From the very beginning of the production of Lada Vesta sedans, two types of gearboxes were installed on them - the French “mechanics” JH and the domestic “robot” AMT 2182.

JH has established itself as a reliable, unpretentious and quiet box. Actually, the noise of the box is the main reason for the refusal of domestic “mechanics” in the Lada Vesta line (according to the former head of AvtoVAZ, Bo Andersson). In addition to the domestic Vesta, this box is equipped with many foreign car brands. The French manual transmission is assembled in Russia (Tolyatti). In 2016, JH was no longer installed on Lada Vesta, but more on that later.

The AMT 2182 gearbox is an excellent solution related to the modification of the switching mechanism of the previous manual gearbox. The functions of the driver's right hand and left foot are now performed electronically. It is the electronic drive that best copes with its task in our winter conditions.

Frequency of oil changes in manual transmission Lada Vesta

If you adhere to official recommendations, then an oil change in a Lada Vesta manual transmission should be performed every 70,000 - 75,000 km or after 4.5 - 5 years, whichever comes first.

But if you act for the benefit of the box, then it is better to change the oil more often - somewhere after 30-40 thousand mileage or after 1.5 - 2 years.

If you buy a new car without mileage, then it is best to do the first oil change in the gearbox after 5 thousand km. This is due to the fact that during this time the parts in the gearbox are ground in and shavings and metal dust may form in the process.

Description of transmission

Below we will consider the most important indicators that affect the operation of the car:

- the gear ratio for the VAZ 21807 shows figures of 3.94, for the French analogue this figure is slightly lower - 3.87;

- with this transmission, the Lada Vesta accelerates to one hundred in 10.2 seconds, which is a second faster than the JH3 - 11.2;

- the maximum speed for the VAZ 21807 is 188 km/h, for the JH3 the figure is 178;

- The fuel consumption of Lada Vesta with a domestic gearbox is 7.5 liters, the French gearbox consumes 7 liters.

Manual transmission

The most important thing the engineers worked on was modifying the transmission tooth profile. They took an example from European models, where the noise of the gearbox should merge during downshifts with the roar of the engine. Lada Vesta designers applied new developments, improving the entire system and adjusting its balance.

Algorithm for changing the oil in a Lada Vesta manual transmission

1. The first step is to remove the engine protection, if installed. This is necessary in order to be able to get close to the drain and fill holes.

2. Next, start the engine and warm up the engine to operating temperature. This is necessary so that the oil in the box warms up and becomes more liquid.

3. We go down under the car and unscrew the drain plug using an 8″ square and drain the oil into a waste container.

4. When the oil has completely drained, screw the drain plug back into place.

5. Find the control plug and unscrew it. It is made of plastic and does not require special keys - everything turns away by hand. However, in some cases, instead of a plastic plug, a metal drain plug may be installed, which will have to be unscrewed with a 17″ wrench.

6. We insert one end of the hose into the control hole, and take the other under the hood and insert a funnel into it.

There is another way to add oil to the box. This can be done through the hole in the reverse light sensor. But to do this you will have to turn it out. This is not difficult to do, but it will require a little effort.

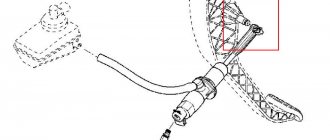

What is an electric drive mechanism?

As for the electrical wire, it directly affects the clutch system fork itself. If the fork rotates, a certain force begins to act through the release bearing on the petals of the pressure spring.

There is no gap in the shutdown drive - this ensures that the spring leaves are constantly pressed against the clutch, and the bearing operates without any interruption.

There is no need to change the lubricant in the bearing - it is provided for the entire service life of this part. If the lubricant has run out, the bearing will make noise.

In this case, it should be replaced - the same must be done when replacing clutch discs, no matter what condition the bearing is in

If a problem with a hydraulic drive can be corrected by bleeding air, then adjusting the clutch on an automatic transmission is a much more complex procedure and is called adaptation. Such an operation can only be carried out at an authorized dealer by specialized technicians - the setup is performed using a computer.

Now AvtoVAZ is introducing into its products a clutch system of an improved design of the world standard, which is distinguished by more durable lining material and durable damper springs. New technologies will make the car start even softer and gear shifting smoother.

