Electric windows (EP) are one of the vehicle elements that contribute to more comfortable driving. Like any other electrical circuit component, EDs tend to break down periodically. What to do if a car window regulator does not work and for what reasons these components break - read below.

VAZ 2114. Why don't the power windows work?

The fact is that after checking the relay and fuse, you forgot that external lighting is also involved in the power supply of the ESP. Personally, I had such a problem, I checked the fuse, relay, removed the door trim and checked the entire circuit. At the service station, the repair took 5 minutes, it turned out that the fog lights, which I don’t have, were burnt out.

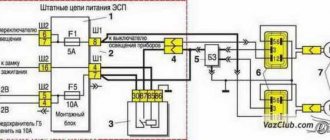

1-mount fuse block.

2-button power window of the right front door.

3-motor (motor gearbox) for the window lifter of the right front door.

4-motor (motor gearbox) for the window lifter of the left front door.

5-button power window of the left front door.

6-ignition switch,

To 5 window relays,

A - to the power source,

In-to the external lighting switch

Of course, the window regulators may not work if something just fell off. Yes, while driving, it also happens that a bolt comes out somewhere. After all, our roads do not really meet the standards. And even more so, if you have electric windows, then the contact may simply fall off. So the reason will have to be found out. And you just need to start by checking whether voltage is supplied to the motor, which raises the windows.

Well, then you’ll have to disassemble the lifting mechanism and see how it works and whether anything got in there.

And only after this is it necessary to check the motor itself. Since it can simply fail.

VAZ 2114 can be equipped with either conventional manual (mechanical) window lifters or electric windows.

If we are talking about electric windows, then as a rule (at least quite often) the cause of the breakdown is in the electric motor! which is responsible for raising and lowering the windows, that is, it simply burned out.

The window lift motor on the VAZ 2114 is not dismountable, only replacement.

Perhaps the problem is in the fuse (the most simple failure) the fuse box, like in its predecessors (VAZ 2109, VAZ 2108), is located under the hood.

True, sometimes just replacing the fuse is not enough; sometimes you need to look for the reason why it (the fuse) blows.

Perhaps the wires are shorted to ground, you need to remove the door trim and see what’s wrong, perhaps the insulation of the wires is broken.

Maybe the reason is in the relay, it is located in the same block under the hood, relay K5, here too only a complete replacement is required.

Or there may be a breakdown in pure mechanics, for example, a worm gearbox has failed, or a problem with the cable drive.

Tips for repairing mechanical breakdowns

The window lifter system on the domestically produced VAZ 2114 car is quite simple and consists of the following mechanisms:

- motor or mechanical crank

- lifting mechanism with a set of gears

- adjustable lifting device

There are several reasons why power windows may not work:

- No current reaches the electric motor connector. The cause could be a blown fuse or a break in the electrical wiring.

- The problem is in the motor, this is either a loss of current through the electrical wiring or a failure of the motor itself. The motor is removed and current is supplied to it with reversal of polarity; the motor should rotate freely in different directions.

- Failure (mainly the teeth are worn out, resulting in the mechanism jamming) of the lifting mechanism. It is not repairable, only replacement.

- The bushings on the adjustable device come off due to wear.

- The glass has jumped off and rested against something, which is why the mechanism simply cannot raise it (or lower it)

- A foreign object has entered the mechanism.

Situations

There are situations where power windows stop working under repeated circumstances. For example, after driving on a dirt road or bumps, the mechanism begins to move the glass in jerks. When opening the casing, it is sometimes discovered that the wire has come out of the chip or from the connector, or after visiting a car wash, incidents begin with the glass. Perhaps the depressurization of the insulation contributed to the fact that moisture penetrated into the electrical components of the system and short circuits or disruption of communication between contacts began.

Chafing of the insulating layer of the wiring is one of the most common causes of problems with ESP. To facilitate diagnosis, it is worth observing what causes the standard fuse F6 to blow.

- If this moment is the activation of the lift itself, then, most likely, this place is somewhere under the door trim.

- If then, when you turn on the ignition, then it is worth checking the insulation of the wires from the door to the safety assembly block.

One of the weak points is where the bundle of wires goes from under the hood to the door trim.

The power windows on the VAZ 2114 do not work - reasons

Many car owners are faced with a situation where the window regulator on a VAZ 2114 does not work. As a result of the malfunction, many problems arise, primarily related to a decrease in comfort. Despite the simplicity of the design of the window lift mechanism, their reliability leaves much to be desired.

