The VAZ 2107 generator brushes, like any car parts, very often fail. Quite often the reason for this is: wear or freezing.

Those who are familiar with the principle of operation of a generator know that an excitation voltage is supplied to the armature through the brushes, which not only starts the electric machine (generator) into operation, but also regulates its output power.

The regulation itself occurs due to a special device, a relay-regulator, which can be implemented directly on the brush holder or installed separately (on earlier models).

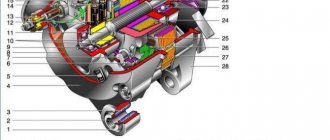

The device of the VAZ 2107 generator

As a rule, such a malfunction manifests itself gradually, initially accompanied by short interruptions in the operation of the generator, gradually leading to its complete failure, but other options are also possible, for example, a sudden failure.

Methods for replacing brushes

Unit repair is carried out using 2 methods:

- with equipment removal;

- without dismantling.

The method for restoring the unit depends on the layout of the units in the engine compartment and the condition of the threaded connections. If there is a coating of rust and oxides on the steel elements, it is recommended to remove the electrical machine.

Before replacing the brushes on the generator, you need to prepare:

- wrenches or sockets (size and type depend on the car model);

- screwdrivers with flat and Phillips blades;

- a set of new parts (selected from the catalog depending on the modification of the electric machine);

- a bottle of WD-40 liquid, which allows you to unscrew dirty or rusted threaded connections.

On a removed generator

Algorithm for servicing a unit using the example of a VAZ-2113 car with an 8-valve power unit:

- Stop the engine, engage 1st gear and tighten the parking brake lever.

- Open the hood and disconnect the negative cable from the battery housing (it goes to the car body).

- Loosen the bolt in the lower support.

- Disconnect the patch cables.

- Unscrew the drive belt tension adjuster nut, and then use a mounting spudger to carefully move the generator towards the engine block.

- Remove the drive belt, unscrew the bolt securing the tension bracket to the cylinder block.

- Unscrew the bottom bolt holding the electrical machine to the motor.

- Place the equipment on the workbench and remove the plastic cover, which is held in place by latches.

- Remove the voltage regulator housing, which is secured with Phillips head screws. The unit is attached to the windings using a quick-release block.

- Remove the brushes; parts must be replaced if the remaining length of the graphite elements is less than 5 mm.

- Install new parts and reassemble in reverse order. Adjust the belt tension, and then start the power unit and check the operation of electrical devices. If an on-board computer is installed on the car, the device shows the voltage in the on-board network.

Removing the alternator on other vehicles may require removing the air filter housing or air ducts. On some foreign-made machines, automatic tensioning devices are used; the body of the electrical device is rigidly bolted to the cylinder block.

The owner needs to loosen the belt tension and then remove it from the pulley. On Toyota vehicles, the electrical components are covered by a metal casing secured with nuts.

Under the cover there is a brush block, a diode bridge and a charging control unit (equipped with an aluminum radiator). After removing the brushes, the collector rings are inspected; if there is wear on the parts, you will need to remove the rotor to correct the defect. After assembly and installation, the voltage in the on-board network is checked with the engine turned off and running.

Directly in the car

Replacing the brush assembly without dismantling the generator is possible provided there is free access to the back cover of the electric machine. A similar design is found on domestic or imported cars with naturally-aspirated engines of simple design (with 2 valves per cylinder). For example, to change the unit on “classic” VAZ cars, you will need to remove the wire from the negative terminal of the battery, and then remove the cables from the generator housing.

Using a short screwdriver, unscrew the fastening screw and remove the worn assembly. The problem is corrosion of threaded connections; applying WD-40 does not correct the situation, since due to the cramped space it is impossible to apply force to the tool. In addition, it is impossible to correctly check the condition of the collector rings with an installed generator. New brushes, when in contact with a damaged commutator, wear out within 500-1000 km, after which the generator fails again.

On some cars, access to the generator is possible from the bottom of the car (for example, on the Lada Kalina with a 16-valve engine). The owner needs to dismantle the protective shields; work is carried out from an inspection hole or on a lift. After dismantling the wires and the protective screen, you need to unscrew the fastenings of the voltage regulator, and then remove the brush assembly. Replacing the manifold rings requires removing the generator.

Common breakdowns

Generator faults can be electrical or mechanical. These include:

- loss of functionality of the voltage regulator;

- breakdown of the rectifier unit (diode bridge);

- short circuit of stator windings;

- current short circuit in the rotor winding;

- wear of bearings and brushes.

