driving off-road. Upgrade costs are negligible; modification requires only the master's understanding of the design itself and a little time.

Transfer case repair

Repair of the transfer case depends on the nature of the breakdown. More often this is mechanical damage, for example, the shaft between the gearbox and the transfer case is cut off. You should sound the alarm if you hear extraneous sounds when the car is moving.

Experts identify the most common types of breakdowns:

- failure of the electronic clutch control unit;

- wear of mechanical parts;

- low-quality materials;

- low quality lubricants.

Among the symptoms of problems with the transfer case, it is worth noting oil leakage, overheating of the gearbox itself, “knocking out” of gears, and problems with turning on.

It is important to follow the entire operating principle of the transfer case to avoid minor damage.

Features of the gearbox on Niva

Real cross-country ability of the VAZ 2121. test video

VAZ 21213 car with an engine capacity of 1.7 liters. can develop power up to 79 horsepower. Fuel consumption averages 10 liters per 100 km. As is typical for gasoline engines, there is a central injection system. Such vehicles should be fueled with AI-95 gasoline.

The Niva gearbox (VAZ 21213) is a five-speed manual transmission. The Niva's transmission has permanent all-wheel drive. It should be noted that there is a reliable gearshift lever extension on the Niva. Thanks to it, speed modes can be changed quickly. The existing camshaft drive is chain driven. The crankshaft includes several connecting rods and main journals. The crankshaft is distinguished by its durability and is made of cast iron. The timing mechanism is covered with a cover. There is an oil filler neck here.

A transfer case is installed on the Niva 2121. Its peculiarity is that it has both high and low gears. It is important to use an increased one if you need to save on fuel consumption. In the event that movement occurs over rough terrain, a lower gear helps out. However, in this case, fuel consumption will increase.

Differential

This mechanism is a kind of distributor of traction forces coming from the motor to the wheels. An important feature is that the latter have the ability to rotate at different speeds. The importance of having a differential mechanism is due to the fact that during turning maneuvers, the wheel located inside makes fewer revolutions when compared with the number of turns of the outer wheel.

In the absence of a differential mechanism, this would cause detrimental consequences, such as wear and damage, because the result would be the following: when turning, one wheel would be in a slip state, and the second would simply rub against the road surface. The design features of the Niva transmission provide for the presence of 3 differentials. They are located in each of the bridges and in the transfer mechanism.

When the car moves on a flat road and in a straight line with differentials, the traction force is divided equally between all 4 wheels. If there is insufficient adhesion of the wheels to the surface or slipping occurs, the differentials will redistribute the load on the slipping and sliding wheel so that the first receives more force, and the second, accordingly, less.

We have already mentioned UAZ. Despite many similarities, it should be understood that the VAZ’s all-wheel drive is made in the “pat-time” style. This means that when connected, the axes are firmly connected to each other, and rotation occurs at the same speeds. This device imposes some restrictions on the use of all-wheel drive - it can only be used in cases where road conditions allow slipping. In cases with hard asphalt roads and highways, it is recommended to switch the car to single-drive mode.

Technical characteristics of the VAZ 21214 gearbox

| Type | Mechanics |

| Number of gears | 5 |

| For drive | full |

| Engine capacity | up to 1.8 liters |

| Torque | up to 140 Nm |

| What kind of oil to pour | Lukoil TM-5 80W-90 |

| Lubricant volume | 1.6 liters |

| Change of oil | once every 65,000 km |

| Replacing the filter | every 65,000 km |

| Approximate resource | 175,000 km |

Other problems

Sometimes there is a knocking sound in the transfer case. The Chevrolet Niva is a more reliable car than the VAZ-2121, but such malfunctions should not be ruled out

The first thing you should pay attention to is the driveline. Previously, Nivas had crosses, the play in which caused a lot of noise and vibration

If you have an old generation Niva, first inspect the crosspieces. As for the new versions, constant velocity joints are used here. There are no backlashes here. Therefore, we look for the reason in the alignment of the gears, which are located in the transfer case itself. If there are any backlashes or gaps, the gears must be replaced. It is also recommended to change the oil in the transfer case. An important point is that if the car overcomes a deep puddle, the lubricant in the box should be replaced as soon as possible. The presence of water in the transfer transmission oil reduces the life of gears and bearings. By the way, the latter also need to be checked and replaced. Perhaps the knocking is due to weak bearing seats. Motorists recommend using anaerobic sealant. They should treat the outer race of the bearings before installing the element into the grooves. Another reason is the so-called helicopter. This is the splined part that secures the breakout with an elastic coupling. If such symptoms occur, check the wear of the splines. If there is play, replace it with a new one.

What do you need to know about the Niva 21213 gearbox?

The Niva car is positioned as an SUV that has increased cross-country ability. Due to this, there is a demand for the car. A durable load-bearing body has been installed. The Niva 2131 model is built on the basis of the LADA 4×4. Its tuning allows you to change the exterior and performance characteristics for the better. Since the mid-1990s. Injection engines have become available for Niva cars.

In addition to passenger cars, self-propelled vehicles are also produced under the Niva brand. In particular, this is Niva SK 5. This vehicle is a combine harvester designed for harvesting crops. The machine runs on diesel fuel.

Disadvantages, breakdowns and problems of the Niva 21214 box

Gear loss often occurs due to self-unscrewing of the shank nut.

Critical wear of gears usually leads to progressive vibrations

Owners of cars with such a gearbox constantly complain about oil leaks from the oil seals.

A drop in lubrication level here is most often expressed in difficult switching

You can contact the site administrator by email: [email protected]

Selection and determination of the main parliaments of the vehicle transmission.

