The Russian automobile industry has begun to seriously work on its mistakes, and the new Lada Granta with an automatic transmission serves as a striking example. Looking at the car body, equipment and interior, you can immediately understand that the car was manufactured by a Russian engineer for a Russian driver. The car is fully prepared for domestic roads, and almost every desire and need of the buyer is satisfied. Increased ground clearance, electric windows and a spacious trunk are ideal for the practical driver. Improved design and thoughtful shapes make the car not only practical, but also a beautiful means of transportation.

But still, the main advantage of the Lada Granta is the presence of an automatic transmission. The domestic car began to be equipped with an automatic transmission from the Japanese company Jatco. The four-speed transmission JF414E (AY-K3) from a subsidiary of Nissan is time-tested and has been serving Almera and March for a long time. Resistant to wear and aggressive driving style, the Japanese mechanism is ideal for both inexperienced beginners and experienced drivers. It is worth noting that the box has undergone minimal changes by Russian engineers, so there is no need to worry about the service life and safety of the unit. The box is time-tested, and its characteristics are not inferior to new models.

Lada Granta gearbox

Technical device of the Jatco JF414E automatic transmission of Lada Granta, Kalina cars

Automatic transmission control controller Lada Kalina, Granta

The automatic transmission control controller is located on the left mudguard.

Control is carried out based on signals coming from sensors, switches and other control devices.

The torque converter converts torque from the engine and transmits it to the input shaft of the Lada Granta, Kalina automatic transmission.

The oil pump is driven by the engine and supplies transmission fluid to the torque converter and control valve block.

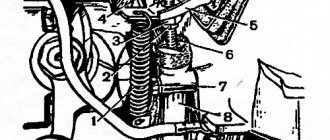

Fig.25. Location of parts on the Jatco JF414E automatic transmission of the Lada Granta, Kalina

1 — gearbox range (mode) switch; 2 - connector; 3 — control valve block; 4 - secondary shaft speed sensor (vehicle speed sensor)

The Lada Kalina, Granta automatic transmission control valve block consists of the following parts:

— transmission fluid temperature sensor;

— input shaft speed sensor;

- downshift clutch solenoid valve;

— brake solenoid valve 2-4 gears;

— gear shift solenoid valve, automatic transmission Jatco JF414E;

— solenoid valve for overdrive/downshift and reverse brake clutch;

— solenoid valve of the torque converter lock-up clutch;

— solenoid valve for regulating pressure in the line;

— ROM module assembly (EEPROM).

The ROM module assembly is located in the control valve block.

This module stores the calibration data (individual values) of each linear solenoid valve. Upon receipt of calibration data, the Lada Granta and Kalina automatic transmission control controller carries out precise hydraulic adjustment.

Automatic transmission range switch

The transmission range switch is located on the top of the transmission housing. It determines the position of the gear selector lever.

Speed sensor of the input shaft of the automatic transmission Lada Granta, Kalina

The input shaft speed sensor is located in the control valve block. It determines the rotation speed of the input shaft.

The sensor generates on-off pulse signals in accordance with the rotor speed. The automatic transmission control controller estimates the rotation speed using a pulse signal.

Output shaft speed sensor (vehicle speed sensor)

The output shaft speed sensor is installed in the upper part of the gearbox housing.

It determines the rotation speed of the secondary shaft by the number of revolutions of the idler gear.

The sensor generates on-off pulse signals in accordance with the rotor speed of the idler gear. The Jatco JF414E Lada Kalina, Granta automatic transmission control controller estimates the rotation speed using a pulse signal.

The control controller determines the vehicle speed based on the signal from the secondary shaft speed sensor.

Transmission fluid temperature sensor (TFTF)

The transmission fluid temperature sensor is located in the control valve block. DTTF determines the temperature of the transmission fluid in the oil pan.

A thermistor is used as a transmission fluid temperature sensor. The output voltage of the thermistor signal depends on the temperature of the transmission fluid.

