Currently, AvtoVAZ OJSC manufactures for production vehicles and supplies for retail sale drive axle gearboxes of the following models: VAZ 2101 (gear ratio 4.3), VAZ 2103 (gear ratio 4.1), VAZ 2106 (gear ratio 3.9). The gear ratio is the result of dividing the number of wheel teeth by the number of gear teeth. You don't need to count the teeth at all. On the driven gear you can read all the necessary information. For example, the marking “VAZ 2106 1143 4537” should be interpreted as follows: “VAZ 2106” - gearbox model; “1143” - 11 teeth on the gear, 43 teeth on the wheel; “4537” is the number of the main gear set. Therefore, the gear ratio of this gearbox is: 4311=3.9. As you can see, the manufacturer of the gearboxes introduced the name of the car model “VAZ 21**” into their markings. This fact often misleads the consumer. So, for example, owners of VAZ 04, 05 and 07 models, out of ignorance, are looking for a gearbox from a “four”, “five” or “seven”, and owners of VAZ 21063 cars (engine capacity 1300 cc) “safely” install a “sixth” » gearbox with gear ratio 3.9. And then they wonder why the car has become “stupid”: the acceleration dynamics have sharply decreased, and despite the fact that a high-speed gearbox is installed, it cannot be accelerated to a speed of more than 120 km/h. Meanwhile, the marking “VAZ 21**” does not mean at all that this particular gearbox is intended for this car, for example: gearbox 2101 is for a VAZ 2101 car, and gearbox 2103 is for a VAZ 2103 car, etc. The overall and mounting dimensions of all gearbox models are the same. In other words, all gearboxes of VAZ cars are structurally interchangeable. But it is necessary to take into account a number of significant limitations associated with a specific gearbox and vehicle model. Let's take a closer look at these restrictions. Features of using gearboxes on all-wheel drive vehicles For all-wheel drive vehicles, the gear ratios of the front and rear axles must be the same. In everyday practice of car maintenance, quite often there are cases of installing gearboxes with different gear ratios on an all-wheel drive vehicle (Niva, Taiga). Most often this happens due to the lack of appropriate knowledge among those people who repair the car. These can be both car owners who repair the car themselves, and unskilled car service workers who provide services to the population to replace units. When installing a gearbox with a gear ratio different from the required one on an all-wheel drive vehicle, the owner will not notice any disturbances in the operation of the transmission. The car will drive normally until the owner tries to engage the center differential lock. The fact is that this differential “works out” the difference in gear ratios of the gearboxes while driving. A simple, but quite dangerous for transmission units, method of checking for differences in gear ratios in gearboxes is as follows: 1. Place the car on a dry, level road with a slight slope to move forward. 2. Check the vehicle’s ability to roll freely downhill when releasing the brake in neutral. The slope should be small, but sufficient for the car to move on its own. 3. Engage the locking of the center differential (transfer case) and allow the vehicle to roll downhill. If the car rolls as freely as in the test according to point No. 2, the gear ratios are the same. If, with the center differential locked, the car is unable to roll in neutral, the gear ratios are different. Operating a vehicle with different gear ratios is unacceptable. Therefore, before installing a new unit on a car, you should ask what models of gearboxes are installed on the car. KEMP specialists will help you evaluate them without disassembling the car. Features of using gearboxes on rear-wheel drive cars Cars with rear-wheel drive, as already noted, are equipped with gearboxes with different gear ratios. The transmission configuration of modern cars is difficult to predict. So, for example, during the years of production of the VAZ 2102* car, one could say with confidence that it had a gearbox with a gear ratio of 4.44. The modern generation of “twos” - VAZ 2104 * - is usually equipped with a gearbox with diametrically opposite parameters - VAZ 2106, 3.9. This is very unusual for a utility vehicle, but the manufacturer is guided by its own considerations. The situation is also the same with the equipment of other models of the classic Zhiguli. In this matter, judging by experience, there are certain patterns, but there are no hard and fast rules. Therefore, in general terms, we can assume that the “classic” can have any kind of gearbox. In order not to make a mistake, the main condition for replacing a faulty unit with a working one should be observed: whichever gearbox model was removed, this should be installed. When replacing one gearbox with another, with a different gear ratio, not only the dynamic characteristics of the car change, but also the speedometer and odometer readings. Example: if there was a standard gearbox 2102 (4.44), and instead of it a 2106 (3.9) was installed, the speedometer and odometer readings must be multiplied by 1.14, i.e. the car will become 14% “weaker”, but “faster” by the same 14%. “Weaker” means that the engine's effective torque (in this example case) will be reduced by 14%. Outwardly, this manifests itself in a decrease in the car’s throttle response and worsening acceleration dynamics. It is more convenient to explain the term “faster” using a figurative example: if a car with a 4.44 gearbox, in order to develop a speed of 120 km / h in direct (fourth) gear, it is necessary to “spin” the engine to 4400 rpm. crankshaft, then with a 3.9 gearbox for the same speed you will need only 3900 rpm. But to reach 3900 rpm, a 1200 cc engine may not have enough torque or, simply put, power. Thus, the term “faster” in this context is used in the following sense: at the same engine speed, a gearbox with a lower gear ratio allows the car to move at a higher speed. However, it should be remembered that a gearbox with a lower gear ratio requires a proportional increase in engine power. In order for the speedometer and odometer readings to correspond to the actual values, the gearbox must have a speedometer drive that matches the gear ratio of the installed rear axle gearbox. Warning! The speedometer drive cannot be replaced from one to another by simple rearrangement, since it is necessary to replace the next gear (catalog number 210*—170 21 5, corresponding to this drive, on the secondary shaft of the gearbox.