In addition, the safety block is mounted under the hood and is located in close proximity to the water drainage area. For this reason, the risk of moisture entering the mounting block, with subsequent shorting of the contacts or their oxidation, is very high.

Let's look at why the window regulator on the VAZ 2114 does not work. There may be several reasons:

- Oxidation of contact connections.

- Damage to one or more controls.

- Loss of power.

In some cases, the part can be repaired, but in others, all that remains is to remove the non-working window regulator and replace it with a new device. The most common cause of window regulator failure is the failure of the button. Let's start with this problem first.

How to find the cause of the malfunction and repair the electric window on a VAZ 2114 - see the video below.

Relay

One of the reasons for the breakdown of the glass door lift mechanism may be that the relay does not work or the fuse has blown.

- Find the safety block under the hood of the car.

- According to the diagram, determine the location of the relay itself and the fuse, which make up the links of the electric glass lifting mechanism (ESM) chain.

- The legs of the elements must be clean, with a pronounced metallic sheen.

- If traces of oxidation, dirt deposits, etc. are found, you need to clean them off. Mechanically or using special means, for example, WD-40.

- You can check the relay for functionality in the same way as a button. The working element should be removed from another unit and mounted into the ESP system.

- If newly installed parts fail again within a short period of time, then the problem is in the wiring itself.

A breakdown may occur with the lift motor. It either burns out completely, or the worm mechanism inside it fails. In the latter case, the device makes a characteristic sound when the button is pressed, but the glass remains motionless.

The reason for the breakdown of the ESP may be that it has a common power source and the external lighting. And if the fuse for the foglights is blown out, the window regulator will not work.

Reason: broken button

Owners of VAZ cars, over time, begin to notice that the operation of the window regulators is slowing down. The cause may be problems with the mechanism buttons. Inside the part, there is contact between the plates, the quality of which deteriorates over the years. Over time, contact may disappear altogether. As a result, the window regulator does not work on a VAZ 2114 or on another model of a domestic manufacturer.

The main reason why a button may break is the failure of one of the window regulators. The likelihood that both buttons will fail is extremely low. It is worth noting that the mentioned parts have an identical design, which makes it possible for experimentation. Instead of a faulty element, you can install a button from a known good part.

Alternatively, replace the driver's door by using a knife or flat-head screwdriver to pry up the buttons and remove them from the chips. Next, install a working button in place of the broken one and connect it. If a previously faulty window regulator starts to work, then the cause of the problem lies in the button and it must be replaced (repaired).

Device classification

Window lifters on the VAZ-2114 are standard for other models of the Samara series.

They are classified according to the type of drive into: The latter are divided depending on the method of transmitting the motor impulse:

By type of construction:

Each model has its own advantages, disadvantages and price. Standard configurations of window lifting mechanisms on the VAZ-2114 consist of two types. Electric drive mechanisms are installed in front, while the rear doors are equipped with mechanical devices.

How to repair a power window button?

The easiest way is to go to any car store and purchase a new button for replacement. If you don’t have the funds or don’t want to spend money, go the other way - dismantle the failed button and repair it. The essence of restoration work involves cleaning and restoring the quality of contacts. By the way, such manipulations can help slow down the operation of the window regulator.

Next, proceed like this:

- Prepare the work area where the work will be done. It should have good lighting.

- Inspect the product. There are latches on both sides of the case that need to be bent and the upper part removed.

- Remove the “rocker” by pressing on it.

- Remove metal plates.

After completing the work discussed, you get access to the board. Get it out by soldering it. Using a marker, make notes so as not to make mistakes with the installation in the future. Place the dismantled board aside and take the following steps:

- Bend the contacts that are on top and press against the bottom contact group. The point is to get enough clearance for cleaning.

- Clean the contacts using sandpaper.

- Assemble the button in the reverse order of disassembling the mechanism.

- Install the button in the machine, then check its functionality.

If everything is done correctly, the button will work and will perform its tasks, no worse than a new part.

Design features of window lifters

The first cars were open, so there was nothing to raise/lower.