The Lada Granta, Kalina automatic transmission control controller determines the temperature of the transmission fluid based on the voltage of the DTT signal.

Downshift clutch solenoid valve

The downshift clutch solenoid valve is located in the control valve block of the automatic transmission Lada Kalina, Granta.

It controls the pressure in the downshift clutch.

A normally open type linear solenoid valve is used as the downshift clutch solenoid valve.

A linear solenoid valve uses the principle that the clamping force of the solenoid core varies in direct proportion to the electrical current.

A normally open valve creates high fluid pressure on the actuator if power is not supplied to the valve.

Brake solenoid valve 2-4 gears automatic transmission Lada Granta, Kalina

The 2nd-4th gear brake solenoid valve is installed in the control valve block.

It controls the pressure of the brake band of 2-4 gears.

This valve is a normally closed type linear solenoid valve.

On-off solenoid valve

The on/off solenoid valve is located in the control valve block of the automatic transmission Lada Granta, Kalina.

It operates the shift valve, which changes the flow of oil to the downshift and reverse brakes and the overdrive clutch.

A normally closed type solenoid valve is used as an on/off solenoid valve.

Solenoid valve for overdrive clutch and downshift and reverse brake clutch

The solenoid valve for the overdrive clutch and downshift and reverse brake clutch is located in the control valve block.

It regulates the pressure in the clutch for overdrive gears and the brake for downshifts and reverse gears.

A normally open type linear solenoid valve is used as a solenoid valve.

Electromagnetic valve of the torque converter lock-up clutch of the Lada Granta, Kalina automatic transmission

The torque converter lockup clutch solenoid valve is located in the control valve block.

It controls the torque converter lockup clutch control valve.

This valve is a linear solenoid valve of the normally closed type.

Line pressure control solenoid valve

The solenoid valve for regulating the pressure in the line is located in the control valve block.

It controls the operation of the pressure control valve in the line.

A linear solenoid valve of the normally open type is used as such a valve.

Fig.26. Cross-sectional view of the Jatco JF414E automatic transmission of the Lada Granta, Kalina car

1 — torque converter housing; 2 - oil pump; 3 — downshift clutch; 4 — planetary reverse gear; 5 — brake for downshift and reverse gear; 6 — forward planetary gear; 7 — overrunning downshift clutch; 8 — overdrive clutch; 9 — reverse clutch; 10 — brake band 2-4 gears (brake band); 11 — drive piston of the band brake; 12 — back cover; 13 — secondary gear; 14 — intermediate gear; 15 — gearbox housing; 16 — drive gear of the reduction gear; 17 — main gear; 18 — differential; 19 — input shaft; 20 - torque converter

The torque converter has a lock-up clutch, when engaged, the torque converter acts as a clutch to more efficiently transfer power from the engine to the transmission.

When the locking clutch is turned off, the speed of the input shaft of the Lada Granta, Kalina automatic transmission is always less than the engine speed. The torque converter lock-up clutch is controlled by a corresponding valve.

The torque converter lock-up clutch control valve is actuated by the torque converter lock-up clutch solenoid valve (ECBMGTr) when a control signal is supplied to the latter from the automatic transmission controller.

To turn on the lock-up clutch, the electromagnetic valve (EKBMGTr) moves the control valve in the blocking direction, as a result of which the pressure on the lock-up clutch increases and it goes into the clutch state.

To disengage the lock-up clutch, the electromagnetic valve (EKBMGTr) moves the control valve in the unlocking direction, as a result of which the pressure on the lock-up clutch is released and it leaves the clutch state.

Continuously adjustable locking

The Lada Granta, Kalina automatic transmission controller regulates the current in the power circuit of the torque converter lockup clutch solenoid valve to control the pressure on the lockup clutch and, accordingly, the degree of clutch of the lockup clutch.

When the lockup is turned on, the controller, by adjusting the current in the power circuit of the solenoid valve, gradually increases the pressure on the lockup clutch and initially puts the lockup clutch into the “half-clutch” state.