Body weight

ATTENTION! A completely simple way to reduce fuel consumption has been found! Don't believe me? An auto mechanic with 15 years of experience also didn’t believe it until he tried it. And now he saves 35,000 rubles a year on gasoline! Read more"

Let’s say right away that the “six” weighs exactly 1045 kg. Its mass is decomposed as follows:

- The weight of the power unit together with additional equipment is 140 kg;

- The gearbox weighs about 26 kg;

- Shaft – 10 kg;

- Rear axle – 52 kg;

- Radiator – 7 kg;

- Body – 280 kg.

It turns out that the body is the heaviest part of the car. It is exactly twice as heavy as the engine. The remaining parts of the machine have approximately the same mass.

Device types

The VAZ gearbox can be of various types depending on the components. The main gears have an unusual shape, and the teeth are at a variety of angles. This is explained by the fact that a hypoid type transmission is used. Its main advantage is low noise level, jerk-free operation and reduced load on each tooth. Thus, the entire mechanism can be operated for a long time and, as experience shows, quite reliably. The same gearbox is installed on many other models of domestic cars.

Types of rear axle gearboxes VAZ 2106

In addition, the main transfer can be performed in other ways. For this purpose, transmissions are installed:

- Conical;

- Cylindrical;

- Worm-shaped.

However, in most cases, it is the first type that is used, since its efficiency is maximum and its cost is relatively low.

Body dimensions of the “six” and their verification

There is a concept of car body size. Along with this, it is customary to talk about geometric dimensions, which imply control standards and distances, the geometry of door and window openings, the distance between axes and much more.

As a rule, a car that has been in an accident is checked for displacement of the main body elements. Particular attention is paid to the following body parts:

- Diagonals. The car is driven onto the overpass, and then the distance from one extreme point of the floor to the other is checked diagonally using a tape measure. If there is a discrepancy between the distances on one side and the other, there is movement of the body;

- Racks. They are subject to mandatory verification. First of all, if the car has been in an accident, the whole side, not damaged, is diagnosed, and only then the damaged side.

Note. As for the choice of body points, in this case you can choose any. For example, you can select from the pillar to the extreme point of the rear door.

- Roof. To make sure that the roof is not leaking, you need to measure the dimensions of the doorways diagonally. The dimensions, of course, must match on both sides;

- Glass. The conformity of the windshield and rear windows is checked. Both are measured diagonally.

What are axle shafts, why are they needed and how are they designed?

In rear-wheel drive cars, which the “seven” actually belongs to, the rear wheels are driving. It is they, rotating, that make the car move. The torque is transmitted to them from the gearbox through the drive (cardan) shaft, gearbox and axle shafts. There are only two axle shafts: one for each rear wheel. Their role is to transmit torque from the corresponding gear of the gearbox to the wheel rim.

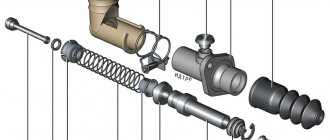

Axle shaft design

The axle shaft is an all-metal shaft made of steel. At one end there is a flange for attaching the wheel disk, and at the other there are splines for engagement with the gearbox gear. If we consider the axle shaft assembly, then in addition to the shaft, its design also includes:

- oil deflector;

- sealing gasket;

- oil seal (cuff);

- bearing.

Each of the axle shafts is installed in the corresponding (left or right) rear axle housing. An oil deflector with a gasket and an oil seal are used to prevent lubricant from leaking out of the casing. The bearing is designed to ensure uniform rotation of the axle shaft and distribute shock loads coming from the wheel to the rear axle of the vehicle.

Main characteristics of the “six”

VAZ 2106 is considered a Soviet and Russian car, produced in the period 1975-2005. The car was manufactured and produced at VAZ, but already in 1998 some production facilities were moved to Syzran and Kherson. In 2002, the “six” was assembled at IzhAvto, where the last model of the legendary car was left on the assembly line.

It will be interesting to know: in total, over 4,300 million VAZ 2106 units have been produced in the entire history of the automotive industry at various factories.

The “Six” was also produced in several modifications. Regarding the body, the following noteworthy points can be made:

- The modification of the VAZ 21061, intended for sale in Canada, had a completely different body installed. This one had special aluminum bumpers and fangs. The bumper also had trims and ends made of black plastic;

- The VAZ 21063 body was equipped with “five” bumpers;

- The body of 21065 was also equipped with aluminum bumpers, and some of the cars going for export were generally modified;

- The VAZ 2121 was equipped with a body with the same bumpers as on the export 21061, only without sidelights.

As for specialized modifications:

- The “six” was produced in a pickup truck. It was a modification of the "Tourist". The pickup truck had a tent built into the bed;

- A single copy of the “six” called “half past six” was produced by order of Leonid Ilyich. It was equipped with a different hood, modified for this modification.

Note. An interesting fact: according to the norms of Soviet industrial economics, the “six” with its dry weight of 1045 kg fell into the group of small class cars, but in terms of the volume of the power unit it fell into the third group.

The body of the “six” and its mass played an important role in compiling the technical data of the car.