When the first closed-type cars began to appear, in order to get some fresh air, you just had to stop and open the doors. In 1928, German automakers first used a mechanical window lifter, and automatic designs with an electro-hydraulic drive appeared in the United States in 1940 on Packard cars. After 5 years, such systems were already installed on many brands (Ford, Lincoln, Cadillac). Those designs were bulky, worked unreliably, often broke down, but were improved over time, facilitated by their parallel development with the folding roof systems of convertibles. Purely electrical devices appeared in 1956, and subsequently their improvement again took place individually. A modern electric window lifter is installed inside the door (the most common option), on the door body or on a separate subframe. The design of the device with an electric drive includes the drive mechanism itself, a control system for raising/lowering the windows and a lifting mechanism. The drive consists of an electric motor, structurally made in one unit with a worm/gear drive. It is the engine that is the heart of the lift, generating the force necessary to move the glass. If a worm gear is used, it will not be possible to move the glass by hand, since the worm-type gearbox only works in one direction, transmitting the moment of movement from the worm to the drive wheel. If you try to rotate the window in the opposite direction, the worm gear will simply be blocked. If everything is more or less clear with the motor, then the lifting mechanism responsible for moving the glass may have a different design. The most common lifts are cable, rack and pinion type. Let's look at them in more detail.

A cable lift is a flexible structure (cable, sometimes a toothed belt or chain) stretched between rollers on the inside of the door. Rotating, the drive drum drives the lift by winding one side of the flexible element onto the roller, while the other unwinds. And since the lift is rigidly connected to the glass (usually through a special plate), the latter also begins to move, lowering or rising.

In lever-type window lifters, the driving element is a lever, at the end of which there is a slider and a plate connecting the lever to the glass. There are single and double lever mechanisms. The latter are more reliable because they allow you to move the glass more evenly and without noticeable jerks. The drive mechanism initiates the transmission of momentum from the electric motor to the wheel, which is connected to the lever. Rotating, it moves the lever along with the glass. Double-lever designs can be equipped with two wheels.

A rack and pinion lift consists of a fixed rack with teeth, which is connected to a guide plate. The latter, moving up/down along the rack, ensures the functioning of the mechanism. The drive gear is located at the end of the plate and is connected to the rack. The glass moves in a given direction thanks to guide gutters installed in the door frame. This kind of car window lifter is used less often than the first two varieties, since it has a fairly large mass.

Malfunction in the fuse box

One of the reasons why the window regulator on a VAZ 2114 does not work is a problem with the mounting block. Open the cover of the block and, using the drawing printed on it, determine the location of the fuse of interest. Assess the condition of the fuse insert through which the window regulators are powered. If it is intact, check the relay.

Inspect the condition of the relay legs and fuse. There should be no plaque on them. If available, use WD-40, but it is better to dismantle the unit completely and, only after that, clean it. The presence of plaque is evidence of moisture getting inside, which leads to a deterioration in the conductivity of contacts. If you conscientiously approach the removal of plaque, the power windows will work. The downside is that, after the next precipitation, the situation may repeat itself - a coating will appear, and the mechanism will stop working.

To test the relay, install a known-good device of the same type in its place. For example, you can take the relay through which the high beam headlight is powered. If, after rearranging, the power windows start to work, throw away the failed relay, buy and install a new part.

If checking the fuse shows that it has burned out, replace the part and check the operation of the power windows. If the mechanism starts working, the problem is solved. On domestic VAZ cars, there are situations when fuses burn out for no reason.

It’s worse if you installed a new fuse-link and it immediately burned out. This indicates a short circuit in the circuit. The reason may be a broken wire or damaged insulation, due to which the “plus” gets to the ground of the machine. In this case, it is better to entrust the solution to experienced auto electricians.

Electrical problems

It is better to start diagnosing a malfunction by checking the condition of the fuse, which is responsible for the operation of the power windows in the VAZ 2110. Usually it is numbered F5. If necessary, the fuse must be replaced with a new one. If it is intact, proceed to the next stage. You will need a 12 volt light bulb with two wires going to its positive and negative side.

Connect the wires to the terminals of the window lift motor and press the button. If the light comes on, the wiring is good, but if not, start looking at the wires for breaks. Also don't forget to check the corresponding relay.

Another problem with the electrical wiring circuit is when the window opens when the button is pressed, but when it is released the glass rises again. In some cases, the button does not work until you turn the ignition off and on. These signs indicate a malfunction of the button, so you can try to remove it and clean the contacts, and if necessary, replace it with a new one.