The "half-clutch" state allows you to avoid shock when the lock is engaged and smoothly connect the lock-up clutch.

Source

Repair of Grant automatic transmission and valve body in our service center

In addition to the wiring, it may be a hydraulic unit that has failed due to the same low-quality oil. Thus, oil clots, coupled with contaminants that have entered the transmission fluid, clog the valve body channels through which the oil circulates, resulting in failures when switching to a particular gear. Repair of the Grant automatic transmission in this case consists of disassembling the valve body and thoroughly washing it.

ATTENTION! A simpler method of flushing the valve body, which does not require disassembling it, is inappropriate if the latter malfunctions, since it does not give a 100% ideal result. It is used only as a preventive measure during complex maintenance of a vehicle’s transmission.

Simultaneously with cleaning the hydraulic unit parts from contaminants, the technician performs a troubleshooting, that is, determines which of them have been subjected to excessive wear. If there are too many of them, then repairing the automatic transmission may simply be unprofitable and for the Grant automatic transmission, replacement will be, from an economic point of view, the optimal solution.

Diagram of the Lada Grants gearbox, features of operation and maintenance of the box

A manual transmission is the easiest and longest-lasting to use. Its main advantage is ease of maintenance and reliability. Operating the mechanics means being sure that a box failure will not hit your pocket.

When purchasing a Lada Granta, the choice of engine is simple - the volume is 1.6 liters, the only differences are in horsepower and the number of valves. A diagram of the “Grants” gearbox design, operating and maintenance features will help you choose a gearbox.

Additional causes and troubleshooting

It is necessary to flush and clean the valve, install a new gear and mount a new gear selector. Insert a new cotter pin and clean the valve system.

It is necessary to fill in the required amount of oil and replace all broken parts with new ones.

If the gear lever is set to “N” and the Lada Granta continues to move, then the cable adjustment is incorrect and the drive lever does not work well. Perhaps the piston clutch is stuck or the discs are not moving away from the plate due to long towing.

The speeds are switched at high speeds - this means that there is a poor setting of the cable that controls the operation of the throttle mechanism, or the centrifugal regulator is jammed. Maybe dirt got in and clogged the filter mesh or the throttle valve got stuck.

When the accelerator pedal is pressed sharply, there is no inclusion of a lower gear, the so-called kickdown. There may be several reasons:

A new pressure sensor and a new switch need to be installed. Clean the switch valve and replace broken wires. Then adjust the cable that controls the throttle valves.

If it is not possible to brake the engine when the second speed is engaged, it means that the brake band is not working and the sealing collar is broken. Maybe the modulating valve is stuck.

When gears are changed, clutch slippage occurs. This means that the filter mesh is clogged or the oil volume is insufficient.

There is a grinding noise where the differential is located. The main differential driven gear is not functioning and the drive gear teeth are broken. Perhaps there was increased wear of the bearings and the clearance on the axle increased significantly, causing differential play to appear.

If reverse gear does not engage and there are no second and third speeds, it means that all the drum splines on the sun gear have been cut off. You just need to install a new drum.

What gearboxes are the Lada Granta equipped with?

When choosing a car, it is important to pay attention to the type of box. Lada Granta comes with 3 types of gearboxes: automatic, robot and manual. You need to understand the features of each type in order to choose the box for yourself.

All types of mechanics

A manual transmission is the easiest and longest-lasting to use. Its main advantage is ease of maintenance and reliability. Operating the mechanics means being sure that a box failure will not hit your pocket.

Manual transmission for Lada Granta

As a standard, the Lada Grant used a 2180 gearbox, this is an improved version of the 2170 series, from which gears and shafts were left. When developing the Lada Grants gearbox with a cable drive, well-known brands took part in the selection of individual components: Atsumitek, Schaeffler, Hoerbiger. On the Lada Granta gearbox, the gear shift pattern looked like this: the rear gear was located to the left of the first and because of this, drivers, especially after wear, could mistakenly engage the rear instead of the first.