VAZ 2107 oil: important recommendations for its selection

Good day, dear blog readers who also happen to be happy owners of a vehicle.

Today we will pay attention to the owners of Zhiguli. There is only one question on the agenda: what kind of oil is needed for the VAZ 2107, as well as the frequency of its replacement

When might you need an oil change?

Let's start by looking at the power units in various modifications of this car. In the old days, the “seven” was equipped with a 1.5 liter carburetor engine. Since 2000, a car with a VAZ 21067 injection engine could be found on sale.

Zhiguli owners, like no one else, know perfectly well that for long-term engine operation it is necessary to change the oil regularly, and we will consider how much oil and how often to change it further. A pressure sensor will help us with this, which automatically analyzes the volume of oil inside all engine systems in various temperature ranges of its operation.

As soon as it becomes necessary to change the oil or top it up, the owner will be notified of this by a light indicator on the dashboard. This may happen for the following reasons:

- dilution of the lubricant mixture

- squeezing it out through connecting hoses, pipes, etc.

- loss due to loose clamps

- engine head gasket wear and much more

In addition to the fact that you need to monitor the oil level, you need to understand that it loses its characteristics during operation. The standard recommendation is to replace the lubricant every 10 thousand kilometers traveled. In cases where the car is not used regularly, replacement must be done every 6 thousand km.

Which lubricant to choose

The circle of experienced Seven car owners has collected a lot of practical data on the topic of when to change the engine oil and what it should be like:

- mineral. It was the only solution for decades, but fewer and fewer Zhiguli owners are currently using it. If frost sets in above minus 20, starting the car becomes very problematic. That is, you have to forcibly dilute the lubricant by heating in order to be able to turn the crankshaft with the starter

- synthetic and semi-synthetic. The best choice for this machine. By all criteria, such products are better than mineral ones. It provides better lubrication of rubbing parts and components, allowing you to extend the service life of the motor. Even at a temperature of -30 degrees or more, there will be no problems with starting. Despite the frost, the starter can start the engine even on the first try if there is a well-charged battery.

To understand how many liters you will need to purchase in the store, you should know the volume of the entire engine lubrication system. According to the instructions, the exact capacity is 3.75 liters, so you will have to buy at least 4 liters. The traditional capacity of most types of motor oils is 5 liters in one canister (if purchased not on tap). It is better to use the remainder for periodic topping up.

The lower the temperature of the engine oil, the thicker it is and the more difficult it will be to start the engine. It is these indicators from SAE, the American Association of Automotive Engineers, that formed the basis for traditional labeling, for example, 10W-30, 5W-40, and so on. These numbers and letters indicate the viscosity and other performance properties of the lubricating fluid.

The letter W itself indicates that the oil can be used in the winter season. The first number in front of it indicates what temperature it can withstand. As for the second number, it is a display of high-temperature viscosity, that is, it shows how many degrees the oil will withstand in the summer heat without changing its qualities.

If you take the advice of AvtoVAZ, then you should make a choice in favor of such manufacturers as Esso, Shell, Lukoil, Norsey Extra, Novoil. In addition, it is useful to adhere to the following general recommendations:

- it is advisable to use the exact type and modification of lubricant that was poured earlier

- For old, worn-out carburetor-type engines, mineral lubricant is quite suitable, since it does not erode deposits that cover microcracks in the engine

- new engines, and especially the injector, require synthetic oil. It prevents overheating of the power unit and extends its service life.

THIS IS INTERESTING: Replacing silent blocks for Renault Scenic 1

Dependence of acceleration parameters on mass

Engineers and designers know that there are a couple of classic methods to help improve vehicle data. And weight, or rather its ratio, plays almost the most important role in this matter.

Purely hypothetically: if you reduce the weight of the “six” by 10 percent, then the acceleration time to hundred (as we remember, it was 16 seconds) will also decrease by 10 percent. And this is already 15 seconds, which, you agree, is a good result.

To be specific, such a linear relationship between weight and acceleration only works in airless space, that is, in space. In fact, the car does not increase its parameters after 130 km/h, since it is impossible not to take into account the ASV (aerodynamic impact). And no matter how you reduce the weight of the car, you won’t help the matter. She will devote a lot to overcoming resistance. For example, if the power is 80 hp, then 40 hp. will definitely go to resistance, and the other half to acceleration.

It turns out that on cars with more power, weight reduction will have a more positive effect. The power unit still has a lot of power left for acceleration.

Another interesting point concerns the following. During maximum acceleration, the rear axle of the “six” is loaded. A portion of the weight moves from the front to the rear. For a rear-wheel drive car, this is only for the better - road traction becomes more effective. For the same reason, if we are talking about reducing weight on the “six”, it is recommended not to touch the rear, but to localize efforts to unload the middle and front zones.

Note. Another advantage in this regard can be considered the transfer of some components from the hood to the luggage compartment. For example, it could be a battery, washer reservoir, etc.

A few tips to ease the “six”

In order to make the VAZ 2106 a little lighter, it is recommended to do the following:

- Operate the vehicle with an incomplete fuel tank. As you know, a tank filled to the brim means an extra 80 kg of weight, which will certainly affect acceleration and fuel consumption.

- Some experienced drivers also keep the washer reservoir empty - an extra 4-15 kg of weight.

- Carrying a spare tire with you is, of course, correct. But without a spare wheel, the car loses about 12-25 kg, and this is no longer trivial.

