In November 2004, the first Lada Kalina model left the factory gates. For various reasons, she overcame a very long path to birth. The first information about the start of design work on the model appeared in 1993. The car belongs to the second group of the small class, has a roomy interior and a pleasant appearance.

All installed power units of this model have a toothed belt in the valve mechanism. In this article we will look at how to replace the timing belt of a Lada Kalina 16 valves.

About engines

Depending on the configuration, one of four modifications of the power unit was installed on the car. Two of them had 8 valves in the cylinder head, two had 16 valves per engine. The cylinders are arranged in one row, the block is cast from cast iron. Three engines have a working volume equal to 1600 cm 3, one of them VAZ 11194 was made with an engine capacity of 1400 cm 3. This engine, just like the VAZ 21126 , has 4 valves per cylinder, that is, there will be 16 of them in the cylinder head Thanks to some modifications, the engines comply with Euro 3.4 standards.

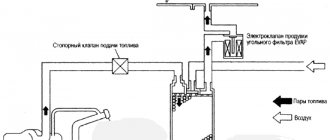

Timing diagram

The engine with a displacement of 1400 cm3 was not produced for long, since the appearance of Kalina 2 was conceived only for power units with a displacement of 1600 cm3. Manufacturers guarantee a service life of engines of more than 200 thousand km. Both engines can be moderately boosted without significantly reducing their service life.

Are the valves bending?

This question worries many owners of Kalina and other VAZ cars with front-wheel drive. This is due to the fact that when there is a break in the valve drive or the teeth of the drive belt are cut, the pistons hit the valve heads. In the best case, the car gets bent valves, but bending connecting rods, damaged pistons, and burst valve guides are also possible. Such a malfunction will entail previously unforeseen costs for engine overhaul.

Don't let drivers be misled by the recesses in the piston heads; they do not save the engine from damage. In this case, only compliance with all recommendations of the engine manufacturers, the use of high-quality spare parts and other consumables, and timely replacement of worn parts can help.

Signs of a Worn Belt

Signs of a worn belt are:

- the appearance of fabric base fibers on its surface;

- hardening, determined by the pronounced shine of the belt;

- loss of elasticity;

- drive extension is greater than permissible;

- cracks and peeling.

Belt wear can also be determined by:

- due to difficulty starting the engine;

- by extraneous noise in the engine;

- overheating

- by changing the color of exhaust gases.

By knowing the characteristic signs of wear on the timing drive and replacing it in a timely manner, Lada Granta owners will be able to protect themselves from engine failure. And when buying a belt, give preference to original spare parts from well-established manufacturers.

Replacement procedure

The time for replacing worn parts in the timing belt is approaching, the driver thinks about the question of how to carry it out. Those who don’t want to get their hands dirty or have never had their car repaired prefer to turn to specialists. However, there are many owners who prefer to maintain or repair the car themselves. They are quite capable of this operation. You can do it in a garage or any suitable area. Work begins by opening the hood of the engine compartment, since most of the driver’s actions will take place in this place.

- First of all, remove the plastic cover covering the power unit. The windshield washer reservoir prevents the removal of the timing mechanism protection; it needs to be dismantled, especially since this does not cause any particular difficulty. Next, it is advisable to unscrew the spark plugs, having first removed the coils from them, this will make it easier to crank the engine in the future. The car is braked with a hand brake, stops are placed under the rear wheels, and the bolts of the right front wheel are removed. This side of the car is lifted with a jack, while not forgetting to place a stop under the car body, and the wheel is removed.

- When this is done, you can remove the upper protective cover of the timing mechanism, which is tightened with 5 screws.

- The next step is to remove the generator set drive belt. Release the tension mechanism and remove the belt. Now you can begin to dismantle the lower protective cover of the timing drive, which is held in place by only two screws.

- Some mechanics also disconnect the alternator belt tensioner rod for ease of operation.

- Now the timing mechanism needs to be aligned to the marks by turning the crankshaft pulley.

To get to it you will have to remove the fender liner, then the engine protection. Removing the pulley is not so easy; the crankshaft must remain stationary. This can be done by placing a flat-head screwdriver between the teeth of the flywheel ring and the clutch housing, or engage fifth gear and press the brake pedal. The pulley is removed along with the washer, and the bolt is put in place. Rotate the motor shaft until all marks coincide.

- There are two camshafts installed in the cylinder head, the gears of which should have their marks strictly opposite the marks of the rear protective housing.

- The gear on the crankshaft also has a boss; it is installed opposite the oil pump housing mark.

- It is also necessary to remove the rubber plug and make sure that the mark on the flywheel is located in the required place.

- After this, proceed to removing the timing belt.

First, its tension is weakened; to do this, the bolts on the tensioner and guide roller are loosened with a “15” head, the belt is removed from the pulleys and pulled out of the engine compartment.

- The tension roller is removed from the cylinder block, since it is usually replaced with a new product.

After this, it is strictly forbidden to turn the crankshaft or camshafts.

- Before reassembling, carefully inspect all parts of the timing drive mechanism. Before installing the rollers, it is advisable to coat the threads on the screws with a special lubricant; the tensioner screw does not need to be tightened too much yet.