On expensive models, gearbox 2181 is used. Since the gearbox on the Grant has changed, the shift pattern has also undergone changes, now the rear gear is located at the bottom right. It is considered more reliable, switching is smoother. We fixed a popular problem where the shift lever vibrated when engaging third gear.

Robot

The robotic gearbox is considered the most capricious to maintain and is not respected among drivers due to its unreliability. The golden mean between manual and automatic transmissions, which, according to the developers, was supposed to be a real breakthrough in the use of transmissions.

But over time, the robot will be improved and, perhaps, will be able to exceed expectations.

Hydraulic automatic

Servicing an automatic transmission is more expensive than a manual transmission, and it is noticeably inferior in reliability. The operation is suitable for those who are used to quiet movement. Acceleration takes a long time and prefers a gentle driving mode. Fans of fast driving constantly complain about this box, and the whole secret is that when moving quickly, the machine asks to be serviced 2-3 times more often. Due to the operation of the gearbox in hard mode, parts wear out faster.

What boxes were installed on different car models

The automatic version of the Lada Granta was launched in 2012. The robotic gearbox was developed in 2014, the first “Grant” with manual transmission appeared in 2015.

Robot

The 5-speed AMT VAZ-2182 can be found on Grants with 16-valve engines under the hood. The robot was installed on Granta on different body types in different years:

- sedan - since 2015;

- hatchback, station wagon, liftback - from 2022;

- "Cross" - from 2022.

Despite the fact that the creators of AMT are AvtoVAZ engineers, this could not have happened without the help of foreign colleagues. The robot is based on the VAZ-2180 rocker manual transmission. The mechanics were supplemented by an actuator from the German company ZF.

Machine

The Japanese automatic is installed on Lada Granta varieties with a 16-valve engine in the body:

- sedan - since 2012;

- liftback - since 2014;

- hatchback, station wagon, “FL” - from 2022.

Automatic on Lada Granta

AvtoVAZ engineers sought to find a cheap and reliable automatic transmission. The Japanese development of Jatco – JF414E – was chosen. It was not immediately possible to reconcile the 4-speed with the domestic engine. The help of Austrian colleagues was needed. Through the joint efforts of AvtoVAZ and AVL engineers, it was possible to integrate Jatco into the Lada system and speed up the operation of the gearbox.

Diagram of the Lada Granta gearbox

The “Grants” gearbox design diagram (section, drawing) will help you understand the principle of operation of a manual transmission:

Gearbox diagram

The “Grants” gearbox design diagram (section, drawing) will help you understand the operating principle of an automatic transmission:

A conventional manual transmission uses 2 gears that are adjacent to each other.

Layout of the Lada Grants gearbox, features of operation and maintenance (usual):

Layout of the Lada Grants gearbox, features of operation and maintenance (planetary):

Features of operation and maintenance

When operating a planetary gearbox, internal gearing is used. It consists of at least three gears, the movement of which resembles the rotation of planets.

For those with automatic

If your car has an automatic transmission. It will not hurt you to know the modes in which your machine can operate:

The automatic transmission also has a button on the mode shift lever with the inscription O/D OFF. When it is turned on, the inclusion is prohibited, increasing the gears of the analogue of the 5th gear of the manual transmission. That is, if your automatic machine has 4 gears for moving forward, then for more dynamic acceleration it will use only three lower gears.

About a faulty automatic transmission, an automatic transmission is much more complex than those encountered with a manual transmission, and the chances of repairing it in your garage are slim. But despite this, you still need to know something about it, if only in order not to harm it through improper use.