- A lot also depends on the type of disk. Thus, it is recommended to use forged wheels. They reduce not only the total, but also the inertial mass by 10-20 kg.

- It is advisable to install the lightest battery. So, a 70-amp battery weighs 5 kg more than a 55-amp battery. We draw the appropriate conclusions.

Which gearbox to choose: 2103 or 2106

In the “nature” of Zhiguli gearboxes there are 4 types:

- VAZ 2101 - gear ratio 4.3

- VAZ 2102 - 4.4

- VAZ 2103 “troika” - 4.1

- VAZ 2106 “six” - 3.9.

The gear ratio is the ratio of the teeth, for example, in a “six” gearbox the large gear is marked 2106 1143. Therefore, to determine the pair, 43/11 = 3.9 is necessary. The larger the number of the pair, the more high-torque the car will be, but it will lose maximum speed. Most often, you can find two types of gearboxes in stores: with a pair of 4.3 and 3.9.

- We hang up the rear axle, drain the oil from the crankcase, remove the wheels and brake drums, and remove the axle shafts. We disconnect the driveshaft from the drive gear flange and move it to the side.

- Using a “13” wrench, unscrew the eight bolts securing the gearbox housing to the rear axle beam.

- Remove the gearbox assembly.

- We install the new gearbox in the reverse order of removal. Apply sealant to the threaded part of the crankcase mounting bolts. After installation, do not forget to fill the rear axle housing with 75W-90 transmission oil. Crankcase volume is 1.3 liters.

How much does the rear axle of a VAZ 2106 weigh?

VAZ 2121

Front

length in compressed position (length measured at the centers of the eyes and the middle of the pins) - 220 mm; stroke - 83.5 mm; rod diameter - 11 mm; tank diameter - 41.5 mm; casing diameter - 50 mm;

Nominal forces at a piston speed of 0.31 m/s, N (kgf) - during the rebound stroke - 120.154 kgf; — during the compression stroke — 17.31 kg.

length in compressed position (length measured at the centers of the lugs and the centers of the pins) - 310.5 mm; stroke - 181.5 mm; rod diameter - 11 mm; tank diameter - 41.5 mm; casing diameter - 50 mm;

Nominal forces at a piston speed of 0.31 m/s, N (kgf) - during the rebound stroke - 114.146 kgf; — during the compression stroke — 22.36 kg.

Shock absorbers VAZ 2123 Front

Connecting dimensions (mm) Maximum 351 Minimum 233

Piston stroke, mm 118

Nominal forces at piston speed 0.31 m/s, N (kgf) compression stroke 329 (33.57) rebound stroke 1740 (177.5)

Connecting dimensions (mm) Maximum 526 Minimum 326

Piston stroke, mm 200

Nominal forces at piston speed 0.31 m/s, N (kgf) compression stroke 329 (33.57) rebound stroke 1740 (177.5)

[img] The reviews are very positive, probably this is not important for the horizontal position of the pendulum. But this scheme has two other drawbacks - delicate SHSs and a lift of more than 4 inches is required.

The rear axle of the VAZ 2101-07 weighs 52 kg The rear axle of the M 412 weighs 55 kg The rear axle of the GAZ 24 weighs 85 kg The rear axle of the GAZ 13 weighs 95 kg The rear axle of the Niva weighs 61 kg The rear axle of the UAZ 469B weighs 100 kg The rear axle of the UAZ 469 weighs 125 kg Rear axle Gas 66 weighs 250 kg (gear ratio 5.5 and 6.cool.gif Rear axle VAZ-21213 - 62 kg GAZ-21 axle - 89 kg, UAZ collective farm axle - 100 kg, UAZ military axle - 121 kg. Front axle Niva -41 kg Front suspension beam VAZ-2121-24 kg front suspension assembly VAZ-2121-135kg Front axle UAZ-452 simple - 131.2 kg Gearbox Gas-66 74kg Transfer case "Niva" -25 kg UAZ -37 kg Gas66- 50-60kg (1-1.982) UAZ gearbox weighs 28kg Gas66-50-60 gear ratios (I-6.55; II-3.09; III-1.71; IV-1.0)

Weight of UAZ springs kg UAZ-452 front assembly 20.9 UAZ-3151 front assembly 17.7 UAZ-469 rear assembly 23.3 UAZ-469BG rear spring 19.4 UAZ-452 1 leaf front with / h 2.9 UAZ-452 2 leaf front with /h 2.9 UAZ-469 1 sheet of front 4.1 UAZ-469 2 sheet of front 4.0 UAZ-469 1 sheet of rear 4.5 UAZ-469 2 sheet of rear 4.4

WEIGHT OF UNITS auto. UAZ: 469B/469(reduced)

engine with equipment and clutch. 170/172 gearbox. 33.5 transfer case. 37.4 driveshafts. 15 front axle. 122/145 rear axle. 100/125 body assembly. 475 frame. .112 wheel and tire assembly. 38.6 radiator. 12

I note that the UAZ can be lightened by almost 500 kg by throwing out the body.