Based on the data specified in the task option, the total mass of the machine mа is determined by the formula:

m=1150.kg - curb weight of the vehicle;

n=4.persons - number of passengers, including the driver;

Selection of pneumatic tires

To select pneumatic tires, you need to determine the maximum load on one wheel of the car. This work is carried out in the following sequence:

1. Based on the sketch of the car being calculated or by analogy with existing cars that are close to the one being calculated in terms of type, class, load capacity (passenger capacity) and purpose, the wheel layout and the position of the center of gravity or the proportion of the total weight of the car attributable to the drive wheels are adopted.

2. The force of gravity of the car per one drive wheel is determined:

km=1 - coefficient (in fractions of unity) that determines the proportion of the total vehicle weight attributable to the drive wheels;

nk=4 - number of driving wheels of the car;

Ga=14,580.kN - total weight of the vehicle.

3. Having determined the gravity force of the car per one wheel, the type and size of the pneumatic tire is selected according to existing standards.

4. Knowing the size of the pneumatic tire, the dynamic radius of the wheels is determined in the same way as for wheeled tractors using the formula:

in which the coefficient taking into account the deformation of automobile pneumatic tires is equal to 0.85. The dynamic radius of the wheel is determined by the formula:

H=185 mm - profile width;

d=16 inches - landing diameter of the wheel rim.

Selecting the kinematic diagram of the vehicle transmission and determining the transmission efficiency

The kinematic diagram of the vehicle transmission is selected based on an analysis of existing transmissions.

Rice. 1.1. Kinematic diagram of the VAZ-2121 transmission

Having chosen the kinematic diagram of the gearbox and mechanisms with a constant gear ratio, a kinematic diagram of the vehicle transmission is drawn up. The kinematic diagram is analyzed and the transmission efficiency is determined:

Determining the efficiency of a car transmission

The transmission efficiency is:

where: ηc=0.98 - efficiency a cylindrical pair of gears, taking into account mechanical and hydraulic losses;

ηк=0.97 - efficiency bevel gear pair, taking into account mechanical and hydraulic losses;

ηk.p=0.99 - efficiency cardan transmission with an angle between the shafts from 0 to 7°;

n is the number of pairs of cylindrical gears operating in the transmission in a given gear.

k is the number of pairs of bevel gears operating in the transmission in a given gear.

m is the number of pairs of bevel gears operating in the transmission in a given gear.

The number of pairs of gears transmitting torque in a particular gear is determined by the kinematic diagram of the vehicle transmission, which is compiled using reference literature.

The results of the analysis of the vehicle transmission are entered into table No. 1:

| Broadcast | Number of cylindrical gear pairs | Number of bevel gear pairs | Number of cardan gears | Designation of gears transmitting power flow in a given gear | ηt |

| 1st | 0,7685 | ||||

| 2nd | 0,7685 | ||||

| 3rd | 0,7685 | ||||

| 4th | 0,7923 |

Determination of the gear ratio of the final drive of the car.

Vehicle speed v

can be expressed in terms of engine revolutions per minute

by

the following formula:

V - vehicle speed, m/s;

n — engine shaft rotation speed, min -1;

io — final drive gear ratio;

ik is the gear ratio of the gearbox and transfer case.

The value of io is determined from the condition of the vehicle moving at a given maximum speed Vmax in direct transmission of the gearbox, i.e. when ik = 1;

Vmax — maximum vehicle speed, m/s;

— gear ratio of the main gear and transfer case

To determine the final drive gear ratio, you need to know: the transfer case gear ratios in high and low gears.

On the highest-4.1937

At the lowest - 2.3571

Vehicle traction calculation

Traction calculation of a car includes plotting: 1) traction balance P = f(v); 2) power balance N = f (v); 3) dynamic factor D = f (v); 4) acceleration of the car j = f(v); 5) acceleration time T = f(v); 6) acceleration paths S = f (v).

The values of the quantities and coefficients included in the formulas are taken from the 1st part of this calculation.

Traction balance chart.

When constructing, they proceed from the traction balance equation;

with steady motion

M is the traction force on the drive wheels, N;

— road resistance force, N;

The force of air resistance has a significant impact on the dynamics of the car. It largely depends on the design, shape and geometric dimensions of the body, the speed of the vehicle and is determined in all gears according to:

k=0.2 - air resistance coefficient; F=2.15m2 – frontal area of the car; Va – vehicle speed, km/h, is determined in all gears depending on the angular velocity of the engine crankshaft:

Diagnostics and repair of the speed box

To carry out a full diagnosis, the speed box must be removed. As a rule, there is a need for this if vibrations, extraneous noise, or oil leakage increase during movement.

How to remove the box? Before you begin removing the gearbox, you must remove the transfer case. Without an inspection hole, it will be difficult to carry out repair work, for example, unscrewing the cardan shafts from the transfer case. The stabilizer can also be removed. The housing of the air filter element must be removed.

In order to remove the gearbox, you should disconnect the lever rod, the clutch housing cover fastenings, the driveshaft, bolts, nuts, and remove the bracket. The suspension of the power unit is adjacent to the body. To remove it you need to unscrew the fastening nuts.

To extend the service life of the VAZ 21213 gearbox, it is advisable to periodically check the level of transmission fluid and change it in a timely manner.

It should be noted that often the appearance of extraneous noise from the gearbox is a consequence of the fact that there is a low level of transmission oil in the system.

Mineral oil can be added to the machine. However, semi-synthetic and synthetic options have better performance. The advantage of the latest types of oils is that even in winter the gears will be easily engaged.

Timely maintenance of the Niva gearbox allows you to avoid a complete overhaul of the gearbox. Assembling all the dismantled parts is a painstaking task, so it should be trusted to professionals. Replacing the gearbox input shaft bearing is a common procedure that is ordered at a service center.