An automatic transmission is much more demanding in terms of accuracy in maintaining the oil level in it than a manual transmission. Both too low and too high oil levels are very harmful to her. Both of these can lead to serious damage. In both cases, oil foaming occurs. When there is a lack of oil due to the fact that the oil pump begins to capture air along with the oil. When there is excess oil, it foams on the rotating parts, which in this case are immersed in it. Foamed oil compresses better and has low thermal conductivity. Therefore, if you operate a machine with such oil, the pressure in its control systems will be low. Which will lead to slipping of the clutches and their intensive wear. Deteriorated thermal conductivity will not allow all excess heat to be removed. Which, together with low pressure, will lead to the machine failing and requiring serious repairs.

Foamed oil has more volume. Therefore, checking the oil will show the level is too high. If you find that the oil level has risen for no apparent reason, you need to turn off the engine and let the oil settle. After this, check the level again. If it turns out to be low, you need to safely add the required amount and repeat the test.

How to check the oil level using a dipstick

Warm up the oil to operating temperature (to do this you need to drive about 15 km).

Select a flat horizontal area for measurement. Put the car on the handbrake.

- Move the lever to select the operating mode of the box through all positions, holding in each position for 3 to 5 seconds, until the machine operates.

- Leave the mode selector in position P, and in this position determine the oil level.

- Without turning off the engine, remove the oil dipstick, wipe it dry and reinsert it into the tube until it stops, then pull it out and read the readings. The upper limit of oil traces on a dry dipstick should be at the mark with the inscription “hot” or in an area with intersecting notches.

If the level is insufficient, you can add oil through the tube into which the dipstick is inserted. Do not forget that the automatic transmission is afraid of dirt, so add only clean new oil. Wipe the dipstick with a clean cloth from which the threads do not fall out.

When checking the oil level, pay attention to its appearance. Dark liquid with a burning smell indicates that not everything is in order in the unit.

First, try changing the oil and filter in the automatic transmission. The milky color of ATF indicates that coolant has entered the box. The coolant softens and swells the material from which the clutches are made. Do not hesitate to change such oil, having first eliminated the cause of antifreeze getting into the box, otherwise significant damage will be caused to the machine. Coolant may enter the box due to a leak in the oil section in the radiator of the cooling system. In this case, the emulsion will be observed both in the box and in the engine cooling system.

The most common machine malfunctions

- The car does not move forward or reverse normally. Possible reasons: wear of the forward clutch clutches, a defect in the piston of this clutch, breakage of the rings of the same clutch, jamming of the valve body valves.

- There is no reverse speed, forward there are only 1 and 2. Probable causes: wear of the reverse clutch clutches, a malfunction of the piston of this clutch, damage to the spline joint in the drum body, another defect of this drum.

- There is no rear, everything works forward. Reasons: wear of the brake band, malfunction of the piston of this band or breakage of its rod, defects in the braking package.

- There is no movement either forward or backward when you turn on any mode, there is a shift push, but the car stands still. Causes: torque converter malfunction, lack of oil, clogged filter.

- Only reverse, 1st and 2nd gears are engaged. Reasons: valve jamming in the valve body, low oil level, general wear of pistons and clutch clutches that do not engage.

Features of repair and maintenance

The car should look good not only from the outside, but also from the inside. In order for the box to please its owner, it must be serviced in a timely manner. Of course, it’s time to fill up the oil, but there are a number of problems that the driver will have to constantly struggle with. And for this you need to know the main “diseases” of the transmission.

All types of mechanics

The manual transmission is reliable, but has a number of significant disadvantages. Gear shifting is not very precise, unlike foreign cars. Also, since the time of the ninth models, the problem of “gearbox rattling” when the second one is turned on has not yet been eliminated.

Robot

The robot uses an electromechanical drive, which quickly wears out when the vehicle is used harshly. Due to the strong pressure on the gas pedal from first gear, the robot, instead of switching to second, jumps to third. Due to such use, the box begins to act up and kick. The robot prefers quiet movement. But if the box starts to kick, you can switch it to manual mode.

Hydraulic automatic

If you service this box on time, it can travel up to 200 thousand km. The fluid needs to be replaced once every 60 thousand km. The hydraulic automatic is very reliable, although many owners complain about it.