ICE VAZ-21083 with all attachments 96 kg Weight of VAZ 1111 Oka units (in kg): Engine power is 30 hp, base torque (50 Nm) 4.51 kgcm (3400 rpm) Gearbox ratios: I 3.7 II 2.06 III 1.27 IV 0.9 reverse 3.67 Final drive ratio 4.1 or 4.3 Engine assembly without clutch and gearbox - 66.5; gearbox with differential - 24.5 body assembly without upholstery and seats - 172; At 3400 rpm ICE = 4.5 kgcm Gearbox = 16.6 kgcm GP = 71.7 kgcm

TORQUE ICE Gas-53 26-29 kgcm at 2200-2500 rpm UAZ-469 17 kgcm at 2200 VAZ 2101-07 8.7 kgcm and 9.6 kgcm at 3400 Gas66 30 kgcm at 2000-2500 rpm UAZ Patriot 22 kgcm at 2 500rpm T-16 10.5 kgcm and 11 .5 kgcm at 1500-2000rpm Zil 157 35 kgcm at 1400rpm

Gear ratios: Model. GAS. M. VAZ. VAZ. VAZ Stage. 24. 412. 2101. 2105. 2106

1st. 3.50. 3.49. 3.75. 3.67. 3.24 2nd. 2.26. 2.04. 2.30. 2.10. 1.98 3rd. 1.45. 1.33. 1.49. 1.36. 1.29 4th. 1.00. 1.00. 1.00. 1.00. 1.00 ZH. 3.54. 3.39. 4.1. 3.53. 3.34

Transfer case VAZ 2121 Transfer case ratios, high gear 1.2 Transfer case ratios, low gear 2.135

Well, and finally, our Typical values of GP 3.9; 4.22; 4.55

Gear ratios of the VAZ-2107 four-speed gearbox

First transfer. 3.67 Second gear. 2.10 Third gear. ………..1.36 Fourth gear. 1.00 Reverse. 3.53 Main pair of rear axle gearbox with this gearbox. 3.9

MOTORCYCLES! Dnepr I-4.11 II-2.28 III-1.70 IV-1.30 z.kh.-3.67 GP 3.89 or 4.62 Gear ratio of winch gas-66 1:21 btr 1:23

Differential device

The planetary gear is mounted on the differential housing. The differential consists of two axle gears, two satellites and a pin. The main, most common differential malfunctions are wear of the pinion pin (play) and wear of the splines on the axle gears.

On a car, the play of the pin of the satellites can be determined by turning the driveshaft by a quarter or more; if there is no play, then the shaft practically remains in place when you try to turn it in one direction or another.

It's also worth noting that there is never any noise coming from the differential. When moving forward (in a straight line), the differential rotates as one unit and it turns out that there is simply nothing to make noise there.

The cause of noise from the rear axle gearbox when gas is added and the noise disappears after releasing gas is (almost 99.9%) wear of the teeth of the main pair. This is clearly visible on the removed gearbox. The forward side of the teeth has significant wear, while the reverse side shows little wear.

If, after disassembling and troubleshooting the parts of the main pair, wear of the teeth is detected, then no repair will help and it will simply be a waste of time and money. Only the main pair needs to be replaced.

Home-couple

The gears of the main pair are selected at the factory based on contact patch, noise and other parameters and are marked. For example, on the planetary gears it is stamped - VAZ 2103 (model), 10 41 (gear ratio), 4091 (pair number). The main pair number 4091 is also marked on the bevel gear.

After marking these parts, they became the “main pair” and are not installed one without the other, that is, “family”. “- 6” is also marked on the “tip”; this is an amendment for assembling the main pair in the gearbox. When troubleshooting a differential, its bearings are also checked for wear and, if necessary, replaced. Bearing wear is often caused by unprofessional replacement of the gearbox seal.

For example, after replacing the oil seal, tighten the shank nut without observing the tightening torque (pull as much as possible) and the force is transferred not to the spacer sleeve, but to the differential bearings.

These are supports on rotating axes and shafts, which receive loads and transfer them to various structures...

As a result, after a short run after replacing the shank oil seal, noise from the gearbox appears. Only in this case, the “hum” noise in the gearbox is constant and unlike the noise from worn teeth of the main gear. In this case, the hum is constant, regardless of whether gas is added or released.

Rear axle gearbox assembly video

Adjusting the gearbox using special devices and control devices...

During assembly, the gearbox is adjusted according to 4 parameters:

1. Selection of the adjusting ring

Parameters from 2.6 to 3.5. The ring serves to adjust the depth of engagement of the teeth of the “tip” and “planetary gear”, which is strictly specified. This is where the “correction -6” is needed for this main pair, which was mentioned above. Of course, this amendment will be individual for each main couple.

In this video, the main pair will be adjusted using a special device. It is clear that the vast majority of motorists do not have such a device and this is just a clear example of adjusting the engagement depth parameter. An option will also be given for adjustment without a “device”.

A “device” with a micrometer is also installed on the device, simulating the gear of the main pair. The indicator shows zero. Then the indicator leg is transferred to the bearing bed and in this case the indicator shows a value of 3.25, which is not good, since it should be within the range of 3.0. On the second landing plane it turned out to be 3.45. The arithmetic mean is 3.3. To adjust, we will use the correction at the “tip” - “-6”. In this case (– 3.3) + (-6) = 3.36. The thickness of the adjusting washer required is 3.36 mm. Using a micrometer, select the washer of the required thickness.

Note. When the shank bearing wears out, it begins to rotate on the “tip” body. As a result, the bearing end, adjusting washer and shank gear bodies wear out. It turns out that when replacing the shank oil seal, even with the correct tightening torque, the adjustment of the depth of engagement of the teeth of the gears of the main pair is lost and the “howl” of the pair is ensured, as is its early failure.