Other causes of power window failure

If the window regulator on a VAZ 2114 does not work, pay attention to the serviceability of the mechanism motor. There are situations when the worm mechanism in it breaks, and then, when you press the button to raise/lower the windows, a loud noise is heard. At the same time, the windows do not move. If you do nothing, the motor may burn out completely.

The window lift mechanism rarely breaks, but this also happens. The malfunction can be determined by the twitching of the glass, but without normal movement up or down. At the same time, noise from the motor is heard.

RESULTS

If the window regulator does not work, start by finding the cause of the breakdown, and then proceed to fix the problem. Most often, the malfunction can be fixed independently, without the involvement of specialists. This also applies to situations where it is necessary to remove the window regulator for repair or replacement.

Video: Repairing the window lifter button

Video: Repair of electric window lifter on VAZ 2114

Didn't find the information you are looking for? on our forum.

How to remove a window regulator and install a new part

To remove the window regulator, do the following:

- Remove the inner door lock handle at the same time as the rod.

- Lower the glass a little so that the mounting bolts are visible in the amplifier hole.

- Using a ten key, unscrew a couple of bolts that hold the windows and the lift.

- Raise the glass as far as it will go and secure it with a screwdriver or tape.

- Discard the wiring harness from the door and power window motor.

- Using an eight-inch wrench, unscrew the seven mounting nuts holding the window regulator to the door.

Remove the window regulator.

Place the mechanism in its original place, in the reverse order of dismantling. Before doing this, treat the glass lift guide with lubricant.

The principle of operation of a car window lifter

The ability to switch between raising and lowering the windows is made possible by equipping the electric motor with a reverse power system. Structurally, the motion vector is changed either using a relay or directly through a switch. Window lifters of the latest generations are more complex, which is caused by the need to increase the safety of their use and increase comfort. Functions of modern mechanisms for automatically raising/lowering windows:

- uniform movement in one of the directions to the end point;

- discrete movement (for example, an inch) in one direction or another;

- slow mechanism locking;

- return movement (used to have time to remove part of the body from the window opening).

The window regulator control unit is the brains of the device, which includes, in addition to the control microcircuit, an electric motor relay, switches and electrical wiring connecting the control unit to the door lock and the top hatch cover. If you activate the window lift mode with one touch or command, it will move in the specified direction. As soon as the switch is moved to the reverse position, the motor will stop. The same will happen if the power window ECU receives a corresponding signal from the door circuit board.

The main problem with using the one-touch mode is the high likelihood of injury to a child who is leaning out of the window, even partially. The return mode helps prevent such situations. To do this, another switch is mounted to the electric motor armature, the task of which is to transmit a special signal to the ECU with a frequency proportional to the rotation speed of the power unit. If, while closing the window, the computer detects a decrease in the engine speed below a certain value, it will immediately issue a command to change the direction of movement of the glass until it is completely lowered.

The control unit is able to calculate the current position of the window based on counting the number of received pulses. This information is used to prevent reversal of the window movement if it is completely closed or, conversely, lowered. However, the ECU must know the initial position of the window. To do this, an initialization operation is performed, which consists of turning on the electric motor until the glass is completely opened, after which the reverse operation is performed - closing it. Without initialization, the power windows will stop working in one-touch mode.

Some models of window regulators are equipped with Hall sensors, which make it easier to determine the current speed of glass movement. Another common way to control speed is to monitor the amount of current consumed by the motor, which is proportional to the speed of rotation of the motor shaft. The “slow blocking” mode is used if it is necessary to completely block the vehicle by issuing a command sent remotely from an infrared remote control. This function uses the connection between the power window/sunroof control unit and the door lock. The order of operation is as follows: windows, hatch, doors. If necessary, it is possible to activate the security mode - in this case, the windows will close one at a time - this reduces the instantaneous current consumption (compared to simultaneous closing).

How to close the windows in a car if the battery is dead?

You close the car and press the lock button on the key fob and hold it - the door windows should go up! As long as you keep the close button pressed, the windows close! It’s the same with lowering the windows, only you press and hold the open button! Good luck!

Interesting materials:

How to set a timer on your phone? How to set up Twitch on your phone? How to protect yourself from losing your phone? How to update the keyboard on your phone? How to update the navigator on your phone? How to update your Redmi phone? How to clear dialogs in VK on your phone? How to clear cache in Lightroom on phone? How to clean the keyboard on your phone? How to clean the phone case from dust?