Changing the oil in manual transmission Lada Vesta video

For those who do not want to read a lot of text, we can suggest watching a video of changing the oil in a Lada Vesta manual transmission, which we posted on the website:

In mid-2016, AvtoVAZ officially abandoned the use of manual transmissions from the French manufacturer Renault. The reason is the high cost of the “product” and the lack of a base for maintenance.

If domestic gearboxes cost 20–25 thousand rubles, then imported ones reached 45–50 thousand. Obviously, such a rise in price automatically increased the cost of the car as a whole. Perhaps because of this factor, many car enthusiasts preferred a model with a classic automatic or robotic option.

However, there are those who claim that the quality of production of domestic new mechanics (21087) is inadequate. They are ready to pay an additional 30,000 rubles for the French version. Let's compare the Renault JH3 (JR5) manual transmission and the VAZ 21087 manual transmission.

Engaging reverse gear

The reverse gear does not have a synchronizer and is engaged in a different way - by engaging two gears. There are 2 gears on the primary and secondary shafts, which are responsible for the reverse speed. But they are not connected and are separated by a gap. The third gear, which, when reverse gear is engaged, engages two gears at once. Due to it, the secondary shaft begins to rotate in the opposite direction.

Because of this design, before engaging reverse gear, all gears involved in this process must be stationary. Otherwise, they will not be able to engage, and you will hear a characteristic crunch and crackle.

If you wait 3 seconds after squeezing the clutch, then the input shaft has time to stop, and reverse gear is engaged without any problems. If you use the second method through 3rd gear, you instantly stop the input shaft. After this, you can safely engage reverse.

Specifications

| Name | Renault JH3 (JR5) | Manual transmission - 21087 |

| type of drive | Wire rope | |

| Number of speeds | 5 | |

| Main couple | 3,9 | |

| Gear ratio | 3,87 | 3,94 |

| Acceleration to “hundreds” | 11,2 | 10,2 |

| Maximum speed (km/h) | 175 | 188 |

| Fuel consumption (l/100 km) | 6,9 | 7,5 |

| Gear ratios for each gear | 3,636; 1,950; 1,357; 0,941; 0,784 | 3,727; 2,048; 1,393; 1,029; 0,795 |

Installing a shorter main pair increased the dynamics of acceleration, taking one second from the French “brand”. Adjusting the gear ratios for each gear made the transitions to higher gears smoother, without jerking, and dynamic.

Design features

The optimal level of acceleration is ensured by the transmission system. In particular, on the version of the car that develops 87 horsepower, the car accelerates to 100 km/h in approximately 12.5 seconds (manual transmission). This indicator is higher only on a car where an automatic transmission is installed. As for fuel consumption, the basic configuration consumes approximately 8 liters per 100 km. This indicator is optimal for cars of this class.

Cross-section of Kalina gearbox

The Kalina 2 gearbox includes a block of drive gears, driven bearings and synchronizers are installed. There is an oil sump near the front bearing. This element is responsible for supplying oil. The mechanical housing on the Lada includes, in addition to the clutch housing, the rear crankcase cover. They are cast from aluminum alloy.

Gearbox device

The solenoid is effective. It is necessary to block accidental reverse gear. The solenoid is located in the gearbox housing. If the solenoid breaks down, reverse gear will no longer engage. However, the occurrence of this malfunction may be due to an electrical circuit break.

Design and diagram of manual transmission on Lada Vesta

with engine capacity

1.6 / 106 hp., 1.8 / 122 hp.

| Name | Data |

| Type | Mechanics |

| Factory index (article) | 21087 |

| Drive unit | Front |

| Engine capacity | 1,8 |

| Torque | 170 Nm |

| Default oil type | ZIC GFT 75W-85 |

| Oil volume | 2,2 |

| Lubricant replacement | Every 75,000 km |

| Filter update | Likewise |

| Average service life before major overhaul | 180000 km |

Transmission operation diagram

To find out the type of transmission of your car, look at the VIN code:

- GFL11: mechanics;

- GFL12 - AMT box;

- GFL13 ─ mechanics from Renault.