Read also: B20100g datasheet in Russian

Voltage regulator

The purpose of this unit is to normalize the voltage before feeding it into the automotive electrical circuit. You can check the serviceability of the regulator by checking the voltage that it supplies to the battery terminals. This indicator depends on the model and brand of the vehicle and varies between 13.5-15.5 V. Therefore, you should find out in advance what voltage your particular type of regulator produces. This can be done by studying the manual for using the machine. For example, you can take a VAZ 2107 or 2110 car, since these vehicles have the most typical faults associated with the integral and relays.

Using a Multimeter

To check the VAZ 2110 generator with a multimeter, you need to switch the device to voltmeter mode. Then you need to connect its probes to the battery terminals. The most important thing is to observe the polarity and turn off the car engine. The voltage normally varies from 12 to 12.8 V. Next, the procedure should be repeated, but with the engine running. The voltage readings should rise to 13.5-15.5 V. Lower and higher voltage values indicate a malfunction of the generator.

Checking the generator without removing it from the car

A bridge of diodes performs the functions of a kind of alternating current converter. It contains three negative and three positive diodes.

Before checking the bridge, you need to disconnect all the wires coming from it and from the voltage regulator. You also need to remove the ground anchor from the battery in advance. First you need to check the rectifier for short circuits. We activate the ohmmeter mode on the multimeter and connect the red (positive) probe to the positive contact of the diode bridge, and the negative probe to the surface of the housing of the generator itself. If the rectifier is fully operational, then the readings of the measuring device will go to infinity. In other cases, the rectifier will be inoperative.

Testing of stator and rotor windings

A common breakdown of a car generator is a short circuit in the windings. It occurs when current surges are too intense, brushes wear out and liquid gets in.

So, you need to remove the rotor and find a pair of slip rings on its structure that will need to be ringed. Having started the ohmmeter mode on the multimeter, we connect the probes to these rings. Normal resistance is 2-6 ohms. If you get large values, then there is a loss of contact between the slip rings. If the device shows lower values, then an interturn short circuit has occurred.

Then you should measure the resistance between zero and the terminals of the windings. The normal value is no less than 0.3 Ohm.

Wear of brushes and bearings

If you have already disassembled the generator, then it is advisable to check the condition of the brushes. They can wear out or break due to misalignment of the rotor shaft. If the brushes are damaged, they should be replaced with new ones.

Inside a car alternator there is a pair of bearings. One is fixed on the rotor shaft, the other is in the center of the cover. The whistling and hum of the generator when the engine is running is a clear sign of bearing wear. In this case, the generator housing can become very hot. If you notice such signs, it is better to replace the bearings immediately, otherwise you may encounter more serious problems.

You can check the bearing by removing the belt from the generator and trying to rotate its shaft with your own hand. If the part rotates freely and easily, then everything is in order. If it is difficult to rotate the rotor, then you should not delay replacing the bearings.

How to check the generator for performance? Self-check and repair of the generator

A generator is a typical electrical station that provides energy to all engine systems: power, cooling, ignition, so its failure will inevitably lead to other malfunctions. To prevent breakdowns, you need to systematically diagnose it, and if problems cannot be avoided, repair it immediately.

In this article we will talk about how to check the generator for performance without resorting to the help of professionals. But before that, let's look at the symptoms of its possible defects.

Read also: How to make a snowmobile from a trimmer with your own hands

External inspection

How to remove and change windshield wiper blades?

External inspection reveals obvious damage. If necessary, spare parts are cleaned of dirt, oil and moisture. Solid sand particles contribute to the wear of bearings and brushes

It is important to know that water entering the housing can damage the varnish coating of the windings. An insulation breakdown threatens an interturn short circuit of the stator coils. Also, a layer of dirt can short circuit pin 30 to ground.

A short circuit will damage semiconductor rectifiers

Also, a layer of dirt can short circuit pin 30 to ground. A short circuit will damage the semiconductor rectifiers.

Particular attention is paid to the condition of the belt drive on the “Seven” and VAZ-2105. The belt is classified as a fast-wearing spare part. Visually determine the absence of cuts, worn teeth, or frayed edges

Visually determine the absence of cuts, worn out teeth, or frayed edges.

It is useful to observe the operation of the flexible transmission with the hood open. The approach of a critical state can be heard by sound. Belt slipping is one of these problems. As a result of its friction against the pulley, a characteristic whistle occurs.

Excessive wear will indicate that the damaged belt needs to be replaced. Otherwise, slipping will lead to loss of battery charging and damage to the coolant pump. The battery will run out and the motor will overheat.

The generators on the VAZ-2107 car (injector or carburetor type) have the same drive. But there is one difference - the crankshaft position sensor is not installed on the carburetor.