The opinion has been established that automatic machines do not pick up speed well, but they “eat” gasoline well. Most of the troubles with a machine gun are the driver's boorish attitude towards his car. The automatic transmission loves a quiet ride, and when moving “gas to the floor,” the seals may begin to leak. Also, due to careless driving, drivers often puncture the automatic transmission pan, adding work to the service station.

Where is the dipstick located?

To fill the oil, you need to check the contents, but first you need to understand where the dipstick is located. On a manual Lada Granta there is no gearbox dipstick; on an automatic it is located behind the air filter.

Checking the oil level

The oil level in the box can be checked using a dipstick, focusing on the maximum and minimum marks. If the dipstick is missing, then you need to use the overflow tube.

If the oil does not flow out, then you need to add it through the filler hole until the oil flows out of the overflow tube.

How to remove extraneous noise

Even after purchasing a new Granta Liftback car, a hum may form in the box. When contacting a service station under warranty, the technicians say that this is a natural sound. Repairing a box under warranty is a complicated matter, but it can be repaired in a non-specialized center. To do this, remove the clutch cable from the mount and replace the insert with a rubberized washer. The rubber on the washer should be softer and then the vibration will subside.

Typical breakdowns: elimination methods

The car does not move forward. Moreover, engaging reverse gear does not cause problems. The cause may be a broken friction disc or a ruptured piston cup. Perhaps the o-rings are broken or the valve that regulates the gear shift is simply jammed.

If the Lada Granta is not able to move backwards, there is no third gear, it means that the clutch regulating the forward movement has failed, or the cuff attached to the piston that turns on the forward movement has broken. In addition, if severe wear appears, then the sealing rings, the front clutch have been destroyed, or the splined mechanism holding the sun gear has simply been cut off.

It happens that it is impossible to engage reverse gear. This means that the brake band has completely worn out or the cuff has broken. The failure of the piston rod must also be taken into account.

The repair consists of replacing the brake band, cuff and the rod itself.

- the hydraulic transformer has failed;

- oil pump failed;

- insufficient oil volume;

- The filter mesh is clogged.

- friction discs are broken;

- brake band defect;

- the cuff is torn;

- O-rings are broken;

- The valve responsible for the first speed is jammed.

You need to start the car, add oil so that the volume corresponds to the upper limit, and flare the filter. Thoroughly wash the mesh; if it becomes unusable, install another filter.

Sometimes the car is stationary, but when the gear is engaged, a strong push is felt. The car slips and continues to stand. This means that the hydraulic transformer has broken down or the automatic transmission oil volume is too low. The oil filter may be clogged. You need to install a new torque converter and simply add transmission oil to the required level. And, of course, clean the filter.

Cable tension and switch limit position adjustment

The most obvious and common causes of poor shifting and switch failures come down to poor settings. Index switches (when you switch to 1st gear with one press of the shift lever) are very demanding on the correct cable tension and the internal cleanliness of the jacket. Over time, the jackets and cables deteriorate, dirt and dust get inside and this inevitably leads to a deterioration in the quality of switching.

If the shifter is reluctant to throw the chain into a higher gear, then most likely you should check and tighten the cable. If this happens when switching to a lower gear, then the cable needs to be released.

Also, very often problems with switching to the highest and lowest sprocket can be caused by incorrect settings of the extreme position adjusting screws.

Shirt length and chain length

A shirt that is too long will only worsen shift quality due to additional friction. And because the shirt is too short, the cable tension may change while turning the steering wheel or operating the suspension.

A chain that is too short will cause unnecessary tension on the rear derailleur and difficulty operating the largest chainrings. This has a bad effect not only on shifting, but also on the service life of the transmission. And if you have a suspension, then when the suspension is activated, a chain that is too short can break and damage the transmission. A long chain will rub against the derailleur on the smallest sprockets, causing additional wear on the chain, possibly damaging the derailleur, and affecting shift quality.