Let's return to the gearbox assembly...

2. Adjusting the preload of the shank bearings

The shank bearing sits on the “tip” and a NEW spacer sleeve MUST be installed. The video clearly shows that the new bushing is smooth without any deformation, while the previously installed one is deformed. What happens is this: When the shank nut is tightened to the prescribed torque (from 12 to 26 kgf), the bushing takes on the tightening force and, when deformed, works like a spring, creating tension. The tightening force for the VAZ 2107 gearbox nut is significant and the shank must be secured against turning.

In the video we see what kind of “device” the master uses. It is necessary to tighten the shank nut until there is no play. When the nut is tightened correctly, the shank should rotate with a resistance force of 0.3-0.4 kg, therefore, the bearing preload is correct. This assembly rule applies to old (used) bearings.

The differential with bearings is installed and secured with covers (tightening torque is about 8 kgf) and the adjusting nuts of the differential bearings are tightened.

3 and 4. Simultaneous adjustment of the thermal clearance of the main pair and the preload of the differential bearings

For these purposes, another “device” with two indicators is needed. Using the adjusting nuts in the video and everything is shown well, we move the planetary gear towards the teeth of the “cone” to achieve the required clearance. Factory clearance adjustment data is from 0.08 to 0.12 mm. However, such a gap is provided for the new main pair (“tips” and “planets”). The gap is checked in 4 planes by turning the gear. The gap for the working main pair after adjustment is 0.13-0.14 mm.

After making the adjustment, the adjusting nuts are locked with special plates for this purpose, with one or two “antennae”. This completes the assembly and adjustment.

Video of adjusting the engagement depth of the main pair

Adjusting the rear axle gearbox with your own hands without using special devices (the VAZ 2107 gearbox is the same).

In this case, it is necessary to select the thickness of the adjusting washer.

So: Instead of the device, we install the “original” shank and tighten the nut until it stops lightly, leaving a gap. The differential with planetary gear assembly, bearing caps are installed and their mounting bolts are tightened.

When replacing the shank oil seal, a number of incorrect actions are allowed, which ultimately lead to premature failure of the gearbox. Before releasing the shank nut, according to the technology for performing the work of replacing the oil seal, it is necessary to remove the axle shafts (which is almost never done, since the amount of work will increase many times). Although according to the price list, the removal of the axle shafts will most likely be included in the list and a fee will be charged for this, since this is required by the plant’s technology for replacing the oil seal. This is a necessary condition, since the axle shaft will create resistance when tightened and correct adjustment will simply be impossible to achieve.

Before releasing the shank nut, it must be secured against turning and the tightening force of the nut must be checked with a torque wrench, around 12 kgf. Before installing the oil seal, if its outer surface is not rubberized, then you need to use a sealant to guarantee it. Thus, a mark of 0.15 mm on the gearbox stocking will be sufficient to pass oil through the outer surface of the oil seal.

Body dimensions of the “six” and their verification

There is a concept of car body size. Along with this, it is customary to talk about geometric dimensions, which imply control standards and distances, the geometry of door and window openings, the distance between axes and much more.

As a rule, a car that has been in an accident is checked for displacement of the main body elements. Particular attention is paid to the following body parts:

- Diagonals. The car is driven onto the overpass, and then the distance from one extreme point of the floor to the other is checked diagonally using a tape measure. If there is a discrepancy between the distances on one side and the other, there is movement of the body;

- Racks. They are subject to mandatory verification. First of all, if the car has been in an accident, the whole side, not damaged, is diagnosed, and only then the damaged side.

Note. As for the choice of body points, in this case you can choose any. For example, you can select from the pillar to the extreme point of the rear door.

- Roof. To make sure that the roof is not leaking, you need to measure the dimensions of the doorways diagonally. The dimensions, of course, must match on both sides;

- Glass. The conformity of the windshield and rear windows is checked. Both are measured diagonally.

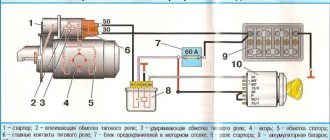

Principle of operation

On a VAZ-2107, switching axes works the same way as on all other cars with a classic driving pattern. Why classic? The answer is simple: the first cars that were produced earlier had a longitudinal engine. So, first came the engine, then the gearbox, the driveshaft and the last element of the chain - the rear gearbox. VAZ-2107 is built on the same principle. But the upcoming 2108 model has a more modern front-wheel drive layout with a transverse engine. It is believed that this design is safer from the point of view of the car coming out of a skid. But in this case, all the components are concentrated in one place (that is, in the engine compartment). In the case of the “seven”, all elements are evenly distributed throughout the body. So, how does the VAZ-2107 gearbox work?

This principle of operation of the gearbox is implemented in most domestic cars, including commercial ones (for example, Gazelle). This device circuit is one of the simplest and most reliable.

Main characteristics of the “six”

VAZ 2106 is considered a Soviet and Russian car, produced in the period 1975-2005. The car was manufactured and produced at VAZ, but already in 1998 some production facilities were moved to Syzran and Kherson. In 2002, the “six” was assembled at IzhAvto, where the last model of the legendary car was left on the assembly line.

It will be interesting to know: in total, over 4,300 million VAZ 2106 units have been produced in the entire history of the automotive industry at various factories.