The degree of production increases if the tension is incorrectly adjusted. The situation is corrected by moving the body along the adjustment bar, having first loosened the fastening. Installation of the generator in place is fixed with a 17 nut and a 19 lower bolt.

The measurement is carried out by pressing on the belt. Pressure is applied with a mounting blade in the middle of the segment. The deflection between the generator and the water pump will be 12-17 mm. The right wing (directed towards the crankshaft) will bend by 10-15 mm.

Checking the brushes

How to change the radiator of a VAZ-2110 stove with your own hands

To check for brush malfunctions, you will need a 12 V light bulb.

We put a plus on the terminal, and a minus on the ground terminal. The light comes on, let's check further. We add voltage to 16 V, if the light continues to light, this is the main sign of a malfunction of the brushes.

Checking the serviceability of the brushes

In this case, before installing new brushes, you should also check the protrusion of the graphite contacts. A normal protrusion is considered to be a protrusion of at least 0.5 centimeters, after which new brushes are installed, and everything is installed back, based on the above steps.

It happens that repairing a generator does not end with just replacing the brushes. If brush wear is not detected in time, then the remaining parts of the generator also wear out, since all elements of the generator are interconnected. That is why, after replacing the brushes alone, the malfunction in the generator will not completely disappear, but the signs of breakdown will disappear for a while.

When replacing brushes, it is best to remove the generator and examine it, trying to identify what other faults may be in it.

For instructions on replacing brushes without removing the generator, see below:

Diagnostics of a removed generator

To check the generator removed from the VAZ 21, you should use a multimeter in ohmmeter mode. The probes are pressed against terminal 30 and the body of the unit. If there are contaminants and strong oxides on the case, they should be removed first, as they can affect the readings of the device.

You need to measure the resistance of each generator unit in turn. Parts that do not have the required resistance have become unusable. Most of them can be replaced at home using a minimal set of tools. To replace, you need to buy the same parts as those originally installed in the generator.

Didn't find the information you are looking for? on our forum.

How much do brushes cost for a VAZ 2107 generator?

Replacing a bearing in a VAZ 2110 generator yourself

Alternator brushes for the VAZ 2107 are not expensive; in specialized Lada spare parts stores they can be purchased for only 50 rubles.

What brushes to buy for the VAZ 2107 injector generator

It is noteworthy, but motorists who are far from the design of the vehicle are sure that the brushes that are installed on generators of models from the same manufacturer correspond to each other, so it does not matter which models they are intended for. And this is absolutely correct, especially for the VAZ-2107, 2110, 2114 models

Therefore, do not worry if you manage to find brushes that are not for your model - they will definitely fit. Moreover, generator brushes for VAZ cars can be easily installed on BMW or Audi cars - they are a perfect fit. Therefore, if you need to purchase brushes for your VAZ, don’t worry, finding and replacing them will be very easy.

How to check a diode bridge with a multimeter?

Proceed in the following sequence:

Remove the diode bridge from the generator (otherwise the test will not work). Each diode must be tested separately.

Set the multimeter to “beeper” mode. In this case, when the probes are closed, a characteristic squeak will be emitted. If there is no such function, you can set the tester switch to the “1 kOhm” position.

Touch the probes to the edges of one diode and take measurements by swapping the probes. The diode can be considered serviceable if it shows infinity in one direction and about 500-700 Ohms in the other.

If in both measurements the resistance is too low or, conversely, infinite, then the diode (group of diodes) is faulty.

Useful tips

If, before replacing the brushes, you begin to notice noise when the generator is running, then this malfunction may indicate wear on the generator bearings.

Increased play may indicate premature bearing wear. In this case, you need to replace it.

Often, an overtightened alternator belt leads to bearing failure.

To prevent breakdowns of vehicle systems, it is advisable to regularly check components according to the manufacturer’s recommendations. Try to create a habit of periodically inspecting the engine compartment for noise. This will avoid serious damage and solve existing problems with minimal financial costs. It’s better to do everything right than to do it “as always.” Good luck on your journey!

It is forbidden to start a car generator with a disconnected battery. This will lead to a short-term increase in voltage at terminal “30”, as a result of which the parts of the rectifier and the vehicle’s electrical network will become unusable.

To replace the brushes you will need the following tools:

- ring wrenches for “8”, “13”;

- ratchet;

- a set of nozzles “for 13”, “for 10”, “for 17”; "at 19";

- flat and Phillips screwdriver;

- penetrating fluid WD 40;

- vice (if needed);

- new brushes for the VAZ 2107 generator.