Why did you abandon the French box?

Previously, Vesta was equipped with a manual transmission with index jh3 and jr5. Undoubtedly, they were better than the VAZ mechanics of that time, but they still had jambs with hum and gear shifts. But the most important factor in refusing French units was the cost: French mechanics are almost 2 times more expensive than domestic ones. The situation is the same with the Nissan engine; they will not install it on Vesta, they will leave the 129 and 179 engines. In addition, box 21807 is capable of withstanding the torque of a 1.8 motor. (In general, the VAZ gearbox holds torque well; as an example, you can use motorsports athletes who install a standard gearbox on turbo VAZs).

“Pros” and “cons” in comparison with an automatic machine (robot)

| Advantages | Flaws |

| Acceleration dynamics have become better, the car picks up speed faster | Increased fuel consumption in the combined cycle |

| The car is 30 - 35 thousand cheaper when purchased with a manual transmission | Crunching, creaking when driving at low speeds |

| Long service life | |

| Cheapness of spare parts and components | |

| The car is more expensive on the secondary market compared to the robotic version |

Problem

However, as experience in operating the model has shown, the manual transmission is also not without some drawbacks. Sometimes owners begin to clearly hear extraneous sounds, similar to crackling and clicking noises in the manual transmission of the Lada Vesta. Moreover, for some they appeared on completely new cars that had not driven even 15,000 km.

In most cases, noises are heard while driving in third gear, however, over time, the situation worsens and a similar sound, only even more pronounced, begins to appear in fourth gear. But only in cases when the accelerator pedal is released.

This is clearly demonstrated in a video made by one of the members of the DRIVE2 community, known there under the nickname Zheka700.

The fact that this is a crackling and clicking sound in the manual transmission of the Lada Vesta is also confirmed by the fact that it is enough to press the lever handle a little and the sound disappears. This means that the problem is directly in the transmission, and not in the lining.

Malfunctions and ways to eliminate them

| Malfunctions | Troubleshooting Methods |

| Transmission howl at 2000 – 3000 rpm | Insulation lining for gearbox control cables |

| Knock at idle | Replacing the pressure bearing |

| Critical wear of gears and teeth | Replacement with new ones, cannot be restored |

| Oil leaks from seals are less common. | Replacement of sealing seals with new ones. Overhaul of gearbox |

AvtoVAZ reaction

It is worth noting that not all sedans are susceptible to this problem, but only the first batch cars.

In September 2016, the issue was resolved - all Vestas began to be equipped with new manual transmission cables. So the Russian automobile concern acted quite quickly.

As for the instructions, if such a defect exists, AvtoVAZ recommends contacting the dealership and having the cables replaced.

However, not all owners are ready to do this. The fact is that such a procedure is quite lengthy, since to replace it it is necessary to dismantle the entire dashboard, then remove the steering column, including the electric power steering, and also the heater. Also, such a replacement involves draining antifreeze and freon.

Naturally, this is quite a long time and not every Vesta owner is ready to give the sedan for service for such a long period of time.

If such a situation arises, but you want to do without replacing the cables, and the car is under warranty, it is strongly recommended that you make an appointment for diagnostics at a dealership. And in order to narrow down the search and help those who decide to fix the defect themselves, we will give recommendations on where to look first.

Service life - from the factory and actual

The manufacturer in the operating instructions indicates an average interval of 180,000 km before major repairs. In fact, the mechanics last up to 200,000 km, provided that the manufacturer’s recommendations for care and maintenance are followed.

At the stage of using mechanics, breakdowns associated with depressurization of the system, oil leakage, and wear of the pressure bearing are most often recorded. Malfunctions are insignificant, not critical, and can be eliminated in a few hours of work by technicians at a service station.

Transporting trailers

Transporting trailers or towing other cars is extremely undesirable for a CVT, since it significantly increases the load on the transmission, and as a result, increased wear.

ATTENTION! For the first 2 thousand kilometers, until the engine and transmission have been fully run-in, towing other vehicles or trailers is prohibited. What tips can you give for operating a car with a CVT? Let us remind you that we previously talked about the main problems and malfunctions of the Jatco variator

What tips can you give for operating a car with a CVT? Let us remind you that we previously talked about the main problems and malfunctions of the Jatco variator.