The “Six” was also produced in several modifications. Regarding the body, the following noteworthy points can be made:

- The modification of the VAZ 21061, intended for sale in Canada, had a completely different body installed. This one had special aluminum bumpers and fangs. The bumper also had trims and ends made of black plastic;

- The VAZ 21063 body was equipped with “five” bumpers;

- The body of 21065 was also equipped with aluminum bumpers, and some of the cars going for export were generally modified;

- equipped with a body with the same bumpers as on the export 21061, only without sidelights.

As for specialized modifications:

- The “six” was produced in a pickup truck. It was a modification of the "Tourist". The pickup truck had a tent built into the bed;

- A single copy of the “six” called “half past six” was produced by order of Leonid Ilyich. It was equipped with a different hood, modified for this modification.

Note. An interesting fact: according to the norms of Soviet industrial economics, the “six” with its dry weight of 1045 kg fell into the group of small class cars, but in terms of the volume of the power unit it fell into the third group.

The body of the “six” and its mass played an important role in compiling the technical data of the car.

Some service issues

If there are no design differences in terms of the internal structure, they are encountered when servicing the rear axle gearbox. First of all, this is dismantling. There are no special problems with rear-wheel drive cars from Tolyatti. But with the Gazelle of early releases they appear: the entire rear axle was non-separable, forming a single unit with the gearbox. Although it gained in reliability, it nevertheless lost in service. There are no difficulties with vehicles produced in recent years.

Many car enthusiasts are interested in the question of whether it is possible to install gearboxes designed for cars of other brands on their cars. The answer from experts is usually clear: if you have never had to do this, then it’s better not to start. The fact is that the parameters of the rear axle unit are directly related to the characteristics of the engine and the design of the gearbox. If the “internals” of the VAZ-2107 and VAZ-2106 are identical, and there is no difference in such replacements, then with the Gazelle the situation is somewhat different.

It is possible to install a similar unit from the “related” Sobol on the Gazelle, and due to this the car will receive a certain “agility”, but the wear period will be reduced.

Having certain skills in servicing passenger cars, an experienced car enthusiast will be able to diagnose and repair the rear axle gearbox of the “classic” Volzhsky Automobile Plant without any problems. But with Gazelle it’s already more difficult. It is better to entrust all necessary manipulations to an experienced car mechanic. This is also associated with such a problem as removing the filler plug of the rear axle. Without special devices, even such a small thing turns into an impossible task.

Device diagnostics and maintenance

It is best to entrust the maintenance of any car to service specialists also because transmission oils, no matter what markings they have, are still quite liquid in consistency. If there are any problems with the rear axle gearbox, then it is also necessary to replace the gaskets and seals, check the breather, bearings, and so on. No one can do this better than a specialist.

Dependence of acceleration parameters on mass

Engineers and designers know that there are a couple of classic methods to help improve vehicle data. And weight, or rather its ratio, plays almost the most important role in this matter.

Purely hypothetically: if you reduce the weight of the “six” by 10 percent, then the acceleration time to hundred (as we remember, it was 16 seconds) will also decrease by 10 percent. And this is already 15 seconds, which, you agree, is a good result.

To be specific, such a linear relationship between weight and acceleration only works in airless space, that is, in space. In fact, the car does not increase its parameters after 130 km/h, since it is impossible not to take into account the ASV (aerodynamic impact). And no matter how you reduce the weight of the car, you won’t help the matter. She will devote a lot to overcoming resistance. For example, if the power is 80 hp, then 40 hp. will definitely go to resistance, and the other half to acceleration.

It turns out that on cars with more power, weight reduction will have a more positive effect. The power unit still has a lot of power left for acceleration.

Another interesting point concerns the following. During maximum acceleration, the rear axle of the “six” is loaded. A portion of the weight moves from the front to the rear. For a rear-wheel drive car, this is only for the better - road traction becomes more effective. For the same reason, if we are talking about reducing weight on the “six”, it is recommended not to touch the rear, but to localize efforts to unload the middle and front zones.

Note. Another advantage in this regard can be considered the transfer of some components from the hood to the luggage compartment. For example, it could be a battery, washer reservoir, etc.

A few tips to ease the “six”

In order to make the VAZ 2106 a little lighter, it is recommended to do the following:

- Operate the vehicle with an incomplete fuel tank. As you know, a tank filled to the brim means an extra 80 kg of weight, which will certainly affect acceleration and fuel consumption.

- Some experienced drivers also keep the washer reservoir empty - an extra 4-15 kg of weight.

- Carrying a spare tire with you is, of course, correct. But without a spare wheel, the car loses about 12-25 kg, and this is no longer trivial.

- A lot also depends on the type of disk. Thus, it is recommended to use forged wheels. They reduce not only the total, but also the inertial mass by 10-20 kg.

- It is advisable to install the lightest battery. So, a 70-amp battery weighs 5 kg more than a 55-amp battery. We draw the appropriate conclusions.

More tips regarding more bodywork:

- Welding the frame will not only increase the rigidity characteristics of the body, but also significantly reduce the weight. The fact is that in this case an unnecessary, extra piece of metal is cut out of the body (no longer needed to maintain rigidity). In addition, it will be possible to install lightweight doors;

- You can replace standard heavy glasses with polycarbonate ones. This will reduce the weight of the car by 30-50 kg;

- You can install bumpers made of lightweight materials instead of standard ones. It will also be necessary to remove standard fasteners and clamps, which will ultimately result in a weight reduction of 20-70 kg;

- The hood and trunk can be replaced with similar ones, but made of composite materials;

- The audio systems in the car, including speakers and a huge subwoofer, also affect the mass;

- You can replace the seats with sports ones;

- Muffler tuning, carried out correctly, results in a weight reduction of up to 40 kg;

- Lightening the power unit by replacing cast iron manifolds;

- Installing a light flywheel results in a reduction of 3-8 kg;

- Standard suspension elements can be replaced with tuning ones, aluminum levers can be installed;

- Replace the steering wheel and gear shift knob.