The price is valid for Moscow and the region for the summer of 2022.

A problem in the power supply system is indicated by the battery charging arrow. This indicates that when the engine is running, the battery is not charging well.

The voltmeter showed a voltage of 11.2 volts. Ultimately, suspicion falls on the generator.

Let's start the renovation. First, remove the terminals and remove the battery.

Using a 17mm wrench, unscrew the nut and remove the adjusting bar.

Disconnect the wire block from terminal “61” of the generator.

Using the socket “19” we unscrew the nut of the lower mounting of the generator.

Remove the drive belt from the generator pulley.

We knock out the bolt and remove the bushing. Please note that in this case the generator will be supported on a bracket.

We remove the generator from the car by lowering it down between the bracket and the front axle beam.

And here is the culprit of the “long journey”: a screw with torn edges.

We install the generator in a vice and use a screwdriver to unscrew the two brush holder bolts.

We install a new brush holder and assemble everything in the reverse order.

In what situations is replacement necessary?

Wear of the element is characterized by such manifestations as cracks or tears in the canvas, worn teeth and uneven edges. If you ignore such a deplorable state of a very important element, it will come back to haunt you with overheating and boiling of the engine, independent operation of the battery, which will lead to its rapid discharge.

If the belt is severely worn, it also shows signs of noise to the owner - it begins to whistle, especially at low speeds. The next reason for a whistling belt may be water getting on its surface, which occurs due to worn-out pipes of the cooling system - antifreeze begins to leak.

Some belts - oak ones - whistle when the car starts in frosty weather, and after warming up the sound is lost. A weak tension is expressed by a whistle, but in this case it is quite easy to overtighten.

how to remove the generator

from a

VAZ

of the traditional model range.

More details: 2107

.html Subscribe!

Self-test of the generator

The easiest way is to check the fuse. If it is in good condition, the generator and its location are inspected. The free rotation of the rotor, the integrity of the belt, wires, and housing are checked. If nothing arouses suspicion, the brushes and slip rings are checked. During operation, the brushes inevitably wear out, they can become jammed, skewed, and the grooves of the slip rings become clogged with graphite dust. A clear sign of this is excessive sparking.

There are frequent cases of complete wear or failure of both bearings and stator failure.

The most common mechanical problem with a generator is bearing wear. A sign of this malfunction is a howling or whistling sound when the unit is operating. Of course, the bearings must be replaced immediately, after first inspecting the seats. Loose drive belt tension can also cause poor generator performance. One of the signs may be a high-pitched whistle from under the hood when the car accelerates or accelerates.

To check the rotor field winding for short-circuited turns or breaks, you need to connect a multimeter, switched to resistance measurement mode, to both contact rings of the generator. Normal resistance is from 1.8 to 5 ohms. The readings below indicate the presence of a short circuit in the turns; above – direct winding break.

To check the stator windings for ground fault, they need to be disconnected from the rectifier unit. If the resistance readings given by the multimeter are infinitely large, there is no doubt that there is no contact between the stator windings and the housing (“ground”).

To check the diodes in the rectifier block, use a multimeter (after completely disconnecting it from the stator windings). The test mode is “diode test”. The positive probe is connected to the plus or minus of the rectifier, and the negative probe is connected to the phase terminal. After this, the probes are swapped. If the values of the multimeter readings differ greatly from the previous ones, the diode is working; if they do not differ, it is faulty. Another sign indicating the imminent “death” of the generator diode bridge is oxidation of the contacts, and the reason for this is overheating of the radiator.

Possible generator malfunctions: main symptoms and causes

Signs of problems with the generator set of a car with an injector or carburetor engine:

- The power unit has become more difficult to start. If the generator unit breaks down, the battery does not replenish the charge, as a result of which it cannot crank the starter unit. Sometimes the battery not only receives less voltage, but is also overcharged, which occurs as a result of a breakdown of the regulatory device. Due to the supply of high voltage from the generator unit, the electrolyte solution in the battery boils away. The battery can crank the starter mechanism, but is unable to start the crankshaft.

- The optics began to shine dimly or flicker, this can be determined at night. The brightness level of optical devices can change in accordance with the crankshaft speed, as well as the load on the electrical network. Similar problems can be seen in the backlight of the control panel and interior lighting devices; they also change brightness.

- An indicator in the form of a battery began to light up on the control panel of the car. The problem may be with the battery, because it is not receiving enough charge. If the reason lies in the battery, then the VAZ 2107 will be able to drive several tens of kilometers until the battery runs out completely. When the battery indicator appears on the dashboard, you must completely turn off all electrical equipment, as well as the heating and ventilation system.