Found an error? Select it and press Ctrl+Enter..

Source

Reviews

| № | Positive |

| 1. | Dmitry , 33 years old (drive2.ru): they can’t say anything bad about the mechanics, the gearbox works properly. The car is only a year old, I regularly undergo maintenance, I don’t drive, I drive carefully. |

| 2. | Vyacheslav Petrovich , 47 years old (prom.ua): in a year and a half I drove about 20,000 km, mileage is above average. Impressions of the new mechanics are only positive. There is something to compare with; before this there was the Lada Granta. Grantmakers understand what I'm talking about. |

| 3. | Alexander Alekseevich , 43 years old (drom.ru): after buying the car, I changed the transmission oil for the first time at the 7000 km mark. I didn’t wait for 75,000 km, as the manufacturer recommends. The waste was of a natural color, metal shavings were present, but their quantity was insignificant. I did the same. |

| 4. | Alexey Petrovich , 48 years old (rozetka.ua): I’ve heard numerous negative reviews about the mechanics, I can’t confirm. I believe that the technical condition and performance of the unit depends on the driver. I don’t have any problems with this, I take care of my equipment. |

| 5. | Semyon Vyacheslavovich , 40 years old (Auto.ru): This is the second year since I bought and actively use a Lada Vesta on the mechanics. The review is positive, there are no comments about the work. |

| 6. | Vasily Timofeevich , 43 years old (Auto.Mail.Ru): for a year and a half of using a car with mechanics, he once made an unscheduled visit to a service station for diagnostics. I was at fault for the hum in the manual transmission, but it was the suspension. I hope that the device reaches the 180,000 km specified by the manufacturer. |

| 7. | Dmitry Gennadievich , 41 years old (drive2.ru): I like the mechanics more than the robot, I drove the AMT for three months, I can compare. Both robot and automatic are not adapted for domestic roads. The units do not last long, so it is better to buy a manual transmission. |

| 8. | Sergey , 35 years old (drive2.ru): on the mechanics, as soon as I pressed the pedal, I pressed it. And overtaking, and maneuverability, without kickdowns, delays in switching. Choice: definitely mechanics. |

| Negative | |

| 9. | Dmitry Semenovich , 52 years old (prom.ua): no matter how hard we tried, a miracle did not work. We decided to save several tens of thousands, but for the wrong reasons. It would be better to make the plastic cheaper than to install a Russian gearbox instead of a French one. Knocking and noise in the manual transmission was detected at 40,000 km. With such a low mileage there are such significant defects. |

| 10. | Gennady , 46 years old (Bibika.ru): after 30,000 km, cases of clutch slipping, delays when changing to higher gears, and howling of the gearbox became more frequent. You need to go to a workshop and order diagnostics. Couldn’t it have been done better from the start? |

| 11. | Boris , 38 years old (drive2.ru): at 25,000 km a gearbox whine appeared on a Lada Vesta. The officials said that the pressure bearing needs to be changed, but this is not certain. The final diagnosis will be announced after a comprehensive diagnosis. |

| 12. | Sergey Gennadievich , 45 years old (Avtodispatcher.ru): a knock in the gearbox was detected already at 31,000 km. Initially the fault was with the suspension, but after diagnostics the technician assured me otherwise. |

GQ7Q0286

And the clearance varies. On a three-pedal Vesta, from the asphalt to the drain plug of the engine oil pan is 190 mm. It's the same distance to the bottom of the box. The units of the robotic Vesta are suspended a little higher: there are 195 mm to the engine oil pan plug, and 200 mm from the robot to the ground. In both cases, the engine compartment is covered with a steel mudguard, the clearance under which is 185 mm.

Of course, we remember that in the comparative test of Vesta with its competitors, we measured 190 mm under protection, but on that pre-production car, tires measuring 205/55 R16 were installed. Serial Vestas are shod with different tires - 195/55 R16. Hence the difference in results.