Remember that the weight of the VAZ 2106 body affects not only the acceleration of the car, but also its other important parameters. Reducing weight affects good handling, braking and much more.

The instructions for lightening the weight of a car given above are not the only one of its kind. Every driver acquires valuable knowledge over time and uses it. In general, competent tuning of a car can be done with your own hands, if you know the nuances and technical data of a particular car model. Videos and photos will greatly help in this matter.

Features of using gearboxes on rear-wheel drive vehicles

Cars with rear-wheel drive, as already noted, are equipped with gearboxes with different gear ratios. The transmission configuration of modern cars is difficult to predict.

So, for example, during the years of production of the VAZ 2102* car, one could say with confidence that it had a gearbox with a gear ratio of 4.44. The modern generation of “twos” - VAZ 2104 * - is usually equipped with a gearbox with diametrically opposite parameters - VAZ 2106, 3.9. This is very unusual for a utility vehicle, but the manufacturer is guided by its own considerations. The situation is also the same with the equipment of other models of the classic Zhiguli. In this matter, judging by experience, there are certain patterns, but there are no hard and fast rules. Therefore, in general terms, we can assume that the “classic” can have any kind of gearbox.

In order not to make a mistake, the main condition for replacing a faulty unit with a working one should be observed: whichever gearbox model was removed, this should be installed.

When replacing one gearbox with another, with a different gear ratio, not only the dynamic characteristics of the car change, but also the speedometer and odometer readings.

Example: if there was a standard gearbox 2102 (4.44), and instead of it a 2106 (3.9) was installed, the speedometer and odometer readings must be multiplied by 1.14, i.e. the car will become 14% “weaker”, but “faster” by the same 14%.

“Weaker” means that the engine's effective torque (in this example case) will be reduced by 14%. Outwardly, this manifests itself in a decrease in the car’s throttle response and worsening acceleration dynamics.

It is more convenient to explain the term “faster” using a figurative example: if a car with a 4.44 gearbox, in order to develop a speed of 120 km / h in direct (fourth) gear, it is necessary to “spin” the engine to 4400 rpm. crankshaft, then with a 3.9 gearbox for the same speed you will need only 3900 rpm... But to reach 3900 rpm, an engine with a volume of 1200 cm3 may not have enough torque or, simply put, power. Thus, the term “faster” in this context is used in the following sense: at the same engine speed, a gearbox with a lower gear ratio allows the car to move at a higher speed. However, it should be remembered that a gearbox with a lower gear ratio requires a proportional increase in engine power.

In order for the speedometer and odometer readings to correspond to the actual values, the gearbox must have a speedometer drive that matches the gear ratio of the installed rear axle gearbox.

Warning!

The speedometer drive cannot be replaced from one to another by simple rearrangement, since it is necessary to replace the next gear (catalog number 210*—170 21 5, corresponding to this drive, on the secondary shaft of the gearbox.

It would seem that nothing can be improved on the classics. However, there are 3 options for gearboxes and 4 rear axle gearboxes. The gearboxes come in 2101, 2105, 2106. The gears (1st, 2nd, 3rd) in 2101 are shorter than in 2105, and longer in 2106. Gearboxes come with gear ratios of 3.9, 4.1, 4.3, 4.44.

How to find out the gear ratio?

Raise the rear wheel, put it in neutral, make 10 rotations of the wheel and count the revolutions of the cardan.

Cardan speed 19.5 20.5 21.5 22.5

Gear ratio 3.9 4.1 4.3 4.44

What does the gear ratio give? The higher it is, the lower the speed in all gears at the same speed. On standard sixes with a 1500 engine, a 2105 gearbox and a 4.1 axle are installed at the factory. If the engine is 1600, then the gearbox is original (2106), the axle is 3.9 or 4.1.

Let's assume that all cars have 175/65R13 tires.

Let's now look at the graph of the dependence of the car's speed on the engine speed (always on the graphs the standard 1500 with a 2105 gearbox and a 4.1 axle will be indicated in green. Why - because there are more of them than all the others).

With a 2106 gearbox and a standard 4.1 axle (raspberry) with a standard engine, we get a gain in dynamics only due to the long 1st gear, the 2.3 has become longer, which is not good (with a standard engine).

If the engine is boosted, then long gears are what you need: maximum power will be delivered over a wider speed range without compromising dynamics. For example, let’s take gearbox 2106 and gearbox 3.9 (raspberry):

Here all the gears are longer (especially the first). For example, in our version in first gear the speed range of 3500-6500 is at a speed of 28-53 km/h, and in the standard it is at 25-45 km/h. Feel the difference! By the way, in this configuration, the first, second, third gears completely coincide with the 11th row on the chisels (with a 3.7 axle), the fourth is shorter, and if the fifth, then it is not much longer than the chisel fourth gear... truly, everything new is well forgotten old :).

Another thing - if we install a bridge 4.44 (raspberry): Compare: 1 is longer