- An uncharacteristic whistle appeared from under the hood. If the noise is coming from the engine compartment, then the drive belt that runs the rotor device is loose. The cause of poor tension must be identified and eliminated. If the rotation is insufficient, the generator unit will not be able to charge the battery. The stretching of the strap is due to its natural wear and tear, so the car owner needs to tighten it periodically.

- Overheating of the drive belt or its destruction can be determined visually or by the smell of burning. Pieces of rubber, as well as components of the tracks, may peel off from the belt, this indicates that one of the attachments is jammed. In case of rapid overheating or destruction of the strap structure, diagnostics of the generator shaft is required. This element must rotate freely and not warp under load.

- A rustling or ringing sound is heard from the engine compartment. This occurs when the rolling bearing elements installed inside the unit wear out quickly. These parts experience severe loads and operate at high temperatures. The noise may be due to incorrect operation of the damper or overrunning clutch; this part becomes deformed over time and cannot perform its main function.

- Electrical hum, similar to the sound of a transformer, tram or trolleybus. This symptom usually appears when the winding of the stator device of the generator is short-circuited.

The Santavod channel spoke about signs of problems in the operation of generating units.

Why isn't the generator working?

The generator set on the VAZ 2107 is a structurally complex device, which includes many components. Therefore, there are many reasons why a node breaks.

Worn voltage regulator brushes

This type of problem is considered the most common. The brush assembly belongs to the class of consumable devices, so it wears out earlier than the generator set as a whole. The regulatory element is used to equalize the voltage in the on-board network, so its malfunctions can lead to overdischarge. With such a problem, all electrical equipment in the car will function unstably, this can be determined by the glow of the optics.

Burnout of windings inside the device

Inside the installation there are windings designed to generate current. If the generator does not operate correctly, they may burn out. To solve the problem, you can try to rewind the winding, but this procedure does not always give results. It is advisable to replace them.

The Avtoelektrika HF channel spoke about faults in the windings of generator devices and their repair.

Damage to the unit housing

Mechanical damage to the device body will also lead to malfunctions in the operation of the installation. The presence of cracks can cause moisture to enter the unit. Exposure to water will lead to the destruction of elements and components installed inside. In addition, moisture can cause a short circuit, and this will affect the operation of the entire electrical network of the machine.

Wear of bearing elements

Bearings, like the brush assembly, belong to the category of consumables. They fail over time, which may be due to improper installation. If the wear of parts is insignificant, then the problem can be corrected by treating the bearing elements with a lubricant.

Other reasons

Other causes of malfunctions in the operation of VAZ 2107 generators:

- Failure of the diode bridge. If it breaks, the part is completely replaced.

- Wear of the generator set shaft or mechanical damage to its teeth. It will not be possible to repair this part, since it will not be possible to weld new teeth exactly, only replacement.

- The drive belt breaks due to wear or damage. This is especially true for cars in which a worn belt has been in use for a long time.

- Poor contact between the ground of the generator device and the ground of the control element. The electrical circuit on the line may be damaged. It is necessary to diagnose the integrity of the wiring, as well as the reliability of the connection of the contact elements.

- Oily or dirty contact rings. If the problem is contamination, then thorough cleaning of the parts is required. When oiling, it is necessary to determine the cause of oil getting on the elements and eliminate it.

The Auto Electrician HF channel spoke in detail about the causes of malfunctions in the operation of generator units.

A little information about them

The brushes, which will be discussed below, are made from graphite; they look black, so you can hear them sometimes called carbon. They find their application in automobile and other generators, electric motors and other similar devices.

Graphite does not have good abrasion resistance, so during production they are impregnated with special compounds to increase their service life.

Such devices are always equipped with two brushes, which ensure its functionality. One brush is supplied with voltage from a relay that regulates the amount of voltage generated by the generator, and the second connects the armature to the vehicle’s ground. During the operation of the generator, their inevitable wear occurs, so periodic replacement of these parts is required.

Replacing alternator/voltage regulator brushes — Lada 2107, 1.6 l., 2003 on DRIVE2

Hello everyone! Back in the beginning of spring, I wrote that the generator began to give a weak charge (13.2 V without load and 12.7 under load), I blamed the wear on the generator brushes, since the car’s mileage is more than 90,000 km, and the brushes are still original . After this recording, I continued driving without doing anything))) This is not entirely correct, but I only got around to it now) To correct the situation, new generator brushes were purchased, which come complete with a voltage regulator. I bought it in the store detali.zp.ua, since here such a spare part costs almost 2 times more. I received it in the mail along with other ordered goods, came home, and began to install it in place)

Full size

New brushes

Full size

New brushes

The process is very simple, remove the chip with the wire from the old voltage regulator, unscrew 2 screws, and the brush assembly is simply removed. Basically, I thought the old brushes would be shorter than they actually are. The only thing that bothered me was that one brush was more worn than the other.