The curb weight was also compared. Vesta with the robot turned out to be 20 kg lighter, and there are several reasons for this. The AMT gearbox is 2.2 kg lighter than the French manual and requires a little less oil. Like the power unit paired with a manual gearbox: it has a different oil pan, and the lubrication system holds 1.2 liters less oil. In addition, the mechanical Vesta has a heavier multimedia unit with navigation and a rear view camera included, while the robotic car has a simpler radio. And for some reason there was no protection for the rear wheel arches. Although both cars have similar Lux trim levels, with the exception of a few options. Just like that, little by little, I gained 20 kg.

I eat as much as I can

On the other hand, try going from second to first even at very low speed. I'm sure AMT will do it smoother than most manual drivers.

If necessary, for example when overtaking, the robot will easily jump down through a gear in both automatic and manual control modes. There is also a rocking function if the car is stuck.

Types of gearboxes for Lada Vesta

In our Vesta, two versions of the gearbox are equally possible:

- Robotic transmission;

- Manual Transmission.

There is no classic automatic transmission on the Lada Vesta! Interesting move. But maybe a CVT will be added soon.

Automatic transmission (actually a robot)

This is what a robotic gearbox lever looks like.

Why might there be interruptions when engaging first gear?

The reasons for the breakdown of this unit worry many Kalina owners, since the failure of certain gearbox elements, due to which the gears are poorly engaged, can already be called a “disease”. And this disease, one way or another, is associated with a certain defect in the production and assembly of serial models of this car at the plant, which, unfortunately, was never eliminated by AvtoVAZ engineers.

In fact, there may be quite a few direct reasons why the first speed does not engage well, as a result of which even experienced specialists will not be able to immediately calculate the breakdown. What can we say about ordinary car enthusiasts?

How to determine the manufacturer of the box on Lada Vesta

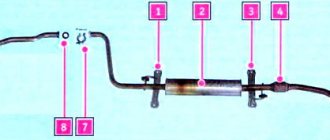

Manual gearbox bottom view.

Today, it is unlikely that you will be able to find copies with French gearboxes, because AvtoVAZ has already stopped their mass production. The only available options are with domestic mechanics. Externally, the box has not changed, the lever in the cabin remains the same.

You can determine the manufacturer of the box only by the VIN number of the car itself. If it has the combination “ GFL13 ”, then this is a new part, “ GFL11 ” indicates our 21807 version, and “ GFL12 ” indicates the installed robotic VAZ transmission.

Problems with manual transmission VAZ 21807

Knowing about the shortcomings and errors of the transmission on the basis of which the 21807 was designed, buyers are subconsciously wary of investing money in a car with such a transmission. Statistics show that almost half of consumers want to buy a Lada Vesta with a French gearbox.

The howl may be mistakenly attributed to the VAZ 21807. If the manual transmission hums in neutral gear when the speed decreases from 3000 rpm, the reason may well be a defect in the muffler vibration compensator.

Dismantling

Before you begin work on eliminating crackling and clicking noises in the manual transmission of the Lada Vesta, you will need to remove the central tunnel. It consists of 2 sections - front and rear, with the rear being noticeably smaller.

To remove the rear section, you need to arm yourself with a ratchet with a Torx 20 bit (asterisk), use it to unscrew the 2 mounting screws, and then remove the plug. The trim itself is carefully pulled out - to do this you will need to remove the handbrake from it.

As for the front part, the tunnel is covered with plastic shields on both sides. They are secured with screws (1 per side), which need to be unscrewed and the plastic removed.

The screws need to be unscrewed

Then, carefully prying up the frame with a knife or screwdriver, the cover of the manual transmission lever is removed, after which the plug is disconnected and the lining is removed.

In the end, all that remains is to unscrew the 4 mounting screws and remove the remaining cladding.

Everything is clearly shown in the plot.

Engine compartment

Near the manual transmission

If modifications in the interior do not produce results, it is recommended to look for the reason under the hood.

To begin with, you can better secure the cable directly in front of the transmission using plastic clamps.

Screed in front of manual transmission

Near the engine shield

The fourth option for independently eliminating crackling and clicking noises in a Lada Vesta manual transmission also involves the use of plastic clamps, but they must be placed not near the place of fixation, but as far as possible from it.

Screed near the engine shield

In this case, you just need to tighten the cables together with a clamp.