- Once again, carefully check the alignment of the timing marks of the timing drive mechanism.

- Install a new belt on the pulleys, making sure that there is no sagging in the belt branch between the camshaft gears. If everything worked out, start tensioning the belt. To do this, the tensioner roller is turned counterclockwise until the movable mark on the outer race coincides with the stationary roller body, where there is also a mark.

- Now you can tighten the screw securing it. Further assembly occurs in the reverse order of removal.

Timing belt for Lada Kalina: originals, analogues, part numbers and price

Drive specifications: length 1305 x number of teeth 137 x width 22 mm.

| Name/article | Price in rubles |

| Original | |

| GATES K015631XS | From 2000 |

| GATES K015521XS | From 2000 |

| GATES K055468XS, K015521, K015539 | From 2000 |

| Analogs | |

| Master-Sport1137-SD-PCS-MS 570 | From 1500 |

| BOSCH 1987948286 | From 1300 |

| BOSCH 1987946329 | From 1300 |

| CONTITECH CT527K2 | From 2100 |

| CONTITECH CT1137K1 | From 2100 |

| DAYCO KTB842 | From 1500 |

| FLENNOR F904410 | From 1500 |

| Grand prix JH8025 | From 1500 |

| LYNXauto 137FL22 | From 1500 |

| Hola TH1372 | From 1500 |

| CT1137 1280 | From 1500 |

| Finwhale BD137 | From 1500 |

| Dayco 941071 | From 1500 |

| Optibelt ZRK1593 | From 1500 |

| Pilenga CT-P11374720 | From 1500 |

| Trialli GD7705060 | From 1800 |

Before purchasing spare parts, be sure to check the compatibility of the part with the model of your technical device. Check the catalog numbers against the data specified in the instruction manual.

Typical causes of belt wear

- Natural factor: duration of operation of the vehicle without intermediate prevention and diagnostics;

- Purchase and subsequent installation of non-original parts, low quality workmanship;

- Mismatch in size, length, width, number of teeth;

- Aggressive driving style;

- High speed limits;

- Inconsistency of temperature conditions, climatic features of the operating region.

Typical signs of belt wear

- Unstable engine starting: Excessive wear or poor tension leads to malfunction of the ignition system. The fuel mixture ignites earlier (later) than expected, as a result of which the engine operates unstable;

- Excessive amounts of smoke from the exhaust pipe: usually associated with melting of the catalytic filler. When some of the fuel enters the intake tract through the valves, which leads to an increase in temperature and melting of the honeycomb. Black (gray) smoke from the exhaust is a likely sign of wear on the drive mechanism;

- The appearance of third-party sounds when the engine is running;

- Presence of oily streaks around the perimeter of the drive mechanism installation;

- Clear, visible cracks, fiber breaks on the belt, broken teeth, other signs of wear;

- The power unit does not start, the starter spins at idle.

Consequences of untimely replacement of the timing drive

- Premature wear of pistons and crankshaft liners;

- Excessive engine oil consumption;

- Wear of the camshaft, valve mechanism;

- Deformation of gears, cylinder heads.

Which belt is better to buy?

The main supplier that supplies timing belts to Lada Kalina is the RTI plant from Balakovo. The quality of its products has been tested by many years of cooperation with the VAZ plant, and there is no doubt.

At the same time, imported components are also installed. Gates products have proven themselves well, guaranteeing a belt mileage of 200 thousand km or more. You can use the services of other well-known companies with global experience, the main thing is not to run into a well-disguised fake.

Recommendations from Lada Granta owners

Experienced drivers recommend replacing the timing belt at the first signs of wear. At each maintenance, do not be lazy and inspect the condition of the drive. If it breaks, the valves will “meet” the piston and the engine will have to be repaired.

Very often you can find feedback that the belt failed after 20 thousand kilometers due to the poor quality of the product. The purchase of a belt must be made at trusted retail outlets and from well-known companies.

Another tip is to check not only the condition of the belt, but also the timing parts. Often the cause of belt failure can be excessive wear of the gear teeth.

The recommendations boil down to one thing - do not be late in replacing the timing belt when it is worn out.

VAZ cars: repair, maintenance, tuning

Replacing the timing belt on a 106-horsepower 16-valve Lada Granta 1.6 service will cost approximately $40-45. This seems like enough incentive to roll up your sleeves and replace the belt yourself. The whole job will take no more than an hour and a half and does not require any special skills.

Basic faults

There can only be three main faults with the timing belt:

- violation of the integrity of the structure;

- under- or overtension;

- break.

In the first case, the belt may simply delaminate, as evidenced by dangling reinforcing threads. In addition, belt teeth are often cut off. These problems are the result of mechanical damage, improper adjustment:

- camshaft stars;

- crankshaft pulley;

- toothed roller;

- pumps;

- tension roller.

The tension roller is designed to tension the belt by rotating around its own eccentric axis. If it is not adjusted correctly, the belt may be too tight, which will sooner or later render it unusable. The same problem will occur if the belt is loose.

The most unpleasant surprise, especially on the road, is a broken timing belt. In this case, the engine will immediately stall, and it will be possible to start it only by installing a new belt.