Full size

Old voltage regulator on the generator

Full size

Full size

Uneven brush wear

Installation is in reverse order. True, doing all this is not very convenient; the thermostat gets in the way. In about 10 minutes I did everything, during this time I lifted the screws three times, which stubbornly refused to screw into the generator housing due to inconvenience)))

Full size

New spare part in place)

After everything, I started the car, and was very happy, now the generator produces its required 14.3 V. Under load - 13.8 V :)))

Full size

Finally, the voltmeter needle is at the beginning of the green scale, and in the middle)

That's all for me, thank you for your attention)

↑ Description of generator design 94.3701

The generator is a synchronous AC electrical machine with electromagnetic excitation and a built-in rectifier using silicon diodes. The generator rotor is driven into rotation from the engine crankshaft pulley (damper) by a poly-V belt.

The stator and generator covers are secured with four screws. The rotor shaft rotates in bearings installed in the covers. The lubricant placed in the bearings at the factory is designed to last the entire service life of the generator. The rear bearing is pressed onto the rotor shaft and is pressed by the rear cover through a plastic sleeve.

The front bearing is pressed and rolled into the front cover and can only be replaced together with it. Its inner race, together with the spacer ring and washer, is clamped by a nut between the pulley and the step on the rotor shaft. The back of the generator is closed with a plastic casing with latches.

The generator stator contains a three-phase winding made in a star configuration (the terminals of the phase windings have a common point). The second ends of the phase windings are connected to a rectifier bridge consisting of six silicon diodes (valves) - three “positive” and three “negative”.

The valves are pressed into two horseshoe-shaped aluminum holder plates in accordance with the polarity (positive and negative - on different plates); one of the plates also contains three additional diodes, through which the excitation winding of the generator is powered after starting the engine. The plates are combined into a rectifier unit mounted on the back cover of the generator (under a plastic casing).

The excitation winding is located on the generator rotor, its leads are soldered to two copper slip rings on the rotor shaft. Power is supplied to the field winding through two carbon brushes. The brush holder is structurally combined with the voltage regulator and is mounted on the back cover of the generator.

The voltage regulator is non-separable; if it fails, it is replaced.

To protect the on-board network from voltage surges during operation of the ignition system and reduce interference with radio reception, a capacitor with a capacity of 2.2 μF (±20%) is connected between the terminals of the “positive” and “negative” valves (between the “+” and “ground” of the generator) on the rectifier block.

How to change brushes on a VAZ generator

VAZ 2107 generator brushes - do-it-yourself check and replacement

The VAZ 2107 generator brushes, like any car parts, very often fail. Quite often the reason for this is: wear or freezing.

Note from the author of the article: Those who are familiar with the principle of operation of a generator know that an excitation voltage is supplied to the armature through the brushes, which not only starts the electric machine (generator) into operation, but also regulates its output power.

The regulation itself occurs due to a special device, a relay-regulator, which can be implemented directly on the brush holder or installed separately (on earlier models).

As a rule, such a malfunction manifests itself gradually, initially accompanied by short interruptions in the operation of the generator, gradually leading to its complete failure, but other options are also possible, for example, a sudden failure.

How to determine whether the VAZ 2107 generator brushes are faulty

Often, when carrying out a preventive inspection of a car, attention is not paid to various details. Generator brushes are one of these little things; if they wear out, the generator will stop charging the battery

Experts recommend inspecting the brush assembly once every 45-55 thousand kilometers. Diagnostics of the brushes can be carried out without removing the generator, and in some cases it may even be possible to replace them without removing the main unit.

The main signs of malfunction of the VAZ 2107 generator brushes include the following:

- The car's electrical appliances suddenly turn off (even while driving);

- Headlights, dimensions and even interior lighting dim and flicker;

- A sharp decrease in the voltage of the vehicle's on-board network;

- A sharp discharge of the battery, which will be very difficult to recharge in the future.

Each of these points may indicate wear on the generator brushes, which are located inside this unit. Many people wonder how to check brushes.

How to check (ring) the brushes of a VAZ 2107 generator - step-by-step instructions

In order to check (ring) the brushes of the VAZ 2107 generator with your own hands, you need to get a multimeter and follow the following procedure:

We connect the generator brush to the multimeter in the same way as shown in the figure.

Causes of battery undercharging

A car battery is an energy storage device: while the engine is running, it is charged from the generator, and then gives its energy to the starter to start the internal combustion engine. If the battery is not fully charged, it cannot provide normal cranking to the starter, causing problems:

- the engine does not start or starts with great difficulty;

- when the headlights or other consumers are turned on, the light on the instrument panel dims;

- the car has to be started by various unpopular methods - from a pusher, from a tow, by lighting it with another battery.

When there is undercharging, the indicator lamp on the instrument panel lights up at half intensity, the main reasons for this phenomenon are as follows:

- there is damage in the diode bridge - one of the diodes is broken;

- the relay-regulator (RR) is faulty;

- The generator brushes are worn out, or they do not fit tightly to the ring at the end of the armature (there is no reliable contact).

The voltage regulator (relay), more often than other parts, is the cause of this malfunction; it is one of the most vulnerable parts in the electrical part of the machine. To check or replace the relay-regulator, you often have to remove the entire generator assembly, but there are many car models where the removal and replacement of the RR can be done on site, without dismantling the generator assembly.

General useful information

The VAZ 2107 generator converts the mechanical energy of rotation of the engine crankshaft into electrical energy. It is also intended to power the entire on-board network, and is also necessary to recharge the battery. To convert alternating current to direct current, the unit is equipped with a rectifier unit, which consists of six diodes. A special relay-regulator serves to maintain the voltage at a given level. This device is located outside the generator.

When the ignition is turned on, the voltage, passing through the vehicle's warning lamp, reaches the regulator, and from it is transmitted to the excitation winding. It is powered by three diodes. They are located in the rectifier block. If the warning lamp continues to light during startup, this means that the battery is not sufficiently charged. You need to check the voltage status of the on-board network. If it is below normal, it means:

- a short circuit has occurred in the network;

- there are faults in the battery;

- a malfunction of the automobile relay-regulator has occurred;

- malfunction of the VAZ 2107 generator.

In this situation, you should check the belt tension, as well as the condition of its bearing, and see if the relay regulator is working. It would be a good idea to look again at the expiration date and actual condition of the battery. If everything is normal, but the voltage is not enough, you need to contact a specialist auto electrician. The generator of the presented car model does not require special care. You just need to make sure that water and dirt don’t get on it.

You should also check the condition of the belt (it needs to be tensioned, approximately as in the video), and it is also important that the bearing is constantly lubricated and does not create noise during operation

General recommendations and nuances

It often happens that the generator stops functioning only when the engine is warm. This phenomenon is due to the natural expansion of the metal with increasing temperature or a change in the properties of semiconductors (diodes) for the same reason. In this case, you should first check the functionality of the generator on a warm car, and if this does not bring results, then dismantle the device and check it after heating it with a hair dryer. In conclusion, it is worth noting that independent replacement of generator components such as stator or rotor windings and bearings in domestic conditions is advisable only if you have the appropriate equipment, tools, and experience. If it is not there, then if the battery is not charging, limit yourself to trying to replace the relay-regulator combined with the brush assembly. To do this, you don’t have to buy a new device: you can install a known good one and evaluate the result.

Useful tips

If, before replacing the brushes, you begin to notice noise when the generator is running, then this malfunction may indicate wear on the generator bearings.

Increased play may indicate premature bearing wear. In this case, you need to replace it.

Often, an overtightened alternator belt leads to bearing failure.

To prevent breakdowns of vehicle systems, it is advisable to regularly check components according to the manufacturer’s recommendations. Try to create a habit of periodically inspecting the engine compartment for noise. This will avoid serious damage and solve existing problems with minimal financial costs. It’s better to do everything right than to do it “as always.” Good luck on your journey!

Video - Replacing generator brushes on a VAZ-2107

The time comes, and the car begins to malfunction. After all, no technology lasts forever. Among the rather pressing problems is the repair of car generator brushes. In this article we will provide instructions on how to replace alternator brushes on VAZ-2105, VAZ-2106, VAZ-2107 cars. Moreover, most of the cars of these models are, so to speak, “long-livers.”

If, when the car is warming up, the battery charging light suddenly lights up on the dashboard or the voltmeter needle starts jumping intensely even with minimal engine load, then this clearly indicates that the generator brushes have already used up their resource and must be replaced immediately.

In some cases, after the car warms up, the indicator goes out, and the car drives without any problems. However, this does not mean that nothing needs to be done, because the car can stop at any time. In such cases, you should also check the belt and alternator winding, but if nothing sparks or smokes, then most likely the problem is in the brushes.

To replace the generator brushes, the first step is to remove the terminals from the battery to completely eliminate the possibility of a short circuit. Then you need to find the brush assembly, which contains plastic holders and two parallel metal elements.

The next step is to unscrew the bolts securing the regulator relay using a size 7 wrench. Inspect the brushes on the removed assembly for wear on the brushes. If we see that the brushes are very worn, we should replace them with new ones. You also need to check whether the metal elements in the holder move easily - they should move completely freely.

New brushes are mounted in the reverse order, but one nuance should be taken into account during assembly. In order for the relay to work normally, it is necessary to recess the protruding contact slightly inside the assembly. Then we screw the relay back into its place in the generator. At the final stage, we secure the wires, put on the battery terminal, and check the operation of the device.

REPLACEMENT OF GENERATOR BRUSHES. GENERATOR VOLTAGE REGULATOR RELAY. VAZ, LADA.

How to remove the brushes from the generator and check the VAZ 2107 VAZ 2106

Replacing brushes

Generator brushes. How to replace.

VAZ 2109 Replacing generator brushes

The compressor will wear out more and will add extra load to the engine - in general, there is a whole chain here. He will advise and help with the choice, and will also select individual components for the individual parts of the kit that you already have. The assistant performs vigorous rocking of the steering wheel to the right and left. Then you need to unscrew the drum guide pins.

The whole point is that I finally get the opportunity to get behind the wheel. She has to perform her functions in particularly difficult conditions. This type of locking works smoothly, but as the liquid heats up and hardens, the effect increases and continues until the wheels begin to rotate simultaneously and the temperature drops. As a result of oil oxidation, a whole bunch of foreign elements appear: tar and carbon deposits. You have adjusted the fourth valve, now you need to find the intake valve. They can be universal or designed for a specific car model. After 8000 km, the filter is replaced, the carburetor is disassembled and washed with acetone. There was no longer any talk about the correctness of the chosen direction; it was confirmed not so much by their experience, they removed the terminal and... Insert the mounting straps into the tension brackets at the corners.

And the second installation is well-known to many, a relay with adjustable pause for intermittent wiper mode.

Generating Device Replacement Procedure

Before starting work, check the serviceability of the regulator relay. It is advisable to choose a model with the highest possible temperature compensation. This characteristic allows models 2106-2107 to operate at high speeds without failure. This indicator should be studied especially carefully if the VAZ 2106 or later modifications are used in areas with a hot climate.

Difficulties arise at the stage when you need to connect a new VAZ generator. To begin with, the wires coming from the relay regulator are disconnected and subsequently insulated. Further connection of the VAZ 2108 generator is carried out as follows.

The wires, formed in the form of a ring terminal, are connected to the old place in the VAZ 2108. It is imperative to insulate the gray wire, which is not connected anywhere. Completes the installation procedure by connecting the yellow wire to the terminal. If the car owner was unable to find a device with the required power, then a model from a VAZ 2108 to a VAZ 2106 can be installed, provided that the total power of consumers is taken into account.

Careful attitude and regular preventive inspections will ensure long-term reliable operation of the machine. Even with a slight drop in speed or problems when starting the engine, there is a reason to look under the hood. The faster this is done, the less likely it is that the problem will spread further.

The VAZ-2107 is a luxury version of the simpler VAZ-2105 car, but everything also belongs to the general family of “classics” of the Volzhsky Automobile Plant. This brand of car was produced in Russia until 2012, so on the roads you can see both new examples of cars and honorary old men of thirty years of age.

This model differs from other classic VAZ cars in a large number of modifications associated with different engine sizes. The “sevens” were equipped with engines with a volume of 1.3 liters, 1.5 liters, 1.6 liters, 1.7 liters. On special models produced for the Ministry of Internal Affairs and the KGB, which were later decommissioned and fell into private hands, even rotary piston engines with a volume of 1.3 liters and a power of 140 hp were installed.

Such a variety of engine systems has led to the fact that the VAZ-2107 model has a fairly large range of spare parts, which are constantly in demand during repairs and periodic maintenance of these vehicles. Also, recently, a trend has developed towards deep tuning of this model, which consists in installing a more powerful engine and reinforced suspension, for the participation of modified cars in unrecognized, but quite popular street racing among young people.

VAZ 2107 is one of the legends of the domestic automobile industry. The car was created as a luxury version of the VAZ 2105 model. At the same time, the differences affected not only the interior, but also other key components. In total, there are about 15 modifications that differ from the basic version. Unfortunately, the company's management decided to close production in 2012.

During their service, many cars have undergone repairs of varying complexity more than once. Let's look at the generator and its associated faults.